OTHER BOOKS BY

MARY WHITE

- HOW TO DO BEADWORK

- HOW TO MAKE BASKETS

- MORE BASKETS AND HOW TO MAKE THEM

Obvious typographical errors have been silently corrected. Variations in hyphenation have been standardised but all other spelling and punctuation remains unchanged.

Blank pages occur in the original around chapter headings. Their numbers have not been displayed.

HOW TO MAKE POTTERY

OTHER BOOKS BY

MARY WHITE

By

MARY WHITE

Illustrated by the Author

NEW YORK

DOUBLEDAY, PAGE & COMPANY

1904

COPYRIGHT, 1904, BY

DOUBLEDAY, PAGE & COMPANY

PUBLISHED, OCTOBER, 1904

Acknowledgment is hereby made to the Bureau of American Ethnology for permitting the use of the illustrations reproduced in Chapter XI.

An art like pottery-making, which is nearly as old as the human race, is naturally approached with some degree of reverence. One thinks of its old masters in various lands and ages—how they were content to spend a lifetime in the study and practice of it.

There is, however, another thought that comes to mind—that this art, like every other, had to have its beginning. Moreover, every potter, from the primitive man who first realised that clay which held water could be moulded into portable vessels for a like purpose, to the artist potter of to-day, has learned the first steps of the craft.

It was this thought that encouraged me to study the beginnings of pottery, and that leads me to offer this book to those who would also start clay-working, with no other qualification than the wish to learn how to make pottery.

| CHAPTER | PAGE | |

| I. | The Clays and Tools | 3 |

| II. | Hand-made Pottery | 15 |

| III. | Working on the Wheel | 27 |

| IV. | Methods of Decoration | 41 |

| V. | The Glaze and How to Apply It | 55 |

| VI. | Pottery for Beauty and Use | 67 |

| VII. | How to Make a Plaster Mould | 91 |

| VIII. | The Making of a Tile | 103 |

| IX. | The Kiln | 113 |

| X. | Basket-Covered Pottery | 125 |

| XI. | Indian Pottery | 149 |

| XII. | Modern American Pottery | 167 |

| Newcomb Pottery Jug | Frontispiece |

| FACING PAGE | |

| Building a Piece of Pottery: | |

| 1. Making the First Coil. 2. Testing the Outline. 3. Continuing the Piece | 18 |

| Working on the Wheel: | |

| 1. A pale-green bowl for flowers. 2. A cream-jug. 3. A flower-jar with two handles. 4. A nasturtium bowl | 38 |

| Methods of Decoration: | |

| 1. A large fruit-bowl. 2 and 3. Low dishes for candy. 4. A lamp-bowl | 38 |

| Where Use and Beauty are Combined | 68 |

| Pottery for Beauty and Use: | |

| 1. Rose-bowl. 2. A low Dutch dish. 3. Fruit-bowl | 80 |

| How to Make a Plaster Mould: | |

| 1. A plaster mould. 2. A rose-bowl | 80 |

| Pottery for Beauty and Use: | |

| 1. Lamp-bowl. 2. Candlestick. 3. Wall-jar for water-plants. 4. A flower candlestick | 80 |

