The Project Gutenberg EBook of Scientific American Supplement, No. 401, September 8, 1883, by Various This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org Title: Scientific American Supplement, No. 401, September 8, 1883 Author: Various Posting Date: October 10, 2012 [EBook #8718] Release Date: August, 2005 First Posted: August 3, 2003 Language: English Character set encoding: ISO-8859-1 *** START OF THIS PROJECT GUTENBERG EBOOK SCIENTIFIC AMERICAN SUPPL., NO. 401 *** Produced by Olaf Voss, Don Kretz, Juliet Sutherland, Charles Franks and the Distributed Proofreaders Team

The cultivated and patriotic city of Barcelona is about to erect a magnificent monument in honor of Columbus, the personage most distinguished in the historic annals of all nations and all epochs. The City of Earls does not forget that here the discoverer of America disembarked on the 3d of April, 1493, to present to the Catholic monarchs the evidences of the happy termination of his enterprise. In honoring Columbus they honor and exalt the sons of Catalonia, who also took part in the discovery and civilization of the New World, among whom may be named the Treasurer Santangel, Captain Margarit, Friar Benardo Boyl, first patriarch of the Indies, and the twelve missionaries of Monserrat, who accompanied the illustrious admiral on his second voyage.

In September, 1881, a national competition was opened by the central executive committee for the monument, and by the unanimous voice of the committee the premium plans of the architect, Don Cayetano Buigas Monraba, were adopted. From these plans, which we find in La Ilustracion Española, we give an engraving. Richness, grandeur, and expression, worthily combined, are the characteristics of these plans. The landing structure is divided into three parts, a central and two laterals, each of which extends forward, after the manner of a cutwater, in the form of the bow of a vessel of the fifteenth century, bringing to mind the two caravels, the Pinta and Niña; two great lights occupy the advance points on each side; a rich balustrade and four statues of celebrated persons complete the magnificent frontage. A noble monument, surmounted by a statue of the discoverer, is seen on the esplanade.

MONUMENTAL LANDING AND STATUE TO COLUMBUS, AT BARCELONA, SPAIN.

The commission appointed in France to consider the phylloxera has not awarded to anybody the prize of three hundred thousand francs that was offered to the discoverer of a trustworthy remedy or preventive for the fatal grape disease. There were not less than 182 competitors for the prize; but none had made a discovery that filled the bill. It is said, however, that a Strasbourg physician has found in naphthaline an absolutely trustworthy remedy. This liquid is poured upon the ground about the root of the vine, and it is said that it kills the parasites without hurting the grape.

Mr. R.W. Raymond gives the following interesting account of the remarkable scenery on this recently opened route from Denver to Salt Lake:

Having just made the trip from Salt Lake City to this place on the Denver & Rio Grande line, I cannot write you on any other subject at present. There is not in the world a railroad journey of thirty hours so filled with grand and beautiful views. I should perhaps qualify this statement by deducting the hours of darkness; yet this is really a fortunate enhancement of the traveler's enjoyment; it seems providential that there is one part of the way just long enough and uninteresting enough to permit one to go to sleep without the fear of missing anything sublime. Leaving Salt Lake City at noon, we sped through the fertile and populous Jordan Valley, past the fresh and lovely Utah Lake, and up the Valley of Spanish Fork. All the way the superb granite walls and summits of the Wahsatch accompanied us on the east, while westward, across the wide valley, were the blue outlines of the Oquirrh range. One after another of the magnificent cañons of the Wahsatch we passed, their mouths seeming mere gashes in the massive rock, but promising wild and rugged variety to him who enters--a promise which I have abundantly tested in other days. Parley's Cañon, the Big and Little Cottonwood, and most wonderful of all, the cañon of the American Fork, form a series not inferior to those of Boulder, Clear Creek, the Platte, and the Arkansas, in the front range of the Rockies.

Following Spanish Fork eastward so far as it served our purpose, we crossed the divide to the head waters of the South Fork of Price River, a tributary of Green River. It was a regret to me, in choosing this route, that I should miss the familiar and beloved scenery of Weber and Echo cañons--the only part of the Union Pacific road which tempts one to look out of a car window, unless one may be tempted by the boundless monotony of the plains or the chance of a prairie dog. Great was my satisfaction, therefore, to find that this part of the new road, parallel with the Union Pacific, but a hundred miles farther south, traverses the same belt of rocks, and exhibits them in forms not less picturesque. Castle Cañon, on the South Fork of the Price, is the equivalent of Echo Cañon, and is equal or superior in everything except color. The brilliant red of the Echo cliffs is wanting. The towers and walls of Castle Cañon are yellowish-gray. But their forms are incomparably various and grotesque--in some instances sublime. The valley of Green River at this point is a cheerless sage-brush desert, as it is further north. To be sure, this uninviting stream, a couple of hundred miles further south, having united with the Grande, and formed the Rio Colorado, does indeed, by dint of burrowing deeper and deeper into the sunless chasms, become at last sublime. But here it gives no hint of its future somber glory. I remained awake till we had crossed Green River, to make sure that no striking scenery should be missed by sleep. But I got nothing for my pains except the moonlight on the muddy water; and next time I shall go to bed comfortably, proving to the conductor that I am a veteran and not a tender-foot.

In the morning, we breakfasted at Cimarron, having in the interval passed the foot-hills of the Roan Mountains, crossed the Grande, and ascended for some distance the Gunnison, a tributary of the Grande, the Uncompahgre, a tributary of the Gunnison, and finally a branch, flowing westward, of the Uncompahgre. A high divide at the head of the latter was laboriously surmounted; and then, one of our two engines shooting ahead and piloting us, we slid speedily down to Cimarron. It is in such descents that the unaccustomed traveler usually feels alarmed. But the experience of the Rio Grande Railroad people is, that derailment is likely to occur on up-grades, and almost never in going down.

From this point, comparison with the Union Pacific line in the matter of scenery ceases. As everybody knows, that road crosses the Rocky Mountains proper in a pass so wide and of such gradual ascent that the high summits are quite out of sight. If it were not for the monument to the Ameses, there would be nothing to mark the highest point. For all the wonderful scenery on the Rio Grande road, between Cimarron and Pueblo, the Union Pacific in the same longitudes has nothing to show. From an artistic stand-point, one road has crossed the ranges at the most tame and uninteresting point that could be found, and the other at the most picturesque.

At Cimarron, the road again strikes the Gunnison, and plunges into the famous Black Cañon. In length, variety, and certain elements of beauty, such as forest-ravines and waterfalls, this cañon surpasses the Royal Gorge of the Arkansas. There is, however, one spot in the latter (I mean, of course, the point where the turbulent river fills the whole space between walls 2,800 ft. high, and the railroad is hung over it) which is superior in desolate, overwhelming grandeur to anything on the Gunnison. Take them all in all, it is difficult to say which is the finer. I have usually found the opinion of travelers to favor the Gunnison Cañon. But why need the question be solved at all? This one matchless journey comprises them both; and he who was overwhelmed in the morning by the one, holds his breath in the afternoon before the mighty precipices of the other. To excuse myself from even hinting such folly as a comparison of scenery, I will merely remark that these two cañons are more capable of a comparison than different scenes usually are; for they belong to the same type--deep cuts in crystalline rocks.

Between them come the Marshall Pass (nearly 11,000 ft. above sea-level), over the continental divide, and the Poncha Pass, over the Sangre di Cristo range. This range contains Harvard, Yale, Princeton, Elbert, Massive (the peak opposite Leadville), and other summits exceeding the altitude of 14,000 ft. To the east of it is the valley of the Arkansas, into which and down which we pass, and so through the Royal Gorge to Cañon City and Pueblo, where we arrived before dark on the day after leaving Salt Lake.

Salt Lake, the Jordan Valley, Utah Lake, the Wahsatch, Castle Cañon, the Black Cañon of the Gunnison, Marshall Pass, Poncha Pass, the Arkansas Valley, the Royal Gorge--what a catalogue for so brief a journey! No wonder everybody who has made it is "wild about it!" If enthusiastic urgency of recommendation from every passenger has any influence (and I know it has a great deal), this road will continue to be, as it is at present, crowded with tourists. It furnishes a delightful route for those who wish on the overland journey to see Denver (as who does not?) and to visit Colorado Springs and Manitou. All this can be done en route, without retracing the steps.

