Title: The Making of a Man

Being a description of Artificial Limbs and how they may be adopted by those who have suffered Loss of their Natural Limbs

[1]

[2]

[3]

[4]

[5]

The Making

of a Man

BEING A DESCRIPTION OF

ARTIFICIAL LIMBS AND

HOW THEY MAY BE

ADOPTED BY THOSE WHO

HAVE SUFFERED LOSS OF

THEIR NATURAL LIMBS

George R. Fuller Company

Rochester, N. Y.

| 23 West Swan Street | } | BRANCHES | { | 50 North 13th Street |

| Buffalo, N.Y. | } | { | Philadelphia, Pa. |

[6]

Copyrighted 1902 by

GEORGE R. FULLER CO.

Note.—The copyright covers the arrangement and phraseology of the text as well as the drawings and engravings. The right of translation is reserved.

[7]

The making of a man is a process of time, of training and of progress. The babe, indeed, may be born perfect in physical proportions and in possession of normal faculties; but no product of Nature may stand still. Growth or decay is the lot of every one, and the man—the full and perfect man—is the result of physical and mental development.

There has never been a time when physical development has received so much attention as at present, or when its importance has been so greatly appreciated. Physical culture and exercise in the open air have resulted in making men and women stronger and healthier, and consequently more graceful in carriage and figure and better fitted to enjoy the pleasures and perform the duties of life. The conviction is now general that to produce the highest type of man the cultivation and development of the physical structure should proceed with the cultivation of the mind; but on the other hand, the wise do not admit that the practice of devoting too much attention to athletics should be encouraged, however prevalent this practice may be said to be at many leading colleges. The proper ratio should be observed.

It is not desirable, to be sure, that the race should become one of ignorant giants, but nevertheless the value of exercise and of physical work cannot be disputed. The right to pursue this value should be shared by all mankind. Fortunately it has been made possible now, as it formerly was not, for those who have lost limbs to indulge in rightful exercise and perform necessary physical work notwithstanding their misfortunes. The[8] activities of life, with their resulting benefit, are no longer denied them.

Surgery, the scientific making of mechanical devices for the correction of deformities, and the manufacture of artificial substitutes for lost limbs, have led in the advance of methods intended to better the condition or ameliorate the suffering of humanity.

Time was when the loss of a leg meant the stumping through the balance of life on a crotched stick. There was Peter Stuyvesant, for instance, whose portrait is shown on the cover of this catalogue. He lost a leg in the wars in the West Indies in 1640. Thereafter, during the time he was the last Dutch Director General of New Netherlands—from 1647 until his surrender to the English in 1664—and to his death in New York in 1682 at the ripe old age of eighty, he pegged his way along. He was a man well able to afford the best in life, but nothing better than the ordinary peg leg was then obtainable, and so for forty years or more Peter Stuyvesant suffered the inconvenience due to the crude device.

Now, fortunately for the afflicted, better things are possible. Science and art have combined so successfully in the manufacture of our artificial limbs that not only is the wearer free from discomfort but he is enabled to continue his career of activity, and pursue, as may be necessary, his labors for a livelihood. Besides, the perfection of design and manufacture of these aids makes their presence difficult of detection.

Not only is ordinary labor well performed, but many remarkable feats are accomplished by wearers of limbs of our manufacture. A few instances are cited below.

A noted pitcher of a baseball team and a remarkable bicycle rider, although deprived in early life of both legs by accident, is able to hold a position of prominence in his profession.

An operator constantly on his feet in a signal tower suffers no inconvenience. After making five experiments he has found finally that the artificial leg with which we have equipped him is the most comfortable he has ever worn.

[9]

A crack bicycle rider, both of whose legs have been amputated, one above the knee and one below, pronounces our substitute faultless. He is able not only to mount and dismount with ease but to perform all manner of tricks and fancy riding, doing this as well as his competitors blessed with sound, muscular, natural limbs. Besides, he has a mile track record of 2.37.

Money will not buy happiness, but it will aid in its attainment. Money will not compensate for the loss of a limb, but it will buy a fair substitute if one knows where to procure it.

One having a valuable and delicate watch needing repairs would naturally be very cautious into whose hands it was entrusted. In the event of sickness we are apt to be very careful into whose care we place the patient. Careful inquiry is made as to the reliability of the physician and his experience, whether or not he has been successful, if he understands his business and is honest in his purpose; if his advice will be given in the best interests of the patient, or whether his own profit is of first importance to him.

It is entirely proper to ask similar questions in regard to the makers of artificial limbs; but too often people are careless in the matter, and place the case in the hands of almost anybody in the business, without regard to responsibility or reliability. Thus the remedy secured is often worse than the disease. The strictest investigation should be made. A competent maker should be selected. The case being entrusted to him, the minor details should be left to his judgment, with faith that his experience and thorough understanding of his business will produce the best result.

No single style of limb is suitable for all cases. Appropriate and distinct construction is necessary, that the limb shall meet the requirements of the person who is to be compelled to wear it. Recognizing the truth of this, we have been led to the study of the peculiarities and individual needs of each case presented to us. Our limbs are constructed with such a variety of joints and attachments that each appliance may be accurately adapted to[10] any variation in the condition or occupation of the patient. If any doubt exists as to the result in any case, we give ample opportunity for experiment at our expense. It is for this reason that so many purchasers have spoken in the highest terms of praise of our efforts and the results.

We do not seek to discredit other manufacturers, but simply, in full confidence, we state that we are the makers of the best goods obtainable. In the pages following we have endeavored to convey some idea of the ingenuity and artistic skill which we bestow upon our work.

For over forty years—in fact, since 1856—we have conducted our business in Rochester without interruption and with increasing prosperity. Until 1876 the business was conducted by Dr. Douglas Bly, who founded it. Then for twenty years Mr. Fuller personally continued the business, until in 1896 the present company was incorporated under the laws of the State of New York with a paid-up capital of $25,000. The patience and skill exercised throughout these years have evolved the limb we term “The Walk-Easy Leg,” and placed us at the head of manufacturers of artificial limbs. Our efforts have been always to improve and perfect—to excel at every point. We are assured that these efforts have met with approval. We enjoy the confidence of those who have found need of our services. As a further evidence that we have successfully sought to excel, it may be stated that during the past twenty years, notwithstanding active competition, we have supplied the United States Government with one-quarter in number of all the limbs furnished to pensioners. We also have supplied officially the States of Virginia, Georgia, South Carolina and Louisiana. Furthermore, our work has been placed in the first class by various scientific boards convened for the purpose, and it has received the endorsement of the world’s most famous surgeons.

Aside from the personal testimony of the multitudes throughout the country who have availed themselves of our experience and skill, and have offered to bear witness to the good we have done them, we refer as to our[11] financial standing and reliability to Dun or Bradstreet mercantile agencies, or to any bank or public man in our city or vicinity.

Intending purchasers are invited to correspond with us, that they may receive, if they are necessary or desirable, fuller details than are covered in this work. We are always glad to receive inquiries and offer suggestions for the comfort of our customers.

GEORGE R. FULLER COMPANY,

Rochester, N. Y.

Patents have been granted us as follows:

| April 19, 1859 | No. | 23,656 | ||

| April 30, 1859 | No. | 25,238 | ||

| February 19, 1861 | No. | 31,438 | ||

| July 20, 1862 | No. | 38,549 | ||

| May 19, 1863 | No. | 38,550 | ||

| July 28, 1857 | Re-issued July 7, 1863 | No. | 1,510 | |

| May 17, 1859 | } | Re-issued July 12, 1864 | No. | 1,724 |

| July 3, 1860 | } | |||

| Dec. 23, 1862 | } | |||

| October 11, 1864 | No. | 44,638 | ||

| September 4, 1866 | No. | 57,666 | ||

| March 9, 1869 | No. | 87,624 | ||

| April 19, 1887 | No. | 361,405 | ||

| October 4, 1887 | No. | 370,774 |

[12]

It is probable that such a publication as this will be read only by those who have lost limbs or by their immediate friends. To advance an opinion here as to the length of stump or the kind of operation best adapted to the subsequent application of an artificial limb would be of little benefit, and might, indeed, suggest dissatisfaction to the sufferer and cause injury to the operator. The preservation of life is the object of amputations. Surgeons generally appreciate the importance of the operation and their own responsibility. They undertake it with reluctance. Often during such an operation exigencies arise or unforeseen conditions so present themselves as to preclude any observance of suggestions relating to the selection of a point for amputation and preparation of the stump for the exercise of the restorative art of prosthesis. Then the surgeon has no choice if he would save life. It is better not to criticise the operation and malign the operator, but to believe the best results possible under the circumstances have been attained and be thankful that the outcome is no worse.

In preparation for the application of an artificial leg, and as soon as it is healed sufficiently to permit it without pain or irritation, the stump should be kept tightly bandaged from the end up to the knee, if the amputation be below, or up to the body if the amputation be above the knee. The bandaging will diminish and solidify the stump, leaving it in a much more desirable condition for fitting and rendering the successful use of a leg more a matter of certainty. If neglected, the chances are that a soft, flabby stump will be the result, which will rapidly reduce after the patient begins the use of a leg, but a refitting or[13] an uncomfortable amount of filling up in the socket to compensate for the shrinkage of the stump will be necessary in order to walk with the least degree of ease or satisfaction. The remaining joints, particularly the knee joint, should be kept in motion as much as can be conveniently, every day; this will prevent their becoming anchylosed (stiff and inflexible). Should this warning come too late, and the joint is already anchylosed, it should be gently and gradually exercised, and oily, relaxing applications applied until straightened and flexible. A free daily use of the cold water bath and brisk rubbing will prove beneficial. An application of a solution of tannin and alcohol will toughen the skin, and in many cases it would be an excellent thing to continue the use of this solution after an artificial leg has been applied.

