The Project Gutenberg eBook of Coal and the coal mines, by Homer Greene

Title: Coal and the coal mines

Author: Homer Greene

Illustrator: Homer Greene

Release Date: October 11, 2022 [eBook #69134]

Language: English

Produced by: Donald Cummings with images made available by the HathiTrust Digital Library.

The Riverside Library for Young People

Number 5

By HOMER GREENE

BY

WITH ILLUSTRATIONS FROM DRAWINGS BY

THE AUTHOR

BOSTON AND NEW YORK

HOUGHTON, MIFFLIN AND COMPANY

The Riverside Press, Cambridge

1898

Copyright, 1889.

By HOMER GREENE.

All rights reserved.

The Riverside Press, Cambridge, U. S. A.:

Electrotyped and Printed by H. O. Houghton & Company.

To

GILES POLLARD GREENE,

WHO WAS BORN ON THE DAY THIS BOOK WAS BEGUN,

AND WHOSE SMILES AND TEARS

THROUGH HALF A YEAR

HAVE BEEN A DAILY INSPIRATION IN THE WORK,

This Completed Task

IS NOW DEDICATED

BY

In treating of so large a theme in so small a compass it is impossible to do more than make an outline sketch. It has been the aim of the author to give reliable information free from minute details and technicalities. That information has been, for the most part, gathered through personal experience in the mines. The literature of this special subject is very meagre, and the author is unable to acknowledge any real indebtedness to more than half a dozen volumes. First among these is the valuable treatise on “Coal Mining,” by H. M. Chance of the Pennsylvania Geological Survey. Other volumes from which the author has derived considerable information are the State geological reports of Pennsylvania, the mine inspector’s reports of the same State, and the “Coal Trade Annuals,” issued by Frederick E. Saward of New York.

The author desires also to acknowledge his indebtedness[vi] for valuable assistance in the preparation of this work to John B. Law and Andrew Bryden, mining superintendents, and George Johnson, real estate agent, all of the Pennsylvania Coal Company, at Pittston, Pennsylvania, and to the officers of the Wyoming Historical and Geological Society of Wilkes Barre, Pennsylvania.

HOMER GREENE.

Honesdale, Pa.,

May 15, 1889.