| The Making of a Tile | 108 |

| Basket-covered Pottery | 126 |

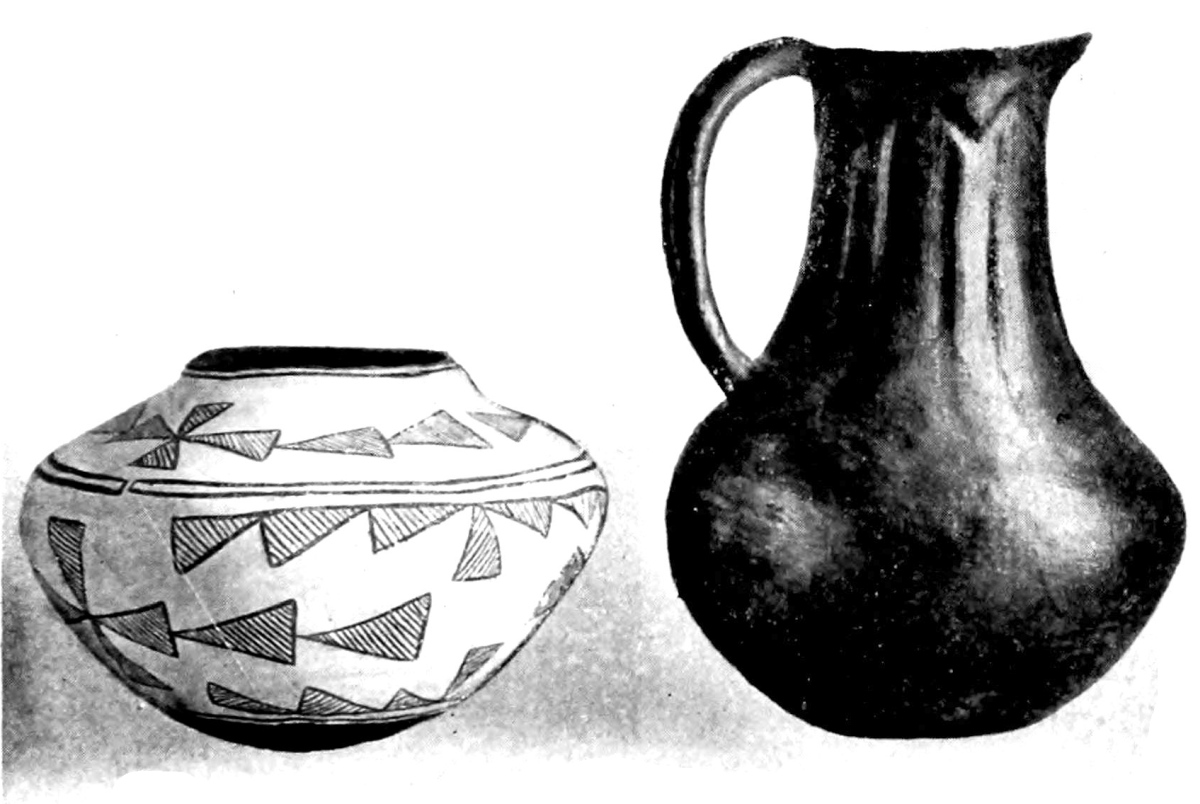

| Indian Pottery | 156 |

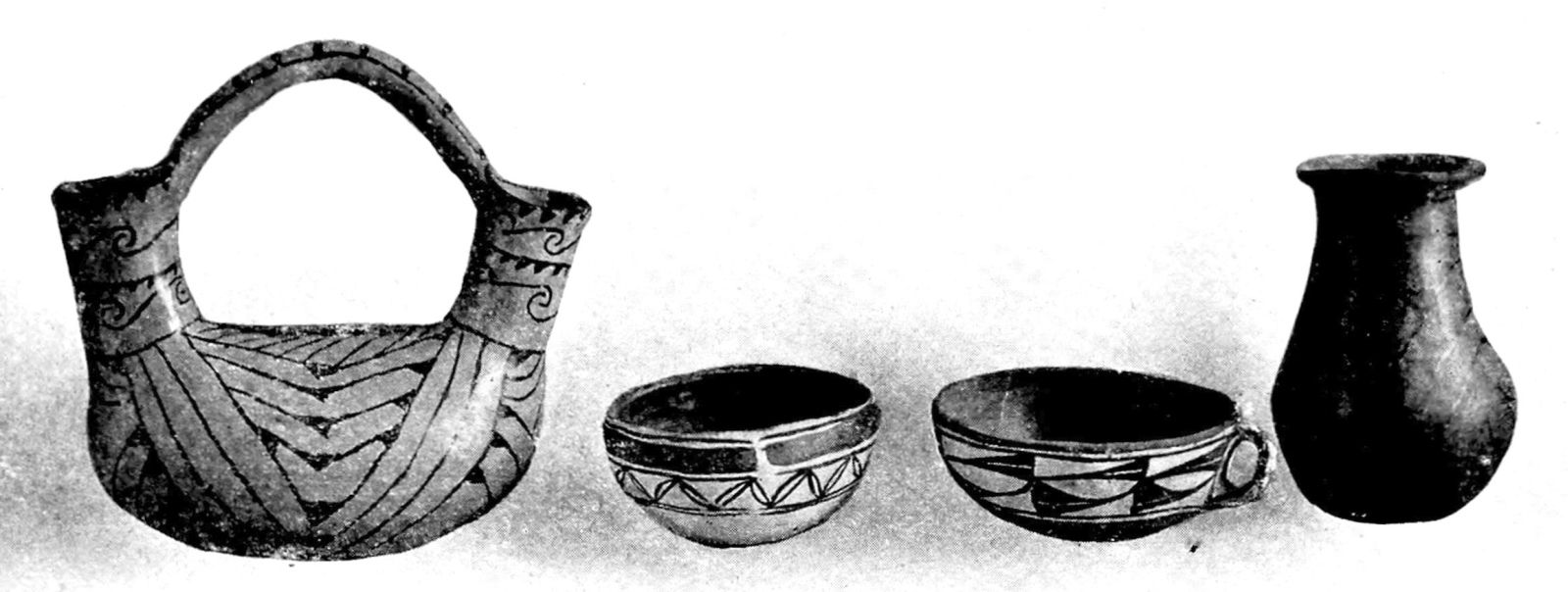

| Indian Pottery | 162 |

| Teco Ware | 172 |

| Some Pieces of Volkmar Pottery | 176 |

| A Piece of Newcomb Pottery | 178 |

| Figures | Page |

| 1 | 10 |

| 2 | 10 |

| 3 | 10 |

| 4 | 10 |

| 5 | 10 |

| 6 | 11 |

| 7 | 11 |

| 8 | 12 |

| 9 | 17 |

| 10 | 27 |

| 11 | 29 |

| 12 | 33 |

| 13 | 33 |

| 14 | 34 |

| 15 | 35 |

| 16 | 35 |

| 17 | 39 |

| 18 | 39 |

| 19 | 39 |

| 20 | 45 |

| 21 | 46 |

| 22 | 49 |

| 23 | 49 |

| 24 | 50 |

| 25 | 70 |

| 26 | 72 |

| 27 | 73 xvi |

| 28 | 77 |

| 29 | 79 |

| 30 | 80 |

| 31 | 84 |

| 32 | 84 |

| 33 | 94 |

| 34 | 96 |

| 35 | 99 |

| 36 | 104 |

| 37 | 104 |

| 38 | 106 |

| 39 | 106 |

| 40 | 107 |

| 41 | 107 |

| 42 | 109 |

| 43 | 109 |

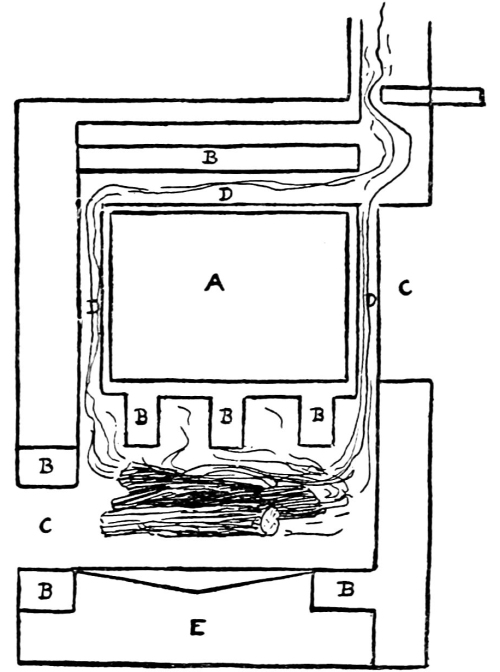

| 44 | 115 |

| 45 | 116 |

| 46 | 120 |

| 47 | 127 |

| 48 | 133 |

| 49 | 138 |

| 50 | 141 |

| 51 | 142 |

| 52 | 144 |

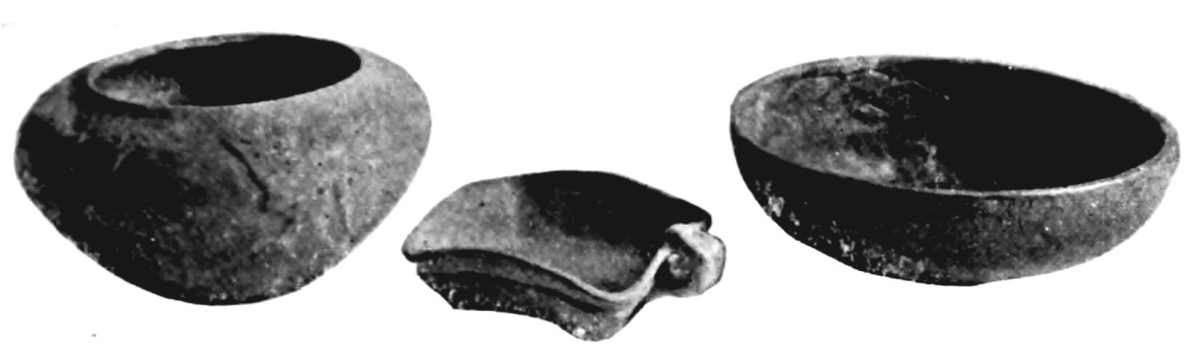

| 53 | 150 |

| 54 | 150 |

| 55 | 151 |

| 56 | 151 |

| 57 | 152 |

| 58 | 153 xvii |

| 59 | 154 |

| 60 | 155 |

| 61 | 156 |

| 62 | 157 |

| 63 | 160 |

| 64 | 161 |

| 65 | 162 |

| 66 | 171 |

| 67 | 171 |

| 68 | 179 |

The Clays and Tools

HOW TO MAKE POTTERY

Clay is what might be called the drift of the rocks of ages past. Most stone consists mainly of silica and alumina. In some bygone age, the potash and other alkalies, under the action of heat, fused these materials into rock. Potash is affected by the atmosphere, so it gradually left the rock, which decomposed, and the many particles, the fine refuse, after various changes became clay. Perfectly pure clay, or hydrated silicate of alumina, is found where some granites and other felspar-bearing rocks have decomposed. In the course of years, the clays, especially those on the surface, gathered impurities. Black clay, for example, which is found at the top of the bed, contains a large per cent. of carbon, formed by decayed leaves and twigs—like coal or peat. Strange to say, this burns whiter than any other pottery clay. It4 contains more potash than the other clays, and fires at a lower heat. The different proportions in which certain minerals are found in clays determine their plastic or non-plastic, fusible or refractory character. Potters have not been able to agree as to the reason for the plasticity of clay. Some believe that the silica gives it plasticity; others that it is due to the water inherent in the clay (which is called the water of combination), and give as their reason for the belief the fact that burned clay loses its plasticity, never to get it again. Yet water alone does not make every clay plastic: other ingredients are sometimes necessary. The early potter used the clay just as it came from the ground, but when he began to bake it in the fire he found that tempering materials were necessary. Sand was often added to make it easier to handle, and coarse, sharp pieces of shell or rock helped to prevent the clay from cracking, by lessening the shrinkage.

Later, as the art advanced, the value of certain materials in regulating the fusible and refractory qualities of the natural clay were recognised. There is in clays the play of melting and non-melting substances. Flint and alumina are hard, and uphold the clay in the fierce fire of the kiln;5 potash and soda make it soft and fusible. It is believed that the value of ground flint in pottery was not discovered until late in the seventeenth century. The story is that a certain potter travelling on horseback was delayed on account of an inflammation of his horse’s eyes. An ostler, wishing to help him out of his difficulty, took a flint from the road, and, after putting it in the fire until it was red-hot, threw it into cold water. It broke into pieces, pure white, which were easily powdered and applied to the animal’s eyes. Delighted as the potter was with the cure of his horse, the discovery of a white, infusible material for his pottery pleased him still more.

The combination of iron and lime in a clay forms a natural flux. For example: Fire-clay, which is quite refractory but which contains a small per cent. of iron, will, by the addition of a proportion of whiting (lime), become more fusible. Iron and lime in larger quantities are found in the clay which is made into red ware—flower-pots, red bricks, and other common articles. The large per cent. of iron gives it its red colour. It does not make as strong a ware as other clays. This red ware, which fires at the lowest heat, we will classify as Group I. To Group II. belongs the6 yellow or Rockingham ware. This fires at a light-orange heat, from 1,800 to 2,000 degrees Fahrenheit. It is often finished with a dark-brown glaze. Mixing-bowls and other kitchen ware come under this group. Group III. contains the buff or cream ware, usually made of fire-clays. This hardens at an intense heat, from 2,200 to 2,500 degrees Fahrenheit. In this group is the fine pottery. Art pottery comes under this head. Group IV. is the buff or cream ware, fired at white heat and beyond. This is the stoneware. On account of the great heat at which it is fired, it is possible to use only certain colours in the glazes. They are limited to gray, brown, green and blue. Ox-blood has been obtained in this ware, but it is uncertain. Claret-and vinegar-jugs and butter-crocks come in this group. Group V. is the white or tableware, and Group VI. the translucent ware or porcelain, made of kaolin, the purest grade of clay. Felspar makes it meltable and translucent, and, to give it plasticity, a small proportion of ball or fire-clay is added.

Pottery clay differs from modelling clay in that it has more stiffening, so to speak. It is not so plastic, but, on the other hand, it will stand the heat of the kiln, which the other will not. The7 addition of whiting or felspar to modelling clay will give the needed stiffness. A pottery clay suitable for the work one can produce in one’s kiln must be so arranged as to harden at the degree of heat at which the kiln fires. Practically, we shall have little to do with any but the blue or ball clay and fire-clay. These are the best for pottery which is to be beautiful as well as useful. It is possible, of course, to use the flower-pot clay, and, perhaps, if one can easily obtain this clay, and is near enough to a pottery where the red ware is fired—so that one’s pieces can conveniently be sent there—it might be wiser to use it than to buy finer clays that come from a great distance, and then be obliged to send one’s pottery to a far-away kiln for firing.