There is a diversity of opinion as to how early a substitute may be applied. Many surgeons strongly urge that an artificial leg cannot be safely fitted for several months after cicatrization occurs, while, on the other hand, some manufacturers of artificial limbs claim that a leg can be satisfactorily fitted just as soon as the stump has healed, no matter if it be but five or six weeks after the amputation.

Much, of course, depends upon the condition of the patient, in circumstance and constitution. It many times occurs that while the edges of the flaps have united, and cicatrization appears, ossification at the sawn end of the bones has not taken place, consequently the necessary pressure and tension on the surrounding integuments and other adjacent parts in wearing a leg will unavoidably cause inconvenience, irritation and pain. It is therefore our opinion, based upon experience and[14] observation, that in most cases an artificial leg should not be fitted within three months after amputation, and that if the edges of the wound have thoroughly united at the end of that time it is unnecessary to wait longer, except to harden and reduce the stump by bandaging, if this has not previously been done. There are many good reasons why a leg should be applied as soon as practicable after this time (provided that the stump has healed), the chief one being that there is nothing that will discipline and strengthen a stump and remaining joints as quickly and as effectually as the use of a properly fitted artificial leg.

The materials used in the construction of artificial limbs are, principally, tough English willow, leather, metal and rubber. The wood parts, when worked to the desired shape, are covered with parchment or rawhide and finished with a flesh-tinted waterproof enamel.

When children have been deprived, by accident or disease, of one or both lower limbs, artificial legs should be applied as soon as the condition of the stump will safely permit. It is too generally presumed that an outgrown limb is of no further use, and that the purchase of an artificial leg before full growth is assured means a foolish expenditure.

This is wrong, at least so far as our work is concerned; there are artificial legs made that it would be very expensive to lengthen or change, but any leg that is made by us, or under our name or supervision, we will agree to lengthen at any future time, as necessity may arise, at a cost not to exceed[15] five dollars, and in many cases not to exceed three or four dollars. When the amputation is above the knee, it is often necessary that the leg be lengthened both above and below the knee-joint. This involves more labor and consequently greater expense, but in no case will the charge exceed five dollars.

For a very young child we would make the artificial foot one or two sizes larger than the natural one; in a year or so the natural foot will reach the size of the artificial, and some months, perhaps years, will elapse before the natural foot will be perceptibly larger than the artificial. This method keeps the feet nearer the same size a longer time than would be the case if the artificial foot were made the same size as the natural foot in the first place. When it is necessary to increase the size of the foot it can be easily and inexpensively done.

When children are deprived of these useful appendages, solely from fear or apprehension that they may be outgrown, a lasting injustice is done them. There is great danger of deformity and disease from the prolonged use of crutches, particularly at a tender and susceptible age; and the most natural, easy, graceful walkers on artificial legs are those who commence the use of them in youth; the habit becomes thoroughly formed, and the continued use of them from childhood develops and strengthens the muscles and joints in a more effectual manner than can be accomplished by any other process or treatment.

It is not possible to reduce the weight of artificial legs below a certain point without sacrificing strength and good wearing qualities. The leg we construct weighs from two to five and one-half pounds, but in some special cases where extreme strength is required this may be exceeded. Much[16] depends, however, upon the weight and occupation of the wearer. Many legs of other makes which weigh no more than ours require more of an effort to carry and swing them, because the action of the rubber spring in the back part of our leg assists materially in carrying the leg forward while in the act of walking, thus relieving the stump from the effort that would otherwise be required to swing it. We aim to have sufficient weight around the joints to support them securely; at other points, where strength is not required, they are left a mere shell. The weight of an artificial arm is much less, varying from one-half to one and one-half pounds.

The occupation of the wearer has much to do with the durability of an artificial leg, but more depends upon the care and attention it receives. We know of limbs that have been in constant use for eighteen or twenty years and are undoubtedly good for several more years of good service, and others, equally well made in every way, that because of neglect and abuse have lasted only three or four years. These are the extremes, however. The average durability of an artificial leg we estimate to be from seven to eight years. Artificial arms not being subject to the strain and wear of a leg will last much longer, the average time, we should say, being double that of a leg. It should be borne in mind, however, that they are but a mechanical imitation of Nature and require attention the same as any other piece of mechanism, and that it pays to keep them at all times clean and in good working order, and that the better the care the better and more lasting will be the service.

Note.—While preparing this article Mr. John S. Havens, of Plainwell, Michigan, called upon us wearing an artificial leg made at this factory in the spring of 1864, and the leg is still in excellent condition.

[17]

A very common error is prevalent in the minds of many that artificial limbs are kept on hand in full assortments and varieties, and that it is only necessary for a person to call and purchase one and wear it away, the same as you would a pair of boots or shoes. Artificial legs are only made to order, and it is preferable that the patient be present at the factory for a day or two to have the leg fitted and give it a thorough and satisfactory trial. Write to us, stating full particulars of the case—when amputated, whether below or above the knee, length and condition of the stump, etc. Also state the price you wish to pay for a leg, and whether or not it will be practicable for you to come here and have it fitted. If you can come here, name a day that will be most convenient for you to do so, and we will be ready for you. If possible, also specify time of day and by which route you will arrive in Rochester; if you are unable to determine in season to advise us by mail, please do so by telegraph, and we will have some one meet you at the station. A shoe will be wanted here for the artificial foot. Your presence will be required from one to two days, depending upon the difficulty in fitting and the number of orders we have on hand; during this time you will have an opportunity of putting the leg on, and giving it a thorough trial in the rough. After you are satisfied with the test, you may return home and the leg will be completed and forwarded to you in about ten days, or, if you prefer to remain and wear it home, it will be finished in about a week. Excellent hotel accommodations can be obtained for one dollar per day or five dollars per week.

For the benefit of persons who do not care to incur the expense and inconvenience of a journey to the factory, we have perfected a chart for[18] measurements, and directions for taking profiles, plaster of paris moulds, etc., that overcome all the difficulty and expense of a personal visit. To make success doubly sure, when so desired we put the leg up in the rough and forward it for trial; this gives the same opportunity of trying it that would be had here. The leg can then be returned to us with directions as to any changes that may be needed. To be sure, there is some expense for transporting the leg, but it is small compared with the cost of a journey here. A good share of our orders are being filled in this manner, and with unvarying success. Indeed, there need be no fear or hesitancy in sending orders to us for artificial legs to be made from measurements, as we guarantee a fit. Should it prove otherwise, we will make any required alterations without charge.

The following is a copy of the warranty given with each leg. The time of the warranty will depend entirely upon the price paid. See prices of the various styles.

Rochester, N.Y., ______ 19__.

In consideration of the sum of __ dollars, received from ______ of ______ for an artificial leg, we hereby warrant the same, as follows: In case any part of said leg should, on account of poor material or bad workmanship, break or give way within __ years from the date hereof, we agree to repair the same without charge, provided that, as soon as any defect is discovered, the leg, or any part thereof that needs to be repaired or replaced, be forwarded to us without delay, and at the expense of the owner. It is not the intention of this warranty to make good without charge the unavoidable wear of the leg, or breakage caused by accident, neglect or misuse.

[19]

Our prices are graded in such a manner as to make it possible for any one to secure one of these reliable limbs, and are governed entirely by the quality of the work and the time for which the limb is warranted, and bear an exact proportion to the cost of production and the probable cost of repairs during the term of the warranty. We have plans, which we will be very glad to explain to any who desire to know about them, whereby these limbs may be obtained without the expenditure of any money whatever. Simply the giving of a little time and persistent work. Scores have earned limbs in this way.

Should be made by express, post office or express money order, registered letter, or New York draft, whichever is most convenient for the sender.

It is our custom, as it is with all makers of special appliances of this kind, to require in each case a cash deposit as a guarantee of good faith. When the purchaser is present at the factory for the purpose of having a limb fitted, the limb may be tried in the rough before making any payment; if the fit and trial are satisfactory, one-half the price will be required. When limbs are made from measurements, without the presence of the patient at the factory, one-half the price of the limb ordered should accompany the order. In both cases when the limb is finished it will be delivered by express C.O.D. with the privilege of examination and trial before making the final payment.

A careful consideration of the following facts should convince any fair-minded person that this plan is not only reasonable and just but very necessary.

[20]

Each limb is made expressly to order for some one individual, and the limb when completed is of little or no value to any one except the person for whom it is made. It requires some degree of patience and perseverance to overcome the awkwardness and possible disappointment associated with the first trial of an artificial limb, and if there be no obligation and no sacrifice on the part of the would-be purchaser provided the limb is not accepted, there is a possibility of its being declined, and the maker, through no fault of his work, becomes the loser. On the other hand, the advance payment made on the limb insures a very persistent effort on the part of the purchaser to wear it, resulting in success and satisfaction.

The purchaser may rest assured that the work will not be slighted in any degree whatsoever, and that it will be our duty and pleasure to make any changes necessary to insure comfortable use of the limb any time within a reasonable period after it is finished.