| CHAPTER | PAGE | |

|---|---|---|

| I. | In the Beginning | 1 |

| II. | The Composition of Coal | 6 |

| III. | When Coal was Formed | 14 |

| IV. | How the Coal Beds Lie | 22 |

| V. | The Discovery of Coal | 35 |

| VI. | The Introduction of Coal into Use | 51 |

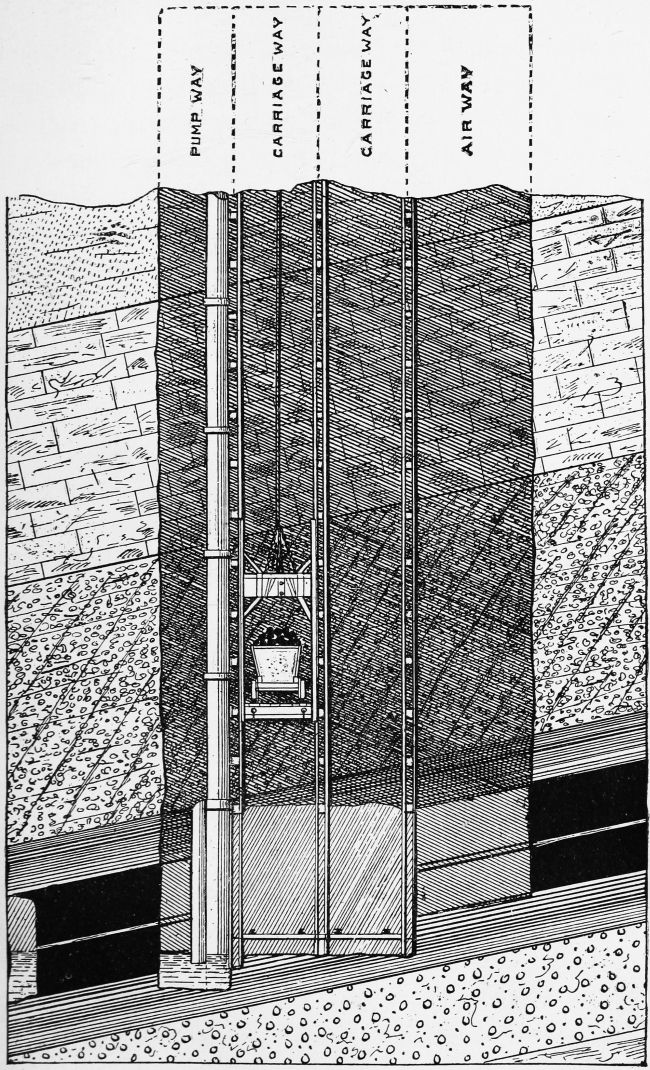

| VII. | The Way into the Mines | 75 |

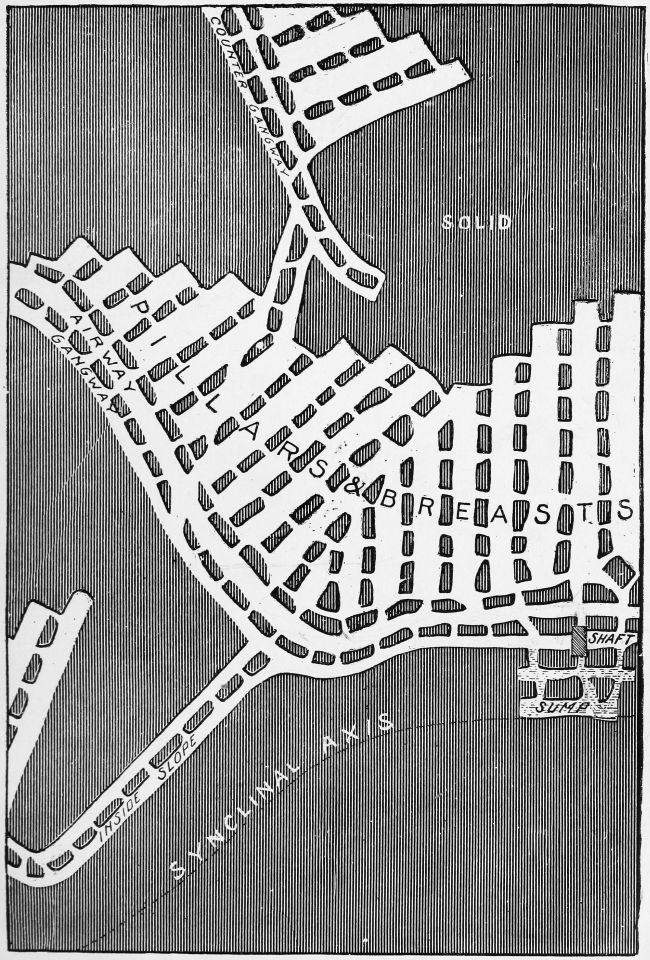

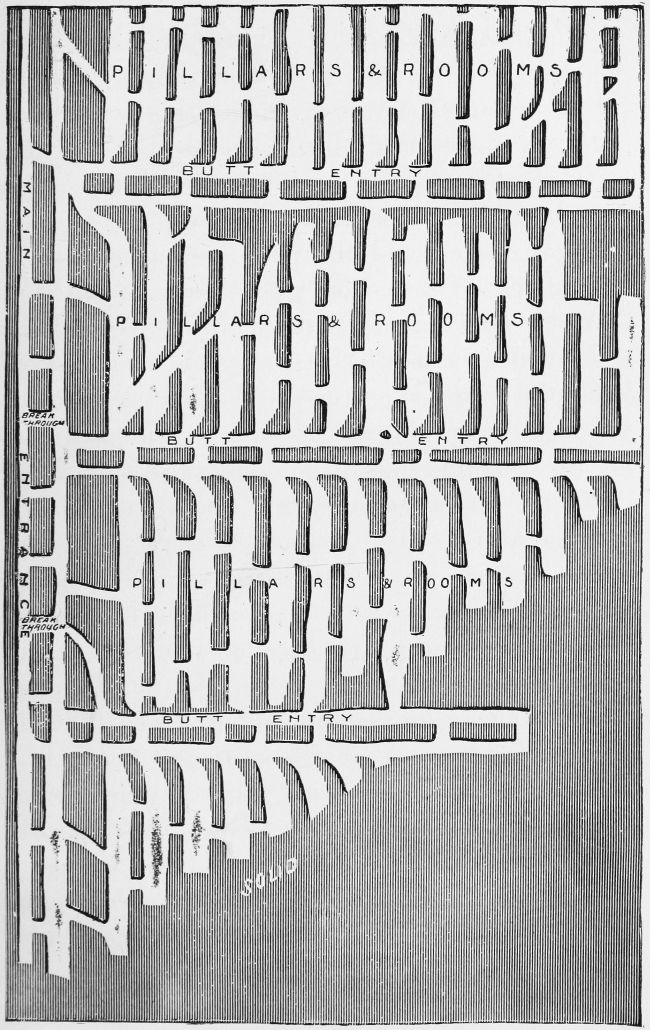

| VIII. | A Plan of a Coal Mine | 94 |

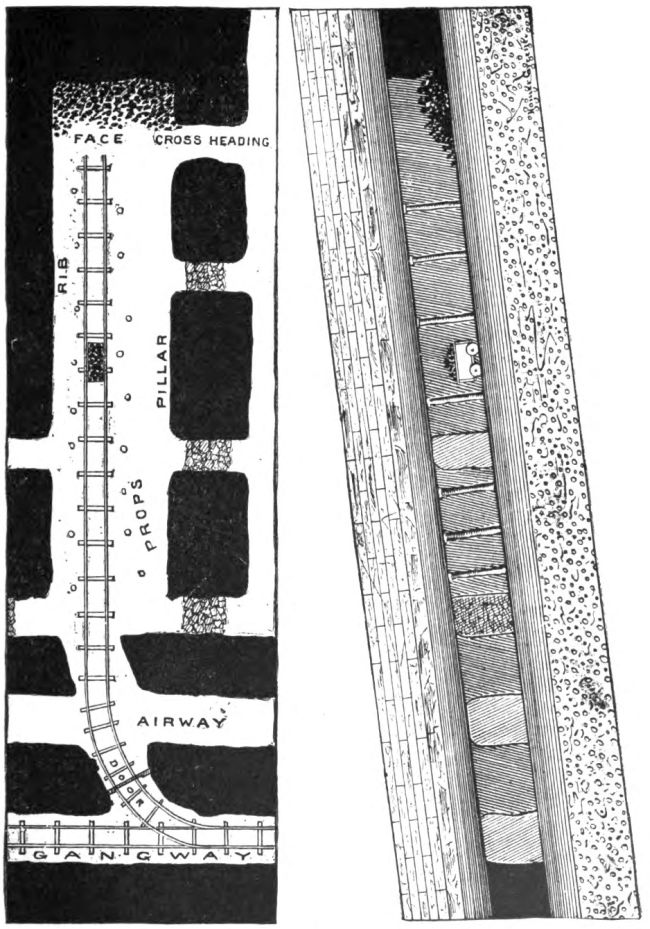

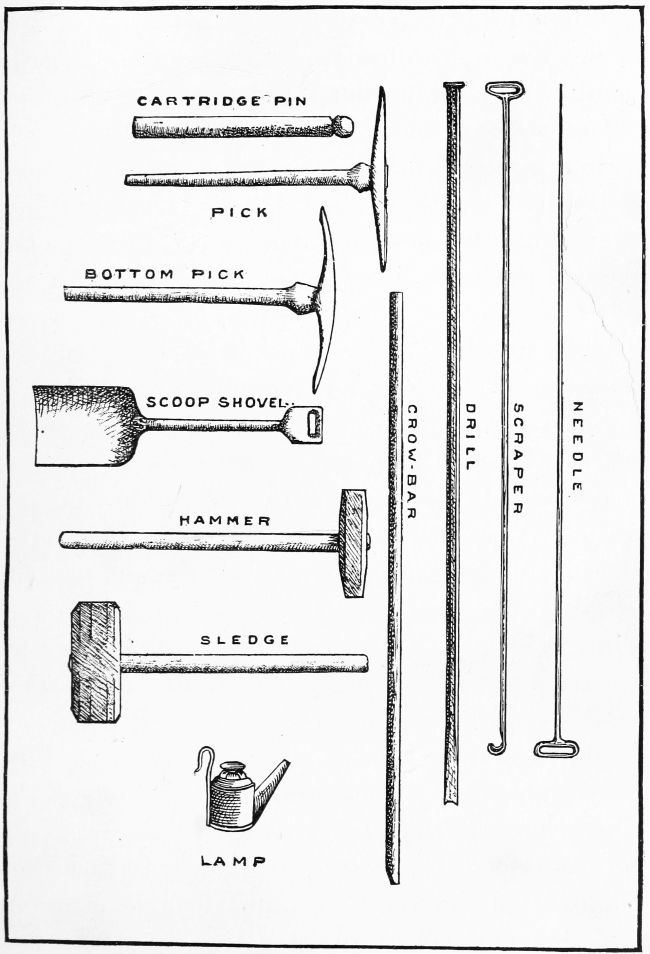

| IX. | The Miner at Work | 112 |

| X. | When the Mine Roof Falls | 127 |

| XI. | Air and Water in the Mines | 147 |

| XII. | The Dangerous Gases | 159 |

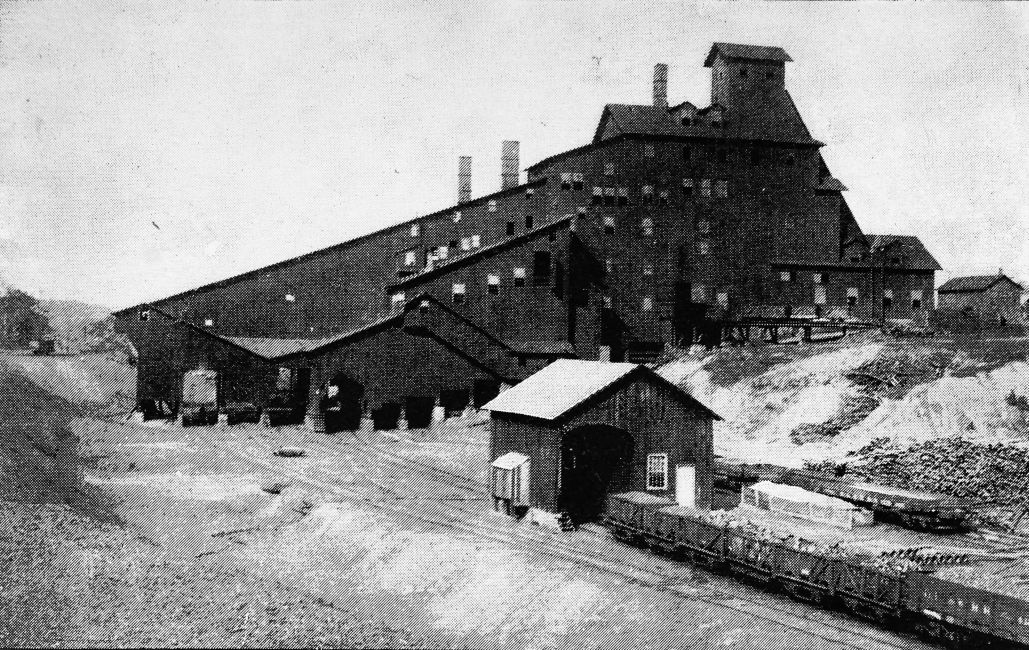

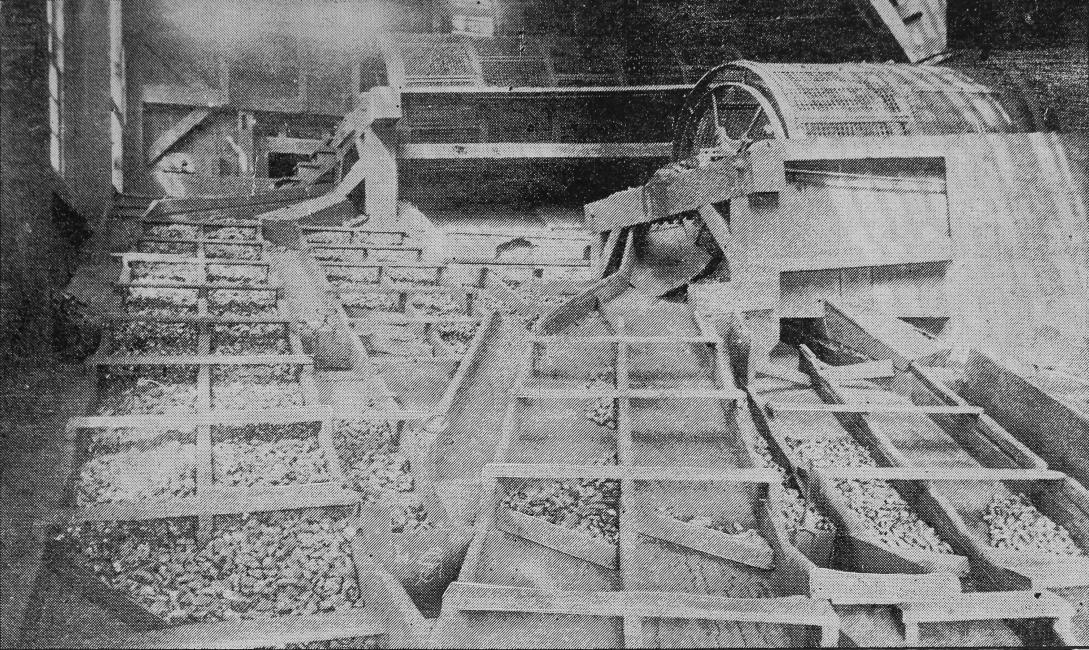

| XIII. | The Anthracite Coal Breaker | 176 |

| XIV. | In the Bituminous Coal Mines | 192 |

| XV. | The Boy Workers at the Mines | 204 |

| XVI. | Miners and their Wages | 222 |

Every one knows that mineral coal is dug out from the crust of the earth. But the question frequently is asked concerning it, How and under what conditions was it formed? In order to answer this inquiry it is necessary to have recourse to the science of geology.

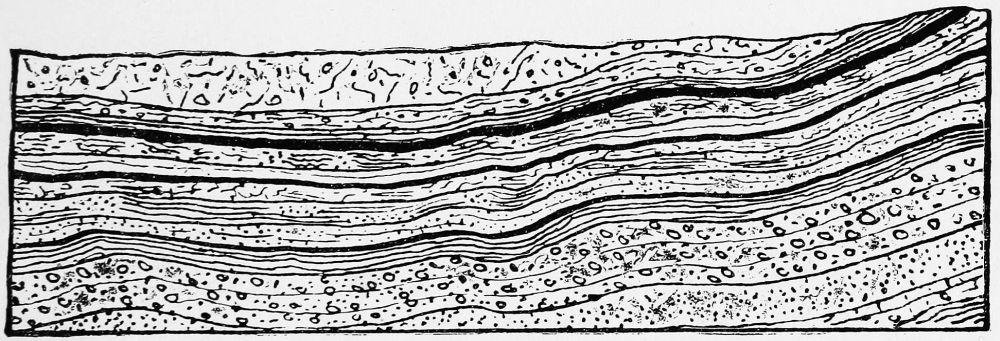

A brief review of the geological history of the earth’s crust will be of prime importance, and it will not be inappropriate to go back to the origin of the earth itself. But no man can begin at the beginning; that is too far back in the eternal mists; only the Infinite Mind can reach to it. There is a point, however, to which speculation can journey, and from which it has brought back brilliant theories to account for the existence of the planet on which we live. The most philosophic of these theories, as it certainly is the most popular, is the one known as the Nebular Hypothesis, propounded by Laplace, the great French[2] astronomer, in 1796. This theory accords so well with the laws of physics, and with the human knowledge of the age, that most of the great astronomers have adopted it as the best that has been given to us, and the world of science may be said to have accepted it as final. Let us suppose, then, in accordance with this theory, that our earth was, at one time, a ball of liquid fire, revolving on its axis, and moving, in its orbit, around the parent sun with the motion imparted to it in the beginning. As cooling and condensation went on, a crust was formed on its surface, and water was formed on the crust. The waters, however, were no sooner spread out than they were tossed by the motion of the atmosphere into waves, and these waves, by constant friction against the rock crust of the earth, wore it down into pebbles, sand, and mud. The silt thus made being washed up on to the primitive rock and left there by the receding waters became again as hard and firm as before. Occasionally a subsidence, due to the contraction of the earth’s body, would take place and the sea would again sweep over the entire surface, depositing another layer of silt on the one already formed, or possibly washing that again into sand and pebbles. This process continued through an indefinite period of time, forming layer upon layer of stratified rock, or excavating great hollows in the surface already formed.