The flower-pot ware is not strong, however, and fine glazes cannot be used upon it, so that, if possible, clay that will fire at a greater heat should be chosen. A mixture of fire-clay and ball or blue clay will give good results, and the pieces made with it may be sent to the nearest art pottery or to a kiln where stoneware is fired. Having once found a good clay, potters rarely change. In fact, this feeling is so strong with some that it amounts almost to a superstition. A8 potter who has obtained a clay that is satisfactory in a certain State will always send to the same State and bed for that clay, no matter how far he may be from it, nor how nearly the clay in his own State may come to the analysis of that which he has used.

The clay is, of course, brought from the clay beds in caked masses. It should be kept out of doors, for the wind and weather are good for it. In preparing it, the great lumps are pounded up fine and put through a sieve in which there are thirty to forty meshes to the inch. It is now ready for soaking. A common mistake is to pour water upon the clay in its rock state and then employ a boy or spend one’s own time kneading it into condition. The more simple and practical process is to sift it as already described, and then add the powdered clay to the water. In this way, each particle is wet at once, and in much less time the clay is ready for use. If it proves that too much water has been provided, pour off some after the clay is well mixed, and, if it is still too moist, spread it upon plaster slabs in the air; which will soon dry it sufficiently—the plaster itself absorbing much of the surplus moisture.

It is often possible, at slight expense, to obtain9 the clay already sieved and mixed from a pottery, and this is, of course, an advantage.

Keep your clay in a large earthern crock in which a little water has first been poured. Make deep holes with the thumb and pour water into them. Cover with a damp cloth and then with the earthen top. When the clay dries out so much that it is difficult to mould, let it dry thoroughly and pound it to a powder on a strong bench or table with an old flat-iron. It may then be re-mixed, as already described.

When ready to begin work, take a good-sized lump of clay, say about ten pounds; pound and knead it upon a table. Then draw a strong wire through it at the middle, dividing it in halves. Press the two outer surfaces together, kneading out the air-holes, which will be found on the inner surfaces. This process repeated a number of times will finally expel all the air-bubbles and leave the clay in good condition for moulding. Clay that is to be used on the wheel will need to be much more thoroughly kneaded than that for hand-moulded or built pottery.

Boxwood modelling tools are useful for the hand-moulded pottery and for decoration. One

pointed tool, like a sharpened pencil (see Fig. 1), and another double-ended one, with points that are more flattened and rounded (see Fig. 2), will be enough to start with. One should also have a11 double-ended steel tool with pointed knife-ends (see Fig. 3), for incising and other decorative work. A steel tool with narrow, flattened ends (see Fig. 4) is necessary for cutting away the background to leave the design in low relief.

The tools for use with the potter’s wheel are mostly of thin steel, and may easily be cut from a12 sheet of steel which one can buy of a dealer in hardware. There should be an oval shape, two and a quarter by four inches, and another of the same size and shape with the edges cut in saw-teeth (see Fig. 5). There should also be a tool with one straight side and the other curved (see Fig. 6), and a rectangular one about two by four inches. A hoe-shaped tool of steel (see Fig. 7) is indispensable for working on the wheel, as is a slender point of steel, an inch and a quarter long, set in a wooden handle (see Fig. 8), and a piece of stout wire. A rubber polisher, the size and shape of the oval tool of sheet steel, will also be found useful. These may be bought of dealers in potters’ tools. A sponge, a ground-glass slab about a foot square, a rolling-pin, and sandpaper are also essential.

Round and square slabs of plaster of paris should be provided upon which to put the pieces of pottery while they are being formed. These may be bought or cast in moulds, according to the directions in Chapter VII.

It is quite important that the potter should have a workshop—be it ever so small—which clay-dust and water will not harm. A light, dry cellar is a good place, or an outbuilding, if one lives in the country. The sense of freedom which comes from working in this way is a help in accomplishing good results. Protected by a long-sleeved apron and in such a place, one need not have a care for clothes or carpets. A stout old table, one or two chairs, and possibly a shelf, upon which to put the finished pottery—with these, and the potter’s wheel and bench (see Chapter III.), one will be well equipped. This is taking for granted that one has been able to buy one’s clay ready mixed. Otherwise there must be a tub for mixing the clay, and a sieve (see Chapter I.). In addition to the clay and the tools already mentioned in Chapter I., a pitcher of water will be needed, and a bowl for the “slip,” or clay thinned with16 water to the consistency of very thick cream. The potter is now ready for work.

Small pieces of pottery, such as dishes and candlesticks, may be moulded with the hands from a single piece of clay (see Chapter VI.); but, for larger pieces, the strong and simple Indian process of building up with coils of clay is more satisfactory. This may be done in a variety of ways. Either the piece is formed by coiling the strips of clay within a mould, as described in Chapters VI. and VII., or by building it up by eye, assisted by a cardboard outline (see plate), or it may be formed entirely by eye, like the rose-bowl with a moth design in Chapter VI. The first method, while it is the simplest, is not the best to begin with, for one relies too much upon the mould, and unconsciously uses it too often, instead of training one’s eye to make a true and beautiful form. The second method—testing the form with a pasteboard outline as the piece is built—will be the best to start with. Having decided upon the shape he wishes to make, the potter draws it in outline (natural size) upon a piece of cardboard. It will be wise to choose a form as nearly like a cylinder as possible; for example, a jar for flowers. The outline sketch is divided by17 a vertical line ruled exactly through its centre. Another straight line, parallel with the first, is drawn three inches to the right of it. The outline is then cut out (see Fig. 9) so as to make a guide for the contour of the jar. A flat, round piece of clay, about five inches in diameter and half an inch thick, is now moulded and placed in the centre of a plaster tile. In the middle of this piece, a circle, two and three-quarters inches in diameter, is drawn with a tool. A lump of clay, which has been well worked to get out all air-holes, is rolled on the table with the palms of the hands (near the base of the thumb) lightly, yet with sufficient push to make the clay revolve wholly each time. If the roll flattens from too hard pressure, pat it into circular form, and continue to roll it until it is of even thickness—about an inch in diameter. It is then flattened evenly, one end is18 cut into a long point, and the coil is started on edge, narrow side up, on the circle drawn upon the clay bottom, which has previously had lines criss-crossed upon it back and forth with a steel tool, to insure the first coil’s clinging to it. To make this even more certain, a touch of slip is brushed lightly here and there over the edge of the circle. While the thumb and middle finger, on either side of the coil, support it, the forefinger presses it down firmly on to the bottom all the way around (see plate). It is so much easier to flare the walls of one’s piece than to make them straight, or bring them in, that they should be kept as nearly vertical as possible, especially in starting. When the circuit has been made, cut the end of the clay strip into a long, flat point which will fit evenly in with the one at the beginning of the coil, and press the edges together with the flat of the nail of finger or thumb. This is also done where the edges of the coil come against the bottom, outside and in. Quick, firm, yet short strokes of the nail up and down join the edges. In putting on the second row, no marking with the tool is necessary—only to brush it with slip. After the second row is added, the jar is put out in the air for half an hour or so, until it has stiffened a19 little. This is supposing that the potter is working at a time when the clay will not freeze. When the weather is cold, the piece must be left to stiffen indoors, as pottery that has once frozen is useless. The inside of the bottom and walls are then smoothed with great care, for, as it is to be a tall jar, this must be done before the walls get too high. Two more rows of coiling are now added as before, testing the shape by pressing the cardboard outline close against it all around the circumference. After this, the jar is again put out in the air for half an hour or so. This method is continued until the jar is built up.

Should the walls become weak and insecure from working them too rapidly, let them dry for a longer time, several hours or over night, before finishing. Test the shape constantly with the cardboard outline. When the jar is as high as the drawing, or even a quarter to half an inch higher, let it dry over night. It should then be smoothed with an oval steel tool, which has a saw-toothed edge (see Fig. 5), to take the worst unevenness off. The tool is bent to fit the shape of the jar and held at right angles with it, smoothing it with short strokes in different directions. This is done inside and out. The hollows are also filled in.20 To do this, wet the spot first with slip and fill in with clay as nearly the consistency of that in the jar as possible. The sides are then made perfectly even with the oval tool with smooth edges, holding it as the saw-toothed tool was held. When there are no hollows or ridges and the walls are about a quarter of an inch thick, the surface of the jar is smoothed with a damp sponge and polished with the fingers and thumb inside and out, taking care in handling it not to hold it by the edge, but rest it in the hollowed hand. Should it have become very dry, as it will in a comparatively short time in warm weather, so that it is light-gray in colour, it will be wise to smooth it with sandpaper instead of with the sponge, as in this state even a little water may cause it to crack. One cannot learn too soon, or have too often impressed upon one’s mind, the risk of adding wet clay to a piece of pottery that is much drier. The natural shrinkage which has already taken place in the dry clay will be repeated in the wet, and, as it shrinks, it will crack the drier clay. Cracks in clay are of two kinds—those caused by shrinkage of the unbaked or green clay, and those that come from cooling too rapidly in the biscuit or baked clay. The former can usually be mended satis21factorily, but for the latter there is no remedy; the piece is spoiled.