We can consistently make a limb and accept installment payments therefor only on the following conditions: On payment of one-half the price of the limb with the order, the balance may be paid in amounts and at times—if within reason—to suit the purchaser; say five dollars each month until paid for, provided that these payments are secured by notes made or endorsed by some reliable business man, or other equally good security. We are perfectly willing to give time for a part payment as stated, but must insist that we be amply secured against loss from any cause whatever, and we cannot entertain any proposition wherein this is not provided for.

[21]

Describe your case as clearly and briefly as possible, stating whether amputation is above or below the knee or elbow, when amputated, length and condition of the stump, your age, weight and occupation, whether you have ever worn an artificial limb, if so, how long and what make or makes, and be particular to write your name and address plainly, giving the post office, county and state. Any inquiries that are made on the subject of artificial limbs will be promptly answered to the best of our knowledge, and any information that we can give will be cheerfully imparted.

Every officer or enlisted or hired man who has lost a limb, or the use of a limb, in the military or naval service of the United States, is entitled to receive once every three years an artificial limb or apparatus. Necessary transportation to the manufactory and return, by the most usual and direct route, will be furnished to those desiring it for the purpose of having artificial limbs fitted, but will not be furnished except for this purpose. Sleeping-car accommodations will be given upon request.

In March, 1891, the law was amended so as to allow an artificial limb every three years instead of every five as before. The reduction in time took effect in various ways but was to be counted from March 1, 1891. The act operates in three ways:

First. Those who were entitled on or after March 3, 1888, are entitled every three years from such last date.

Second. Those who were entitled between March 3, 1886, and March 3, 1888, were again entitled March 3, 1891, and every three years from that date.

Third. Those who were entitled before March 3, 1886, were again entitled five years from such date, and again every three years.

[22]

On request of any soldier we will give him the exact date on which he is entitled to an order for a leg or for commutation.

Each officer and soldier has his choice either to receive a limb or its equivalent in money. All who want limbs will gain by taking one from the Government, because the Government will give transportation to and from the manufactory, the cost of which in many cases is equal to the value of the limb. Besides, the Government requires each manufacturer to warrant his work and material used. The soldier who draws his money and buys a limb for himself loses all these advantages. Many manufacturers of limbs will advise soldiers to draw the money and then buy of them, so they will not be obliged to warrant their limbs to the Government, or give a bond for the same.

We furnish legs and arms for all kinds of amputations, on Government orders. The necessary blanks on which the applications should be made for limbs and transportation will be furnished to any soldier on application.

[23]

The Walkeasy leg is one of the more recent of the long list of our artificial limb products. The name signifies more than is ordinarily supposed by the public at large, and is only comprehended as it should be by those who are so unfortunate as to require an artificial leg possessing the requisites indicated by the name Walkeasy. To make the new leg such as to truly maintain this name will be our aim and effort in all cases.

As the weight of the body is imposed upon the artificial leg, under a high pressure, changing from naught to the entire weight of the body, and at times to double that weight or more, the least particle of chafing or friction would soon cause soreness and might continue to that extent that the limb would be impossible of good, and, moreover, a source of much injury to the wearer. The amputation of a leg, therefore, requires on the part of the artificial leg a double degree of responsibility; the limb must not only fit the remaining mutilated part of the leg comfortably, but must reproduce the general motion to a greater or lesser degree of perfection. These are delicate features of artificial limb production, and in no way are they more perfectly reproduced than in the Walkeasy leg.

The improvements represented by the Walkeasy leg are not simply theoretical. We have been quietly experimenting with them for years, not in the shop only, but they have been put into practical use by wearers, of various professions and occupations—the correct way of testing an[24] appliance of this kind; otherwise we would not dare hazard our reputation on their success.

The most approved points of excellence in both the ordinary rubber and wooden feet are combined in the Walkeasy foot. The rubber and wooden feet, as commonly constructed, while possessing desirable features, are objectionable and unsuitable in many cases—the rubber foot on account of its rigid, motionless ankle, and the wooden foot on account of the hard, unyielding, springless material of which it is constructed. In the Walkeasy foot both of these features are entirely done away with and the desirable ones preserved.

The following are the eminently desirable features of the Walkeasy leg, a combination of which is not to be found in any other artificial leg manufactured:

First. The removable sponge-rubber sole of the foot imparts a soft, noiseless tread, does not cut the stockings, gives a natural appearance in the shoe, relieves the wearer of much strain and jar in walking, greatly assists the ankle springs in their action, producing an increased lifelike motion, and greatly reduces the chances of breakage of any part of the leg.

Second. The yielding rubber at bottom of foot provides for a little lateral or side motion, enough for all practical purposes.

Third. The ankle joint is strongly constructed. A substance composed of fibre, in which plumbago (black lead) is incorporated, is used as a bearing on the ankle bolt or cylinder, making a lubricating and most satisfactory joint.

Fourth. The sponge-rubber or felt sole, which can be easily and quickly removed and cheaply renewed or repaired without the necessity of procuring a new foot in case of wear or breakage.

[25]

Fifth. No mechanical toe joint, the flexibility of the rubber or felt giving the desired motion.

Sixth. The cords or tendons come in contact with no surfaces to cause friction or wear and are adjustable so as to give any desired mobility to the ankle joint.

Seventh. Knee joints, for amputation below the knee, with four bearings, taper phosphor bronze bushings, and taper bolts, giving the greatest degree of wearing surface and requiring the least possible lubrication.

Eighth. The purchaser has the choice of a wood socket, leather lacing socket, or the Neverchafe spring socket, which ever is best adapted and most suitable for the peculiarities of his case, and for amputation below the knee an extra attachment is included for use in place of the knee joint and thigh lacer, at such times as it may suit the wearer to try it.

The best product in this line, if within the means of the purchaser, should be the one chosen; but while the Walkeasy leg possesses so many eminent features it is not more costly than the average product of other manufacturers. Moreover, our guarantee is that if it fails in realizing to the wearer what is promised to him, we are more than willing to secure the point of perfection without extra charge, and make of it for the wearer his ideal and not ours.

[26]

[27]

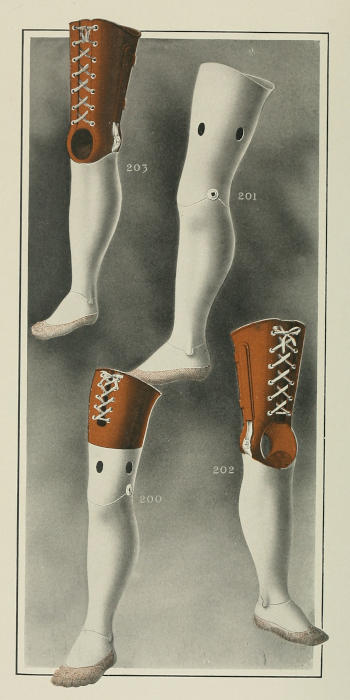

Number 200

Walkeasy leg for amputation above the knee, with adjustable leather lacing socket; any style of suspenders desired. Price $100. Warranted five years.

Number 201

Walkeasy leg for amputation above the knee, with wood socket; any style of suspenders; also Neverchafe socket, if desired, without extra charge. Price $100. Warranted five years.

Number 202

Walkeasy knee-bearing leg, leather socket; used for very short stump below the knee, or for an inflexible knee-joint; wood socket made if preferred. Price $100. Warranted five years.

Number 203

Walkeasy end-bearing leg for knee-joint amputation, leather socket; socket will be made of wood if preferred. Price $100. Warranted five years.

[28]

[29]

Number 204

Walkeasy leg with adjustable leather lacing socket, for amputation below the knee; clasp thigh lacer; any other style used. Price $100. Warranted five years.

Number 205

Walkeasy leg with wooden socket, for amputation below the knee; Neverchafe socket used, if desired, without extra charge. Price $100. Warranted five years.

Number 206

Walkeasy leg with leather lacing socket, without knee-joint or thigh support, for amputation below the knee; not suitable for short stumps. Price $75. Warranted five years.

Number 207

Walkeasy leg with wooden socket, without knee-joint or thigh support, for amputation below the knee; not suitable for short stumps; Neverchafe socket used, if desired, without additional expense. Price $75. Warranted five years.

[30]

[31]

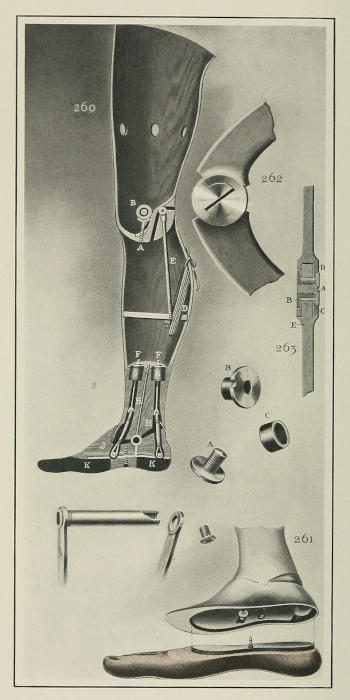

No. 260. Some changes have been made in the ankle joint, but the notable modifications are a foot with thick sponge-rubber removable sole, K-K, in place of the rubber-covered core; for thigh amputations an adjustable steel knee cord and spring piston, combined in one piece, E, and knee-joint tightener, A.