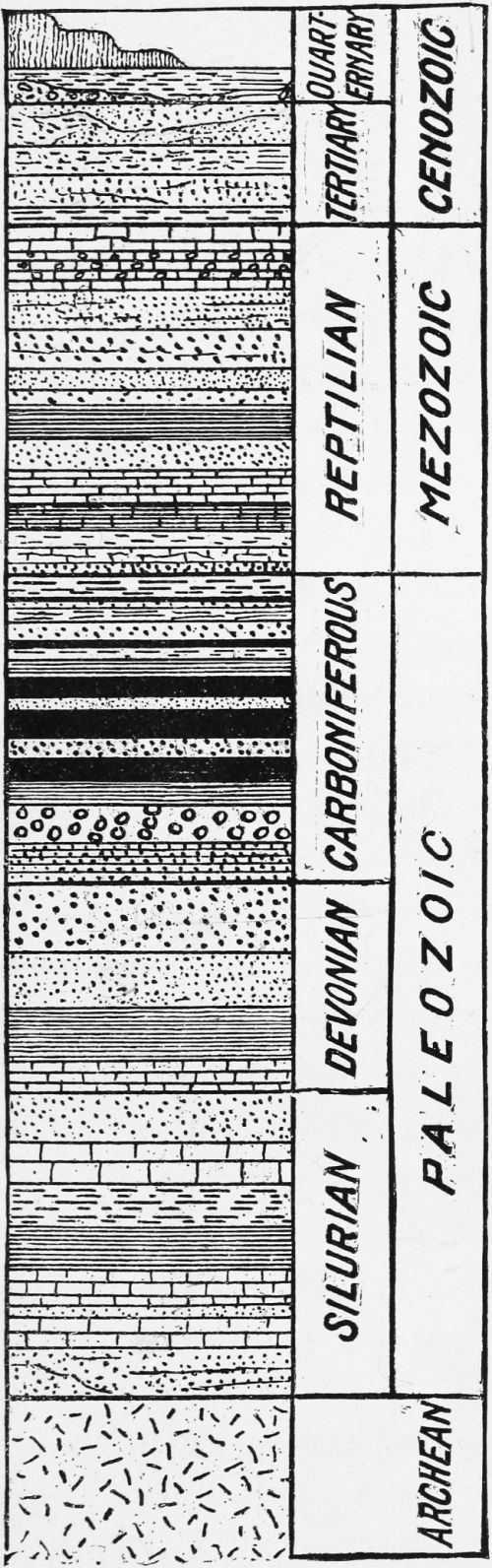

That period in the history of the earth’s crust[3] before stratification began is known as Archean time. This was followed by the period known as Paleozoic time, which is divided into three ages. The first is the age of Invertebrates. It was during this age that life made its advent on the earth. The waters were the first to bring it forth, but before the close of the age it began also to appear on the land, in isolated spots, in the simplest forms of vegetation. The next age is known as the age of Fishes, during which vegetable life became more varied and abundant, winged insects floated in the air, and great sharks and gars swam in the seas. Then came the Carboniferous age or age of Coal Plants, in which vast areas of what are now the Middle, Southern, and Western States were covered with low marshes and shallow seas, and were rich and rank with multitudinous forms of vegetation. But these marshes were again and again submerged and covered with material washed up by the waves before the final subsidence of the waters left them as a continuing portion of the dry land. It was at the close of the Carboniferous age that great disturbances took place in the earth’s crust. Before this the rock strata had been comparatively level; now they were folded, flexed, broken, rounded into hills, pushed resistlessly up into mountain ranges. It was at this time that the upheaval of the great Appalachian Range in North America took place. Following this came Mesozoic time, which had[4] but one age, the age of Reptiles. It was during this age that the type of reptiles reached its culmination. The land generally brought forth vegetation, though not with the prolific richness and luxury of the Carboniferous age. Birds, insects, and creeping things were abundant, and monsters of the saurian tribe swam in the seas, roamed through the marshes, crawled on the sandy shores, and took short flights through the air. The last great division is known as Cenozoic time, and covers two ages, the age of Mammals and the age of Man. It was during the mammalian age that trees of modern types, such as oak, maple, beech, etc., first made their appearance, and mammalian animals of great variety and size, both herbivorous and carnivorous, roamed through the forests. True birds flew in the air, true snakes crawled upon the ground, and in the waters were whales and many kinds of fishes of the present day. But the marine monsters and the gigantic and ferocious saurians of an earlier age had disappeared. So the world became fitted to be the dwelling-place of the human race. Then began the age of Man, an age which is yet not complete.

Such, in brief, is the history of the earth as the rocks have told it to us. Without their help we could know but little of the story. Through all the periods of time and all the ages, they were being formed, layer upon layer, of sand and silt, of mud and pebbles, hardening with the passing[5] of the centuries. But while they were still soft they received impressions of the feet of birds and of beasts, they were marked by the waves and were cracked in the fierce heat of the sun, and their surfaces were pitted by the rain-drops of passing showers. Shells, corals, and sponges were imbedded in them; the skeletons of fishes and the bones of animals that walked or crept upon the land or flew in the air were covered over by them; they caught and held the drooping fern, the falling leaf and twig and nut; they closed around the body of the tree itself and buried it from sight; and as the soil hardened into rock, bone and shell, leaf and stem, hardened with it and became part of it. To-day we find these fossil remains, sometimes near the surface of the earth, sometimes hundreds or thousands of feet below it. We uncover them from the soil, we break them from the rock, we blast them out in the quarries, we dig them from the mines of coal and ore. It is by them and by the structure of the rock which contains them that we read the history of the earth, a history covering so long a period of time from the beginning of the stratification of the rocks to the age when man appeared upon the globe that no one has yet dared to reckon the millions upon millions of years which intervened, and give the result of his computation to the world as true.

COLUMNAR SECTION OF THE EARTH’S CRUST.

The first question that would naturally be asked concerning the subject with which we are dealing is, What is coal?

In reply it may be said that it is a mineral. It is black or brown in color, solid, heavy, and amorphous. The specific gravity of the average Pennsylvania anthracite is about 1.6, and of the bituminous coal about 1.4. There are four varieties of mineral coal, namely: anthracite, bituminous, lignite or brown coal, and cannel coal. To this list it would not be improper to add peat, since it partakes of most of the characteristics of mineral coal, and would doubtless develop into such coal if the process of transformation were allowed to continue undisturbed. The principal element contained in each of these different kinds of coal is carbon. An analysis of an average piece of Pennsylvania anthracite would show the following chemical composition:—

| Fixed carbon | 86.4 |

| Ash | 6.2 |

| Water | 3.7 |

| Volatile matter | 3.1 |

| Sulphur | .6 |

| —— | |

| Total | 100 |

The composition of the bituminous coals of Pennsylvania, as represented by the gas coal of Westmoreland County, is shown by analysis to be as follows:—

| Fixed carbon | 55. |

| Volatile matter | 37.5 |

| Ash | 5.4 |

| Water | 1.4 |

| Sulphur | .7 |

| —— | |

| Total | 100 |

An analysis of coal from the Pittsburgh region would show its percentage of carbon to be from 58 to 64, and of volatile matter and ash to be proportionately less.

There is no strict line of demarcation between the anthracite and the bituminous coals. They are classed generally, according to the amount of carbon and volatile matter contained in them, as:—

Hard-dry Anthracites,

Semi-Anthracite,

Semi-Bituminous,

Bituminous.

Coals of the first class contain from 91 to 98 per cent, of carbon, and of the second class from 85 to 90 per cent. The volatile matter in the third class is usually less than 18 per cent., and in the fourth class more than 18 per cent. of its composition.

The anthracite coal is hard and brittle, and has a rich black color and a metallic lustre. It ignites with difficulty, and at first burns with a small blue flame of carbonic oxide. This disappears, however, when ignition is complete. No smoke is given off during combustion. Semi-anthracite coal is neither so hard, so dense, nor so brilliant in lustre as the anthracite, though when once fully ignited it has all the characteristic features of the latter in combustion. It is found principally at the western ends of the anthracite coal basins.

Bituminous coal is usually deep black in color, with little or no lustre, having planes of cleavage which run nearly at right angles with each other, so that when the coal is broken it separates into cubical fragments. It ignites easily and burns with a yellowish flame. It gives off smoke and leaves a large percentage of ashes after combustion. That variety of it known as caking or coking coal is the most important. This is quite soft, and will not bear much handling. During combustion it swells, fuses, and finally runs together in large porous masses.

Following the question of the composition of coal comes the question of its origin, of which, indeed, there is no longer any serious doubt. It is generally conceded that coal is a vegetable product, and there are excellent reasons for this belief. The fragments of which coal is composed have been[9] greatly deformed by compression and decomposition. But when one of those fragments is made so thin that it will transmit light, and is then subjected to a powerful microscope, its vegetable structure may readily be distinguished; that is, the fragments are seen to be the fragments of plants. Immediately under every separate seam of coal there is a stratum of what is known as fire clay. It may, under the beds of softer coals, be of the consistency of clay; but under the coal seams of the harder varieties it is usually in the form of a slaty rock. This fire clay stratum is always present, and contains in great abundance the fossil impressions of roots and stems and twigs, showing that it was once the soil from which vegetation grew luxuriantly. It is common also to find fossil tree-stems lying mashed flat between the layers of black slate which form the roof of the coal mines, also the impressions of the leaves, nuts, and seeds which fell from these trees while they were living. In some beds of cannel coal whole trees have been found, with roots, branches, leaves, and seeds complete, and all converted into the same quality of coal by which they were surrounded. In short, the strata of the coal measures everywhere are full of the fossil impressions of plants, of great variety both in kind and size.

If a piece of wood be subjected to heat and great pressure, a substance is obtained which strongly resembles mineral coal.

That coal contains a very large proportion of carbon in its composition has already been noted. If, therefore, it is a vegetable product, the vegetation from which it was formed must have been subjected to some process by which a large part of its substance was eliminated, since wood or woody fibre contains only from 20 to 25 per cent. of carbon. But wood can be transformed, by combustion, into charcoal, a material containing in its composition 98 per cent, of carbon, or a greater percentage than the best anthracite contains. This cannot be done, however, by burning wood in an open fire, for in that case its carbon unites with atmospheric oxygen and passes invisibly into the air. It must be subjected to a process of smothered combustion; free access of air must be denied to it while it is burning. Then the volatile matter will be freed and expelled, and, since the carbon cannot come in contact with the oxygen of the air, it will be retained, together with a small percentage of ash. The result will be charcoal, or coal artificially made. The principle on which this transformation is based is combustion or decomposition out of contact with atmospheric air. But Nature is as familiar with this principle as is man, and she may not only be discovered putting it in practice, but the entire process may be watched from beginning to end. One must go, for this purpose, first, to a peat bed. This is simply an accumulation of the remains of[11] plants which grew and decayed on the spot where they are now found. As these remains were deposited each year, every layer became buried under its succeeding layer, until finally a great thickness was obtained. When we remove the upper layer we find peat with its 52 to 66 per cent. of carbon, and the deeper we go the better is the quality of the substance. It may be cut out in blocks with sharp spades, the water may be pressed from the blocks, and they may be stacked up, covered and dried, and used for fuel. In most peat bogs the process of growth is going on, and may be watched. There is a certain kind of moss called sphagnum, which in large part makes up the peat-producing vegetation. Its roots die annually, but from the living top new roots are sent out each year. The workmen who dig peat understand that if this surface is destroyed the growth of the bed must stop; consequently in many instances they have removed the sod carefully, and after taking out a stratum of peat have replaced the sod in order that the bed may be renewed. There is little doubt that if these beds of peat could lie undisturbed and covered over through many ages they would take on all the characteristics of mineral coal.

A step farther back in geological history we reach the period of the latest formations of lignite or brown coal. This coal is first found in the strata of the glacial period, or first period in the[12] age of Man. But it is found there in an undeveloped state. The woody fibre has not yet undergone the complete transformation into coal. The trunks and branches of trees have indeed become softened to the consistence of soap, but they still retain their natural color. Going back, however, to the strata of the Miocene or second period of the Tertiary age or age of Mammals, we find that this wood has become black, though it has not yet hardened. But when we reach the upper cretaceous or last period of the age of Reptiles, the transformation into coal has become complete. The woody fibre is now black, hard, and compact, though it may still be easily disaggregated by atmospheric action, and we have the true lignite, so called because of its apparent woody structure.

The next step takes us back to the bituminous coal of the Carboniferous age, the character and consistency of which has already been noted, and finally we reach the complete development in anthracite. It is, however, the opinion of the best geologists that the bituminous and anthracite coals are of the same age, and were originally of the same formation and character. That is, they were all bituminous; but during the violent contortions and upheavals of the earth’s crust at the time of the Appalachian revolution at the close of the Carboniferous age, the bituminous coals involved in that disturbance were changed by heat, pressure,[13] and motion, and the consequent expulsion of volatile matter, from bituminous to anthracite.

Cannel coal is a variety of bituminous coal, burning with great freedom, the flame of which affords considerable light. It was called “candle coal” by the English people who first used it, as it often served as a substitute for that household necessity. But the name soon became corrupted to “cannel,” and has so remained. It is duller and more compact than the ordinary bituminous coal, and it can be wrought in a lathe and polished. A certain variety of it, found in the lower oölitic strata of Yorkshire in England, is manufactured into a kind of jewelry, well known by its popular name of jet.

It becomes of interest now to examine briefly into the causes and process of the transformation from vegetable substance into coal, to note the character of the vegetation which went to make up the coal beds, and to glance at the animal life of the period.