In the natural course of things it must necessarily have occurred to practical men to utilize photography in the case of terra-cotta, as it has already been employed in connection with so many other wares; but I have not to this day known of its successful application to terra-cotta. Now this is strange, if one considers how fashionable plaque and plate painting have become of late, and the good photographic results that are easily obtained on these as on sundry articles of this same "burnt earth." Portraits, animals, landscapes, seascapes, and reproductions are one and all easily transferred, whether for painting upon or to be left purely photographic. As a matter of business, too, one fails to see that it would not be remunerative, but rather the contrary. It was with something of this feeling that I was led to try and see what could be done to attain the end in view, and as I knew of no data to go by, I had to use my own experience, or rather experiment on my own account.

Since emulsion was constantly at hand in my establishment, in the commercial production of my gelatine dry plates, it was but natural I should first have turned to this as a mode of obtaining the desired results; but, alas! all attempts in that direction signally failed--the ware most persistently refused to have anything to do with emulsion. The bugbear was the fixing agent or hypo., which not only left indelible marks, but, despite any amount of washing, the image on a finished plate vanished to nothing at the end of an hour's exposure in the show window. There was nothing left but to seek other means for the attainment of my object. I would not have troubled the reader as to this unsuccessful line of experiment but that I wished to put him on his guard and save him useless researches in the same direction. To cut matters short, the method I found best and most direct was the now old but still excellent wet collodion transfer. I will now proceed to detail my system of working to facilitate the matter to the inexperienced in collodion transfer.

The first and indispensable operation, in the preparation of the surface to receive the transfer, is the "sizing of the surface." It simply consists of a solution of gelatine chrome-alumed, as follows:

Gelatine. 10 grains. Water. 1 ounce. A trace of chrome alum.

Coat with a soft camel's hair brush and let dry. It is needless to say that numbers of plaques, plates, vases, etc., may be coated right off, and will then be ready for use at any time.

Having settled on the subject and carefully dusted the negative, as well as placed it in situ for reproduction, the next thing required is a suitable collodion, and the following will be found all that can be desired:

TRANSFER COLLODION.

Cotton. 3 drachms. Iodide of cadmium. 65 grains. Ammonium iodide. 25 " Bromide of cadmium. 19 " Ammonium bromide. 11 " Alcohol. 15 ounces. Ether. 15 "

The plate thoroughly cleaned and coated with the collodion is now transferred to a bath, as follows:

Nitrate of silver (common) 25 grains to the ounce.

Made slightly acid with nitric acid.

After sensitizing, the plate is exposed in the usual way and taken to the room where pictures are ordinarily developed, and quantum suff. of the following poured into the developing cup to bring out the image:

DEVELOPING SOLUTION.

A Winchester of water, i.e. 80 ounces. Protosulphate of iron. 240 grains. Citric acid. 240 "

Or the following may be used:

Pyro 3 grains\ Citric acid 2 " } per ounce of water. Glacial acetic acid 30 drops /

After perfect development the picture is well washed and then fixed in a saturated solution of hypo.; after which it is thoroughly washed.

It will now be found that the picture is not altogether satisfactory; it lacks both vigor and color. To improve matters recourse is now had to

Gold. 1 grain. Water. 5 ounces.

With this a very fine depth is soon attained, and a nice picture the result. Leave out the toning, and only a poor, sunken-looking picture will be the outcome; but directly the toning bath is employed richness at once comes to the fore. I have, however, known of instances where the picture needed no toning.

This is still a secret with some in the profession. A limited number of workers have succeeded in bringing out good opals, and their modus operandi is kept from the many. Now this is a pity, when one considers the great charm attached to a good picture on opal, with pure whites and rich blacks, and in many localities the demand that might be created for them. Apart from their beauty, another charm attaches to opals--their absolute permanence; and this, it must be allowed, is no trifle. What, in fact, can be more painful to the worker who values his work, and sets store by it, than to feel it must ere long fade and pass into oblivion! A properly executed opal will no more fade than the glass pictures so common at one time, and which, wherever taken care of, are as perfect now as they were when first taken.

Now, excellent pictures are to be made on opals by means of emulsion; but I propose first taking the transfer method (mainly applicable to ground opal and canvas) as given above for pottery, since in practice it is found very ready, easy of manipulation, and safe. The details are much the same as above, and necessitate double transfer.

After the picture had been obtained on the plate (ordinary glass plate), and after thoroughly fixing, washing, and toning, the picture (and this, remember, is the case likewise with terra-cotta) then has to be loosened from its support, and this is done with a solution of sulphuric acid--one drachm to fifteen ounces of water--which is made to flow between the image and the glass, after which perfectly wash and mount. When the image is loosened a piece of tracing paper is put on the image, evened out, raised (assisted by some one else to hold the two opposite corners during the operation), and with the aid of the helper the picture is carefully centered, gently pressed out or down, and the transfer is so far effected. But what will happen, and does happen, in the case of vignettes, is impurity of the whites, when the picture becomes positively objectionable. Now the way to remedy this lies simply in the application, to the dirty-looking parts, of a solution of iodine dissolved in iodide of potassium to sherry color; after which, well wash and apply a weak solution of cyanide of potassium, and wash well again. This, by the way, is equally applicable to paper transfers; and it is to be remembered that the toning comes last of all. It is a rather difficult matter to clean a ground opal which has been used two or three times, and acid must then be had recourse to (nitric acid is as good as any); but by transferring from the support on the ground surface, all stains are at once avoided.

On the flushed glass, or on the pot metal (unground), after well cleaning the surface it should be covered with a substratum of egg. Then the picture is taken direct, not transferred; that is, the plate is exposed direct in the camera, regularly proceeded with, and, when dried, varnished with a pale negative varnish, or with dead varnish if intended for chalk or water-color. This, when a good negative is used, gives a remarkably fine picture, not requiring a vestige of retouching, and having likewise the invaluable advantage of being perfectly durable if varnished with the negative varnish. Moreover, on that, effective pictures may be made in oil with simply tinting.

A gentleman, who has a right to be considered a good judge in all art matters, on looking at one of these pictures transferred on flushed glass, said it was one of the finest productions of photography. He urged that negatives ad rem should be taken most carefully, and that, like the picture I showed him, they should be full of half-tone and detail, and yet have plenty of vigor. They should, he said, be robust in the high lights, have perfectly clear glass in the few points of deep shadows, and thus have powerful relief. Moreover, the negatives should be retouched only by a competent hand, and care taken that the likeness shall be in no way altered, which is so frequently the case now.

If done as thus suggested there is no doubt that remarkably fine pictures are to be produced on opal, whether ground or not. Most artistic results are to be obtained, and, with proper care, absolute permanency. In this age of keen competition, all have to think of what may be really recommended to one's clientèle, and likely to meet with approbation from strangers and friends when the picture has once been delivered; and I candidly think that the opal, of all, is the picture most likely to meet with this general approbation.

I hope I have left it clearly to be understood that the class of opal picture to which I have chiefly alluded is one that remains untouched after the transfer--that is, absolutely unpainted upon. It is pure photography in every sense of the word, and the resultant picture one hardly to be surpassed in any way. I have rather laid a stress on this point, well knowing how pictures are at times irretrievably ruined by the barbarous hand of would-be artists, who by far exceed the true artists in number; and the hint on retouching should not be lost sight of, either, at a period when the tendency is to stereotype every one in marble-like texture, or rather lack of texture, as if the face were devoid of all fleshiness and as hard and rigid as cast-iron. It might be wise to weigh this point carefully, and act upon it, before the enlightened public have raised a cry against the pernicious practice and made photographers smart for their want of applying timely remedial measures to a decided evil.

On reading the above again, fearing lest any misconception should arise in the mind of the reader, I deem it expedient, to clearly state that for terra-cotta recourse is had to double transfer; that is, the picture first taken is lifted from the support on tracing paper, put in the right position on terra-cotta, and pressed down while wet with blotting-paper, left to dry, and is then so far ready.

Respecting the production of pictures by means of emulsion, ground opal being the best, the system I employ is as follows: After well cleaning the glass, coat it with emulsion (which had better not be too thick). When dry it is exposed and developed with the usual oxalate developer, to which a little bromide of potassium has been added. The remainder of the operations is as usual. Those varnished with dead varnish can be tinted and worked up with colored crayons or black lead pencil and make very pleasing pictures. It is needless to add that they are also to be finished in water-colors if thought preferable.--G. W. Martyn, in Br. Jour. Photo.

The process of A.C.A. Thiebaut is as follows: the paper has the following advantages:

First. The sensitive coating is regular, and its thickness is uniform throughout the entire surface of each sheet.

Second. It can be exposed for a luminous impression in any kind of slide as usually constructed.

Third. It can be developed and fixed as easily as a negative on glass.