The removable sole gives us an opportunity of strengthening the upper part of foot with a rawhide covering. Between the wooden part J and the rubber K at the toe part, layers of canvas and sole leather are placed to prevent breaking or turning up of the toe. This, however, is hardly necessary in most cases, but we consider it an additional protection. With rubber-covered cores the rubber first breaks away from the top of the core at the toe part, resulting in turning up of the toe, leaving little chance to repair it satisfactorily without making a new foot. This cannot very well take place with the rubber sole, as there is no rubber above the wood to break away. If, however, it becomes necessary for any reason to renew the rubber, the sole can be removed by simply taking a screw out at the bottom of foot, and a new sole or part of a sole put on at a trifling expense without sending the leg to us, as we keep on file a pattern of each individual foot made. The greater security by which the cord ends and the ankle-joint rods are kept in place, and the convenient method of getting at them, are additional strong points commending the change. See No. 261.

The combination knee cord and spring consists of a steel rod carefully bushed at the joint and extending through a hickory bar in calf of the leg, with a thick, soft leather washer on the rod under the bar, and a nut at the end of rod that is reached[32] with thumb and finger through holes in back of leg for readily adjusting the length. For the knee spring a suitably protected heavy elastic web is slipped over end of the rod and adjusted from outside of leg with buckskin strings; as leg is flexed in act of walking, the rod is forced through the hickory bar, stretching the web and forcing the lower part of the leg forward in position for next step; when lower part of leg is flexed at right angles with the thigh, as in sitting, the pressure of spring is automatically released. This change simplifies the knee-joint construction, is lighter and more convenient of adjustment.

Figs. 262 and 263 illustrate a new knee joint for amputation below the knee. This is the latest and decidedly the most compact, lightest, and at the same time the best wearing joint that we have ever adopted, not excepting the ball-bearing joint, and is recommended in all cases.

Joints of medium weight are usually applied. A heavier joint of same pattern is used, however, when the wearer is unusually heavy or desires an extra strong joint and does not mind the additional weight. Let us see if we can describe the uniqueness of it, so that it will be understood.

The head of the joint is very thin (three-eighths of an inch), permitting the trousers to set smoothly; at the same time there is as much wearing surface as in an ordinary joint of twice the thickness. C is a phosphor bronze (the toughest of metal) taper bushing fitted into a taper hole. B is a taper bolt fitting a taper hole in the bushing; when drawn into place with screw A, the bushing is wedged into male joint head E tightly, so that it is practically a part of this male head. In swinging the leg the movement or wear is on the bolt B inside the cone bushing, giving as much[33] wearing surface as a joint with male head as thick as this bushing is long. Perhaps it will be better understood by reference to separate cuts of the bolt B and bushing C, and stating that the bolt turns or moves inside the bushing only, and that there is no wearing surface except between these two parts.

Parts A, B and C are all made to a size and interchangeable. Any one of them taken from stock will fit any joint head of this pattern without special fitting, so that it may be conveniently replaced in case of wear.

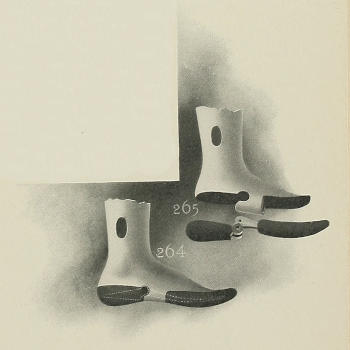

The novelty of this invention is in the point of articulation being near the bottom of the foot instead of at the ankle. It does not give as much motion as the ankle-jointed foot, but is much superior to the rigid ankle without a joint. The construction is so simple that little explanation is required. The dotted lines in No. 264 represent hickory plates, covered with sponge rubber, and No. 265 shows the manner in which the parts are put together. The heel part is slipped into the round hole in hollow of foot, and the piece taking the place of the ball and toe part of foot is passed through into the heel part, as shown by dotted lines in No. 264, and locked together with a steel pin, making a complete hinge. In finishing, the sponge rubber parts are covered with buckskin or kid. The entire arrangement is so simple there is very slight probability that any repairs will be required that the wearer cannot make himself, and the ease and little expense with which the parts can be renewed commend it to all who require a strong, serviceable leg. It seems to be a favorite among miners and others following rough, heavy work who have given it a trial.

[34]

Under contract with the patentee we have the exclusive right to manufacture this foot in the United States and Canada. We have made a good many of them, and have yet to hear the first complaint from any of the wearers. Wood or leather lacing sockets may be used with this foot. Price of leg with the Haberl foot, for any amputation above the ankle, $75, with five-year warranty.

Note.—This foot is patented in the United States, Great Britain, Canada, Germany, France and Spain.

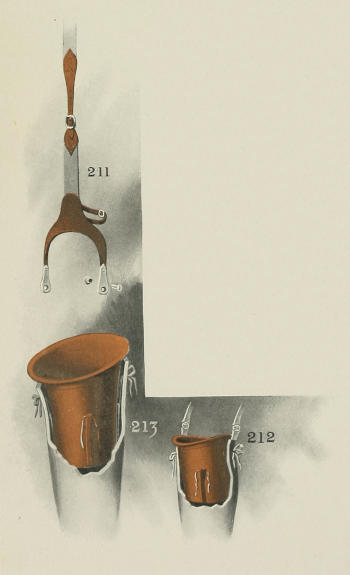

In most cases of amputation below the knee, if stump is sound and of good length, it is possible to comfortably use a leg without the steel knee-joint and thigh support. Many express a desire to try a leg of this description, but hesitate to have a leg so constructed, fearing the result of continually taking the entire weight or bearing on the stump, with no provision for relieving it. For such as would like to try, at their convenience and pleasure, a leg without the thigh support, we make attachment No. 211. The thigh lacer and upper joints can be removed by taking the knee-joint bolts out and this attachment substituted. At such times and in such work, when the thigh support would be more desirable, it can be readily replaced. This attachment is included with the $100 Walkeasy leg without extra charge; with any other style of leg, price $5.

This is a leather socket moulded over a cast of the stump, and suspended to the inner side of a wooden socket or shell with adjustable rubber webbing in such a manner as to avoid all friction or chafing of the stump and to give a comfortable, helpful spring at each step of the wearer, the sensation being much the same as though the weight[35] were on an air cushion, with no pressure on the end of the stump whatever. No. 212 for amputation below the knee; No. 213 for amputation above the knee.

This socket is particularly suitable for short stumps. The inner socket, being made of stiff leather, practically lengthens the stump, giving increased leverage, a condition greatly to be desired in such cases. It is also a very great relief to tender and sensitive stumps; the slipping and rubbing occasioned more or less in walking on an artificial leg, takes place with this attachment between the inner spring socket and the outer wood socket; the pressure of the springs keeping the inner socket snugly against the stump in all positions, precludes the possibility of any friction on the stump.

For stumps that become swollen in hot weather, or that require extra covering in cool weather, or for such as have never used an artificial leg, with the consequent probability of the stump rapidly reducing, this inner socket may be made adjustable by lacing.

While this is undoubtedly the most suitable and comfortable socket for very short and sensitive stumps, some prefer the highly polished wooden socket, and others the adjustable leather lacing socket. All purchasers of the Walkeasy leg have their choice of socket; the selection should be influenced by the length and condition of the stump, the weight and occupation of the wearer, and other considerations. In all cases we guarantee a comfortable socket and one that will not chafe.

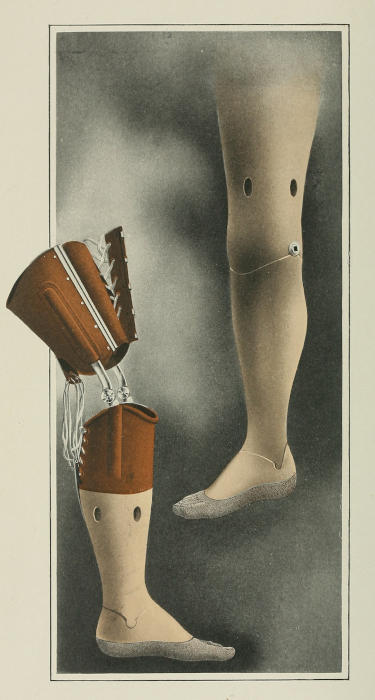

This new socket is for amputation below the knee. The adjustment is made at the back of the socket instead of at the front, as in the lacing[36] sockets heretofore made. The improvement is so marked that the wonder is we did not make the change earlier. Much of the weight on the stump is taken just where the socket was previously made to open, and it was necessary to reinforce the lacing with a strap. When laced in the back of socket the front is stronger, more comfortable, and dresses more smoothly; furthermore, there is more shrinkage of a stump in the calf than in front; and in being able to make the adjustment in the back part of the socket, it is kept nearer the shape that will conform to the shape of the stump than when laced in front. This socket is illustrated in the various engravings representing legs for below the knee amputation. See frontispiece, No. 204, No. 227 and No. 228.

[37]

In this part we give descriptions and illustrations of ordinary styles of legs, such as we have made here—with various modifications and improvements, as suggested by time, wear and experience—for forty-five years. Excepting the Walkeasy leg, described in Part I, there are no better nor more reliable artificial limbs made anywhere by anyone, and the prices are much below those charged by other manufacturers.

The various styles are:

Wooden foot with ball-and-socket ankle joint and wooden socket.