As has already been said, the plants of the Carboniferous age were exceedingly abundant and luxuriant. They grew up richly from the clayey soil, and formed dense jungles in the vast marshes which covered so large an area of the earth’s surface. Ferns, mosses, and tufts of surface vegetation, and the leaves, branches, and trunks of trees fell and decayed on the place where they grew, only to make the soil more fertile and the next growth richer and more luxuriant. Year after year, century after century, this process of growth and decay went on, until the beds of vegetable matter thus deposited had reached a great thickness. But condensation was still in progress in the earth’s body, and in consequence of it her crust, of necessity, at times contracted and fell. When it did so the land sank throughout vast[15] areas, these beds of incipient coal went down, and over the great marshes the waters swept again, bringing drift of vegetation from higher levels to add to that already buried. Then over these deposits of vegetable matter the sand and mud and gravel were laid up anew, and the clayey soil from which the next rich growth should spring was spread out upon the surface. This process was repeated again and again, as often, indeed, as we find seams of coal in any coal bed. Thus the final condition for the formation of coal was met, the exclusion of atmospheric air from this mass of decaying vegetation was complete, and under the water of the ocean, under the sand and silt of the shore, under the new deposits of succeeding ages, the transformation went on, the wood of the Carboniferous era became the coal of to-day, while above and below it the sand and clay were hardened into rock and shale.

The remarkable features of the vegetation of the coal era were the size and abundance of its plants. Trees of that time whose trunks were from one to three feet in diameter, and which grew to a height of from forty to one hundred feet, are represented in our day by mere stems a fraction of an inch in diameter and but one or two feet high. A comparison of quantity would show differences as great as does the comparison of size.

But at that time all the conditions were favorable for the rapid and enormous growth of vegetation.[16] The air was laden with carbon, which is the principal food for plants; so laden, indeed, that man, who is eminently an oxygen-breathing animal, could not have lived in it. The great humidity of the atmosphere was another element favorable to growth. Vegetation never lacked for an abundance of moisture either at root or leaf. Then, too, the climate was universally warm. Over the entire surface of the earth the heat was greater than it is to-day at the torrid zone. It must be remembered that the internal fires of the globe have been constantly cooling and receding, and that the earth, in the Carboniferous age, was subjected to the greater power of a larger sun than shines upon us to-day.

With all these circumstances in its favor, warmth, moisture, and an atmosphere charged heavily with carbon, vegetation could not help but flourish. That it did flourish amazingly is abundantly shown by its fossil remains. The impressions of more than five hundred different species of plants that grew in the Carboniferous era have been found in the coal measures. There are few of them that bear any direct analogy to existing species, and these few have their counterparts only in the torrid zone. The most abundant of the plants of the coal era were the ferns. Their fossil remains are found in great profusion and variety in most of the rocks of the coal-bearing strata. There was also the plant[17] known as the tree fern, which attained a height of twenty or thirty feet and carried a single tuft of leaves radiating from its top. Probably the species next in abundance, as it certainly is next in importance, to the ferns is that of the Lepidodendrids. It doubtless contributed the greatest proportion of woody material to the composition of coal. The plants of this species were forest trees, but are supposed to have been analogous to the low club mosses of the present. Fossil trunks of Lepidodendrids have been found measuring from one hundred to one hundred and thirty feet in length, and from six to ten feet in diameter.

Similar in appearance to the Lepidodendrids were the Sigillariæ, which were also very abundant. The Conifers were of quite a different species from those already named, and probably grew on higher ground. They were somewhat analogous to the modern pine.

The Calamites belonged to the horsetail family. They grew up with long, reed-like, articulated stems to a height of twenty feet or more, and with a diameter of ten or twelve inches. They stood close together in the muddy ground, forming an almost impenetrable thicket, and probably made up a very large percentage of the vegetation which was transformed into coal.

One of the most abundant species of plants of the coal era is that of Stigmaria. Stout stems, from two to four inches in diameter, branched downward[18] from a short trunk, and then grew out in long root-like processes, floating in the water or trailing on the mud to distances of twenty or thirty feet. These are the roots with which the under clay of every coal seam is usually filled.

The plants which have been described, together with their kindred species, formed the largest and most important part of the vegetation of the Carboniferous age. But of the hundreds of varieties which then abounded, the greater portion reached their highest stage of perfection in the coal era, and became extinct before the close of Paleozoic time. Other types were lost during Mesozoic time, and to-day there is scarcely a counterpart in existence of any of the multitude of forms of plant life that grew and flourished in that far-off age of the world.

The animal life of the Carboniferous era was confined almost entirely to the water. The dry land had not yet begun to produce in abundance the higher forms of living things. There were spiders there, however, and scorpions, and centipedes, and even cockroaches. There were also land snails, beetles, locusts, and mayflies. Reptiles, with clumsy feet and dragging tails, prowled about on the wet sands of the shore, leaving footprints that were never effaced by time or the elements, and are found to-day in the layers of the rocks, almost as perfect as when they were formed, millions of years ago. But the waters[19] teemed with animal life. On the bottom of the shallow seas lay shells and corals in such abundance and variety that from the deposits of their remains great beds of limestone have been formed. Broken into minute fragments by the action of the waves and washed up by the sea during periods of submergence, they were spread over the beds of carboniferous deposits, and became the rock strata through which the drills and shafts of to-day are sunk to reach the veins of mineral coal.

Fishes were numerous. Some of them, belonging to species allied to the modern shark, were of great size, with huge fin spines fully eighteen inches in length. These spines have been found as fossils, as have also the scales, teeth, and bones. Complete skeletons of smaller fishes of the ganoid order were preserved in the rock as it hardened, and now form fossil specimens which are unequaled in beauty and perfection.

Besides the fishes, there were the swimming reptiles; amphibian monsters, allied to the ichthyosaurs and plesiosaurs which were so abundant during the Reptilian age that followed. These animals are known as enaliosaurs. They attained great size, being from twenty-five to fifty feet in length; they had air-breathing apparatus, and propelled themselves through the water with paddles like the paddles of whales. Their enormous jaws were lined with rows of sharp, pointed teeth, and their food was fish, shell-fish, and any other kind[20] of animal life that came within their reach. They devoured even their own species. Living mostly in the open seas or fresh-water lagoons, they sometimes chased their prey far up the rivers, and sometimes basked in the sunshine on the sands of the shore. Frightful in aspect, fierce, and voracious, they were the terror and the tyrants of the seas.

Such were the animals, such were the plants, that lived and died, that flourished and decayed, in the age when coal was being formed and fashioned and hidden away in the crust of the earth. That the fauna and flora of to-day have few prototypes among them should be little cause for regret. There was, indeed, hardly a feature in the landscape of the coal era that would have had a familiar look to an inhabitant of the world in its present age. In place of the hills and valleys as we have them now, there were great plains sloping imperceptibly to the borders of the sea. There were vast marshes, shallow fresh-water lakes, and broad and sluggish rivers. Save by isolated peaks the Rocky Mountains had not yet been uplifted from the face of the deep, and the great West of to-day was a waste of waters. In the wide forests no bird’s song was ever heard, no flashing of a wing was ever seen, no serpent trailed its length upon the ground, no wild beast searched the woods for prey. The spider spun his web in silence from the dew-wet twigs, the locust hopped drowsily from leaf to leaf, the mayfly floated[21] lightly in the heavy air, the slow-paced snail left his damp track on the surfaces of the rocks, and the beetles, lifting the hard coverings from their gauzy wings, flew aimlessly from place to place. In seas and lakes and swampy pools strange fishes swam, up from the salt waters odd reptiles crawled to sun themselves upon the sandy shore or make their way through the dense jungles of the swamps, and out where the ocean waves were dashing, fierce monsters of the sea darted on their prey, or churned the water into foam in savage fights with each other.

But in all the world there were no flowers. Stems grew to be trunks, branches were sent out, leaves formed and fell, the land was robed and wrapped in the richest, most luxuriant foliage, yet the few buds that tried to blossom were scentless and hidden, and earth was still void of the beauty and the fragrance of the flowers.

The process of growth, deposition, submergence, and burial, described in the preceding chapter, continued throughout the Carboniferous age. Each period of inundation and of the covering over of beds of vegetable deposit by sand and silt is marked by the layers of stratified rock that intervene between, and that overlie the separate seams of coal in the coal measures of to-day. The number of these coal seams indicates the number of periods during which the growth and decay of vegetation was uninterrupted. This number, in the anthracite coal regions, varies from ten to thirty or thereabouts, but in the bituminous regions it scarcely ever exceeds eight or ten. The thickness of the separate coal seams also varies greatly, ranging from a fraction of an inch up to sixty or seventy feet. Indeed, there are basins of small extent in the south of France and in India where the seam is two hundred feet thick. It is seldom, however, that workable seams of anthracite exceed twenty feet in thickness, and by far the largest number of them do not go above eight or ten, while the seams of bituminous coal do not[23] even average these last figures in thickness. Neither is the entire thickness of a seam made up of pure coal. Bands of slate called “partings” usually run horizontally through a seam, dividing it into “benches.” These partings vary from a fraction of an inch to several feet in thickness, and make up from one fifth to one seventh of the entire seam.

The rock strata between the coal seams range from three feet to three hundred feet in thickness, and in exceptional cases go as high as five or six hundred feet. Perhaps a fair average would be from eighty to one hundred feet. These rock intervals are made up mostly of sandstones and shales. The combined average thickness of the coal seams of Pennsylvania varies from twenty-five feet at Pittsburgh in the western bituminous region to one hundred and twenty feet at Pottsville in the eastern anthracite district, and may be said to average about one fiftieth of the entire thickness of the coal measures, which is placed at 4,000 feet.

Some conception may be had of the enormous vegetable deposits of the Carboniferous era by recalling the fact that the resultant coal in each seam is only from one ninth to one sixteenth in bulk of the woody fibre from which it has been derived, the loss being mainly in oxygen and hydrogen. It is probable that the coal seams as well as the rock strata had attained a comparative[24] degree of hardness before the close of the Carboniferous age. It was at the close of this age that those profound disturbances of the earth’s crust throughout eastern North America took place which have already been referred to. Hitherto, through the long ages of Paleozoic time, there had been comparative quiet. As cooling and contraction of the earth’s body were still going on, there were doubtless oscillations of surface and subsidence of strata in almost continuous progress. But these movements were very slow, amounting, perhaps, to not more than a foot in a century. Yet in Pennsylvania and Virginia the sinking of the crust up to the close of the Carboniferous age amounted to 35,000 or 40,000 feet. That the subsidence was quiet and unmarked by violent movement is attested by the regularity of strata, especially of the carboniferous measures, which alone show a sinking of 3,000 or 4,000 feet. Neither were the disturbances which followed violent, nor were the changes paroxysmal. Indeed, the probability is that they took place gradually through long periods of time. They were, nevertheless, productive of enormous results in the shape of hills, peaks, and mountain ranges. These movements in the earth’s crust were due, as always, to contractions in the earth’s body or reductions in its bulk. On the same principle by which the skin of an apple that has dried without decay is thrown into folds and[25] wrinkles, the earth’s crust became corrugated. There is this difference, however: the crust, being hard and unyielding, has often been torn and broken in the process of change. Naturally these ridges in the earth’s surface have been lifted along the lines of least resistance, and these lines seem to have been, at the time of the Appalachian revolution, practically parallel to the line of the Atlantic coast, though long spurs were thrown out in other directions, isolated dome-shaped elevations were raised up, and bowl-shaped valleys were hollowed out among the hills.