To mend a crack in clay that is only partially dry, put a little slip into the crack and then work in, with a modelling tool, clay of the consistency of the piece. If, after drying longer, the piece cracks again—a long, deep crack, that goes through to the inside—there is no way to mend it except by cutting the clay out on either side for quite a space beyond the crack, brushing both sides with slip, and filling in with clay as nearly as possible the consistency of the piece. This is pressed in in small bits, little by little, until the gap is filled. If it should crack again in small, short places, fill them with dry, powdered clay, pressed in and moulded with a steel tool.

In case of the piece cracking when it is bone dry—that is, after it has dried for several days and is pale-gray in colour—grind some pieces of baked clay to a fine powder, add enough water to make a soft, yellow paste, and fill the cracks with it.

The edge of the jar is cut as even as possible with a tool, and then made perfectly true by the following method: A little water is poured on a ground-glass slab, and the jar, held bottom up, is moved firmly but rapidly round and round on the22 wet surface, and then quickly taken up (by sliding it off at the edge of the slab) before it clings to the glass. The bottom must now be finished. The jar is first placed bottom up on a slab or table, then a circle is drawn with a pencil at about half an inch from the edge of the bottom. This is outlined with the pointed steel tool, and the bottom within the circle is evenly and carefully cut out with strokes of the oval, smooth-edged tool, so that the outside ring shall form a ridge not over one-sixteenth of an inch above the depressed interior of the circle. The potter now cuts his initial or mark, which is made in as simple lines as possible, into the bottom with firm, deep strokes. If the jar is not very dry, a wooden modelling tool may be used for this. Otherwise, the pointed steel tool is chosen. Care should be taken not to cut under the edge in making these incised lines. The edges should instead be bevelled, so that, when the glaze is put on, it will flow more freely over them.

If possible, this jar, being large, should be fired in the biscuit—that is, before it is glazed, and then again after it has been glazed; unless one is obliged to send it a long distance to be fired, so that more than one firing is impracticable, in23 which case it must, of course, be glazed on the unbaked clay.

A pale green glaze (see directions in Chapter V.) will complete it.

In packing to send pieces to a far-off kiln by express, use a wooden box, and, after lining it with newspaper, wrap the pieces in soft paper, and pack them carefully in sawdust.

Working on the Wheel

That the primitive potter did not mould his pottery on a wheel we can be reasonably sure. The Egyptians, however, as early as 4000 B. C., used the simplest potter’s wheel, as is proved by fragments of pottery still in existence. This wheel was a small, round table revolving on a pivot (see Fig. 10). The potter set it in motion with his hand, and from time to time gave it a spin to keep it revolving. The same wheel is used to this day in many parts of India. An improvement on this simple contrivance was made in Egypt under the Ptolemies. A larger circular table was fixed lower down on the same axis. This the potter set and kept in motion with his foot, leaving his hands28 free at all times to mould the clay, while the wheel was kept at a regular speed.

What is technically known as “throwing” or moulding pottery on the wheel is a process that is not learned in a moment, or even in a day. It takes time and patience, but it is certainly one of the most fascinating parts of the craft. One would have lost half of the charm of pottery-making who had not felt the plastic clay, on the potter’s wheel, rise and fall between his hands, almost as if endowed with life!

The rapidity with which pieces can be formed on the wheel is an advantage over other processes, while the regularity of shape, refinement and perfection of finish give wheel-made pottery a beauty all its own. Until lately, few women potters have worked on the wheel, because the ordinary form of potter’s wheel, which was turned with one foot, the potter standing on the other, made the work too difficult and laborious for a woman to attempt. Now, however, a wheel copied from an old French model is in use which enables the potter to sit while at work. This is the wheel shown in Fig. 11. It is obtainable from makers of potters’ tools. The cost of such a wheel, with an iron top and shaft, and wooden flywheel made of three thicknesses of29 boards, is eighteen dollars, but second-hand wheels can sometimes be bought for much less. When the wheel is set up, the shaft box (a square box below the upper wheel) is fastened to the edge of a strong table or shelf, which has been placed in a good light. A seat which slants forward, not unlike a reading-desk in form, is made of wood (see Fig. 11), and set up near enough to the wheel for a person sitting on it to reach the wheel comfortably. It is braced by a board on either side extending diagonally forward, from the leg of the seat to the floor, and by a board fastened on the right of the top of the seat and reaching to the table. Under the table a foot-rest, roughly made of boards, is needed.

At first, it will be wise to learn how to set the wheel in motion. Suppose we practice this a few times before beginning to mould. When one is seated on the inclined bench, the left foot on the rest, the right foot starting just below the body,30 near the outer edge of the wheel, swings the flywheel from right to left. The point of the foot is used for this. Four or five vigorous turns are given, and then the foot, swinging nearer the iron shaft, gives five or six more pushes to the flywheel, and is placed on the foot-rest. Expert potters can turn with the foot while the hands are busy moulding, but we who are beginners will do wisely to start the wheel revolving, then, keeping both feet on the rest, give all our attention to the hand-work, until the slower revolutions warn us that it is time to give the wheel another start. One caution should be given, and it may not be out of place here: Do not work too long a time at the wheel. Half or three-quarters of an hour’s steady work at a time will be enough. After that, leave it for half an hour and you will not get physically or nervously tired; besides, the work will go much better. Have your tools and a bowl of thin slip within easy reach as you sit at the wheel.

In beginning your piece, a lump of clay, say about two pounds, well worked, is made into a ball. Wet the top of the wheel, then rub it off so as to leave the wheel just moist enough for the clay to stick, but not slippery, so that it will slide. The lump of clay, held in both hands, is then thrown31 firmly on to the centre of the wheel. The bottom of the lump should be well down on the wheel, and it is most important to have it exactly in the centre. The hands are wet with slip, which is also rubbed over the lump of clay with both hands so that it is thoroughly moist.

The wheel is now set in motion as already described, and when it is well started, and both feet are up on the rest, the hands held one on either side of the clay starting close to the wheel, move slowly up the sides of the lump, drawing it up into a cone shape. The elbows should be well braced against the sides of the body, so as to hold the hands absolutely steady, for they should never waver or swing with the wheel, but hold true and firm. If the mass is not exactly in the centre of the wheel, or the cone shape is not even, the hands are again wet with slip, a few drops of which are shaken on to the clay. The thumbs are laid together, and the hands at the bases of the thumbs are pressed firmly down on the clay (as the wheel turns), pressing it again into mound shape. The hands and clay are wet once more, and the wheel started. The clay is now pressed up again into the cone form, taking great care to have the pressure even and slow. The hands should move, after each revo32lution, not more than a quarter of an inch. When a good cone shape is made exactly in the middle of the wheel, the piece is “centred.” In order to prove that the cone is absolutely in the centre, set the wheel going, brace the arms against the body, and, steadying the right hand with the left, move the forefinger of the right closer and closer to the cone, until it all but touches it. If the figure hits in any one place, that will prove that the cone is not centred, and it must be pressed again into mound shape as already described, but if it just clears it all the way round, the potter proceeds to the next step.

The thumbs, held close together above the clay, are aimed at the exact centre of it, and their ends pressed firmly but lightly in, while the wheel revolves once or twice. This is to mark the centre. The next step is to hollow out the piece. This is also done with the thumbs. The hands and clay being wet with slip, and the wheel started well, the fingers inclose the outer walls of the piece, while the thumbs are pressed into the centre of the clay firmly and decidedly down to within less than half an inch from the bottom. This is something that the potter learns to know almost by instinct—how close he can come to the top of the wheel and yet leave a bottom thick enough to trim and finish.

A form as nearly cylindrical as possible will be the simplest to begin with. Suppose one wishes to make a jar of the shape shown in Fig. 12. The next step is to make the walls of equal thickness, hollowing the bottom more. To do this, the elbows are braced against the sides, and the fingers placed in the position shown in Fig. 13. This is one of the ways in which the hands are made to support each other and work in unison. The different placings of the hands, to accomplish various results, are known as potter’s grips. In this one, the right hand, which remains outside the piece (lying close against it), supports the left by the thumb which rests against it, the forefinger of the right hand having previously been coiled around its thumb (see34 Fig. 13). The middle finger of the left hand lies against the wall of the piece inside. The piece is thus supported outside and in by a hand.

Starting at the bottom, as the wheel turns, the hands, held steady and firm, rise slowly with each revolution of the wheel. The right presses more than the left, hollowing the bottom and walls of the piece. Slowly, slowly, the hands rise, until the top is reached. If the shape is not quite true, the hands start in the same position at the bottom and again go up, pressing hardest when pressure is needed, and going lightly where it is not necessary to alter the shape. Another position of the hands (see Fig. 14) may be used to press the clay into a narrower form. This must be done with great deliberation and care, however, as too much pressure may make a crease in the clay wall which will35 spoil the piece. When the walls are of even thickness (not more than a quarter of an inch) and the shape about what one wishes, the top must be finished.

First the edge is cut even. We will use for this the tool shown in Fig. 8.

Holding the tool, which has been wet with slip, firmly in the right hand, brace the left by resting the thumb near where the steel is inserted in the wood (see Fig. 15). As the wheel turns, lay the left forefinger, wet with slip, just inside the top of the piece, and directly opposite (at the point where one wishes to cut the top) run the point of the tool through, till it touches the finger, and hold it steady and firm till one revolution of the wheel has been made. The wheel is then stopped, and the edge that was cut lifted off deftly and quickly.