Wooden foot with ball-and-socket ankle joint and leather lacing socket.

Wooden foot with hinge ankle joint (army and navy or two-ball) and wooden socket.

Wooden foot with hinge ankle joint (army and navy or two-ball) and adjustable leather lacing socket.

Foot with sponge-rubber or felt removable sole and rigid ankle and wooden socket.

Foot with rigid ankle and adjustable leather lacing socket.

The cords and springs used in the legs with articulated ankle joints are the same as are used in the Walkeasy leg. The springs are rubber used by compression, imparting easy, uniform motion, their power and action being regulated by simply turning a nut, so that the wearer may adjust them to suit his own peculiar gait.

In walking, when the weight of the body rests on the ball of the foot, the spring in the back part of the leg (heel spring) is firmly compressed, and when the weight of the body is thrown forward[38] on to the other foot the spring rises and carries the foot forward to its place with very little effort of the wearer, assisting greatly in carrying the weight of the leg.

The prices for legs described in this part, for amputation at any point above the ankle, are, including suspenders, stump socks, etc., complete:

$50, warranted for one year.

$60, warranted for three years.

$70, warranted for five years.

A copy of the warranty is given on page 18.

Just as good a leg in every way is made for $50 as is made for $70, the difference in price being determined wholly by the time the warranty is made to cover.

If undetermined as to which leg would be best adapted to any particular case, and it is left to our judgment to select, upon receipt of measurements and full particulars we will construct the one we honestly and conscientiously believe will give the most lasting and comfortable service. We are equally interested with the purchaser in doing this, as the continued good name of our establishment, as well as our future prosperity, depend wholly upon the durability of our work and the comfort with which it is worn.

This joint is formed by a polished glass ball plying in a socket of vulcanite, the foot and ankle being joined together with four tendons, passing through rubber springs in the ankle; this joint admits of every motion the natural ankle has. In walking on the side of a hill or inclined plane, or where the foot is used to brace the body, the ankle flexes laterally and the foot remains flat on the ground, thus giving a firm base of support. The[39] motion closely imitates the movement of the natural ankle, and this joint is desirable for light work and short, tender stumps. Notwithstanding it is more complicated than any of our other styles, requiring more care and attention, there are hundreds of people using it with such comfort and satisfaction that under no circumstances whatever could they be induced to use any other. No. 216, on page 40.

This joint is a unique invention, and the idea of its construction was suggested by the single ball-and-socket joint. It consists of two polished glass balls plying in sockets of fibre. There is no substance that could be used for this purpose that presents a harder, smoother surface than glass, and when in the shape of solid polished spheres, plying in perfectly fitted sockets, they are practically indestructible; there is no such thing as wearing them out. A linked steel rod and a back and front tendon securely connect the foot and ankle. The tendons, also the rubber springs, are the same as used in all of our legs, and are applied in the same manner. This is a somewhat lighter joint than the army and navy joint and is recommended for persons of light or medium weight. No. 217, on page 40.

The axis of this joint consists of a hollow steel bolt securely fastened in the foot with two vertical rods with nuts at the lower ends. The bolt is stationary in the foot, the ankle working on the upper surface of the bolt, leaving no possible chance for an accumulation of any grit or dirt, thus making a self-cleaning joint. The steel rod, together with the front and back cords, connects the foot and the ankle. Provision is made for[40] tightening the ankle rod with a nut on the upper end, so as to regulate the friction on the bolt and to compensate for any wear that may take place at the joint. This is recommended as being the strongest and most serviceable of the wooden feet. No. 218.

This is not properly a rubber foot, but a modification of the so-called rubber foot suggested by improvements on our Walkeasy foot. In the construction of the old-style rubber foot a wooden core is covered with rubber and properly cured or vulcanized by heat. It is impossible to strengthen or reinforce this wooden core with a covering of rawhide as is done on the other parts of an artificial leg, because the heat necessary in vulcanizing the rubber burns and ruins the rawhide. This is obviated by the method of construction of this new foot.

The upper part of the foot is firmly attached to the ankle part by a pin, and the entire wood part is covered with rawhide. Thus the upper part of the foot forms practically one piece with the ankle, and strength is gained without adding weight. The sponge-rubber removable sole is fitted into a recess channeled in the foot and is securely held in place by one screw. No rubber is used at the top of the foot, but more is used on the sole where it is most needed.

If a foot needs be made extremely light a fine quality of felt is used in place of the rubber. The felt does not give as much spring and elasticity to the tread of the foot as the sponge rubber, and nothing is gained by using it except reduction in weight.

To prevent wear at the part corresponding with the toe joint of the natural foot, layers of[41] canvas are cemented on the upper surface of the rubber sole where it comes in contact with the extreme forward part of the wooden portion. Should the rubber sole give way or wear out, the worn part, or indeed the entire sole, may be renewed at small expense without the necessity of replacing the entire foot as in the old style of rubber foot.

Altogether this is a lighter, stronger and more serviceable foot, more easily and inexpensively kept in order. A sectional view of this foot is shown in No. 267.

[42]

[43]

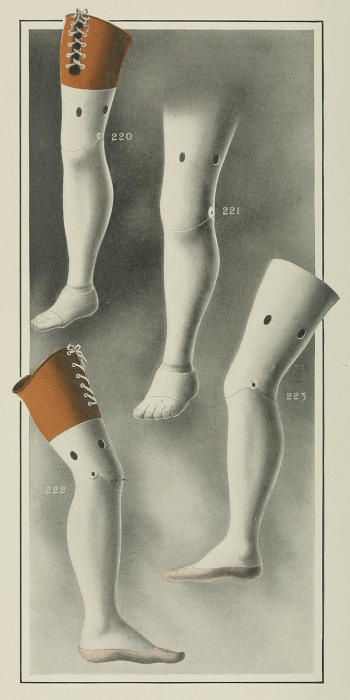

Number 220

Full length leg for thigh amputation, with wooden foot, ankle joint No. 216, 217 or 218, and adjustable leather lacing socket. Price, complete, $50, warranted for one year; $60, three years; $70, five years.

Number 221

Full length leg for thigh amputation, with wooden foot, ankle joint No. 216, 217 or 218, and wooden socket. Price, complete, $50, warranted for one year; $60, three years; $70, five years.

Number 222

Full length leg for thigh amputation, with new foot, with rigid ankle No. 267, and adjustable leather lacing socket. Price, complete, $50, warranted for one year; $60, three years; $70, five years.

Number 223

Full length leg for thigh amputation, with new foot, with rigid ankle No. 267, and wooden socket. Price, complete, $50, warranted for one year; $60, three years; $70, five years.

[44]

[45]

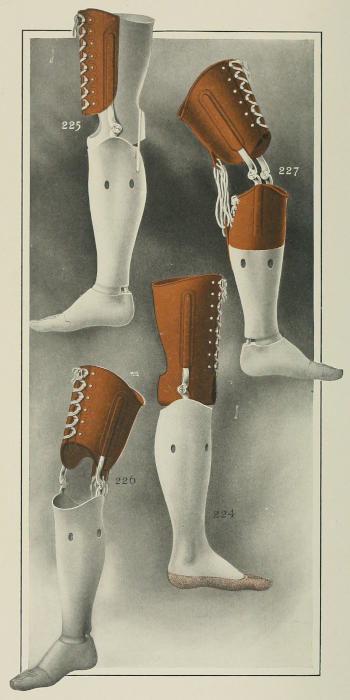

Number 224

Knee-bearing leg for amputation below the knee when the knee joint is stiff and inflexible, or when stump is too short for the successful use of a socket leg; new foot with rigid ankle No. 267, and leather socket. Price, complete, $50, warranted for one year; $60, three years; $70, five years.

The sockets on Nos. 224 and 225 may be transposed, using the leather socket on No. 225 or the wooden socket on No. 224.

Number 225

Knee-bearing leg for amputation below the knee when the knee joint is stiff and inflexible, or when stump is too short for the successful use of a socket leg; wooden foot, ankle joint No. 216, 217 or 218, and wooden socket. Price, complete, $50, warranted one year; $60, three years; $70, five years.

Leg for knee-joint amputation is made similar to the knee-bearing legs and prices are the same. The upper part of leg for this kind of amputation is made same as shown by No. 203 on page 26.

Number 226

Leg for amputation below the knee, wooden foot, ankle joint No. 216, 217 or 218, and wooden socket. Price, complete, $50, warranted for one year; $60, three years; $70, five years.

Number 227

Leg for amputation below the knee, wooden foot, ankle joint No. 216, 217 or 218, and adjustable leather lacing socket. Price, complete, $50, warranted for one year; $60, three years; $70, five years.

[46]

[47]

Number 228

Leg for amputation below the knee, with new foot, with rigid ankle No. 267, and adjustable leather lacing socket. Price, complete, $50, warranted for one year; $60, three years; $70, five years.

Number 229

Leg for amputation below the knee, with new foot, with rigid ankle No. 267, and wooden socket. Price, complete, $50, warranted for one year; $60, three years; $70, five years.