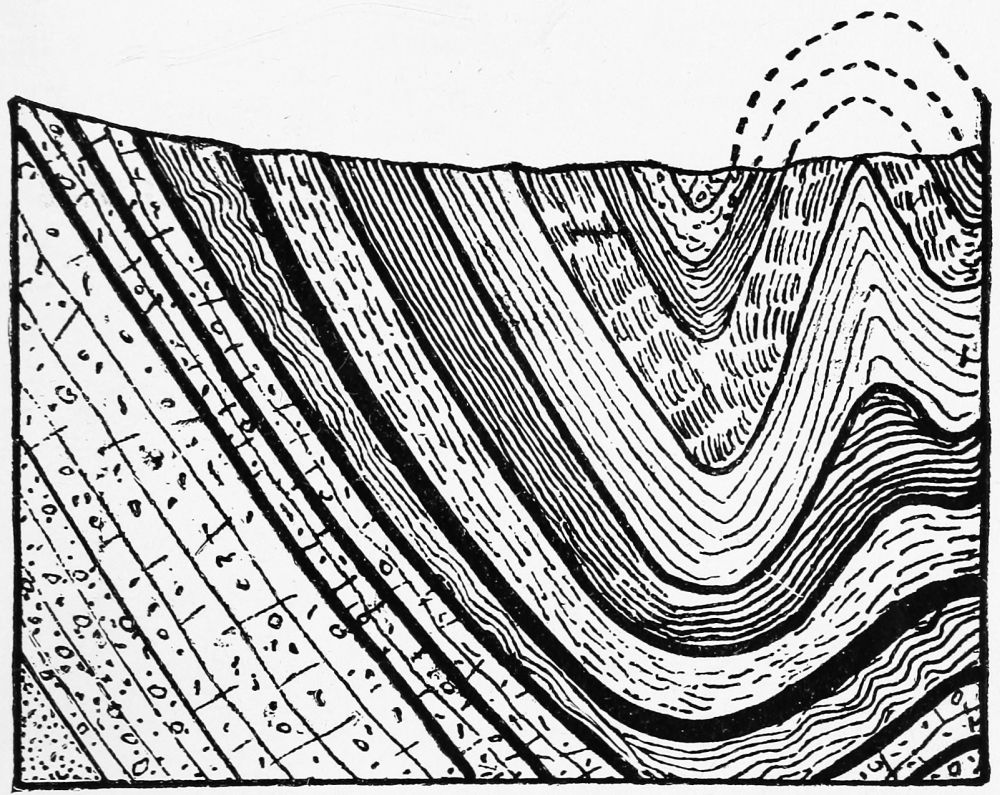

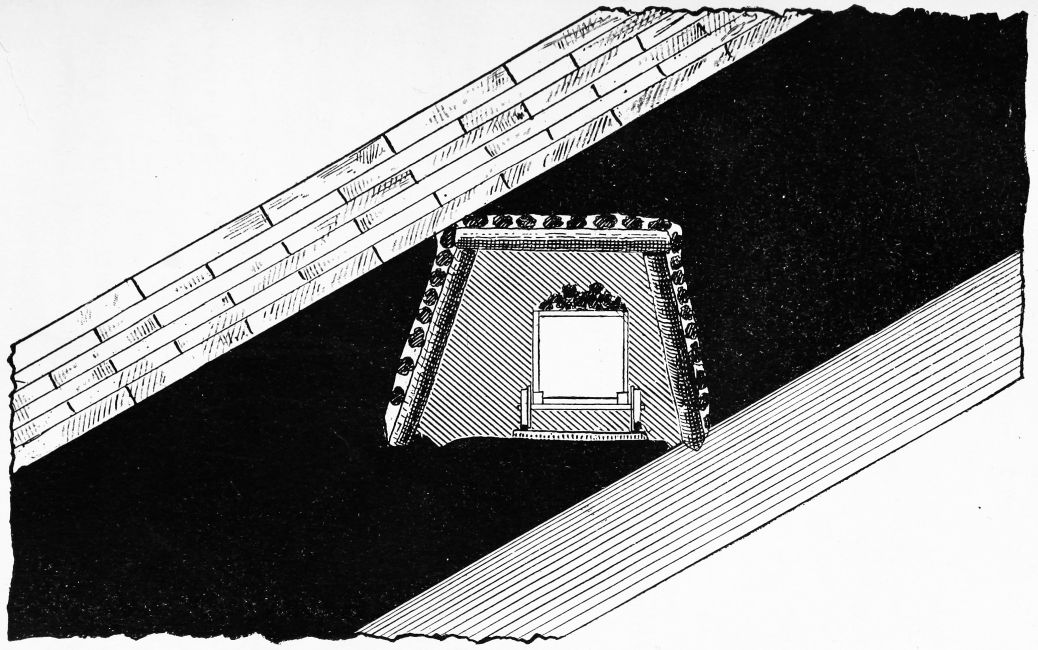

The anthracite coal beds were in the regions of greatest disturbance, and, together with the rock strata above and below them, assumed new positions, which were inclined at all angles to their old ones of horizontality. More than this, the heat and pressure of that period exerted upon these beds of coal, which up to this time had been bituminous in character, resulted in the expulsion of so large a portion of the volatile matter still remaining in them as to change their character from bituminous to anthracite. Although the strata, in the positions to which they have been forced, are at times broken and abrupt, yet as a rule they rise and fall in wave-like folds or ridges. These ridges are called anticlinals, because the strata slope in opposite directions from a common plane. The valleys between the ridges are called synclinals, because the strata slope from opposite[26] directions toward a common plane. One result of this great force of compression exerted on the earth’s crust was to make rents in it across the lines of strata. These rents are called fissures. Sometimes the faces of a fissure are parallel and sometimes they inclose a wedge-shaped cavity. This cavity, whatever its shape, is usually filled either with igneous rock that has come up from the molten mass below, or with surface drift or broken rock fragments that have been deposited there from above. Where there is displacement as well as fracture, that is when the strata on one side of a fissure have been pushed up or have fallen below the corresponding strata on the other side, we have what is known as a fault. Sometimes the displacement seems to have been accomplished with little disturbance to the sides of the fissure; at other times we find, along the line of fracture, evidences of great destruction caused by the pushing up of strata in this way. A fault may reach a comparatively short distance, or it may traverse a country for miles. The vertical displacement may be only a few inches, or it may amount to hundreds or thousands of feet. In the bituminous coal regions, where the strata lie comparatively undisturbed, faults are but little known. In the anthracite districts they are common, but not great.

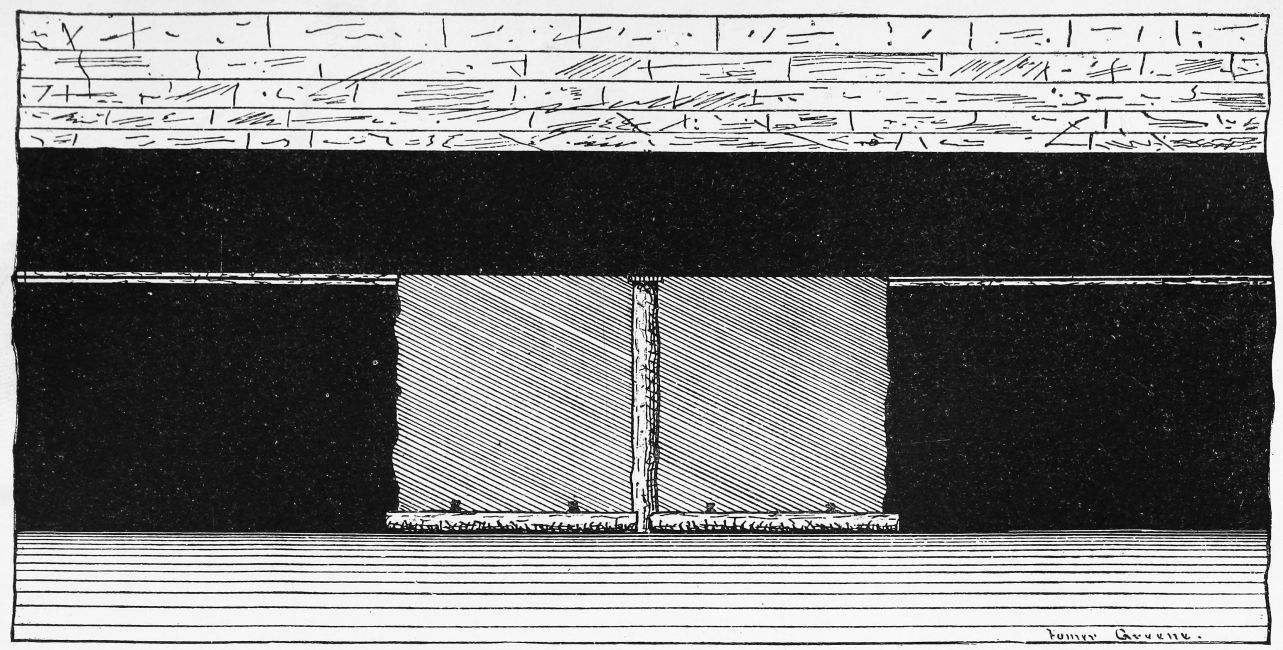

VERTICAL SECTION THROUGH SOUTHERN COAL FIELD.

VERTICAL SECTION THROUGH NORTHERN COAL FIELD.

Besides the great folds into which the earth’s crust was crowded, there are usually smaller folds[27] corrugating the slopes of the greater ones, sometimes running parallel with them, oftener stretching across them at various angles. A marked instance of this formation is found in the Wyoming coal basin, the general coal bed of which is in the shape of a canoe, about fifty miles long, from two to six miles broad, and with a maximum depth of perhaps one thousand feet. Running diagonally across this basin, in practically parallel lines from one extremity to the other, is a series of gentle anticlinals, dividing the basin into some thirty smaller synclinal valleys or sub-basins.

The irregularities produced by folds, fissures, faults, and partings are not the only ones with which the miner has to deal. So far we have supposed the coal seams to have been laid down in horizontal layers of uniform thickness, with smooth and regular under and upper surfaces. This is true only in a large sense. As a matter of fact each separate seam varies greatly in thickness, and its roof and floor are often broken and irregular. The beds of clay on which the deposits were laid were pushed up unevenly by the exuberant growth of vegetation from them. The action of waves and ocean currents made hollows in them, and laid down ridges and mounds of sand on them, around and over which the decaying vegetation rose and hardened. The same forces, together with the action of running streams, made channels and hollows in the upper surfaces of these beds of incipient coal,[28] which cavities became filled by sand and gravel, and this also hardened into rock. These irregularities are found by the miner of to-day in the floor and roof of the coal seam, and are called rolls, horses, or horse-backs. When the coal seam thins out so rapidly that the floor and roof come nearly together, this state of things is called a pinch, or squeeze, though the latter term is more properly applied to the settling of the roof rock after the coal has been mined out. The inequalities of a coal seam that have now been mentioned, although perhaps but a small portion of those that are daily met with in the process of mining, are neverthless characteristic of the whole.

The hills and mountain ranges that were thrown up at the close of the Carboniferous age were many times higher and broader then than they are to-day. Heat and cold and the storms of a thousand centuries, working by disintegration and erosion, have worn away their substance, the valleys and low lands are filled with it, and the rivers are always carrying it down to the sea. The peaks and the crests have been the portions of the elevations that have suffered most. It is often as though the tops of the anticlinal folds had been sliced off for the purpose of filling the valleys with them to the level of the decapitated hills. A great part of the coal measures have thus wasted away; in some portions of the anthracite district by far the greater part, including many valuable coal seams.