Fourth. The negative obtained dries quite flat on blotting paper.

Fifth. The film which constitutes the negative can be detached or peeled from its support or backing easily and readily by the hand, without the assistance of any dissolving or other agent. Thus this invention does away with all sensitive preparations on glass, which latter is both a brittle and relatively heavy material, thus diminishing the bulk and weight of amateur and scientific photographers' luggage when traveling; it produces photographic negatives as fine and as transparent as those on glass, in so much that the film does not contain any grain; and, lastly, it admits of printing from either face of the film, as regards the production of positives on paper or other material, as well as plates for phototypy and photo-engraving, which latter processes require a negative to be reversed.

For the manufacture of my sensitized film paper:

First. A gelatinized sheet of paper is properly damped with cold water, and when evenly saturated it is placed on a glass, to which it is attached by means of bands of paper pasted partially on the glass, and partially on the edges of the said sheet; in this state it is allowed to dry, whereby it is stretched quite flat.

Secondly. I coat the dry sheet with a solution of ordinary collodion, containing from one to two per cent. cubic measure of azotic cotton (1½ per cent. gives very good results) and from 1½ to 2½ per cent. of castor oil (2 per cent. gives very good results); this coating is allowed to dry; and,

Thirdly. The glass, with the prepared paper upward, is leveled, and then it is coated, in a room from which all rays but red rays of light are excluded, with a tepid emulsion of bromide of silver to the extent of about one millimeter thick, and after leaving it in this position until the gelatine has set (say) about five minutes, with the film paper still attached, it is placed upright in a drying-room, where it should remain about twelve hours exposed to a temperature of from 62 to 66 degrees Fahrenheit; and,

Fourthly. The film paper is detached from the glass ready for exposure, development, and fixing in the usual manner. For the purpose of developing, oxalate of iron or pyrogallic acid answers equally well; for the purpose of fixing, I have found that a mixture by weight, water, 1,000, hyposulphite of soda 150, and powdered alum 60, produces excellent results, after being allowed to dry.

Fifthly. The film is peeled off the paper by hand, and can be immediately used for producing negatives recto or verso as above mentioned.

I claim as my invention:

First. The preparation or formation of gelatino-bromide film paper for photographic negatives, in the manner and for the purposes above described; and,

Secondly. The use for this purpose of castor oil, or any other analogous oil, more especially with the view of peeling off the film from the paper backing as above described.

A substance very much used by photographers of late years--in fact, so much used that no well-appointed laboratory could be considered complete without it--is the substance known is common alum, or potash alum, being a double sulphate of alumina and potash; but it is interesting to note that much of the commercial alum met with at the present time is ammonia alum, or the double sulphate of alum and ammonia. It is quite a matter of indifference to the photographer whether he uses potash alum or ammonia alum.

Besides its great value to the autotype, Woodburytype, and mechanical printers as an agent for hardening the gelatine films, it has been recommended for all sorts of ailments photographic. The silver printer adds a small portion to his sensitizing bath to keep it in working order, and to prevent blistering of the albumen; then, again, silver prints are soaked in a dilute solution of alum, having for its object the thorough elimination of the last traces of the fixing salt. A very good proportion to use for this latter purpose is four fluid ounces of a saturated solution, diluted with one gallon of water, the prints being well agitated during an immersion of ten minutes.

Of all the uses to which alum is put, perhaps not in any single instance can so much satisfaction be derived as when it is used to arrest frilling of gelatine plates. This it has the power to do instantaneously, and many of the most careful workers, both amateur and professional, or at least those who do net care to run any unnecessary risks with negatives which have cost them a good deal of anxiety and trouble to secure, but prefer to make assurance doubly sure--such individuals may be numbered by the hundred--make it a point in every-day practice to immerse all their plates in a solution of alum, either before fixing, or immediately afterward. In fact, some operators have two alum baths in use, one a normal bath, as above mentioned, for immersing the plates in when of the ordinary printing intensity; and the other a saturated solution strongly acidified by means of a vegetable acid (such as citric) or a mineral acid (such as sulphuric), for use when there is too much printing density, since it has been found in practice that an acid solution of alum in contact with sodium thio-sulphate on the gelatine image (after fixing, but before washing) not only removes the color or stain caused by the alkaline or pyrogallol, but perceptibly reduces the strength of the image. Moreover, the color does not again reappear after washing, as it does sometimes when the fixing salt has been partially washed away. In cases where there is great tendency to frill--such, for instance, as when a soft sample of gelatine has been employed, or old decomposed emulsion worked in with the fresh emulsion--it will in such cases be safer to put the plates in the normal-bath for a few minutes previous to immersing them in the acid bath.

Potash alum is obtained tolerably pure in commerce in colorless transparent crystalline masses, having an acid, sweetish, astringent taste. It is soluble in 18 parts of water at 60° F., and in its own weight of water at 212° F.; but the excess crystallizes out upon cooling. The solution reddens litmus paper, and, when impure, usually contains traces of oxide of iron. Upon the addition of either caustic soda or potash, a white gelatinous precipitate is formed (hydrate of alumina), which is soluble in excess of the reagent employed. The precipitate thus obtained has much of the character of the opalescent film sometimes observed on gelatine plates, when dry, which have been soaked in alum, and not well washed afterward.

Alkaline carbonates--such as washing soda, for instance--precipitate hydrate of alumina, which does not dissolve in an excess of the reagents, and carbon dioxide is evolved.

Ammonia hydrate produces a precipitate in a much finer state of divison, which does not dissolve in excess when examined in a test-tube, it somewhat resembles thin starch paste.

The presence of traces of iron may be known by adding a few drops of hydrochloric acid to a small quantity of a saturated solution of alum in a test-tube, to which add strong liquid ammonia; should any iron be present, the mixture will have a reddish-brown tinge when examined over a sheet of white paper. Other alums exist, such as the double sulphate of alumina and sodium, and sodium or aluminum and ammonium; but hitherto their uses have been confined to the experimental portion of the community rather than the practical.--Photo. News.

As is well known, in the process of bleaching and dyeing, cotton cloths become considerably contracted in the width, in consequence of carrying on the operations when the cloth is in the form of a rope. The effect is that, together with the tension, although slight, and the drying, the weft partly shrinks and partly curls up, the latter, however, being scarcely observable to the naked eye. It may almost be said that as regards the width the shrinkage is due to a number of minute crumples because the cloth is easily streatched again by the fingers almost to its gray width. The main use of a stretching machine, therefore, is not so much to make the cloth more than it is as to bring it again to its normal or woven width after operations that tend to shrinkage have been performed upon it. The stretching operation, therefore, is especially useful to calico printers, as it enables them to obtain when desired a white margin of even width, the irregularities due to bleaching being corrected before printing.

IMPROVED CLOTH STRETCHING MACHINE.

The machine now illustrated is one we have recently seen in operation in a Salford finishing works. It is an improved form of another stretching machine which had been turned out in considerable numbers by Mr. Archibald Edmeston, engineer, of Salford, who makes a specialty of calico printers' and finishers' machinery. The improvements consist mainly of a simplification of the working parts and thoroughly substantial construction of the machine. The principle adopted is a well-known one. The selvages of the cloth, or more strictly the two edges of the cloth, of a width of about two inches, are caused to pass over and at the same time are held by the rims of two diverging pulleys. The rims are further apart where the cloth leaves them than where they seize it, hence the stretching is gradually, certainly, and uniformly performed. The cloth is gripped by the pressure of an endless belt acting against the lower half of each pulley, the edges being held between them. In the engraving these stretching pulleys are indicated by the letters AA; the endless leather band passes over the pulleys, CC, of which there are a set of four provided for each stretching pulley. The lower pair of pulleys in each case may be tightened up by a screw for the purpose of imparting the requisite tension to the bands. The stretching pulleys are mounted upon and driven by the same shaft, an ingenious but simple swiveling joint in their bosses enabling them to be set at any angle to the shaft and yet to revolve and be driven by it without throwing any undue strain upon the working parts. The piece, wound upon the ordinary batch shell, is placed upon the running-off center, D; it is led off over the rails, EE, and then downward to the nip of the bands and pulleys, AA. As explained, the selvages are here gripped between the bands and stretching pulleys, the rims of which are wider apart at the back than the front, and thus, in being conveyed underneath, the piece is suitably stretched. Leaving the grip at the back it passes over leading-off rollers, FF, and the scrimp or opening rail, G, and thence downward to the winding-on center, which cannot be seen. The winding-on center is driven by friction. As the batch fills it and tends to wind faster than the machine delivers the cloth, the driving slips. In addition to a capability of being set at an angle to the shaft, the stretching pulleys, AA, may be slided upon, so as to separate or bring them closer together, to allow for the treatment of different widths of cloths. This adjustment is provided for by mounting the stretching pulleys, AA, and the band pulleys, CC, etc., on frames, BB, the ends of which rest, as shown, upon rails, at the back and front of the machine. The adjustment either for width of piece or for the angularity (extent of stretching) is easily made by the hand-wheel, L. By the bevel wheels shown, two cross screws having nuts connected to the ends of frames, BB, are actuated in such a way that as desired the space between the back and front of the pulleys may be closed in or opened out, or the two wheels, maintaining the same angularity, may be separated or closed in, either adjustment being expeditiously made. The wheels, HHH, are called center stretching wheels, the use of which is sometimes advantageous. They act in conjunction with a set of stretching pulleys, of which one, K, may be seen in illustration. By a proper adjustment at the latter the piece is bent into a wavy form, where it passes between the whole of them, the effect of the corrugation being to loosen the center threads and to allow the piece to be more equally stretched with those near the selvages and more easily. This part of the machine may be used or not as required. The production, we observe, was about 120 yards per minute. The machine is solidly built and well fitted together, as was obvious to us from an inspection of some in course of construction at the maker's works. It is also claimed to be of considerable advantage to bleachers and finishers of white goods, on account of the uniformity of the stretching causing but small disturbance to the stiffening.--Textile Manufacturer.

