The Project Gutenberg EBook of Holcomb, Fitz, and Peate: Three 19th Century American Telescope Makers, by Robert P. Multhauf This eBook is for the use of anyone anywhere in the United States and most other parts of the world at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org. If you are not located in the United States, you'll have to check the laws of the country where you are located before using this ebook. Title: Holcomb, Fitz, and Peate: Three 19th Century American Telescope Makers Author: Robert P. Multhauf Contributor: Amasa Holcomb Julia Fitz Howell F.W. Preston William J. McGrath, Jr. Release Date: January 21, 2019 [EBook #58747] Language: English Character set encoding: UTF-8 *** START OF THIS PROJECT GUTENBERG EBOOK HOLCOMB, FITZ, AND PEATE: *** Produced by Colin Bell, Joseph Cooper and the Online Distributed Proofreading Team at http://www.pgdp.net

Contributions from

The Museum of History and Technology:

Paper 26

Holcomb, Fitz, and Peate:

Three 19th-Century American Telescope Makers

| INTRODUCTION—Robert P. Multhauf | 156 | |

| I. | Amasa Holcomb—Autobiographical Sketch | 160 |

| II. | Henry Fitz—Julia Fitz Howell | 164 |

| III. | John Peate—F. W. Preston and William J. McGrath, Jr. | 171 |

Practically all the telescopes used by amateur scientists in 18th-century America were of European origin. Our dependence upon foreign sources for these instruments continued well into the 19th century, and the beginning of telescope making in this country has conventionally been associated with the names of Alvan Clark and John Brashear, whose work dates from the 1860’s.

Presented here are biographical sketches of two predecessors and a contemporary of Clark and Brashear whose obscurity is not deserved. The accounts relate some hitherto little-known aspects of telescope making in America as it progressed from mechanic art to science.

The Author of the Introduction, Robert P. Multhauf, is head curator of the department of science and technology in the United States National Museum, Smithsonian Institution.

Robert P. Multhauf

The telescope was invented about 1600. It was brought to America about a half-century later, and within another century had become a commonplace appurtenance to the library of the cultivated gentleman.[1]

Throughout this period, from Galileo to Herschel, the telescope found use in scientific astronomy, although the possibility of contributing to the science of astronomy by simple observation diminished continuously after the time of Galileo. Herschel’s work had aimed at the advancement of scientific astronomy through increasing spectacularly our powers of vision, just as had that of Galileo in the 17th century and of Hale in the 20th. But even in Herschel’s time the monstrous size of the instrument required made the project something of a national effort. The telescopes of the 18th-century American gentleman were already toys, as far as the astronomer was concerned.

However, the telescope had another, if less glamorous, use in the 18th century. This was its use in positional astronomy, in the ever more precise measurement of the relative positions of objects seen in the heavens. Measurement had been the purpose served by pre-telescopic astronomical instruments, the sighting bars of the Ptolemaic observers of Alexandria and the elegant quadrants of Tycho Brahe. For a time[157] after the invention of the telescope the professional astronomer resisted the innovation, but by the end of the 17th century the new optical instrument was being adapted to the quadrant and other instruments for the precise measurement of the positions of heavenly bodies in relation to the time-honored astronomical coordinates. By the late 18th century telescopes were found serving three relatively distinct purposes: the increased magnification of the sky in general (in which use Herschel’s 48-inch reflector had made all others obsolete): the more precise measurement of planetary and stellar positions (and, conversely, of the Earth’s shape) by means of the quadrant, vertical circle, zenith sector, and similar instruments; and the simple edification of the educated but not learned classes, who wished not only to see what the astronomer saw, but to have an instrument also useful for looking occasionally at interesting objects on earth.

Of these three purposes the second was the most unimpeachably scientific. It is remarkable that the earliest American-made telescopes of which we have knowledge were made for this purpose and not for the mere gratification of the curiosity of the educated layman. These are the telescopes of the remarkable Philadelphia mechanic, David Rittenhouse (1732-96). In an atmosphere not unlike the intellectual democracy that characterized the formation of the Royal Society a century earlier in London, Rittenhouse began as a clockmaker and ended as president of the American Philosophical Society, our counterpart of the Royal Society, in Philadelphia. He demonstrated not merely that an instrument-maker was capable of being a scientist, but also that the work of the instrument-maker, as it had developed by the late 18th century, was in itself scientific work. One of several observers assigned by the Society to the observation of the transit of Venus in 1769, he constructed instruments of the most advanced types, apparently employing European lenses, and used the instruments himself. Of these, a 1¾-inch refractor mounted as a transit instrument stands in the hall of the Philosophical Society. It is probably the oldest extant American-made telescope.

Rittenhouse made other telescopes which survive, notably two zenith sectors now in the U.S. National Museum of the Smithsonian Institution,[2] but he does not appear to have made them for commercial sale. In the history of telescope-making in America he seems to have been something of a “sport.” Not only were the instruments which still grace the desks of Washington, Jefferson, and others, of European manufacture, but the earliest observatories in the United States (eleven between 1786 and 1840) were outfitted exclusively (except for the Rittenhouse observatory) with European instruments.[3] In its endeavor to establish a permanent observatory even Rittenhouse’s own Philosophical Society seems to have thought exclusively in terms of instruments of European manufacture.