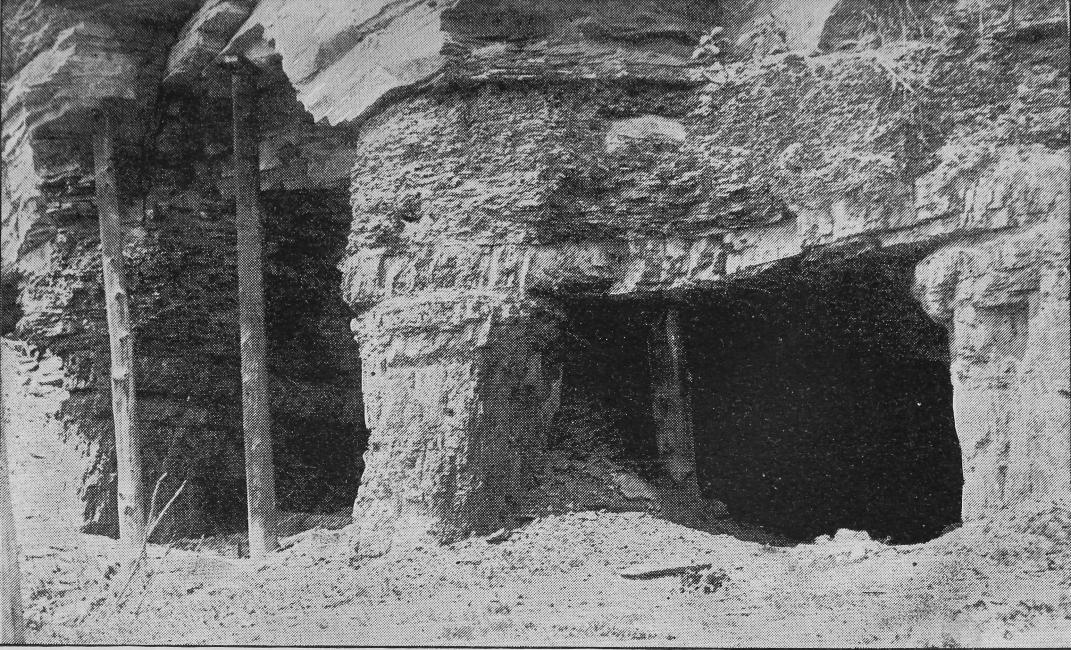

When a fold or flexure of the earth’s crust has been decapitated in the manner mentioned, the exposed edge of any stratum of rock or coal is called its outcrop. The angle of inclination at which any stratum descends into the earth is called its dip. The direction of a horizontal line drawn along the face of a stratum of rock or coal is its strike. It is obvious that the strike must always be at right angles to the dip. That is, if the dip is downward toward the east or toward the west, the direction of the strike must be north and south. It is now apparent that if one begins at the outcrop of a coal seam and traces the course of the seam downward along the line of dip, his path will lie down the inclination for a longer or shorter distance, until the bottom of the synclinal valley is reached. This is known as the basin or swamp. Here the seam may be comparatively level for a short distance; more often it has a mild vertical curve, and starts up the dip on the other side of the valley, which inclination may be followed till the outcrop is reached. If now the decapitated portion of the fold could be replaced in its natural position, we could trace the same seam up to and over the anticlinal axis and down upon the other side. As it is, we must cross on the surface from the outcrop to the place where the corresponding seam enters the earth. In the southern and eastern anthracite coal districts of Pennsylvania decapitation of folds to a point below the coal[30] measures is general; the coal seams dip into the earth with a very sharp pitch, and the coal basins are often very deep and very narrow, striking into the earth almost like a wedge. In the northern or Wyoming district decapitation is not so general, the angle of inclination of strata is mild, and the basins are wide and comparatively shallow. In the bituminous districts, where the disturbance to the earth’s crust has been slight, the coal beds lie very nearly as they were formed, the dip seldom exceeding an angle of five degrees with the horizon. The exposures here are due generally to the erosive action of water.

OLD OPENING INTO AN OUT-CROP OF THE BALTIMORE VEIN.

The carboniferous measures are the highest and latest geological formation in the great coal fields of the United States. Therefore where the strata have not been disturbed by flexure the coal seams lie near the surface. This is generally the case in the bituminous districts, and it is also partially true in the northern anthracite coal field. Deep mining is necessary only in the middle and southern anthracite coal fields, where the folds are close and precipitous, and the deep and narrow basins formed by them have been filled with deposits of a later geologic age.

Some of the difficulties to be met and overcome in mining coal will by this time have been appreciated by the reader. But some of them only. The inequalities of roof and floor, the pitching seams, the folds and faults and fissures, all the[31] accidents and irregularities of formation and of location, make up but a few of the problems which face the mining engineer. But the intellect and ingenuity of men have overcome most of the obstacles which Nature placed in the way of successful mining when she hardened the rocks above her coal beds, crowded the earth’s crust into folds, and lifted the mountain ranges into the air.

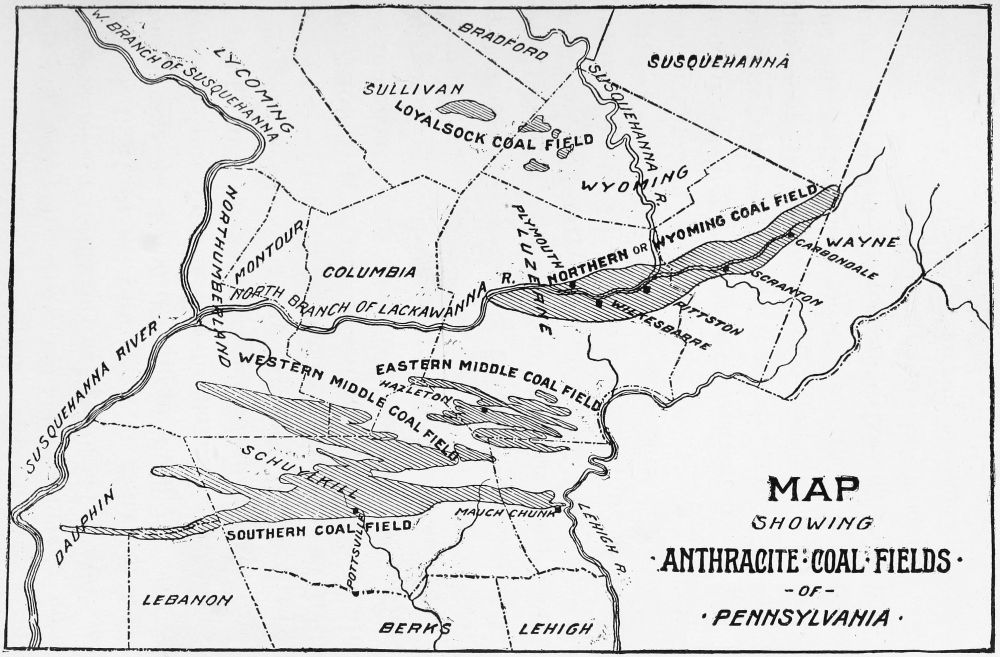

It will not be out of place at this time to make mention of those localities in which coal is found. Indeed, there are few countries on the globe in which there are not carboniferous deposits of greater or less extent. Great Britain, with Ireland, has about 12,000 square miles of them. In England alone there is an area of 8,139 square miles of workable coal beds. In continental Europe the coal fields are numerous, but the character of the deposit is inferior. Coal is found also in the Asiatic countries, in Australia, and in South America; and in Nova Scotia and New Brunswick there is an area of 18,000 square miles of coal measures. The combined areas of coal measures in the United States amount to about 185,000 square miles. The Appalachian or Alleghany region contains about 60,000 square miles, included in the States of Pennsylvania, Virginia, West Virginia, Maryland, Ohio, Kentucky, Tennessee, Georgia, and Alabama. The Illinois and Missouri region contains also about 60,000 square miles, and has areas not only in the States named,[32] but also in Indiana, Iowa, Kentucky, Kansas, and Arkansas. Michigan has about 5,000 and Rhode Island about 500 square miles. There are also small areas in Utah and Texas, and in the far West there are workable coal fields in Colorado, Dakota, Indian Territory, Montana, New Mexico, Washington, Wyoming Territory, Oregon, and California. The entire coal area of the United States, with the exception of that in Rhode Island and a few outlying sections in Pennsylvania, contains coal of the bituminous variety only. Both the area and supply are therefore practically without limit. In the coal regions of Rhode Island the disturbances affecting the earth’s crust have been very violent. The motion, heat, and compression have been so great as to give the rocks associated with the coal measures a true metamorphic or crystalline structure, and to transform the coal itself into an extremely hard anthracite; in some places, indeed, it has been altered to graphite. The flexures of the coal formation are very abrupt and full of faults, and the coal itself is greatly broken and displaced. Its condition is such that it cannot be mined with great profit, and but little of it is now sent to market. The only areas of readily workable anthracite in the United States are therefore in Pennsylvania. These are all east of the Alleghany Mountains, and are located in four distinct regions. The first or Southern Coal Field extends from the[33] Lehigh River at Mauch Chunk, southwest to within a few miles of the Susquehanna River, ending at this extremity in the form of a fish’s tail. It is seventy-five miles in length, averages somewhat less than two miles in breadth, and has an area of one hundred and forty square miles. It lies in Carbon, Schuylkill, and Dauphin counties. The second or Western Middle field, known also as the Mahanoy and Shamokin field, lies between the eastern headwaters of the Little Schuylkill River and the Susquehanna River. It has an area of about ninety square miles, and is situated in the counties of Schuylkill, Columbia, and Northumberland. It lies just north of the Southern field, and the two together are frequently spoken of as the Schuylkill Region. The Eastern Middle or Upper Lehigh field lies northeast of the first two fields, and is separated into nine distinct parallel canoe-shaped basins. These extend from the Lehigh River on the east to the Catawissa Creek on the west, and comprise an area of about forty miles. They are principally in Luzerne County, but extend also into Carbon, Schuylkill, and Columbia counties. The Northern or Wyoming field is a crescent-shaped basin about fifty miles long and from two to six miles broad, with an area of about two hundred square miles. Its westerly cusp is just north of the Eastern Middle field, and it extends from that point northeasterly through Luzerne and Lackawanna counties, just cutting[34] into Wayne and Susquehanna counties with its northern cusp. It lies in the valleys of the Susquehanna and Lackawanna rivers, and in it are situated the mining towns of Plymouth, Wilkes Barre, Pittston, Scranton, and Carbondale. There is also a fifth district, known as the Loyalsock and Mehoopany coal field, lying in Sullivan and Wyoming counties. It is from twenty to twenty-five miles northwest of the Wyoming and Lackawanna field, its area is limited, and its coals are not true anthracite.

It will thus be seen that aside from this last field the anthracite coal area of Pennsylvania contains about four hundred and seventy square miles.

Although it has been within comparatively recent times that coal has come into general use as a fuel, yet there can be no doubt that it was discovered, and that its qualities were known, many centuries ago. To prove its use by the ancients, mention is sometimes made of a passage from the writings of Theophrastus, a pupil and friend of Aristotle and for many years the head of the peripatetic school of philosophy. This passage dates back to about 300 B. C., and is as follows: “Those substances that are called coals and are broken for use are earthy, but they kindle and burn like wooden coals. They are found in Liguria where there is amber, and in Elis over the mountains toward Olympus. They are used by the smiths.”

The word “coal,” however, as used in the Bible and other ancient books, usually means charcoal, or burning wood. It is claimed, and not without plausibility, that coal was mined in Britain prior to the Roman invasion. The cinder heaps found among ruins of the time of Roman supremacy in the island point to quite an extensive use of coal[36] by the people of that age. But no writings have been found recording the use of coal prior to 852 A. D. In that year twelve cartloads of “fossil fuel,” or “pit coal,” were received by the abbey of Peterborough in England, and the receipt was recorded. It is said that coal first began to be systematically mined in Great Britain about the year 1180.

It is certain that by the end of the thirteenth century the exportation of coal from Newcastle was considerable, and the new fuel had come to be largely used in London. But the people of that city conceived the idea that its use was injurious to the health of the inhabitants generally. The coal, being of the bituminous variety, burned with considerable flame and gave off a good deal of smoke, and the ignorance of the people led them into the belief that the air was contaminated and poisoned by the products of combustion. So they presented a petition to Parliament asking that the burning of coal be prohibited in the city of London. Not only was the prayer of the petitioners granted, but in order to render the prohibition effectual an act was passed making it a capital offense to burn the dreaded fuel. This was in the reign of Edward I., and is characteristic of the policy of that strong, unyielding king, whose ends, great and just perhaps, were too often attained by harsh and cruel means.