Number 230

Leg for amputation below the knee, without knee joints or thigh support. This style of leg is hardly suitable for stumps less than six inches in length. With a sound stump of sufficient length it may be worn with much satisfaction, as it is about one-third lighter than one with the knee joints and thigh band, and the wearer experiences much less restraint in its use, both in walking and sitting. It is, however, not recommended if the stump is sore or sensitive, as the entire pressure or bearing must be taken on the stump, with no provision for relieving it as with the leg with thigh band. No. 230 shows the leg with new foot, with rigid ankle No. 267, and adjustable leather lacing socket. A wooden socket with the same foot will be used if desired. Price, complete, $45, warranted for one year; $55, three years; $65, five years. If this leg is purchased, and it subsequently proves unsatisfactory, knee joints and thigh bands will be put on for $10.

Number 231

Leg for amputation below the knee, without knee joints or thigh support, wooden foot, ankle joint No. 216, 217 or 218, and wooden socket, or adjustable leather lacing socket if desired. Price, complete, $45, warranted for one year; $55, three years; $65, five years. Any time after leg is finished joints and thigh band will be put on for $10.

Amputations at or below the ankle joint are usually performed with the expectation that much of the weight of the body can be borne on the end of the stump or plantar surface of the remaining part of the foot, and in most cases this can be done. Owing to the little space below the end of the stump, it is desirable, with few exceptions, to construct feet for these amputations without articulated ankle joints.

[48]

[49]

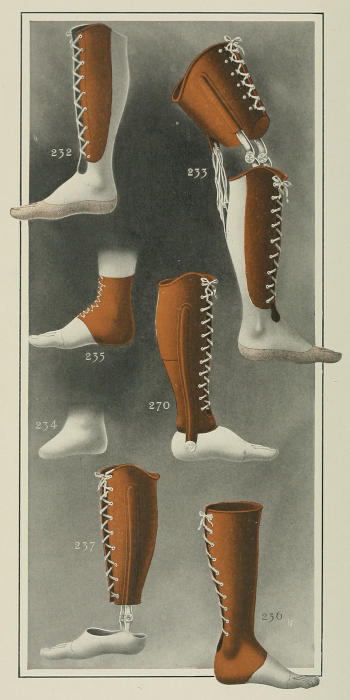

Number 232

Leg for ankle-joint (Symes) operation, with new foot with rigid ankle No. 267, without knee joints or thigh support. Price, complete, $40, warranted for one year; $50, three years; $60, five years.

Number 233

Leg for ankle-joint (Symes) amputation, with new foot with rigid ankle No. 267, with knee joints and thigh support, used when little or no pressure or weight can be taken on the end of the stump. Price, complete, $50, warranted for one year; $60, three years; $70, five years.

Number 234

Stump after amputation through or near the instep.

Number 235

Appliance for partial amputation of foot. The foot is made of wood, covered with rawhide, and has an articulated toe joint; leather sheath coming up above the ankle, laced in front. Price, $25.

Number 236

Appliance for amputation through the instep similar to No. 235, with sheath extending well up on the leg, and laced in the back. Price, $30.

Number 237

Appliance for partial amputation of foot. Wooden foot, toe joint, leather sheath extending to the knee, with side joints. This is used when little or no weight can be taken on the end of stump, the weight being supported by the leather sheath on the leg below the knee. Price, $40.

Number 270

An entirely new style of foot for amputation at the ankle joint. The leather sheath encases the stump from the knee to the end. The articulated joint is made by putting the bolt or cylinder entirely through the foot, giving a good wearing surface similar to the artificial knee joint used for amputations above the knee. If there is little room below end of stump the foot would be made of hard wood.

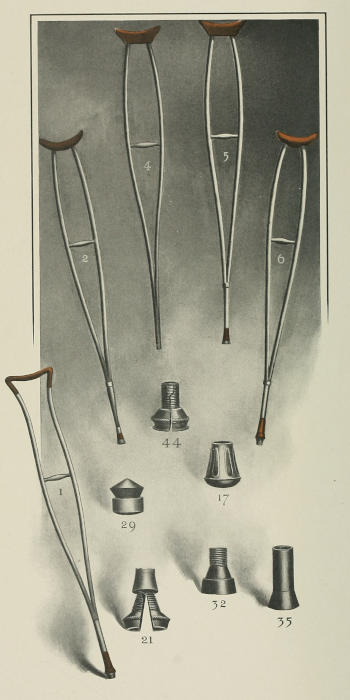

These low-priced legs are carefully fitted, and, excepting No. 242, are covered with rawhide and enameled the same as the legs with feet. They have heavy iron ferrules screwed to the bottom, in which a rubber cushion is used. If desired at some future time, a foot and ankle may be attached. Measurements, mould, profiles, etc., same as for leg with foot, excepting that no foot measurements are required, and length of sound leg should be taken with shoe on.

The prices include suspenders and stump stock.

[50]

[51]

Number 238

Peg leg without knee joint, for amputation above the knee; wooden socket; adjustable leather lacing socket used if preferred. Price, including suspenders, $18.

Number 239

Peg leg with knee joint, for amputation above the knee; shown with wooden socket; adjustable leather lacing socket used if preferred; automatic lock, making knee stiff in standing; pressing the button in the back part of joint releases the knee lock so that joint may be flexed in sitting. Price, including suspenders, $25.

Number 240

Peg leg with wooden socket, for amputation below the knee. Price, including suspenders, if desired, $25.

Number 241

Peg leg with adjustable leather lacing socket, for amputation below the knee. Price, including suspenders, if desired, $25.

Number 242

Skeleton peg leg for amputation below the knee, to be used with knee resting on pad. The measurements required: distance from knee to floor, diameter through the knee from side to side outside clothing. State whether for right or left leg. Price $8.

All artificial legs for thigh amputations require support from shoulders or waist. For amputations at or below the knee, except ankle joint and partial foot amputations, it is desirable to have suspenders attached for beginners. Many, however, discard them after a time. All legs that we make requiring suspenders are equipped with them, any form desired, without extra charge. We are not confined to the styles illustrated; they will be modified to suit the purchaser or any peculiarities of the case.

[52]

[53]

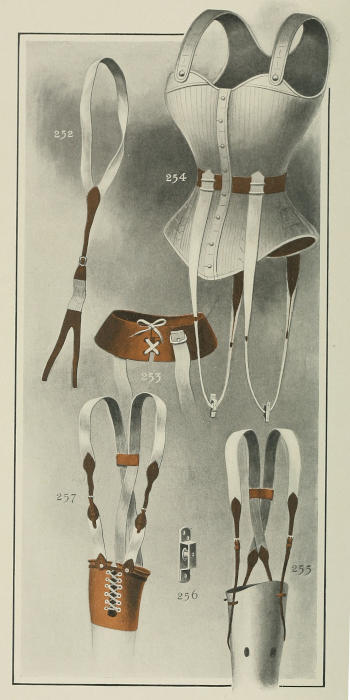

Number 252

Suspender for leg amputation with forked straps to be attached to artificial leg below the knee; heavy elastic web between the buckle and fork; this is a popular style. Price, $1.50.

Number 253

A waist belt for women to which elastic straps are attached in back and front, or the forked strap in front only. This is for amputation below the knee. It is, however, often used in connection with suspenders, which pass over the shoulders, on legs for thigh amputation. Price, complete for leg amputation, $2.

Number 254

For women. Corset with roller suspenders attached to waist belt, used when amputation is above the knee. This is a much more convenient and comfortable support for women than any kind of suspender straps. The belt or straps can be made to attach to any corset. Price, including corset, $5.

Number 255

Roller suspenders for leg for thigh amputation. Crossed or looped behind and looped in front if desired. Price, $4.

Number 256

The roller or pulley used on the roller suspenders. The action of the straps under these rollers prevents drawing over the shoulders, in stooping, sitting or lying down, the suspenders remaining stationary on the shoulders. Price, 25 cents each.

Number 257

Suspenders, partial elastic, of the ordinary pattern, for thigh amputation; riveted so as to swivel on a leather strap laced around the upper part of the socket. Price, $3.

The back part of the sockets of all legs for thigh amputations is padded. This prevents the wear and cutting of the clothing when sitting on a hard seat of any kind. Without the padding, destruction of the clothing can hardly be avoided.

[54]

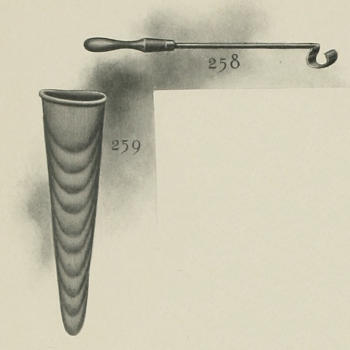

Fitting Tool

Number 258. There are changes in stumps from time to time requiring slight smoothing or easing out in the socket. A wooden socket can most conveniently and effectually be cut out with one of these fitting tools, such as are used by artificial limb makers. Price, $1.50.

Stump Socks

Number 259. Socks made from soft woolen yarn are the most convenient and comfortable covering that can be worn on a stump, with or without an artificial leg. With a properly fitted socket, either wood or leather, it is as much padding as is required. To compensate for shrinkage of the stump, two or three extra socks may be added from time to time as required. It is desirable, however, if the stump has become so much reduced that more covering than this is needed, to have the socket lined with leather or felt, and if it should still further reduce, a new socket or top is the best remedy.