All known methods for chemically purifying woolen stuffs from vegetable fibers depend on the action of acids or substances of acid reaction. The excessive temperature, hitherto unavoidable in the operation, acts injuriously on the woolen fibers, especially during the formation of hydrochloric acid, with which process especially the development of an injuriously high temperature has been hitherto unavoidable. The best method of absorbing the heat developed is in the evaporation of the moisture naturally present in the wool. The patentees find agitation of the fabric and the use of an exhauster during the process of material assistance. The operation maybe successfully performed in two ways--either by acting on the fabric at the ordinary pressure with constant agitation, or by saturation without agitation in a vacuum. For the first method the patentees employ a wooden cylinder with an aperture at one end for inserting and removing the cloth, and having apertures all round to allow free access of air. This cylinder rests on a hollow axle, closed at one end and perforated with holes, through which the acid gas is passed. By the rotation of the cylinder the gas is drawn through the material and the latter exposed to the atmosphere, whereby it gives up a quantity of aqueous vapor. An average temperature of 30° Cent. is best suited to the operation, and it can be regulated according to the supply of gas by opening or shutting a three-way cock between the gas generator and the revolving cylinder. This process is assisted by the use of an exhauster of the usual construction. When fully saturated, the fabric is allowed to remain until the vegetable fibers are sufficiently friable. The treatment in vacuo is as follows:

The hydrochloric acid gas passes into a vessel of suitable material provided with a perforated false bottom. From under this false bottom a pipe connects with a second similar vessel connected itself with a vacuum pump having a let-off pipe. As soon as the maximum vacuum is attained, the gas is turned on through a three-way cock at a pressure of 40 mm. mercury. The gas fills the first vessel and saturates the cloth. The warmth set free (about 500 calories per kilo, gas) is taken up by the combined water in the wool, as, owing to the low pressure, a quantity of vapor is formed sufficient to take up the heat. This vapor streams through the second vessel at a temperature of 35° Cent., penetrates the material, and passes out through the pump. After saturating the contents of the first vessel the gas passes into the second. AS soon as this is one-quarter or one-third saturated the first vessel is taken out and replaced by a third, which receives the overplus from No. 2 in like manner, and so on. This plan of working prevents gas passing through and damaging the pump. Instead of working under reduced pressure, the desired low temperature can be maintained by passing alternately with the gas currents of air which absorb heat in evaporating the moisture of the material. The cloth, after saturation by these processes, is left from six to twelve hours in the vessels, after which it is freely exposed to the air until the vegetable particles are friable. As soon as this occurs, the fabrics are washed. It is advantageous to add to the wash water powdered carbonate of baryta, strontia, magnesia, or preferably lime, and subsequently to rinse in pure water. Phosphate of lime containing carbonate may also be employed for neutralizing the acid, and the residue recovered and separated from the organic residues mixed with it.--"H. J.," Journal of the Society of Chemical Industry.

It is a recognized fact that chemical bodies in a nascent state are characterized by peculiarly energetic affinities, and the results of numerous experiments permit us to affirm that animal and vegetable fibers are rapidly bleached when they are placed in contact with oxides and chlorides which, when submitted to electrolysis, permit oxygen and chlorine to disengage themselves in the nascent state.

The coloring matter that impregnates the majority of vegetable textile substances, such as cotton, flax, and hemp, to cite only those most generally known, is in fact completely destroyed only by the combined action of oxygen and chlorine, which always act in the same manner, whether the fibers be in a raw or woven state.

In the application of electrolysis to the bleaching of textile materials, it is only necessary to have the electrodes of any sufficiently powerful generator of electricity end in a vessel containing in aqueous solution such decolorizing agents as the hypochlorites in general, and chlorides, bromides, and iodides that are capable of disengaging chlorine, and iodine or an iodide in a nascent state. These gases perform the role of oxidizing or decolorizing agents.

The fibers that are immersed in the solution during the passage of the electric current must necessarily remain therein for a greater or less length of time, according to the nature of the material to be bleached, and must, after this first operation, be washed, rinsed, and dried.

The use of an electric current for decomposing the metallic chlorides and disengaging their elements is not new, and there have been specially utilized for this purpose, up to the present time, the alkaline hypochlorites that are obtained by well known processes.

In the latter case the metal is brought to the state of oxide in presence of the water that is necessary for the reaction. But the results obtained in practicing this method are deceiving, as far as bleaching is concerned, and it is evidently more rational and economical to endeavor to compound the hypochlorite directly by borrowing all its elements from the metallic chloride itself, and from the water by means of which such transformation is to be effected. This is a reversal of the problem, and, à propos thereof, we would call the attention of the reader to an apparatus invented by Messrs. Naudin & Schneider for effecting such synthesis in a simple and practical manner.

If a solution of chloride of sodium or kitchen salt, NaCl, be submitted to electrolysis in a hermetically closed vessel containing the material to be bleached, a formation of hypochlorite of soda is produced in the following way:

2NaCl + 2 H2O = NaCl + NaO, ClO + 4H.

In operating in this manner we shall have the advantage that results from the nascent body through the electrical double decomposition of the chloride of sodium and water, which puts the chlorine, the metal, the hydrogen, and the oxygen simultaneously in presence. The chlorine and oxygen will combine their action to decolorize the textile material.

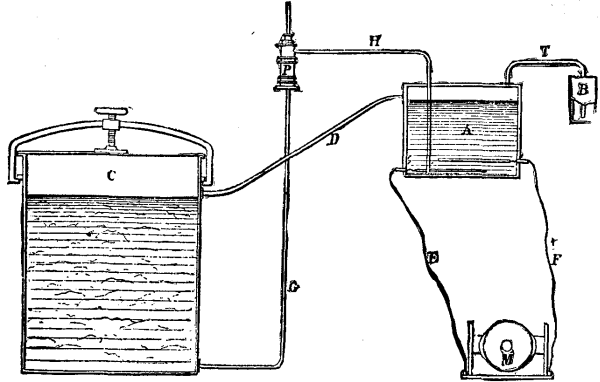

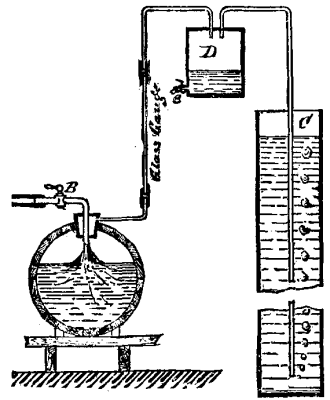

While starting from this idea, it will nevertheless be preferable to adopt Naudin & Schneider's arrangement.

The apparatus consists of a hermetically closed electrolyzer, A, into the lower part of which enters the electrodes, E and F, of any electrical machine whatever. The receptacle, A, is provided with a safety-tube, T, that issues from its upper part and communicates with a reservoir, B. A second tube, D, forms a communication between the electrolyzer and the vessel, C. The liquid contained in this latter is sucked up by a pump, P, and forced to the lower part of the vessel, A, by means of the tubes, G and H.