To soften the edge, hold the forefinger and middle finger of the right hand apart (see Fig. 16). Wet their inner surfaces thoroughly with slip, then, as the wheel revolves, hold them straight and firm (while the left hand steadies the wrist of the right) and press the rounded joining of the two fingers gently but firmly down on the top of the piece, holding it there steadily till one or two whole revolutions of the wheel have been made. If one wishes to have a more flaring top, lay the forefinger of the right hand inside the edge with ever so slight an outward pressure, while the wheel turns once. Before perfecting the bottom, it may be as well to let the piece stiffen for half an hour.

The hoe-shaped tool is used for cutting away the extra clay under the bottom. Set the wheel in motion, then take the tool, well moistened with slip, in the left hand. Hold it firmly with its long edge on the top of the wheel (if it is to be a long and gradual slope into the bottom of the jar), while the right hand steadies the top outer angle of the tool. It is then run in under the bottom and there held till one or more revolutions have cut away the surplus clay.

Should one wish to make a more abrupt line up from the bottom, the process is reversed, the right37 hand holds the tool, the short side of which is laid on the wheel, while the left hand holds the outside top angle, to steady it.

After an hour or two, when the piece has stiffened somewhat, it may be smoothed, and the form refined or improved, if necessary, with the smooth-edged oval tool of sheet steel. When the wheel is in motion, this tool, moistened with water and bent to fit the curves of the piece, is held in the right hand at right angles with the piece, while the left hand supports the wrist of the right. Too abrupt angles may be softened and roughness removed with this tool. Start at the bottom with it, and move it up gradually, with each revolution of the wheel, lightly, except where the form needs much trimming. The rubber polisher, wet with water, is now passed over the surface in the same way, taking care that it is held at right angles with the piece and the hand that holds it is braced by the other. A stout wire held close to the piece on either side is then drawn under it once or twice to prevent its clinging to the wheel.

The next day, or as soon as the piece is stiff, it is removed to a plaster tile. In finishing the bottom, the wheel is first scraped and wiped clean of all clay; the piece is then placed on it bottom up and centred.38 This is done by putting it as near the middle as possible by eye; then when the wheel is going well, hold the right forefinger or a wooden tool, well braced, close to the piece. See if it touches at any point, and if so, move that side nearer the centre. Roll four short pieces of rather stiff clay. With two of these make supports on the wheel about an inch high, close to the piece on either side to hold it steady—not close enough to cling to it. Two more supports are placed half-way between the first two.

Get the wheel going well, and holding the hoe-shaped tool so that its middle angle will strike the bottom of the piece about half an inch from the edge, aim it truly and hold it steadily till the wheel has made one or more revolutions, which will mark a circle. Within this line depress the bottom slightly by cutting out a thin layer of clay. This is done with the rectangular sheet steel tool held first near the line, then with each revolution nearer the centre till it reaches it. The potter next cuts his mark on the bottom with a wooden tool, if the piece is not very dry, otherwise it should be made with a pointed steel tool, taking care to bevel the edges of the incised lines.

The large fruit-bowl on the left has an incised design of orange leaves near the rim. Beside it is a low dish for candy, with a built-up decoration of rings. A design of maple leaves is incised on the other small dish, and the lamp bowl at the right of the plate has a pierced decoration.

The jar is finished with a handle on each side. Roll out two strips of clay five and a half inches long; flatten them, and trim the edges. Now mark a place on each side of the top of the jar, so that a line drawn from one to the other would exactly divide the top. Make two other marks in the same way at the bottom, directly under those at the top. These are for guides in attaching the handles. Starting at the top, below one of the marks, criss-cross lines with the steel tool for an inch down the side of the jar. Do this on the other side of the jar, and then, starting an inch above the mark on either side of the bottom, cut criss-cross lines for an40 inch up the side of the jar. Now take one of the clay strips, brush the upper criss-crossed lines on one side of the jar with slip, and press the end of the strip upon it, working the edges close against the side of the jar with the flat of the nail. The other end of the strip is cut in a long point to fit the form of the jar, and bent into the shape shown in the plate. Wet the criss-crossed lines below it with slip, and attach this end in the same way as the first. The other handle is put on in the same manner.

A mat-glaze of gray green (see Chapter V.) will complete the piece.

Such forms as are shown in Figs. 17 and 18 can be made without any difficulty, and they will be most attractive for short-stemmed flowers—violets, sweet peas, or nasturtiums. A cream-jug (see plate) is comparatively simple. The lip is formed with a deft touch of the finger after the piece is moulded, and the handle added afterward. A dull-green mat-glaze will make a charming finish for this piece. The jar shown in Fig. 19 is more difficult to shape, but it is an excellent one for flowers.

The more simple and strong pottery designs are, the better. Those that are intricate, no matter how beautiful, are out of place on the big, substantial forms; while delicate traceries are lost under the glaze. Here, as in basketry, we can learn much from the work of primitive peoples.

In applying such designs, simple methods, too, are best—incising, building up the outline so that the design shall be raised above the background, cutting away the background to leave the design in low relief, and piercing. These are good processes, easy to learn, and effective in result.

In starting, suppose we decorate a wheel-made piece—a low dish for candy, with a built-up design of rings.

Materials required:

A wheel-made dish or bowl,

Ultramarine blue water-colour paint,

A small water-colour paint-brush with a fine point,

A saucer of ground, baked clay, mixed with water,

A pitcher of water.

The low bowl shown in the plate is not difficult to mould on the wheel. After it has become bone dry—as it will in three or four days—it will be safe to decorate it in this way. Be careful, in handling the piece, not to grasp it by the edge, which, in all unbaked pottery, but especially in that that is bone dry, is the most fragile part. It should be held in the hollow of the left hand, while the right does the work. Have ready some ultramarine blue water-colour paint mixed with water in a cup, a small paint-brush tapering to a fine point, and a saucer in which is some baked or biscuit clay, pale yellow in colour, ground fine and mixed with water to the consistency of thick cream. A jug of water nearby is also necessary, to thin the clay mixture when it stiffens.

The design chosen is one large and two small rings, alternating around the bowl near the top (see Fig. 20). First measure the circumference of the top of the bowl. Divide it into fifths and mark the divisions with the paint-brush and blue paint. Starting a quarter of an inch below one of these45 marks, draw a small ring, about half an inch in diameter, with the blue paint. Should you make a mistake, the paint will erase easily after it is dry.

Half an inch below the first ring another is drawn. One of these groups of two small rings is made below each of the five marks around the top of the bowl. Then starting half an inch below the top of the bowl, and midway between two groups, draw a larger ring about an inch in diameter. One of these rings is outlined in the same way in each of the five spaces. When the design is perfected and the paint dry, dilute a little of the baked clay in the saucer to the consistency of thin cream, and with it and the brush, thoroughly cleansed from blue46 paint, trace the outlines of the decoration. Use a full brush, and make the lines as uniform as possible in width and thickness. There should be four or more coats of this material applied in order to build up the design sufficiently, but only the first one is thin. This is so that it shall cling to the clay underneath. The next and subsequent coats are made with a thicker consistency of the creamy mixture, which must, however, be thin enough to flow freely from the brush. Do not add a coat until the one underneath is thoroughly dry.

The piece is now ready for glazing.

A pale-green glaze may be used (see Chapter V.).

Incising is an absolutely simple process, which gives a charming effect. Examples of this method of decoration are shown in the fruit-bowl with a garland of orange leaves just below the rim on the inside (see plate and Fig. 25), and the smaller bowl with a maple-seed design (see plate and Fig. 21). Incising also helps the pierced design on the rose-bowl described in Chapter VII.

Materials required:

A small wheel-made bowl,

A pointed steel tool,

A pointed boxwood tool,

A boxwood tool with curved point.

The bowl, a low one, is made on the wheel according to the directions in Chapter III. After it has dried for a day, it may be decorated with an incised design.

Suppose we choose for this a winged maple-seed, the simple outlines of which any one can draw. From tip to tip of the wings should measure at least an inch and three-quarters. If the bowl is small, not more than four and a half inches in diameter at the top, six seeds should be made at equal distances around it. First measure the circumference of the top of the bowl. Divide it into sixths, and with a pencil mark off as many divisions on the edge of the bowl.

The design, which is drawn so that the seed portion is down and the little wings turn up, is first outlined in pencil near the top of the bowl. Begin by drawing the seed part, which should be about an inch below a pencil-mark on the edge. With a boxwood point deepen the line, and then make the48 incision still deeper, using the wooden tool with a curved point. Take care not to make a double line in deepening the first outline; it should be a clean, firm line, with a bevelled edge. Avoid cutting under the edge, as the glaze will not run smoothly over it.

If the piece is too dry to admit of incising with a wooden tool, use a pointed steel tool at first and finish with a wooden one. Certain parts of the design should be accented by deepening the line—for example, the rounded seed portion, particularly where it joins the wings.

This bowl may be finished with a pale-green mat-glaze (see Chapter V.) or with a soft brown one.