Delivered by mail or express on receipt of price.

| Length of Sock | Circumference at largest part of Stump |

Price Each |

Price per Dozen |

|

|---|---|---|---|---|

| 10 inches or less | Under | 15 inches | $0.35 | $3.50 |

| 10 to 16 inches | Under | 15 inches | .45 | 4.50 |

| 10 to 16 inches | Over | 15 inches | .55 | 5.50 |

| 16 to 22 inches | Under | 15 inches | .55 | 5.50 |

| 16 to 22 inches | Over | 15 inches | .65 | 6.50 |

| 22 to 28 inches | Under | 15 inches | .65 | 6.50 |

| 22 to 28 inches | Over | 15 inches | .75 | 7.50 |

| 28 to 34 inches | Under | 15 inches | .75 | 7.50 |

| 28 to 34 inches | Over | 15 inches | .85 | 8.50 |

One-fourth or one-half dozen at dozen rates.

Length of sock should be two or three inches longer than the remaining part of the mutilated leg.

State whether amputation is above, below, or at the knee; give length and circumference at top and two inches from the end of stump.

[55]

We make limbs for all manner of deformities, each one specially designed and constructed to conform to the individual peculiarities. With a fair degree of strength in the deficient limb, comfortable support and probability of easy locomotion are assured the wearers of these appliances. Rubber or wooden foot can be used. Prices vary from $50 to $100, according to the difficulties to be overcome in proper construction and comfortable fitting. After receiving full description, exact price will be given. A plaster mould or cast of the deformed limb should be forwarded, together with measurements of sound limb, same as in case of an amputation.

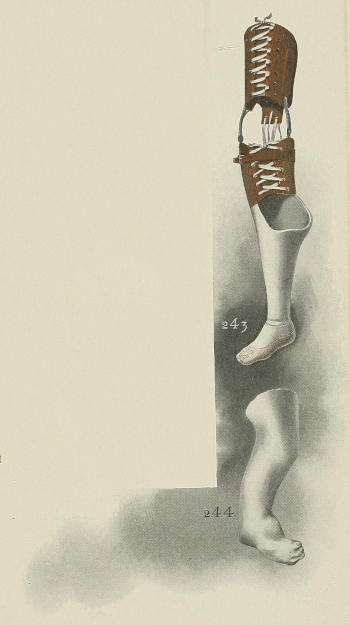

Number 243

This cut represents one of the more difficult of the many legs we are called upon to make for malformations. This particular limb was made from measurements and cast of deformed leg (No. 244) without the presence of the applicant at the factory. After one or two trials in the rough it was finished and is being used with the utmost satisfaction.

[56]

| Elastic Web, 5 inches wide, per yard | $1.00 |

| Elastic Web, heavy, 2 inches wide, per yard | .60 |

| Elastic Web, heavy, 1½ inches wide, per yard | .50 |

| Elastic Web, heavy, 1 inch wide, per yard | .40 |

| Elastic Web, heavy, ¾ inch wide, per yard | .30 |

| Non-elastic Web, cotton, 2 inches wide, per yard | .20 |

| Non-elastic Web, cotton, 1½ inches wide, per yard | .15 |

| Non-elastic Web, worsted, tubular, 2 inches wide, per yard | .30 |

| Buckle, brass, 2 inches wide, each | .05 |

| Buckle Roller, single prong, ⅞, ¾ or ⅝ inch wide, each | .05 |

| Buckle Snaps | .05 |

| Felt, best fine wool, per ounce | .25 |

| Knee Spring, made from 5-inch web, complete, each | 1.00 |

| Knee Spring Rod, C, cut No. 260, each | 1.25 |

| Knee Bolt, for amputation above knee, complete, each | 1.50 |

| Knee Bolt End Screw, each | .25 |

| Knee Cord, with adjustable attachment, each | 1.00 |

| Knee Cord, without adjustable attachment, each | .50 |

| Knee Joint Bolts and Screws, each | .25 |

| Bushings for same, each | .05 |

| Lacing Strings, rawhide or buckskin, each | .10 |

| Lacing Hooks, each 3 cents, per dozen | .25 |

| Lacing Eyelets, ¼ or ⁵⁄₁₆ inch, per dozen | .10 |

| Ankle Cords, with adjustable top, complete with spring; heel, each | 1.00 |

| Ankle Cords, with adjustable top, complete with spring; front or side, each | .75 |

| Ankle-Cord Loops, without top or spring, each | .50 |

| Ankle-Cord Springs, heel or front, each | .20 |

| Ankle-Cord Wrench, each | .25 |

| Ankle Bolt, steel, each | 1.25 |

| Ball Socket for ball-and-socket ankle, each | .50 |

| Rotary Stopper for ball-and-socket ankle, each | .50 |

| Toe Cord or Rod with Bracket, each | .25 |

| Toe-Spring Rubber, each | .15 |

| Toe Fasteners, each | .10 |

| Rubber Cushion for bottom of peg leg, 2 inches diameter, each | .50 |

Sent post-paid on receipt of price.

In ordering cords, if with the screw tops, give length from inside of loop at one end to the other extreme end; if without the screw attachment, give length from inside of loop at one extreme end to inside of loop at the other extreme end.

[57]

| Neverchafe Socket, for amputation above or below the knee. Inner leather, $5.00; outer wooden shell, $15.00; both | $20.00 |

| Wooden Socket, for amputation above or below the knee | 15.00 |

| Leather Lacing Socket, for amputation above or below the knee | 15.00 |

| New Knee, complete, for thigh amputation leg | 15.00 |

| New Knee, upper part only | 8.00 |

| New Knee, lower part only | 7.00 |

| New Walkeasy Ankle | 15.00 |

| New Walkeasy Foot, sponge-rubber sole | 15.00 |

| New Walkeasy Foot and Ankle | 25.00 |

| New Wooden Foot | 10.00 |

| New Rubber Foot with rigid ankle | 10.00 |

| New Foot and Ankle; wooden foot with ankle joint, or rubber foot with rigid ankle | 15.00 |

| New Knee Joints | 7.00 |

| New Thigh Lacer, for amputation below the knee | 3.00 |

| Covering leg with rawhide and enameling, for thigh amputation | 7.00 |

| Covering leg with rawhide and enameling, for leg amputation | 5.00 |

For other repairs, difficult of enumeration, a charge of 50 cents per hour will be made.

[58]

The construction of artificial arms may be said to have commenced with the sixteenth century. “The distinguished Chevalier Göetz fought at the head of the army of Margrave Frederick from 1504 to 1562 with an artificial iron hand. The fingers of this hand were closed one after the other by the action of several springs. We are further informed that this hand, which possessed enormous weight, enclosed the stump, and was attached to the armor which covered the body.”

During the sixteenth century many very defective artificial arms were made, which, however, served the purpose for which they were intended, as they enabled the wearers to engage in battle, guide their horses, etc. The artificial hand being once attached to the weapon or bridle rein, mechanism for articulating the fingers was not deemed necessary.

Ambrose Parè, a noted French physician, born in 1500, and called the father of French surgery, describes an artificial hand made of iron, with more perfect mechanism than the one worn by Göetz; in this hand the thumb is immovable and all the fingers are opened and closed simultaneously under the influence of a single spring.

During Ambrose Parè’s time efforts were made to restore natural movements of the lost parts in order to enable the maimed to perform all ordinary labor. Leather, paper, and other metals were substituted for iron. Parè leaves a figure of a leather hand, but without details as to its mechanism; it is apparently made with immovable fingers and thumb, but with a sheath inserted between the thumb and index finger for receiving a pen, etc.[59] He further describes an artificial forearm, which can, by the aid of the sound hand, be brought into any degree of flexion and maintained there by the use of a pawl caught into meshes of a cog wheel. The artificial arms described by Ambrose Parè, although extremely heavy, seem to have been in favor until the latter part of the eighteenth century; at this time a monk of the order of Carmelites designed a hand made of sheet tin, with movable fingers and thumb, to be articulated by movement of the stump, but we are informed that it was too complicated to be used with any degree of success except in cases of amputation near the wrist joint. We have a description of an arm made subsequently of leather and covered with sheepskin, colored in such a manner as to represent the appearance of the human skin, and to make it appear more natural the nails were made of white horn. The improvements in the hand were mostly in the appearance, without any important addition to its utility or usefulness.

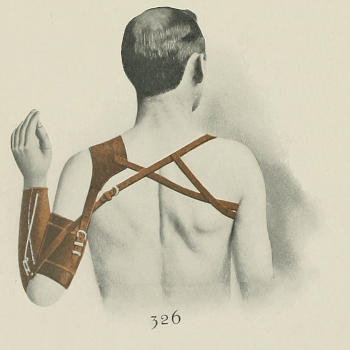

In 1818 a Dr. Graefe suggested the construction of an arm susceptible of manipulation by means of cords attached to a corset surrounding the shoulders, the arm to be moved without the aid of the sound hand. This principle of attachment for the movement of the forearm and fingers is followed to the present time with various modifications.

The early history of artificial arms seems to refer mainly to their special construction and application for people of renown who had suffered the loss of their natural extremities. Until a comparatively recent period the impracticability, on account of complicated heavy mechanism, and the great expense of these appliances, precluded anything like a general demand for their use. As the inventive[60] geniuses of modern times have devised and produced so many labor and time-saving instruments and machines, that are, however useful, nevertheless the cause of much horrible mutilation of humanity, so also have they in some measure made compensation to the maimed by the progress and improvement attained in the utility of the appliances for the substitution of lost members. Simplicity of mechanism, the application of extremely light material in such a manner as to preserve the necessary strength, are the prominent features of progress in artificial arm construction, and in combination with the prevailing moderate prices, bring them into popular favor with those who have use for them.