The apparatus operates as follows:

The closed vessel, C, in which the material to be bleached is put, is filled, as is also the electrolyzer, with a solution of chloride of sodium. This solution is then submitted to the action of an electric current, when, as a consequence of the chemical decomposition of the chloride and the water, the elements in a nascent state form hypochlorite of soda. When the partial or total conversion of the liquid has been effected (this being ascertained by chlorometric tests), the pump, P, is set rapidly in operation, and, as a consequence, draws up the chloride of sodium from the bottom of the vessel, C, to the lower part of the electrolyzer, A. The hypochlorite that has formed passes through the tube, D (as a natural consequence of the elevation of the level of the liquid in A brought about by the entrance of a new supply of chloride), and distributes itself throughout the vessel, C, where it acts upon the textile material.

APPARATUS FOR BLEACHING TEXTILE FIBERS

BY ELECTRICITY.

The safety-tube, T, which is attached to the electrolyzer, permits of the escape of the hydrogen which is produced during the chemical reaction, and fixes, through an alkaline solution contained in the reservoir, B, the chloride whose escape might discommode the operator.

As may be conceived, the slow transfer of the saline solution from the receptacle, C, to the electrolyzer, and its rapid conversion into decolorizing chloride, as well as its prompt application upon the materials to be bleached, presents important advantages.

While, in the present state of the industries that make use of bleaching chlorides, the chloride of sodium is converted into hydrochloric acid, which, in order to disengage chlorine, must in its turn react upon binoxide of manganese, we shall be able, with this new method, to utilize the chloride of sodium, which is derived from ordinary salt works, and extract from it the constituent elements of the hypochlorite by a simple displacement of molecules produced under the influence of an electric current.

Another and very serious advantage of electric bleaching is that of having constantly at hand a fresh solution of hypochlorite possessing a uniform decolorizing power, which may be regulated by the always known intensity of the current.

We must remark that the hypochlorites require a certain length of time to permit the chlorine to become disengaged, and that, besides, all chlorides, bromides, and iodides that are isomorphous are capable of undergoing an analogous chemical transformation and of being employed for the same purpose. This is especially the case with the chlorides of potassium or barium, the bromides of strontium or calcium, and the iodides of aluminum or magnesium. On another hand, as sea water contains different chlorides, it results that it might serve directly as a raw material for bleaching textile fibers. Then, when the solution of chloride of sodium has been deprived of its chlorine by electrolysis, there remains a solution of caustic soda which may be utilized for scouring fibers.--H. Danzer, in Le Génie Civil.

Messrs. J. & H. McLaren, of the Midland Engine Works, Hunslet, Leeds, England, for several years past have devoted considerable attention to the question of mounting traction engines on springs. The outcome of this is the engine in question, the front end of which is carried by a pair of Timmis spiral springs, resting on the center pin of the front axle, which is on Messrs. McLaren's principle, which enables it to accommodate itself to the inequalities of the road without throwing any undue strain on the front carriage. The chief difficulty hitherto has been to mount the hind end on springs without interfering with the spur gearing, which must be kept perfectly rigid to prevent breakage of the cogs. This is entirely provided for by the new arrangement, whereby all the spring is allowed for in the spokes of the wheel itself, which will be clearly seen on reference to the illustrations, in which Fig. 1 is a perspective view of the engine, while Fig. 2 shows a detail view of the wheel. The rim of the wheel is built up in the ordinary way of strong T-iron rings, with steel crossplates riveted on. The nave of the wheel has wrought-iron ribs to which the spokes are bolted. These spokes are made of the best spring steel, specially manufactured and rolled for the purpose, 9 inches wide and ½ inch thick. They are bent in a pear shape, with the narrow ends fastened to the nave, and the crown resting upon the rim of the wheel, where they are divided, and held in their places by means of clip fastened with bolts. When the weight of the engine comes on these spokes, those nearest the ground are compressed and those, at the top are elongated a little. In order to avoid any of the driving strain passing through the springs, a strong arm is fixed on the differential wheel and attached to the rim as shown in Fig. 2, so that the springs have really no work to do beyond carrying the weight of the engine. Messrs. McLaren naturally felt a certain amount of diffidence in placing their invention before the public until they had thoroughly tested it in practical work. This, we are informed, they have done, with the most satisfactory results, during the last five or six months; and they have a set of springs which ran during that time between 2,000 and 3,000 miles, besides which there are several of these spring engines in daily use.--Iron.

FIG 1. IMPROVED SPRING TRACTION ENGINE.

FIG. 2

DIAMETER | AREA

|

B.W.G Inch. Milli- | Circu- Square Square

No. metres | lar inches. Milli-

| Mils. metres.

|

0000 .454 11.5313 | 206116 .161883 10.4435

000 .425 10.795 | 180625 .141862 9.152

00 .38 9.6518 | 144400 .113411 7.3165

0 .34 8.6358 | 115600 .0907922 5.8573

1 .3 7.620 | 90000 .070686 4.5602

2 .284 7.2134 | 80656 .0633472 4.0867

3 .259 6.5784 | 67081 .0526854 3.3989

4 .238 6.0451 | 56644 .0444881 2.8701

5 .22 5.5879 | 48400 .0380133 2.4523

6 .203 5.1561 | 41209 .0323655 2.088

7 .18 4.5719 | 32400 .0254469 1.6417

8 .165 4.1909 | 27225 .0213825 1.3794

9 .148 3.7591 | 21904 .0172034 1.1098

10 .134 3.4035 | 17956 .0141026 .9096

11 .12 3.0479 | 14400 .0113097 .7296

12 .109 2.7701 | 11881 .00933133 .60199

13 .095 2.4129 | 9025 .0070882 .4573

14 .083 2.1082 | 6889 .00541062 .34906

15 .072 1.8288 | 5184 .00407151 .2486

16 .065 1.6510 | 4225 .00331831 .21407

17 .058 1.4732 | 3364 .0026421 .17045

18 .049 1.2446 | 2401 .00188574 .12165

19 .042 1.0668 | 1764 .00138544 .0894

20 .035 0.8890 | 1225 .000962115 .06207

21 .032 0.8128 | 1024 .00080425 .05188

22 .028 0.7112 | 784 .000615753 .03972

23 .025 0.635 | 625 .00049087 .03167

24 .022 0.5588 | 484 .000380133 .02452

25 .02 0.508 | 400 .00031416 .02027

26 .018 0.4571 | 324 .000254469 .01642

27 .016 0.4064 | 256 .000201062 .01297

28 .014 0.3556 | 196 .000153938 .00993

29 .013 0.3302 | 169 .000132732 .00856

30 .012 0.3048 | 144 .000113097 .007296

LENGTH AND WEIGHT

B.W.G Pounds Pounds Pounds Pounds Feet Yards 1.000 feet Miles

No. per per per 1.000 per per lb. per lb. per lb. per lb.

foot. Yard ft. mile.