A decoration that is left in low relief by cutting away the background is admirable for some pieces. The moth design on the rose-bowl in Chapter VI. is made in this way. The design is first drawn on the piece in pencil. Next it is outlined with firm, sure strokes, using a pointed steel tool, and taking great care not to cut under the edge of the outline, but bevel it, as in other processes. Go over the whole outline of the design again with a boxwood point, making the lines deeper. Then start close to the edge of the outline with the steel tool, which has a flat point, and scrape away from it, cutting as deep49 as the outline, close to the design, and sloping gradually up to nothing at about half an inch from it. Certain parts of the design may be emphasised by cutting the outline somewhat deeper at those points. Be sure to cut away enough clay about the design to leave it in decided relief, for the glaze softens the edges, and makes them too indefinite if they are not firm and clear in the beginning.

Pierced decorations are particularly good on pottery. Such simple designs as those in Figs. 22, 23, and 24 will be found the most satisfactory.

In planning a pierced decoration for the top of a piece, take care not to start it too close to the rim;50 three-quarters of an inch or more should be left between the edge and the decoration, otherwise the piercing will weaken the piece.

Outline the design first in pencil, then with firm, clear strokes follow the line with the pointed steel tool. The line is traced a second time still more deeply. All the clay within the outlines is cut out as far as the incision has been made, and then the sharp point of the tool is run through the wall close to the line. While the clay is being cut away with the right hand, the left supports the inner wall of the piece.

When the whole design has been pierced, moisten the finger with water and soften the edges of the decoration, that the glaze may flow freely over it. Decorations in high relief are made as follows:51 Small lumps of clay, as nearly as possible the consistency of the piece of pottery, are applied to the portions which are to be decorated, and which have previously been criss-crossed with a steel tool, and wet with slip. The design is then moulded with the hands and wooden modelling tools, working the edges close on to the surface of the piece.

The Glaze and How to Apply It

Clay that is simply baked, without a glazed coating, will not hold water perfectly.

One can imagine what a blow it must have been to the early potter when he found that this was the case. Some say that he used wax at first to close the pores of his pottery, and later—perhaps by the overheating of a kiln—glazed pottery was discovered. Pottery that is soft will develop a semi-glazed surface when overfired, and it is probable that some such accident suggested the use of the glaze.

The first glaze was doubtless a pure silicate of soda. Oxide of lead added to this made it more fusible, but it was not as hard or durable.

What is known as biscuit is baked clay porous and without gloss—for example, a flower-pot.

Glossy pottery has a very thin layer of glaze upon it. The Samian ware of the Greeks furnishes56 examples of this finish. Glazed pottery is covered with a perceptible coating of glass.

Enamelled ware, or pottery with a mat-glaze, has a glazed coating made opaque with oxide of tin. This finish is used on some of the most beautiful art pottery. Glazes may be coloured with certain metallic oxides without losing their transparency.

One is often confused by hearing the terms enamel and glaze carelessly used. Enamel should be used to describe a vitreous coating that is opaque, and glaze a glossy, transparent surface—both may be coloured. The term mat-glaze is an exception to this rule. This means an opaque glaze with a glossy finish.

The materials of which glazes are composed are about the same as those that enter into the composition of clays with a few additions. There is in glazes, as in clays, the play of soft and hard materials, or the flux and frit. Flint, aluminum, or china clay forms the frit or hard, refractory portion; potash, soda, lead or borax the melting part or flux. The addition of clays gives durability.

In preparing the flux, it is melted like glass and then crushed to powder. The frit must first be57 melted, then dropped from the crucible into water before it can be powdered.

The making of glazes is not often done by amateurs, and unless one is planning to start pottery-making as a business, and requires large quantities of glazes, it is best to buy them from a reliable dealer. They come in the form of powder—soft glaze, hard glaze, and stannifère, which is a hard glaze with some oxide of tin added, to make it opaque. The soft glazes are used on ware which fires at a low heat, and is therefore not durable. A large proportion of hard glaze must be added to make the preparation applicable to a pottery which is fired at an intense heat, while if one wishes a mat-glaze the stannifère is also used.

The colouring materials may be bought of the same dealer. They are as follows: Antimony for yellow, cobalt for blue, copper for green, chrome for green, manganese for brown, and iron for brown. Red oxide of iron colours a purplish red, and carbonate of copper makes a gray green that is very beautiful. A ground glass or stone slab, on which to mix the glaze, and a palette knife, will be required; also a small quantity of gum-arabic and of gum tragacanth, a small teacup, and a measuring-glass. These, with two or three soft paint-brushes58 of various sizes—one that is an inch wide, one smaller, and another larger—will be enough of an outfit to start with.

The gum-arabic should be dissolved in water to the consistency of honey. It is used in the first coat of glaze to bind the glaze and prevent it from rubbing off. Quite a little of it may be prepared at a time and kept in a covered glass jar until needed. The gum tragacanth is bought in small quantities—five cents’ worth at a time. Cover this amount with one pint of water and let it stand over night. In the morning, strain it through a fine sieve and put it away in a glass jar till it is needed.

If possible, very large pieces of pottery should be fired before they are glazed—in the biscuit, as it is called. Small and medium-sized pieces may be glazed on the green clay—the term by which unbaked clay is known among potters. The piece should have dried thoroughly for several days, until it is light gray in colour, and what is known as bone dry. It is decorated, if decoration is required, and then glazed. All vessels that are used to hold or measure glaze should first be dipped in water to prevent waste from the glaze clinging to them. The hands should be washed thoroughly59 after working with glazes, as some of the materials used are poisonous.

For the inside of most pieces a transparent glaze is used, whether the outer glaze is to be transparent or opaque.

All of the odds and ends of transparent glaze, no matter what the colour, that are left after each glazing, are poured into a large bowl or other vessel which is kept for the purpose. The mixture of all colours in this combination of glazes makes a neutral tint which harmonizes most agreeably with the outer glaze, whatever its colour.

It is applied as follows:

Take a small cupful of transparent glaze, and, holding the piece of pottery over the large vessel containing the liquid, pour the cupful of glaze into it, rolling it around the inside of the piece quickly but carefully, so as to have it cover the entire inner surface. Then turn the piece deftly and suddenly bottom up, so as to empty it into the large vessel without letting any of it drip over onto the outside of the piece. Should this happen, by accident, rub it quickly off with the fingers.

The most satisfactory finish for the outside of fine pottery is a mat or opaque glaze in any soft dull shade of green, brown, blue, yellow, or the red obtainable with red oxide of iron. For an art pottery, composed of fire-and blue-clay, which requires a strong heat, the following glaze is applicable:

Mix

1 tablespoonful of soft glaze,

½ tablespoonful of stannifère, and

½ tablespoonful of China clay,

together on a stone or glass slab with a palette knife, adding ¼ teaspoonful of gum-arabic and enough water to make the consistency a little thicker than thick cream. About ¼ teaspoonful of carbonate of copper added to this mixture (and ground thoroughly into it with the palette knife) will make a light gray-green. For deeper shades increase the quantity slightly. The tint appears much lighter than it will when fired; indeed, in the colouring of glazes, as in painting on china, the worker needs a great deal of faith, for until the magic of the kiln brings out the colours one would never guess what they were to be.

In applying the glaze, place your piece bottom61 up on a table, or other flat surface. Dip a soft, flat paint-brush into the bowl of glaze, and beginning with the bottom, paint it on in short strokes in every direction—what an artist would call cross-hatching—and overlapping slightly like the shingles on a house. The bottom receives but one coat of glaze, as it is liable to stick in firing and be uneven if it has more than one. Next start at the sides, near the bottom (as the piece stands upside down), and paint down for an inch or two all around. The piece is then set right side up, providing, of course, that the bottom is dry, which it will be undoubtedly, and the rest of it is glazed. From time to time stir up the glaze from the bottom, that it may be thoroughly mixed.

The edge especially should be carefully covered, and the outer glaze may even be brought over inside the piece a little. Before applying the second and third coats (for the piece receives three) two teaspoonfuls of gum tragacanth, well mixed according to directions, are added to the glaze. In putting on the second coat, the piece is again placed upside down on the table, and beginning where the sides join the bottom, the glaze is applied as before. The sides and top edge only are glazed this time. The third coat, which is put on when the second is62 dry, is begun at the top edge, covering it well, and is ended gradually and unevenly half way down the sides.

To make a lighter shade of green, with just a hint of yellow to soften it, add to half the quantity of the glaze first mixed as much again of the uncoloured glaze and a slight sprinkling of yellow.

It will be seen from these directions how much the colouring of glazes is like the blending of pigments for a picture. It is a delightful field for experiment, and the element of chance is supplied by the kiln, which often does unexpected and interesting things to one’s colours and glazes—leaving here, a touch of brown about the rim to relieve an expanse of green; there, a metallic tinge almost like lustre; and again the biscuit peeps through the glaze, giving a warmer tone to the edge of a decoration.

In mixing the glaze for a piece that has been fired in the biscuit, make it a little thicker than that for use on the green clay—about the consistency of whipped cream. It is applied somewhat differently, too. A potter would tell you to "rag it on"—that is, put it on with firm, short strokes, using the63 ends of the hairs of the brush instead of the flat part. Let each coat dry well before the next is applied. Three or four coats will be necessary, except for the bottom, which receives but one. After the first coat, gum tragacanth is added, as in glazing on green clay. The fourth coat need not entirely cover the piece, but the top should be carefully glazed. If for any reason the pottery has to be re-fired, it should be reglazed, but two coats only will be necessary, and the glaze need not be quite so heavy as that used on the biscuit. Do not be discouraged if your pieces need a second or even a third firing, for often the most beautiful results are obtained by re-firing. Quality—that combination of richness, and depth of colour and texture—rarely comes with the first firing.