The coal industry was checked, but it was not[37] destroyed; for, half a century later, we find Edward III. granting a license to the inhabitants of Newcastle “to dig coals and stones in the common soil of the town without the walls thereof in the place called the Castle Field and the Forth.” Afterward this town, owing to the fine coal beds in its vicinity, became one of the great centres of the British coal trade, from which fact doubtless arose that ancient saying concerning useless trouble or labor, that it is like “carrying coals to Newcastle.”

In Scotland coal was mined in the twelfth century and in Germany in the thirteenth, and the Chinese had already become familiar with its use. But in Paris the same prejudice was excited against it that had prevailed in London, and it did not come into use in that city as a household fuel until about the middle of the sixteenth century. This was also the date of its introduction into Wales, Belgium, and other European countries.

That coal was familiar, in appearance at least, to the natives of America, long before the feet of white men ever pressed American soil, cannot well be doubted. They must have seen it at its numerous outcrops; perhaps they took pieces of it in their hard hands, handled it, broke it, powdered it, or cast it away from them as useless. Indeed, it is not improbable that they should have known something of its qualities as a fuel. But[38] of this there is no proof. The first record we have of the observation of coal in this country was made by Father Hennepin, a French explorer, in 1679. On a map of his explorations he marked the site of a coal mine on the bank of the Illinois River above Fort Crevecœur, near the present town of Ottawa. In his record of travel he states that in the country then occupied by the Pimitoui or Pimitwi Indians “there are mines of coal, slate, and iron.” The oldest coal workings in America are doubtless those in what is known as the Richmond or Chesterfield coal bed, near Richmond in Chesterfield and Powhatan counties in the State of Virginia. It is supposed that coal was discovered and mined there as early as 1750. But by whom and under what circumstances the discovery was made we have only tradition to inform us. This says that one day, during the year last named, a certain boy, living in that vicinity, went out into an unfrequented district on a private and personal fishing excursion. Either the fish bit better than he had thought they would, or for some other cause his supply of bait ran out, and it became necessary for him to renew it. Hunting around in the small creeks and inlets for crawfish with which to bait his hook, he chanced to stumble upon the outcrop of a coal bed which crosses the James River about twelve miles above Richmond. He made his discovery known, and further examination[39] disclosed a seam of rich bituminous coal, which has since been conceded to be a formation of Mesozoic time rather than of the Carboniferous age. Mining operations were soon begun, and were carried on so successfully that by the year 1775 the coal was in general use in the vicinity for smithing and domestic purposes. It played a part in the war for independence by entering into the manufacture of cannon balls, and by 1789 it had achieved so much of a reputation that it was being shipped to Philadelphia, New York, and Boston, and sold in those markets. But the mines were operated by slave labor, and mining was carried on in the most primitive fashion for three quarters of a century. So late as 1860 the improved systems of mining, long in use in the North, were still comparatively unknown at the Virginia mines.

During the war of the rebellion these mines were seized by the Confederate government and operated by it, in order to obtain directly the necessary fuel for purposes of modern warfare; and upon the cessation of hostilities the paralysis which had fallen upon all other Southern industries fell also upon this. But with the revival of business, mining was again begun in the Richmond field, and from 1874 to the present time the industry has prospered and grown, and Virginia has furnished to the country at large a considerable amount of an excellent quality of bituminous[40] coal. This coal bed covers an area of about 180 square miles, and has an average thickness of twenty-four feet. It is supposed to contain about 50,000,000 of tons yet unmined.

Another of the early discoveries of coal in the United States was that of the Rhode Island anthracite bed in 1760. Mines began to be regularly worked here in 1808, but only about 750,000 tons, all told, have been taken from them. For reasons which have been already given these mines cannot be profitably worked in competition with the anthracite mines of Pennsylvania, in which the location and formation of the coal beds are greatly superior.

It is impossible to say when the coal of the great bituminous district of Pennsylvania and Ohio was first seen by white men. In the summer of 1755 General Braddock led his army through western Pennsylvania by a military road to that terrible defeat and slaughter in which he himself received his death wound. This road, laid out by the army’s engineers and graded by its men, was so well built that its course can still be traced, and it is seen to have crossed the outcrop of the Pittsburgh coal seam in many places. It is not improbable that a large number of the soldiers in the English army were familiar with the appearance of coal, and knew how to mine it and use it. Indeed, Colonel James Burd, who was engaged in the construction of the road, claims to[41] have burned about a bushel of this coal on his camp-fire at that time.

Some of the English soldiers who survived that terrible disaster to their arms afterward returned and purchased lands in the vicinity, and it is reasonable to suppose that the coal was dug and put to use by them. A lease, still in existence, dated April 11, 1767, making a grant of lands on “Coal Pitt Creek,” in Westmoreland County, indicates that there were coal openings there at that date. Captain Thomas Hutchins, who visited Fort Pitt (now Pittsburgh) in 1760, mentions the fact that he found an open coal mine on the opposite side of the Monongahela River, from which coal was being taken for the use of the garrison.

From 1770 to 1777 it was common for maps of certain portions of the Ohio River country to have marked on them sites of coal beds along the shores of that stream in regions which are now known to contain seams of the great bituminous deposit.

Probably the Susquehanna River region was the first in which this coal was dug systematically and put to use. It was burned by blacksmiths in their forges, and as early as 1785 the river towns were supplied with it by Samuel Boyd, who shipped it from his mines in arks. In 1813 Philip Karthaus took a quantity of coal to Fort Deposit, and sent it thence by canal to Philadelphia. After this he sent cargoes regularly to Philadelphia and Baltimore, and sold them readily at the rate of thirty-three[42] cents per bushel. This trade was stopped, however, by the building of dams across the Susquehanna, and it was not until many years afterward that the mineral resources of this section of the coal field were developed again through the introduction of railroads.

In the Pittsburgh region the demand for coal increased with the increase of population, and at the beginning of the present century it was in general use, not only in the manufacturing industries but also as a domestic fuel, throughout that section of country. The first coal sent from Pittsburgh to an eastern market was shipped to Philadelphia in 1803. It was carried by the Louisiana, a boat of 350 tons burden, and was sold at the rate of thirty-seven and a half cents per bushel. From that time the increase in the mining of bituminous coal in the Pittsburgh region has been steady and enormous. Its presence, its quality and abundance, have induced the establishment of great manufacturing enterprises in that section of the State, and many millions of tons of it are sent every year to the markets of the seaboard.

Pennsylvania was a region much in favor with the North American Indians, and it is more than probable that they were aware, to some extent, of the existence of mineral wealth beneath her soil, long before white men ever came among them.

Besides the numerous outcroppings of coal which, in their journeyings, they must have[43] crossed and recrossed for centuries, there were many places where the coal seams, having been cut through by creeks and rivers, were exposed fully to view. In this way, in the Wyoming district, the seven feet vein along the Nanticoke Creek had been disclosed, and the nine feet vein on Ransom’s Creek at Plymouth; while at Pittston the Susquehanna River had bared the coal seams in the faces of its rocky banks, and up the Lackawanna the black strata were frequently visible. But whatever knowledge the Indians had on the subject was, with proverbial reticence, kept to themselves. It is said that about the year 1750 a party of Indians brought a bag of coal to a gunsmith living near Nazareth in Pennsylvania, but refused to say where they had obtained it. The gunsmith burned it successfully in the forge which he used for the purpose of repairing their guns.

The presumption that the Indians knew something of the uses of coal, and actually mined it, is borne out by the following incident: In the year 1766 a trader by the name of John Anderson was settled at Wyoming, and carried on a small business as a shopkeeper, trading largely with the red men. In September of that year a company of six Nanticoke, Conoy, and Mohican Indians visited the governor at Philadelphia, and made to him the following address:—

“Brother,—As we came down from Chenango[44] we stopped at Wyoming, where we had a mine in two places, and we discovered that some white people had been at work in the mine, and had filled three canoes with the ore; and we saw their tools with which they had dug it out of the ground, where they had made a hole at least forty feet long and five or six feet deep. It happened formerly that some white people did take, now and then, only a small bit and carry it away, but these people have been working at the mine, and have filled their canoes. We desire that you will tell us whether you know anything of this matter, or if it be done by your consent. We inform you that there is one John Anderson, a trader, now living at Wyoming, and we suspect that he, or somebody by him, has robbed our mine. This man has a store of goods there, and it may happen when the Indians see their mine robbed they will come and take away his goods.”

There is little doubt that the mines referred to were coal mines. The presence of coal on the same side of the river a few miles below Wyoming was certainly known, if not at that time then very soon afterward; for in 1768 Charles Stewart made a survey of the Manor of Sunbury opposite Wilkes Barre for the “Proprietaries’” government, and on the original map of the survey “stone coal” is noted as appearing on the site of what is now called Rosshill.

This valley of Wyoming, the seat of such vast[45] mineral wealth, was first settled by people from Connecticut in 1762, and in the fall of that year they reported the discovery of coal.

These energetic, enterprising Yankee settlers could not fail to know the location of the coal beds before they had been long in the valley. Some of them were probably familiar with the English bituminous coals, which were then being exported in small quantities to America under the name of “sea coal;” and from the fact that our anthracite was known to them as “stone coal” it is probable that there were those among them who knew that the English people had a very hard coal which they could not burn, and to which they had given the name “stone coal.” Specimens of this Wyoming valley stone coal had already been gathered and sent to England for examination. Indeed, there is no doubt that the first anthracite coal ever found by white men in the United States was discovered in this valley. But these Yankee settlers could not make their stone coal burn. Repeated trials met with repeated failures. There was one among them, however, Obadiah Gore, a blacksmith, who would not be discouraged. In 1769 he took a quantity of these coals to the blacksmith’s shop conducted by him and his brother, put them in his forge, and continued his efforts and experiments until finally the black lumps yielded to his persistency, and he had the satisfaction of seeing the blue flames dart[46] from them, and the red color creep over them, and of feeling the intense heat sent out by their combustion. But their ignition and burning were dependent upon the strong air current sent through them by the bellows; without that he could do nothing with them.

So this Yankee blacksmith, who was afterwards one of the associate judges of the courts of Luzerne County, became, so far as is known, the first white man to demonstrate practically the value of anthracite coal as a fuel. The success of Gore’s experiments soon became known, other smiths began to recognize the merits of the lately despised stone coal, and it was not long before the forge fires of nearly every smithy in the region were ablaze with anthracite.

The fame of the new fuel soon spread beyond the limits of the valley, and if the difficulties of transportation checked its use elsewhere, the knowledge of how to use it in forges and furnaces was not uncommon. The demand for it overcame, at times, even the obstacles in the way of shipment, and it was sent to points at long distances from the mines.

In 1776 the proprietary government of Pennsylvania had an armory at Carlisle in that State, in which they were manufacturing firearms to be used by the Continental troops in the war with Great Britain; and the first coal ever sent out from the Wyoming valley was shipped by them[47] to Carlisle during that year and the succeeding years of the war, for use in their armory.