0000 .623924 1.871772 623.924 3294.32 1.60276 .534253 .00160276 .00303553

000 .54676 1.64028 546.76 2886.89 1.82895 .60965 .00182895 .0034639

00 .437105 1.311315 437.105 2307.92 2.28777 .76259 .00228777 .004333

0 .349928 1.049784 349.928 1847.62 2.85773 .9525766 .00285773 .0054124

1 .272435 .817305 272.435 1438.43 3.6706 1.22353 .0036706 .0069519

2 .244151 .732453 244.151 1289.11 4.0958 1.365266 .0040958 .0077573

3 .203058 .609174 203.058 1072.15 4.9247 1.641566 .0049247 .009327

4 .171463 .514395 171.465 905.333 5.8321 1.944033 .0058321 .0110457

5 .14651 .43953 146.510 773.56 6.8255 2.275166 .0068255 .012927

6 .124742 .374226 124.742 658.638 8.0165 2.672166 .0080165 .015183

7 .098076 .294228 98.076 517.844 10.1962 3.39873 .0101962 .019311

8 .082411 .247233 82.411 435.135 12.1345 4.04483 .0121345 .022981

9 .066305 .198915 66.305 350.089 15.0818 5.027266 .0150818 .028564

10 .054354 .163062 54.354 286.99 18.398 6.13266 .018398 .034845

11 .04359 .13077 43.590 230.152 22.9413 7.6471 .0229413 .04345

12 .035964 .107892 35.964 189.893 27.805 9.2683 .027805 .05266

13 .027319 .081957 27.319 144.245 36.6046 12.20153 .0366046 .069326

14 .020853 .062559 20.853 110.1088 47.954 15.98466 .047954 .09082

15 .015692 .047076 15.692 82.855 63.7267 21.24223 .0637261 .12069

16 .012789 .038367 12.789 67.5276 78.1902 26.0634 .0781902 .14809

17 .0101828 .0305484 10.1828 53.7665 98.202 32.734 .098203 .18589

18 .00726795 .02180388 7.26796 38.3748 137.590 45.8633 .137590 .260587

19 .00533972 .01601916 5.33972 28.1937 187.276 62.4253 .187276 .35469

20 .00370815 .01112445 3.70815 19.579 269.676 89.892 .2696676 .51075

21 .00309972 .00929910 3.09972 16.3665 322.610 107.5366 .322610 .61100

22 .00237312 .00711936 2.37312 12.5301 421.384 140.4613 .421334 .798078

23 .0018910 .0056757 1.8919 9.9892 528.570 176.190 .528570 .100108

24 .0014650 .0043950 1.4650 7.7357 682.55 227.5166 .68255 .129271

25 .00121082 .00363246 1.21082 6.39315 825.880 275.2943 .825883 .156417

26 .00098077 .00294231 .98077 5.17844 1019.61 339.870 1.01961 .193108

27 .00077492 .00232476 .77492 4.0916 1290.44 430.1466 1.29044 .24440

28 .0005933 .0017799 .5933 3.13264 1685.48 561.8266 1.68548 .31922

29 .000511571 .001534713 .511571 2.7011 1954.76 651.5866 1.95476 .370220

30 .0004359 .0013077 .4359 2.30152 2294.13 764.710 2.29413 .434496

LENGTH AND RESISTANCE

B.W.G Feet Yards 1.000 feet Miles Ohms Ohms Ohms Ohms

No. per Ohm. per Ohm. per Ohm. per Ohm. per foot. per yard. per 1.000 per mile.

foot.

0000 19966.5 6655.5 19.9665 3.7815 .000050684 .00156252 .050084 .264443

000 17497.15 5832.3833 17.49715 3.31385 .0000571522 .0001714566 .0571522 .301763

00 13988.64 4662.68 13.98804 2.64925 .000071489 .000214467 .071489 .377465

0 11198.17 3732.7333 11.19817 2.12086 .0000893002 .0002679006 .0893002 .471505

1 8718.30 2906.10 8.71830 1.6512 .00011470 .0003441 .114701 .60562

2 7813.50 2604.50 7.81350 1.47973 .00012799 .00038397 .12799 .67580

3 6498.14 2166.0466 6.49814 1.23071 .00015389 .00046167 .15389 .81254

4 5487.107 1829.0357 5.487107 1.03923 .000182245 .000546735 .182245 .962256

5 4688.51 1562.8366 4.68851 .887975 .000213287 .000639861 .213287 1.12616

6 3991.91 1330.6366 3.99191 .756045 .000250506 .000751518 .250506 1.32267

7 3138.59 1046.1966 3.13859 .59443 .000318614 .000955842 .318614 1.68228

8 2637.29 879.0966 2.63729 .499486 .000379177 .001137531 .379177 2.00206

9 2121.84 707.280 2.12184 .401864 .000471289 .001413867 .471289 2.488405

10 1739.40 579.80 1.73940 .329432 .000574911 .001724733 .574911 3.03553

11 1394.93 464.9766 1.39493 .264191 .000716882 .002150646 .716882 3.78514

12 1150.91 383.6366 1.15091 .217976 .000868875 .002606625 .868875 4.58766

13 874.252 291.4173 .874252 .165578 .00114383 .00343149 1.14383 6.03945

14 667.338 222.446 .667338 .12639 .00149849 .00449547 1.49849 7.91203

15 502.175 167.39166 .502175 .095109 .00199134 .00597402 1.99134 10.5142

16 409.276 136.42533 .409276 .077514 .00244334 .00733002 2.44334 12.9008

17 325.871 108.62366 .325871 .061718 .0030687 .0092061 3.0687 16.20274

18 232.585 77.52833 .232585 .04405 .0042995 .0128985 4.2995 22.7014

19 170.879 56.95966 .170879 .032363 .0058521 .0175563 5.8521 30.8991

20 149.3915 49.797166 .1493915 .022475 .00842703 .02528109 8.42703 44.4947

21 99.195 33.065 .099195 .018787 .01008110 .03024348 10.08116 53.2285

22 75.9461 25.315366 .0759461 .014384 .0131672 .0395016 13.1672 69.5230

23 60.54377 20.181256 .06054377 .011467 .0165170 .0495510 16.5170 87.2096

24 46.8851 15.628356 .0468851 .0088798 .02132874 .06398622 21.32874 112.616

25 38.748 12.916 .038748 .0073386 .025808 .077424 25.808 136.265

26 31.3859 10.461966 .0313859 .0059443 .03186144 .09558432 31.86144 168.229

27 24.79873 8.266243 .02479873 .0046967 .0403246 .1209738 40.3246 212.914

28 18.98653 6.328843 .01898653 .0035959 .05266892 .15800676 52.66892 278.092

29 16.3710 5.4570 .0163710 .0031006 .0610834 .1832502 61.0834 322.521

30 13.9493 4.649766 .0139493 .0026419 .07168825 .21506475 71.68825 378.514

RESISTANCE & WEIGHT

B.W.G Ohms Lbs. No. per lb. per Ohm.

0000 .000080272 12457.5 000 .000104529 9566.7 00 .000163553 6114.24 0 .000255196 3918.58 1 .00042102 2375.18 2 .00052422 1907.59 3 .00075786 1319.50 4 .0010629 940.844 5 .0014558 686.911 6 .0020082 497.96 7 .00324863 307.822 8 .00460101 217.343 9 .00710791 140.689 10 .0105772 94.543 11 .0164462 60.842 12 .0241593 41.392 13 .0418692 23.8839 14 .0718583 13.9163 15 .126788 7.8872 16 .191045 5.2344 17 .301355 3.31835 18 .59157 1.6904 19 1.09596 .912445 20 2.27254 .44003 21 3.25229 .30748 22 5.54843 .18023 23 8.73035 .11454 24 14.5579 .068691 25 21.3142 .046917 26 32.4863 .030782 27 52.0367 .019217 28 88.7724 .011265 29 119.404 .008375 30 164.4762 .0060804

PURE COPPER weighs 555 lbs. per cubic foot. The Resistance of 1 mil. foot at 60° Fahr. is, according to Dr. Matthiessen, 10.32311 ohms. Upon these data the above Table has been calculated.

The Resistance of Copper varies with the temperature about 0.38 per cent. per degree Centigrade, or 0.21 per cent. per degree Fahrenheit.

STRANDED WIRES.--With a conductor of a definite lenght, made of Stranded Wires, the total weight is greater, and the Resistance less than is a similar length of Conductor with Wires not Stranded.

To convert--Inches to Millimetres multiply by 25.3994

Feet to Metres " .3048

Yards to Metres " .9144

Miles to Kilometres " .6214

Pounds to Kilogrammes " .45359

PEPARED BY WALTER T. GLOVER & CO., ELECTRICAL WIRE AND CABLE MAKERS, 25, BOOTH STREET MANCHESTER.

The gang mill is regarded as possessing material advantages in the rapid and economical manufacture of lumber. Among the recent improvements tending to perfect such mills, those which are shown in the iron frame stock gang, manufactured by Wickes Bros., East Saginaw, Mich., are eminently valuable. Our large engraving represents one of these mills, constructed to be driven by belt, friction, or direct engine, as may be desired. The important requisite in this class of mills is such design and proportion of parts as will insure durability and continued movement at the highest speed, safely increasing the quantity and improving the quality of work done at a lesser feed, and admitting the use of thinner saws than is practical in the slower moving sash. These are among the advantages gained in the iron frame machine, overcoming the necessity of an expensive mill frame, saving time and expense in setting up, and avoiding the liability of decay or change of position.

IMPROVED IRON FRAME GANG SAW MILL.

Many improvements have been made in the mechanism of oscillation, and from these the builders of this mill have adopted what is known as the Wilkin movement, which oscillates the top and bottom slides. The top slides are pivoted at the top end, and the bottom ones from the bottom end, both being operated by one rock shaft from the center. This movement when properly adjusted gives an easy clearance and the easiest cut yet obtained. It adds no extra weight to the sash, and avoids the cumbrous rock shaft and its attendant joints, usually weighing from three hundred to five hundred pounds, which have been found so objectionable in many other movements. The feed is continuous, and is made variable from ¼ to 1¼ inch to each stroke, controllable by the sawyer. Power is applied to the press rolls in the double screw form with pivot point, also operated by the same hand. A special feature of this machine is the spreading of the lower frame so that its base rests upon an independent portion of the foundation from the main pillow block or crank shaft. The solidity of the whole structure is thus increased, both by the increased width at the base and the prevention of connecting vibrations, which necessarily communicate when resting upon the same part, as in other forms of such machines heretofore in use.