Pottery for Beauty and Use

When one thinks of the limitless possibilities of pottery in household decoration—the great dishes for flowers and fruit, the lamp-bowls, candlesticks, and tiles—one may make, one can hardly wait to begin. Now is the chance to work out a long-treasured idea for a match-bowl, or a plant-jar to hang against the wall or window frame. Now one can show the superiority of one’s conceptions over the stupid things in shops! Let us hasten to get out the clay and begin.

Materials required:

About 4½ pounds of clay,

A plaster mould for a bowl, 10 or 11 inches in diameter at the top,

The oval tools of sheet steel,

The wooden modelling tools,

The pointed steel tool,

A flint bag,

A rolling-pin,

A bowl of slip,

A small sponge.

Take a good lump of clay, about four and a half pounds, well worked and free from air-bubbles. Beat out a piece with the flat of the hand on a table until it is about three-quarters of an inch thick and more than large enough to cover the bottom of the plaster mould you have chosen. It should be of even thickness, and may be rolled with a rolling-pin to make it smooth. Be sure that the plaster mould is clean and free from scraps of clay. Then dust it with powdered flint tied up in a cotton cloth. Now fit the flat piece of clay carefully into the bottom of the bowl mould, pressing it firmly, but lightly, against it. Cut the edge evenly around. Next a long rope of clay is rolled as described in Chapter II. It should be an inch in diameter, and long enough to go around the bowl just above the bottom. Pat it flat and even, and cut one end into a long point. After cross-cutting the edge of the bottom piece (to insure its holding firmly to the coil above), brush it with slip and lay the coil along, pressing it firmly on to the edge of the bottom piece. Work the edges of this piece and the coil together with firm, short strokes of the flat part of the thumb or forefinger nail. Where the coil joins the other end it is cut into a long, flat point that will fit exactly the point at the beginning, completing the row.

For the next coil no cross-cutting with the tool is necessary, but otherwise the process is the same in joining this and subsequent coils. Care should be taken to press the clay firmly against the walls of the mould, as well as upon the coil below. When the inside of the mould is covered, if a deeper bowl is desired, add one or two more coils above the edge, taking care to have them slope in such a way as to continue the lines of the bowl. It is then set away to harden. The next day the clay will have dried and shrunk sufficiently to come easily away from the plaster. The bowl is then placed bottom up on a table or flat slab, and the hollows left between the coils on the outside are wet with slip and filled in evenly, with clay of the consistency of that in the piece. This will take time and care. The bowl is then allowed to dry for an hour or two. Next it is carefully scraped and made even; first with the oval steel tool with a saw edge, held at right angles with the bowl and curved to fit the form: this is to get the large bumps off. It is then carefully evened off with the smooth-edged oval tool bent to fit the curves of the bowl. The inside is made smooth and even in the same way, brushing any deep hollows with slip and filling them in with clay. This process should be carefully and70 conscientiously done, so that the walls of the bowl, as one feels them between finger and thumb, are even and free from lumps. They should not be more than a quarter of an inch thick.

A damp sponge is then passed over the bowl, and the fingers and thumb smooth and polish it outside and in. The edge is trimmed as evenly as possible by eye with a steel tool and then bevelled as follows:

On a large slab of ground glass pour a little water, which should be spread over the glass till it is thoroughly wet. Now, holding the bowl bottom up, firmly with both hands, press its edge quickly and with a circular motion flat on the glass. It must be done so rapidly and deftly that it will not stick, but makes the edge even and true. Slip it off at the side of the slab instead of lifting it up from the centre. The bottom is finished as described in Chapter II. If this is done in the morning, the bowl will be ready for the decoration in the afternoon. This is a band of orange leaves (see Fig. 25), deeply71 incised near the top of the bowl on the inside (see Chapter IV.). More character will be given to the design if the line is broad and deep, particularly at the points of the leaves, which are thus emphasised. This piece being so large, should, if possible, be fired in the biscuit and then finished, inside and out, with a dark-green mat-glaze (see Chapter V.), and fired again.

Materials required:

About 1¼ pounds of clay,

The boxwood modelling tools,

The pointed steel tool,

A plaster slab,

A small sponge.

This sturdy little candlestick shows that it is hand moulded by the marks of the potter’s thumb on base, handle and candle cup. The square base is moulded from a single large piece of clay. This is patted flat and even with the thick part of the hand, and then cut square and the sides turned up for about an inch, making the base about five inches square and three-eighths of an inch thick. It is then placed on a plaster slab, and the corners are pressed in with a firmly held thumb. The sides of the square base are moulded into a gradual inward curve, and the corners are slightly depressed (see72 plate). A cup for the candle (see Fig. 26) is made by rolling a piece of clay into cylindrical form, about an inch and three-quarters in diameter and two inches and a quarter long. At the top of this roll, the finger makes a hollow for the candle. It should be remembered that the clay shrinks both in drying and firing, so this hole should be a trifle large and deep for the candle. The sides of the cup, at about an inch from the top, are squared and pressed in so that the four corners will stand out like columns. The hollowed sides between the corners show the mark of the thumb (see Fig. 26). The centre of the base is now wet with thick slip and the candle cup pressed firmly on to it, while the edges are moulded closely on to the base.

A piece of clay is then rolled and flattened into a handle an inch in diameter and five inches long. This is put on at one corner of the base, and is not attached at any other point. Before moulding it on to the base, touch the corner lightly with thick slip, to insure its holding. Where the handle joins the base it is made thick and substantial by adding73 a little extra clay. The print of the thumb is made where the handle joins the corner, another is pressed on the top, and another still on the end of the handle (see plate and Fig. 27). To support the handle until it dries, roll a ball of soft paper under it. After the candlestick has stood for a few hours out-of-doors or indoors overnight, it is carefully trimmed with one of the wooden tools or the sharp-pointed metal one, taking care to leave sufficient thickness to give it a sturdy, substantial character, yet not enough to make it clumsy. It is then rubbed over with a damp sponge and polished with the thumb and finger, which will smooth away any lumps and give the piece a hand-moulded look. Should there be any very deep hollows to make it uneven, they should be wet with slip very slightly and filled in with clay as nearly the consistency of that in the candlestick as possible. When it is bone dry, it will be ready for the glaze (see Chapter V.).

Materials required:

About 3½ pounds of clay,

A plaster mould for a bowl,

The wooden modelling tools,

The oval sheet steel tools,

The pointed steel tool,

A rolling-pin,

A flint bag,

A small sponge.

Having chosen a good mould for your bowl, brush it inside with ground flint tied in a cotton cloth, so that the clay will not stick to it. Now beat out a piece of well-worked clay on a board, with the flat of the hand, until it is perhaps two inches more in diameter than the bottom of the mould, and half an inch thick. It should be rolled smooth with the rolling-pin. Lay it in the mould, pressing it firmly against the bottom and sides. It may not be out of place here to say that no tool but a wooden one should be used in working in moulds, as metal tools are liable to injure the plaster. The edge of the bottom piece is next cut even with a wooden modelling tool, and a lump of clay is formed into a rude cube shape between the hands and then rolled out on a table or board with the flat of the hand till about three-quarters of an inch in diameter. This roll of clay is flattened evenly for its whole75 length. The top edge of the bottom piece is marked with criss-cross lines and wet with slip. The roll of clay is then started on edge, along the top of the bottom piece, pressed firmly down upon it and against the sides of the mould. It is joined to the bottom with firm, even strokes of the thumb or forefinger nail. When the circuit has been made, the two ends, each cut in a long, flat point, so that they will unite perfectly, are joined. Another roll is now made, the upper edge of the previous coil is wet with slip, and the coil is attached in the same way, being careful to start at a different place from where the previous coil was joined. Thus the whole bowl is built up. Where there are any decided hollows made by joining the coils, they should be filled in with clay of the consistency of the piece, and the bottom and sides smoothed with dampened finger or modelling tool. If a moderately deep mould has been chosen, after the sides are covered with layers of clay, four or more coils may be added above the mould to make a deeper bowl, continuing the sides in a graceful line. To do this, when the first coil above the mould has been attached, the bowl is set away, out of doors for fifteen or twenty minutes if it is in summer or indoors for a longer time if one is working in the winter. Whenever two coils have76 been built up, the piece is set away to harden. These coils, being free from the mould, can be joined on the outside as well as within. They are brought gradually in (see plate) until there is a space five and a half inches in diameter at the top. If a central-draught lamp is to be used in this bowl, a pierced design will be practical, as it does away with the necessity for a hole at the bottom of the bowl. There is much to be done, however, before the piece is ready for the design. When it has stood for four or five hours or overnight, the bowl can be lifted from the mould, the cracks on the outside where it was impossible to join the coils are wet with slip and filled in with clay of the consistency of the bowl, using the finger or a wooden tool. When the bowl is quite dry, it is smoothed inside and out, first with the oval tool with saw teeth, and then with the smooth-edged one, as described on page 19. The strokes with these tools should be short and firm, in every direction. The piece is then turned bottom up, a circle is drawn half an inch in from the edge of the bottom, and the clay within it scraped out, so as to leave a flat surface slightly lower than the outer rim. This is where the potter cuts his mark—a simple, quickly made initial in lieu of a signature.