However light, strong and mechanically perfect an arm and hand may be made, its success or failure—provided the stump is sound and of sufficient length—depends much upon the continued patience and perseverance of the wearer in getting accustomed to its use. The preservation of the form and the general improvement in the appearance produced by a properly constructed and comfortably fitted arm, to say nothing of its usefulness and convenience, should be an incentive to persistent effort on the part of the wearer to habituate himself to it, and if this is practiced for a few weeks there need be no fear of the ultimate result.

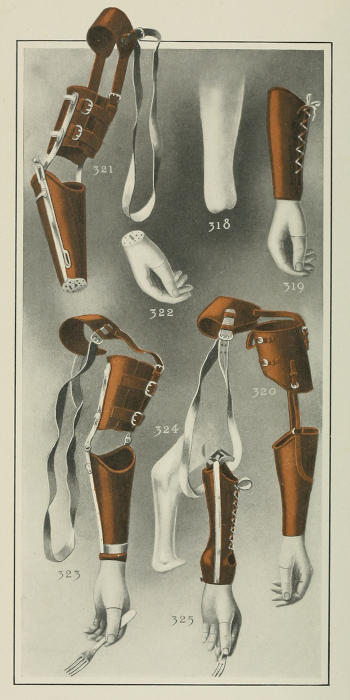

For amputation below the elbow the neatest and best fitting socket is made from specially prepared stiff leather moulded over a cast of the stump, supported with a framework of steel and lined with buckskin or kid. The advantages over a wooden socket are that it is less clumsy, adheres more closely to the stump, that there is no danger[61] of splitting, and withal is equally as durable. We make them, however, of wood if desired. For amputation above the elbow the artificial elbow is made of wood, and it is sometimes desirable to extend the wood upward in one piece to form the socket.

Much has been anticipated and hoped for in artificial limb work from this new and extremely light metal, but it has proved objectionable for any parts in both arms and legs that come in near contact with the stumps, owing to the rapid oxidization that takes place from perspiration, and its practical use is confined to fingers, toes, and such other minor fixtures as are not likely to come in contact with any part of the body.

Whatever their mechanical perfection, artificial hands can, in fact, possess but one useful quality, that of seizing objects like pincers. In nearly every act performed by the natural fingers are combined flexion, extension, prehension, and many other different movements; this combination no mechanic has ever been able—and probably none ever will be able—to successfully reproduce in an artificial hand. It is, therefore, practically useless that the fingers should be movable, since a less complicated, lighter and stronger hand can be made with fingers rigid, in a half-closed, natural position, articulating the thumb only, which results in a more powerful spring and consequently a greater degree of firm grasping power. The fingers being strengthened with steel plates running through them, reinforced with a covering of rawhide, and securely fastened to the hand, heavy objects may be lifted without danger of the fingers straightening out and the object dropping to the ground.

While we furnish the hand with movable[62] fingers, and the rubber hand with ductile rubber fingers, the wooden hand with rigid fingers and movable thumb is recommended as giving the most practical, durable, and satisfactory service.

Artificial hands are covered with a delicately tinted enamel, as nearly a flesh color as it is possible to make; but in order that they may be less conspicuous and the illusion more complete a glove should be worn at all times. We furnish a pair of gloves with each hand.

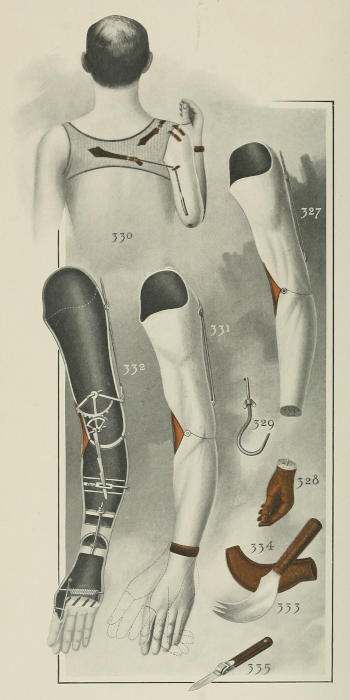

Tools and implements in almost limitless variety can be used in an arm in place of the hand. Those most frequently used are the plain hook, double hook, ring, knife, fork, brush, and spoon. People who have never worn arms hardly know what will be of service to them. Special tools are required for special work, and these can be subsequently provided when it has been determined what will be most useful. With all arms with detachable hands, or rubber hands with the palm socket, we furnish a plain hook, knife, fork, and brush, without extra charge, or the price of any of these implements that are not wanted will be deducted from the price of the arm.

Usually the fingers for artificial hands are made of a single piece of wood, and it is obvious if the finger is curved or flexed that at some point the grain of the wood will be directly across the finger and will quickly break if subjected to any considerable strain. To obviate this difficulty we make the fingers for the wooden hands of two pieces of wood; on one side the grain or fibre runs lengthwise, and on the other crosswise, and between these two pieces of wood is placed a steel plate, and all are firmly riveted together, the steel plate projecting[63] sufficiently to be securely riveted to the hand. The fingers are next entirely covered with rawhide, which, together with the other precautions taken against breakage, make them sufficiently strong to support the weight of the wearer. See No. 300, page 64.

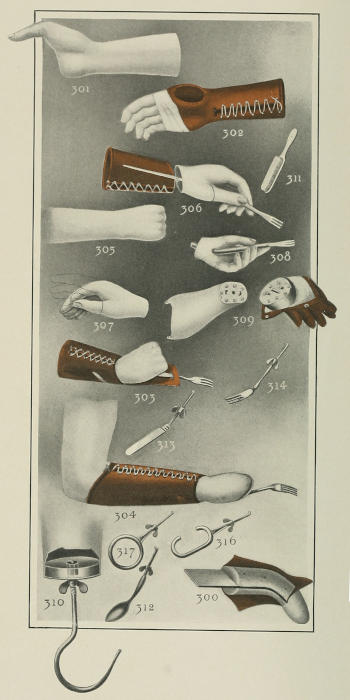

No. 301 (page 64) represents a stump after partial amputation of the hand, leaving free use of thumb, but it is with difficulty that this can be brought in contact with the remaining stump so as to be of service. No. 302 represents, for stumps of this description, a wooden sheath, terminating in immovable fingers partially closed, the hand being attached to the wrist and forearm by means of a leather lacing attachment. The sheath is covered with rawhide and enameled, and the fingers made as shown in No. 300. Price $40.

Should there be amputation at the base of two or three fingers only, with no impairment in the movements of the remaining one or two, so that they can be brought in firm contact with the thumb, what is left of such a mutilated hand is far more useful than anything that can possibly be made to supplement it, but to conceal the loss and give the hand a more perfect appearance, fingers can be made and applied as represented by No. 302, over which a glove should be worn.

Nos. 303 and 304 (page 64) show an apparatus useful in all kinds of labor for persons who have undergone a partial amputation of the hand. It consists of a leather sheath, laced to the forearm. Attached to the under surface of this sheath is a steel plate, which extends downward under the stump, turning up slightly at the end. At the end is an aperture through which it is possible to slip the handles of tools and implements, passing them beneath the stump, where they are securely held in place by pressure of the stump. Price $20.

[64]

[65]

No. 305 represents a stump after an amputation of all the fingers and thumb, and No. 306 an artificial wooden hand for same, with stationary fingers and articulated thumb with a powerful spring to be opened with the assistance of the sound hand. Price $40.

With the assistance of the other hand, or by pressing against some resisting body, the ductile rubber fingers of the hand No. 307 may be changed in position to suit the needs of the wearer as shown by the dotted lines in the illustration. For those who prefer the rubber to the wooden hand it will be furnished with any of the arms we make. It can be attached permanently to the forearm, detachable at the wrist, with provision for using a hook of other implement in place of the hand, or furnished with a palm socket and lock for the use of hook, knife, fork, etc., without removing the hand. See No. 308.

No. 309 represents a new method for connecting the hand and arm. Heretofore the devices in use could not be absolutely relied upon to keep the hand or tools in place. It mattered not how strongly the fingers were made for lifting heavy weights, the customary spring or set-screw used for locking this connection was liable to loosen or give way without warning and cause much annoyance, if not injury. On the hand plate two studs are riveted, the heads of which pass into keyholes in the arm plate. With a slight turn of the hand the heads pass into the slots of the keyholes, bringing the heads of the studs under the arm plate; they are kept immovable with a spring that automatically slips into a slot in the edge of the plate; the spring is released by a pressure of the thumb of the sound hand in twisting the artificial hand off. The hook and other tools have a lug at the end of the spindle or shank; after passing the shank through the hole in the center of the arm plate, it is turned to any desired position and held firmly in place with the wing nut, as shown in No. 310.

[66]

[67]

Some of the implements that may be attached in the wrist plate when the hand is removed are also shown in the illustration. All excepting the brush are made of steel, or other suitable metal.

| No. 310—Single Hook | Price | $1.00 |

| No. 311—Brush | ” | 1.00 |

| No. 312—Spoon | ” | 1.00 |

| No. 313—Table Knife | ” | 1.00 |

| No. 314—Table Fork | ” | 1.00 |

| No. 316—Double Hook | ” | 3.00 |

| No. 317—Ring | ” | 2.00 |