The mill shown in the perspective view is one of twenty-six saws 4½ feet long, sash 38 inches wide in the clear, and stroke 20 inches, capable of making 230 strokes per minute. The crank shaft is nine inches in diameter, of the best forged iron. The main pillow block has a base 6½ feet long by 21 inches bearing, weighing 2,800 pounds. The cap is secured by two forged bolts 3½ inches in diameter, and by this arrangement no unequal strain upon the cap is possible. A disk crank is used with suitable counterbalance, expressly adapted to the weight and speed of sash; a hammered steel wrist pin five inches in diameter, and a forged pitman of the most approved pattern, with best composition boxes. The iron drive pulley is 4 to 4½ feet in diameter and 24 inches face; the fly-wheel six feet in diameter, and weighing 4,700 pounds, turned off at rim. When a wider and heavier sash is required, a proportionate increase is made in all these parts.

In the construction of the sash the stiles are made of steel; the lower girt and upper heads are made in one solid piece, without rivets, giving the greatest strength possible, with the least weight. The outfit also includes eight iron rollers for the floor, 8½ inches in diameter, with iron stands, and geared as live rolls when desired, a full set of Lippencott's steel saw hangings, and gauges for one-inch lumber. The weight of the machine here shown is 18½ tons. They are, however, built in larger or smaller sizes, adapted to any locality, quality or quantity of work desired.

It is said that the St. Gothard Tunnel is diverting the bulk of the Italian trade into the hands of the Belgians, Germans, and Hollanders with startling rapidity. Without breaking bulk, early fruits are taken from all parts of Italy to Ostend, Antwerp, and Rotterdam, whence they are carried by fast steamers to London and other English ports. But, on the other hand, Germany is sending into Italy large quantities of coal, iron, machinery, copper, and other articles of which the latter received nothing before. In two months alone, the Italians imported 1,446 tons of paper.

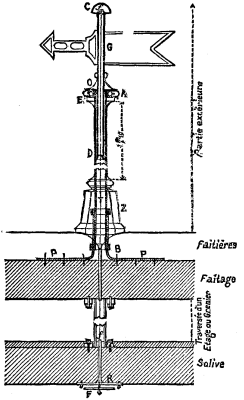

The system of heat regeneration in the firing of gas retorts, in accordance with the principle which Dr. C.W. Siemens has worked out in such a variety of ways in the industrial arts, has lately been applied with very marked success at the Dalmarnock Station of the Glasgow Corporation Gas Works. Notwithstanding the fact that a period of about twenty years has elapsed since Dr. Siemens successfully adapted his system to the firing of retorts at the Paris Gas Works, it seems to have made but little progress up to the present time; for what reasons it is perhaps difficult to explain. It is certain, however, that so-called regenerator furnaces of various forms have, from time to time, been brought into use at gas works for the purpose in question both on the Continent and in this country; and in recent years the subject has received much attention from gas engineers, the general opinion eventually being that the adoption of such a system of working would be certain to result in so great an amount of economy as to put gas as an illuminating agent on a more secure footing to compete successfully with its modern and somewhat aggressive rival, the electric light. Of course, it is now admitted that the mode of adapting the heat regenerative principle at the Paris Gas Works was attended with a degree of complexity in the structural arrangements that was so great and so expensive as to place it practically beyond the reach of gas companies and gas corporations generally, when the expense as well as the scientific beauty and practical efficiency of the new mode of applying and utilizing heat had to be considered. Fortunately, however, Dr. Siemens was enabled two or three years ago to demonstrate that there was no such thing as "finality" in that department of invention which he had made almost exclusively his own. About the time mentioned he placed his most advanced views on gas producers and on the regeneration and utilization of heat before the world, and within that period a most decided step in advance has been made, the structural arrangements now required for gas producers and regenerator furnaces having been immensely simplified and cheapened, while their practical utility has in no way been interfered with.

Scarcely had Dr. Siemens announced his new form of gas producer and regenerator than communication was opened with him by Mr. W. Foulis, the general manager to the Glasgow Corporation Gas Trust, with the view of entering into arrangements for its adoption on an experimental scale at one of the stations under his charge. Encouraged by the hearty co-operation of the gas committee, two or three of whose members were well known engineers, Mr. Foulis very soon came to an understanding with Dr. Siemens to have the regenerative system put to a thorough test at the Dalmarnock Gas Works, situated in the extreme east end of the city, and the largest establishment of the kind in Scotland, the total number of retorts erected being about 750. The system in its most recent shape was applied to four ovens, each of which had seven retorts, but which number has since been increased to eight, owing to the space occupied by the furnace in the ordinary settings being rendered available for an additional retort in the new or "Siemens" setting. For each oven or chamber of eight retorts there was erected a separate gas-producer, so that even one set of eight retorts might alone be used if thought necessary.

GAS RETORTS WITH REGENERATIVE FURNACES .--GLASGOW CORPORATION GAS WORKS.

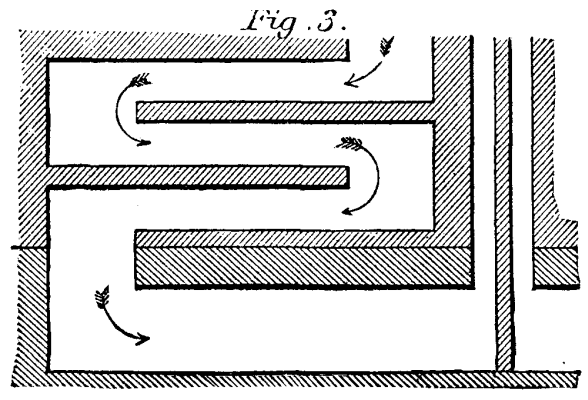

In Figs. 1 and 2 of our illustrations, the general arrangement and the relationship of the gas producer, the regenerators, and the retorts to each other are clearly shown. It was a sort of sine qua non of the new method of firing the retorts that the producer should be in as close proximity as possible to the place where the gaseous fuel was to be used, and it was concluded that the most convenient situation would be immediately in front of its own set of eight retorts, and with its top on a level with the working floor of the retort house. To place it in such a position meant a good deal of excavation, which was also required, however, for the regenerator flues. The excavation was carried down to a depth of 10 ft. below the level of the retort house floor, and as a matter of course the operation of underpinning had to be resorted to for the purpose of carrying down the foundations of the division walls, which, together with the main arches and the hydraulic main, were in no way otherwise disturbed. As in most new inventions, a good deal of difficulty was experienced at first in connection with these gas producers and heat regenerator furnaces; but by dint of application and by the adoption of modifications made here and there in the arrangements from time to time, as also by a determination not to be beaten, although often disheartened, Mr. Foulis was ultimately rewarded with complete success. The new system of firing being made so simple that there was scarcely any possibility of failure likely to arise in ordinary practice if it was superintended with but a moderate amount of care.

Fig. 3.

The results which were obtained in course of time with four ovens, or a total of 32 retorts, were so exceedingly promising that it was forthwith resolved to extend the new mode of firing to the whole of a double bench of twelve ovens, now containing 96 retorts; and all the improvements which had suggested themselves during the working experiments with the four ovens were adopted from the first in the reconstruction of the remaining eight ovens in the bench. More recently the regenerator system has been applied to other 22 ovens, or 176 additional retorts, being the whole of one of the main divisions of the retort house; and during the very depth of the present winter, when the demand for gas was at its greatest height, all the retorts of the converted or "Siemens" settings, amounting to 272, were in full working activity, in which condition they still remain. It is intended to make another very considerable extension of the heat regenerative system of firing during the ensuing spring and summer. The reconstruction of the present year will extend to the ovens of seven retorts each, giving in this case eighty gas fired retorts; and to twenty ovens of five retorts each, which will become sixteen ovens, each having eight retorts, making 128 retorts in this division, and the total being 208 retorts in place of 170 in the same amount of space. It is confidently anticipated, therefore, that by the month of August of the present year, 480 full sized retorts will be available for working out the new method at the Dalmarnock Gas Works. Furthermore, the confidence which has been inspired in the minds of the members of the Glasgow Corporation Gas Committee and their engineer regarding the actualities and possibilities of the Siemens system of firing gas retorts, in its most improved state, is such that arrangements are being made for starting shortly to apply it throughout at the Dawsholm Station, which is situated in the suburban burgh of Maryhill, and some four or five miles distant from the Dalmarnock Works in a northwestern direction. The station just named, which is also a very large one, will probably require two years for its conversion.