The next discoveries of anthracite were made in what is now known as the Southern coal field. It had long been a matter of tradition among the stolid German farmers of Pennsylvania that coal existed in the rugged hills along the Lehigh River, but no one succeeded in finding it there until the year 1791. It was then discovered by one Philip Ginther, a hunter and backwoodsman, who had built a rough cabin in the forest near the Mauch Chunk mountain, and there gave to himself and his family a precarious support by killing game, large and small, carrying it to the nearest settlement, and exchanging it at the village store for the necessaries of life. Telling the story afterward, himself, he said that at one time the supply of food in his cabin chanced to run out, and he started into the woods with his gun in quest of something which should satisfy the hunger of those who were at home. It was a most unsuccessful hunting expedition. The morning passed, the afternoon went by, night approached, but his game-bag was still empty. He was tired, hungry, and sadly disappointed. A drizzling rain set in as he started homeward across the Mauch Chunk mountain, darkness was coming rapidly on, and despondency filled his mind as he thought of the expectant faces of little ones at home to whom he was returning empty-handed. Making his way[48] slowly through the thick, wet undergrowth, and still looking about him, if perchance something in the way of game might yet come within the range of his gun, his foot happened to strike a hard substance which rolled away before him. He looked down at it, and then bent over and picked it up, and saw by the deepening twilight that it was black. He was familiar with the traditions of the country concerning the existence of stone coal in this region, and he began to wonder if this, indeed, was not a specimen of it. He carried the black lump home with him that night, and the next day he set out with it to find Colonel Jacob Weiss at Fort Allen, now Weissport, to whom he exhibited what he had found. Colonel Weiss became deeply interested in the matter, and brought the specimen to Philadelphia, where he submitted it to the inspection of John Nicholson, Michael Hillegas, and Charles Cist. These men, after assuring themselves that it was really anthracite coal, authorized Colonel Weiss to make such a contract with Ginther as would induce him to point out the exact spot where the mineral was found. It happened that the hunter coveted a vacant piece of land in the vicinity containing a fine water-power and mill-site, and on Colonel Weiss agreeing to obtain a patent for him from the State for the desired lot of land, he very readily gave all the information in his possession concerning the “stone coal.”

In the Pottsville district of the Southern anthracite region coal was discovered at about the same time as in the Mauch Chunk field. This discovery too was made by accident, and the discoverer in this case also was a hunter, Nicholas Allen. He had been out with his gun all day, and at nightfall had found himself too far away from his home to make the attempt to reach it. He accordingly built a fire under a projecting ledge at the foot of Broad Mountain, and, lying down by it, soon fell asleep. He was wakened in the night by a strong light shining on his eyes, and by the sensation of great heat. Springing to his feet, he discovered that the ledge itself was burning, or, as he afterward expressed it, “that the mountain was on fire.” He could not understand the phenomenon, and remained in the vicinity until morning, when he saw, by daylight, that what he had thought to be a ledge of rocks was really a projecting outcrop of mineral coal, which had become ignited from his camp-fire of sticks. Whether this story is or is not authentic, it is certain that no practical results attended the discovery of coal in this region. It was not until twenty-six years after Obadiah Gore’s experiments in the Wyoming valley that coal was successfully burned here in a blacksmith’s forge. The attempt was made by one Whetstone, and met with the same marked success that had attended the earlier effort. But owing to the difficulty still ordinarily[50] experienced in combustion, the coal of this region was not generally used until after the year 1806. In that year David Berlin, another blacksmith, experimented with it in his forge, with such complete success that a new impetus was given to the coal trade, mining was resumed, and the new fuel came into general use in the blacksmiths’ shops of the vicinity.

In the Middle anthracite district coal was not discovered until 1826. This discovery also was made by a hunter, John Charles. On one of his hunting expeditions he chanced to find a groundhog’s hole, and, laying down his rifle, he began to dig for his game. In the course of the excavation he uncovered a projecting shelf of stone coal. He made his discovery known, further explorations were set on foot, the coal bed was located, and a company called the Hazleton Coal Company was formed to work the field.

From these several points of discovery the search for anthracite coal was extended in all directions, the limits of the beds were eventually defined, and each field was surveyed and mapped with much care.

At the beginning of the present century the anthracite or stone coal was in general use, in all the districts where it was found, as a fuel for the blacksmith’s fire and the iron worker’s forge. This, however, was the limit of its utility. It was thought to be necessary to force a strong artificial air current up through it to make it burn, and since this could not well be done in grates, stoves, or furnaces, there was no demand for coal for domestic use, or for the great manufacturing industries. Efforts were indeed made to overcome this difficulty. Schemes without number were set on foot and abandoned. It was proposed, at one time, to force air through a tube to the under part of the grate by means of clockwork operated by a weight or by a spring. But the cost of such an arrangement made it impracticable.

It seems, however, that Weiss, Cist, and Hillegas, who were developing the discovery made by Ginther in the Mauch Chunk mountain, also solved the problem of burning the stone coal without an artificial draft. They had sent specimens of their coals to Philadelphia, and presumably had[52] accompanied them with instructions as to the proper method of burning them. This presumption is borne out by certain letters sent to Jacob Cist of Wilkes Barre, a son of Charles Cist the printer, who was in company with Weiss and Hillegas. Two of these letters are now in the possession of the Wyoming Historical and Geological Society at Wilkes Barre. An extract from one of them reads as follows:—

“I have experienced the use of them” (the Lehigh coals) “in a close stove and also in a fireplace that may be closed and opened at pleasure, so constructed, as to cause a brisk current of air to pass up through a small contracted grate on which they were laid. I find them more difficult to be kindled than the Virginia coal, yet a small quantity of dry wood laid on the grate under them is sufficient to ignite them, which being done, they continue to burn while a sufficient amount be added to keep up the combustion, occasionally stirring them to keep down the ashes. They produce no smoke, contain no sulphur, and when well ignited exhibit a vivid bright appearance, all which render them suitable for warming rooms.”

This letter is dated “Philadelphia, Feb. 15th 1803,” and is signed “Oliver Evans.”

The second letter is similar in its recommendation and report of success, and states that the [53]writer, “Fredk Graff, clerk of the Water Works of Phila ... made a trial of the Lehigh coals in the year 1802 in the large stove at the Pennsylvania Bank in Phila.”

So far as is known these are the first recorded instances of any successful attempts to burn anthracite coal in grates and stoves. Dr. James of Philadelphia has also left on record the fact that he made constant use of anthracite coal for heating purposes from the year 1804.

These well-authenticated instances of the use of anthracite appear to destroy the commonly accepted belief that Judge Jesse Fell of Wilkes Barre was the first person whose attempts to burn this coal in an open grate were rewarded with complete success. Nevertheless the value of Judge Fell’s experiments cannot be questioned, nor can he be deprived of the full measure of credit due to him for bringing those experiments to a successful issue.

Until the year 1808 all efforts in the Wyoming valley to burn the “stone coal” of the region without an artificial air blast had utterly failed. People did not believe that it could be done. The successes of Evans and Graff in this direction were either not known or not credited. It is certain that Judge Fell had not heard of them. His opinion that this coal could be made to burn in an open fireplace was based wholly on the reasoning of his own mind. He was a member of the Society of Friends, and had come to Wilkes[54] Barre some years before from Berks County. He was a blacksmith by trade, the proprietor of the best hotel in town, and he came afterward to be one of the associate judges of Luzerne County. When he had fully considered the matter of burning the stone coal, and had reached definite conclusions, he began to experiment. At first he constructed a grate of green hickory sticks, and the presumption is that the fire he kindled in it was a success; for he began, immediately afterward, to make an iron grate similar to the grates now in use. The work was done by his nephew Edward Fell and himself in the blacksmith shop of the former, and was completed in a single day. Judge Fell took the grate home late in the afternoon and set it with brick in the fireplace of his bar-room. In the evening he kindled in it, with oak wood, a glowing coal fire, and invited a large number of the most respected citizens of the place to come in and see the stone coal burn. Only a few came, however, in response to his invitation; they believed his theory to be impracticable, and feared that they might be made the victims of a hoax. But to those who came the fire was a revelation. It cleared the way for immense possibilities. Judge Fell himself realized the importance of his discovery, and thought the incident worthy of record. Being a devoted member of the order of Free and Accepted Masons, he chose from his library a book entitled “The Free Mason’s[55] Monitor,” and wrote on the fly-leaf, in a clear, bold hand, this memorandum:—

“Fe’b 11th, of Masonry 5808. Made the experiment of burning the common stone coal of the valley in a grate in a common fire place in my house, and find it will answer the purpose of fuel; making a clearer and better fire, at less expense, than burning wood in the common way.

[Signed] Jesse Fell.

“Borough of Wilkesbarre,

February 11th 1808.”

The complete success of Judge Fell’s experiment was soon noised abroad, and a new era of usefulness for anthracite coal set in. From Wilkes Barre up and down the entire Wyoming valley fireplaces for wood were discarded and grates were set for the burning of the new domestic fuel. This was followed, not long after, by the introduction of stoves, so that by 1820, says Stewart Pearce in his “Annals of Luzerne County,” grates and coal stoves were in general use throughout the valley, coal for domestic purposes selling at three dollars per ton. At the time of Judge Fell’s experiment there was no outside market for the product of the mines of the Wyoming valley. The distances to the large cities and manufacturing centres were too great, the means of transportation too rude, and the knowledge of the use of anthracite too limited, to warrant any serious effort to create a foreign market for it. The attempt[56] had nevertheless been made in 1807 by Abijah Smith, who shipped an ark-load of coal down the Susquehanna River to Columbia, and was obliged to leave it there unsold.

In 1808 the experiment was repeated by Abijah and his brother John, who, profiting by the success of Judge Fell’s late experiment, took with them an iron grate, set it up at Columbia, and proceeded to demonstrate to the doubting inhabitants the practical value of their coal as a domestic fuel. The venture proved successful, and after this they found no difficulty in selling at the river towns all the coal they could mine. After 1812 they extended their trade by running their coal to Havre de Grace, and sending it thence by schooner to New York.

The success which attended the efforts of the Smiths appears to have been an inducement to other enterprising citizens of the Wyoming valley to embark in the coal trade, and in 1813 and 1814 Colonel George M. Hollenback, Colonel Lord Butler, Joseph Wright, Esq., and Crandal Wilcox all engaged in the mining and shipping of coal. They sent the product of the mines down the river in arks, and up to 1830 85,000 tons had been mined in the valley for such shipment. After that year coal was sent by the North Branch Canal just completed to Nanticoke, and in 1846 the Lehigh and Susquehanna Railroad pierced the valley, and opened a new era in[57] transportation. So it came about that this region, which in 1807 opened the anthracite coal trade with a shipment of fifty-five tons, sent to market in 1887 a grand total of 19,684,929 tons.

MAP

SHOWING

·ANTHRACITE·COAL·FIELDS·

-OF-

·PENNSYLVANIA·

In the mean time Weiss, Cist, and Hillegas pushed their coal enterprise on the Mauch Chunk mountain, opening what was afterward known as the Great Summit Mine, and in 1803 started six ark-loads of coal down the Lehigh River, to be floated to its junction with the Delaware, and thence to Philadelphia. Only two of the arks reached their destination, the others having met with disaster on the way, owing to swift currents and unskillful navigation. Of the two cargoes that arrived safely at Philadelphia not a lump could be sold. The owners made strenuous efforts to find a market for it, but people did not wish to purchase a fuel that they could not make burn. At last the city authorities were appealed to, and, after some hesitation, they agreed to take the coal and try to make use of it for a steam-engine employed at the city waterworks. This they did; but all their attempts to make the alleged fuel burn proved unavailing. They finally gave up the task in disgust, declared the coal to be a nuisance, and caused what remained of it to be broken up and spread on the footpaths of the public grounds, in place of gravel. This was indeed a most ignominious failure. It caused a sudden cessation of mining operations at Summit[58] Hill, and for several years the Lehigh Mine Company, utterly discouraged, made no effort to retrieve its fallen fortunes. William Turnbull attempted to revive the project a few years later, but his effort also met with a dismal failure.