The top edge, after it has been cut as true as possible by eye, is made absolutely even by the method described on page 70. The whole piece is then rubbed with a damp sponge and smoothed and polished with the fingers. It is now ready for the design (see Fig. 28).

The top edge of the bowl is marked off into fifths, and at three-quarters of an inch from the top the design is drawn with pencil, so that each time it is repeated the centre shall be directly below a mark on the edge. It is first incised with a metal tool, in firm, sure lines. Again the outline is traced, this time more deeply. Then the clay within the lines is cut out as deep as it has been incised, and finally the sharp edge of the tool cuts through the wall, close to the line. The left hand should support the inner wall of the bowl during this process. When the whole design has been made, dip the finger in water and soften the edges of the cut portion. The bowl is now ready for glazing. If pos78sible, it will be better to fire such a large piece as this in the biscuit before glazing. It will look well if glazed with gray blue or dark green (see Chapter V.).

Materials required:

About 4½ pounds of well-mixed clay,

A plaster slab about 10 by 12 inches,

The oval tools of sheet steel,

The pointed steel tool,

A rolling-pin,

Ultramarine blue water-colour paint,

A medium-sized paint-brush with fine point,

A saucerful of ground, baked clay, mixed with water.

An Indian water-jar of basketry, smeared with pinon gum, pointed at the bottom so that it could be set upright in the ground or hung by leather thongs to a tree, suggested the form of this jar. One side is made flat, so that it can hang against the wall of library or piazza holding some long trailing plant that grows in water, ivy, or wandering Jew, or wild flowers gathered on a walk through woods and lanes. What more appropriate way to make it than the Indian process described in Chapter II.? We shall need about four and a half pounds of clay, well mixed. A large lump, almost two pounds, is flattened out on a table, with the thick part of the79 hand and then made even with the rolling-pin. The sheet of clay should be ten by twelve inches, and not less than three-eighths of an inch thick. Upon it the jar form shown in Fig. 29 is outlined with a pencil, making it as large as possible to allow for shrinkage. It is then cut out with the pointed steel tool and transferred very carefully to a large plaster slab, where it remains while the walls are being built upon it. A coil of clay is rolled out, as described in Chapter II., and beginning at the left side of the jar shape, at the top, it is attached to the edge (which has previously been criss-crossed with a steel tool and wet with slip), all the way around to the opposite side of the top.

The jar is then put in the air until quite hard, when the next coil is added in the same way. The third coil is brought in a little toward the centre, and subsequent coils come in still more, so as to make the form that of a jar cut exactly in half. After each coil is attached, it should be left in the air to stiffen, or the clay beneath will not support80 the coil in progress, so great is the strain in forming such a shape. Each time a coil is added the wall below should be criss-crossed with the steel tool (an extra precaution) and wet with slip. Care should be taken not to make the walls too thick, and to join the coils and finish the inside as it is made; for, when the jar is completed, it is impossible to get the hand and tool in far enough to smooth and finish it well.

When the jar is made, except for a diamond-shaped gap in the middle of the front wall, the piece to fill it is cut and fitted in. It will lie almost parallel with the back wall. Take care to make it full large for the opening, and join it to the inner edges most carefully, for here, if anywhere, is the jar liable to crack. The top is now made even by eye, using the pointed steel tool.

When the jar is somewhat dry, two handles (see plate) are formed of rolls of clay (the consistency of that used in making the jar), five and a half inches long by an inch wide and half an inch thick. These are firmly attached to the back wall of the jar at the top (see plate), according to the method described on pages 39 and 40. The decoration (see Fig. 30) is drawn on the rounded front wall of the jar with ultramarine water-colour, and then built up with powdered burnt clay and water (see directions in Chapter IV.). If possible, this piece should be first fired in the biscuit. A glaze of dark gray green (see Chapter V.) will finish it most attractively.

Materials required:

About 1½ pounds of clay,

The wooden modelling tools,

The sharp-pointed steel tool,

A plaster tile,

A rolling-pin.

A quaint Dutch dish, brought from Holland years ago, was the model for this sturdy little piece of pottery. It may be used for candy or to hold a vase of flowers, or a potted plant, protecting a polished table. A lump of clay is rolled on a table with the hands and a rolling-pin to the thickness of half an inch. Upon this clay sheet a rectangle four and a quarter by four and a half inches is drawn with a pencil and cut out with the pointed steel tool. It is then transferred to a plaster tile.

To the edge of this rectangle a coil of clay is attached according to the directions in Chapter II., and flared slightly outward, taking care not to make the corners sharp, but rounded and even. After the first coil has stiffened, and the sides have been made somewhat uniform and thin, it is cut even by eye, curving the edge up gradually toward the middle of the sides and depressing it slightly at the corners.

A second coil is now added, but instead of attaching it to the top of the first one, it is joined just below the top and inside the first coil. When it has stiffened sufficiently in the air, the dish is smoothed carefully inside and out with the hand and the wooden modelling tools, making the walls even and thin and perfecting the shape.

The effect of legs is given by cutting under the sides, beginning half an inch above the bottom. If this is started three-quarters of an inch from the corners, it will leave a sturdy, short leg an inch and a half wide at each of the four corners of the dish.

A roll of clay about five and a half inches long, an inch wide, and three-eighths of an inch thick is made into a handle (see plate), which is attached at the middle of one of the sides of the dish. At the two points where it is to be joined, the side of83 the dish is criss-crossed with the steel tool and wet with slip.

The bottom is finished by drawing a square with a pencil, half an inch in from the edge, and depressing it within the square, so as to leave a flat, even surface. The potter’s mark is then made within this square.

A pale green mat-glaze (see Chapter V.) makes a charming finish for this piece.

Materials required:

About 5 pounds of clay,

A rolling-pin,

The oval sheet-steel tools,

The pointed-steel tool,

The steel tool with a flat end,

A plaster tile.

This rose-bowl, which is shown in the plate, was built up without a pasteboard outline. If one’s eye is reasonably true this is not a difficult matter, but otherwise the outline process (see Chapter II.) may be followed.

A piece of clay is first patted flat with the hand, and then rolled out with the rolling-pin, until it is six inches square and about five-eighths of an inch thick. Upon this clay sheet a circle is marked, five inches in diameter, cut out and placed on a84 plaster tile. The edge is criss-crossed with a steel tool and wet with slip, and the first coil is attached (see Chapter II.).

Two coils are built up, and then they are pressed outward to form the beginning of the outline, shown in Fig 31. This outline was taken from the lower sweep of the wings of a lunar moth, and the same moth forms the relief design upon it (see Fig. 32).

The bowl is then put out-of-doors until the clay is sufficiently firm to support two more coils. These are added; flaring them to follow the outline, and then the bowl is put away to harden—in the air, if the temperature is not too cold, otherwise indoors. It is built up exactly as was the flower jar in Chapter II., except that there is no cardboard outline to test it; the eye alone is the guide. Great care should be85 taken not to add the coils until those below are quite stiff, for the decided flare makes it difficult to keep the sides firm and true in outline. The circumference of the bowl, at its widest part, should be about thirty inches. When it is finished, the sides within and without are smoothed, first with the saw-edged oval tool, then with the smooth one. The edge is cut as true as possible by eye, and made perfectly level by pressing it quickly and lightly on the ground-glass slab, wet with clear water, as already described. A damp sponge is then passed over the piece, inside and out, while the fingers rub and polish it dry.

The bottom is finished and the potter’s mark made as described in Chapter II.

When the bowl is thoroughly dry—say the following day—it is ready for the decoration.

Divide the circumference of the top of the bowl into fifths, with pencil marks, lightly made. Then draw the design upon it, so that the top of the upper wings shall be not less than an inch from the edge of the bowl. Make the moths as nearly life size as the bowl will allow. Three and a half inches across, from tip to tip of the upper wings, with spaces an inch and a half between them, will86 look well, if the bowl is large enough. Having drawn the design in pencil, outline it firmly with the sharp steel tool, taking care to bevel the edge of the design. Never cut under the edge, as the glaze will not flow well over it. Go over the outline, making it firm and deep, with a wooden point. Now, starting close to the edge of the moth, with the flat-pointed steel tool scrape away from it, so as to cut as deep as the outline, close to the design, and shave off to nothing at about half an inch from it. This will give a low relief effect, which is very attractive. The antennæ are incised (see Chapter IV.), and the markings of the moth may be built up with ground, baked clay, so as to heighten the relief. The bowl may be glazed a pale green with a slight yellow tinge (see Chapter V.) to suggest the colour of the moth. It should, however, if possible be fired first in the biscuit.

Materials required:

About 1½ pounds of clay,

The wooden modelling tools,

A plaster tile.

A candlestick in flower form may be made in green and white, for a bedroom in a country house.