We shall now give some account of the structural arrangements adopted for producing cheap gaseous fuel, and for turning that fuel to the greatest advantage in firing the retorts for the purpose of carbonizing the cannel coal used as the source of the gas.

The gas producer, which is represented in vertical section in Fig. 2, is a cylinder of brickwork inclosed in a casing of malleable iron. It is 7 ft. 6 in. deep, and 3 ft. in diameter, which becomes reduced to 20 in. above, where it is closed by means of a cast-iron lid, which is continuous with the floor of the retort house. There are no firebars at the bottom, so that the fuel rests on a floor of firebrick. At the bottom of the walls of the producer there are several holes about 1 ft. in length by 6 in. in height. By means of these openings any clinker that may form and the ashes of the spent fuel can readily be withdrawn. They also allow of the admission of air to maintain the combustion in the lower portion of the mass of fuel; and at each opening there is a malleable iron tube for delivering a jet of steam direct from a steam boiler. We shall subsequently explain the functions performed by the steam.

The fuel employed is the coke or char resulting from cannel coal when it has yielded up its hydrocarbons and other gases during the process of carbonization in the gas retorts. Being entirely made from Scotch cannel the coke is very poor in quality, as it contains a large percentage of mineral matter or ash relatively to its fixed carbon. The retorts are worked with three-hour charges, but the producer is only charged once in every six hours For each set of eight retorts the charge of raw cannel is about 18 cwt., and it is found in practice that the coke drawn from five of the retorts is quite sufficient to fill up the producer to the top. Formerly a set of seven retorts fired in the ordinary way from a furnace underneath, required from 60 to 75 per cent. of the coke made, but now, with eight retorts in each oven, the quantity has been reduced to about 30 per cent., or less than one-half of what it formerly was. Before the retorts are drawn the lid is removed from the top of the producer, and any fuel still remaining unconsumed is touched up a bit by way of leveling it on the surface, and as soon as it has been filled up to the constricted portion a shovelful of soft luting is spread over the top of the coke, and the lid is laid upon it and driven home, thereby making a perfectly air-tight joint. The contents of the other three retorts, as also the contents of the whole of the retorts at each alternate drawing, are taken to the coke heap in the yard. We have already spoken of a charge of cannel as being about 18 cwt. for each set of eight retorts, but in connection with that matter we should mention that it was formerly about 13 cwt. per oven containing seven retorts, and that there is every prospect of it being increased without increasing the length of time occupied in carbonizing the cannel of each charge.

It may be worth while now to notice briefly what takes place among the mass of coke in the gas producer. The atmospheric air admitted at the several openings previously spoken of ascends through the lower layers of the incandescent coke, the carbon of which burns to carbonic acid gas at the expense of the oxygen of the air. Among the middle and upper layers of the incandescent coke the carbonic acid gas takes up a further quantity of the fixed carbon, and becomes transformed into carbonic oxide gas (CO2+C=2CO), which is an inflammable body, and possesses considerable calorific power. Unless the carbonic acid gas is very completely "baffled" in its ascent through the coke in the producer, a quantity of it passes into the furnace along with the carbonic oxide, the efficiency of which is diminished in proportion as the former increases in quantity. Of course, also, the nitrogen associated with the oxygen in the air admitted to the gas generator passes on with the carbonic oxide gas, this nitrogen acting as a dilutant and being of course absolutely useless as a generator of heat. The steam which we previously spoke of serves two good purposes. In contact with incandescent coke it suffers decomposition, its oxygen uniting with some of the fixed carbon to form carbonic oxide, while the hydrogen which is set free passes onward, and mixes with the other gases to be subsequently consumed with them. The admission of the steam thus causes the absorption of heat in the gas generator where the decomposition takes place, this heat being again evolved on the subsequent combustion of the hydrogen. Then, again, as the steam is delivered in among the coke in a jet, or a series of jets, it has the effect of almost entirely preventing any clinkering or slagging of the earthy and silicious materials, which form such a large portion of the substance of the coke obtained from Scotch cannels, sometimes as much as from 15 to 20 per cent. It is scarcely necessary for the stokers to go down below to the bottom of the producers to remove the ash above once in every six hours. Referring to the composition of the gaseous fuel obtained from cannel coke in one of these gas producers, we give the following typical analysis on the authority of Dr. William Wallace, F.R.S.E., gas examiner, and one of the public analysts for the city of Glasgow:

Per cent.

Hydrogen 8.7

Carbonic oxide 28.1

Carbonic acid 3.5

Oxygen 0.4

Nitrogen 59.3

-----

100.0

By again referring to Fig. 2, it will be observed that an opening is provided for the passage of the gaseous matter as it is formed into the mass of brickwork, the upper half of which is occupied by the retorts of the setting and the lower by the regenerators.

Before following the gas we may first direct attention to the

arrangements for dealing with it, and with the air that has to be

admitted for the combustion of so much of it as is of a combustible

nature. It will be seen by reference to Fig. 1 that the oven proper

is occupied by eight  shaped retorts. These are 9 ft. long (set back to back) by 18 in.

by 13 in., and they are placed on arches which are 8 ft. 6 in.

wide. Underneath the level of the retort oven there are two

regenerators or regenerator chambers, which differ very materially

in form from the regenerators formerly applied by Dr. Siemens to

gas retort ovens, and which are still employed for high temperature

furnaces like those used for steel and glass melting. In the case

of these latter the regenerators are on the alternating

system--that is to say, a mass of brickwork is heated by the waste

heat of the effluent gases, and when that is made sufficiently hot,

the current of waste gases is turned into a second mass of

brickwork, while air is admitted to pass through the brickwork

already heated. The system thus briefly described entails a certain

amount of attention on the part of the workmen in the altering of

the valves or dampers to reverse the currents. The regenerator now

adopted consists of an arrangement of six zigzag flues, three on

each side of the setting. These flues run the whole length of the

setting. As indicated by the arrows pointing downward in Fig. 3,

the waste gases on their way to the chimney stack pass to and fro

through the side flues, thus giving up a large portion of their

contained heat by the process of conduction or contact to the

central flue through which the incoming air passes. The air

necessary for combustion is first admitted into a large chamber in

the center, and then it is divided into two currents, which pass

right and left into the central passages of the two regenerators.

As the air flue is at a very bright heat for a considerable

distance before the air leaves it, the temperature of the air must

be equally great, or nearly so. In its most improved form one of

these heat regenerative furnaces provides an amount of heating

surface extending to 234 square ft., which is exposed to the air on

its way to the combustion chamber.

shaped retorts. These are 9 ft. long (set back to back) by 18 in.

by 13 in., and they are placed on arches which are 8 ft. 6 in.

wide. Underneath the level of the retort oven there are two

regenerators or regenerator chambers, which differ very materially

in form from the regenerators formerly applied by Dr. Siemens to

gas retort ovens, and which are still employed for high temperature

furnaces like those used for steel and glass melting. In the case

of these latter the regenerators are on the alternating

system--that is to say, a mass of brickwork is heated by the waste

heat of the effluent gases, and when that is made sufficiently hot,

the current of waste gases is turned into a second mass of

brickwork, while air is admitted to pass through the brickwork

already heated. The system thus briefly described entails a certain

amount of attention on the part of the workmen in the altering of

the valves or dampers to reverse the currents. The regenerator now

adopted consists of an arrangement of six zigzag flues, three on

each side of the setting. These flues run the whole length of the

setting. As indicated by the arrows pointing downward in Fig. 3,

the waste gases on their way to the chimney stack pass to and fro

through the side flues, thus giving up a large portion of their

contained heat by the process of conduction or contact to the

central flue through which the incoming air passes. The air

necessary for combustion is first admitted into a large chamber in

the center, and then it is divided into two currents, which pass

right and left into the central passages of the two regenerators.

As the air flue is at a very bright heat for a considerable

distance before the air leaves it, the temperature of the air must

be equally great, or nearly so. In its most improved form one of

these heat regenerative furnaces provides an amount of heating

surface extending to 234 square ft., which is exposed to the air on

its way to the combustion chamber.

Passing from the producer through the flue provided for it, the gas enters the retort setting underneath the side retorts, where it meets the air coming from the regenerator. It enters the setting, not by a number of small openings, but by one large opening on each side, and meets the air entering also by a large opening, the effect of which is to avoid the localization of intense heat, as all the retorts of the setting become enveloped in an intensely heating flame, due to the combustion of the carbonic oxide and hydrogen gases.