It must therefore have required some courage for Amasa Holcomb, 43-year-old Massachusetts surveyor, to approach Professor Silliman of Yale in 1830 with a telescope of his own construction. In the autobiography printed here, Holcomb states that all the telescopes used in this country before 1833 had been obtained in Europe, and indicates that thereafter “the whole market was in his hands during thirteen years,” a period which would fall, apparently, between 1833 and 1845. It should be mentioned, although it is no conclusive negation of Holcomb’s claim, that the New York instrument-maker Richard Patten in 1830 built a telescopic theodolite that was designed by Ferdinand Hassler for use on the Wilkes Expedition, and was subsequently used at the observatory of the Navy’s “Depot of Charts and Instruments” in Washington.[4] We do not know the source of Patten’s lenses.

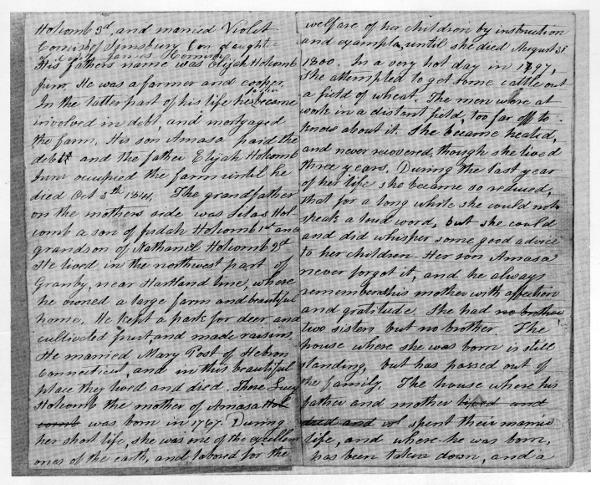

Holcomb would appear to have succeeded as a commercial maker of telescopes. He claims to have sold his instruments “in almost every state in the Union,” and also abroad, but we know nothing of what use was made of any of them. The telescope he showed Professor Silliman was a refractor. Another, preserved in the Smithsonian Institution,[5] is like Rittenhouse’s 1769 instrument, a transit. But Holcomb seems to have specialized in reflectors of the Herschelean type, i.e., instruments, in which the image is viewed through an eye-piece located at the mouth of the tube. It is probably reasonable to doubt that the serious astronomer of this period shared Holcomb’s enthusiasm for this type of difficult-to-adjust instrument in the small sizes he produced (10-inches is the largest reported). In 1834, 1835,[158] and 1836 he presented instruments of this type to the Franklin Institute in Philadelphia, where committees compared them with the best available European refractors and found them more than adequate. One of Holcomb’s instruments of 1835, apparently his only surviving reflector, is now in the Smithsonian Institution (see appendix, p. 184).

Toward 1845, Holcomb tells us, “one after another went into the business,” and indeed they did. At the American Institute Fair in New York that year a gold medal was given Henry Fitz “for the best achromatic telescope.” In Cambridge, Massachusetts, Alvan Clark is supposed to have already taken up the hobby of lens and mirror making. And in McKeesport, Pennsylvania, an amateur telescope-maker now known only as “Squire Wampler” made a small achromatic refractor which he demonstrated in 1849 to a 9-year-old boy named John Brashear, of whom more later.

Some of Holcomb’s telescopes must have come to the attention of Henry Fitz during his wide travels as a locksmith after 1830, if, as is reported, he was at that time pursuing his avocational interest in astronomy. It is interesting to note that both Holcomb and Fitz seem to have pursued feverishly the new photographic process of Daguerre in 1839, the former near the end of his career as a telescope-maker, the latter near the beginning of his.

The decade before 1845, when “one after another went into the business,” seems to have been marked by the flowering of observational astronomy in the United States. The professional work of the Navy’s Depot of Charts and Instruments (forerunner of the Naval Observatory) began about 1838. In 1844 the first instrument larger than 6 inches came to this country, an 11-inch refractor for the Cincinnati Observatory. The Bonds established what was to be the Harvard Observatory in 1839, and by 1847 Harvard had obtained its famous 15-inch refractor from Merz and Mabler.[6] Fitz was to have a more sophisticated market than had Holcomb.

Despite the glowing recommendations of the Franklin Institute committee,[7] no actual use of Holcomb’s instruments by astronomers has come to light. We may owe to the rapid progress of American astronomy after 1840 the fact that we have evidence of a more distinguished history for some of Fitz’s instruments. It will also be recalled that Holcomb specialized in Herschelian reflectors. Fitz, on the other hand, made few reflectors. He specialized in achromatic telescopes mounted equatorially, the type of instrument which was in greatest demand among professional astronomers at the time.

Some of Fitz’s instruments had individual histories and were associated with important events in astronomy. One was taken in 1849 on the Chilean astronomical expedition of Lieut. James M. Gilliss. Another was used by L. M. Rutherfurd in his epochal astronomical photography at Columbia University. One, made for the Allegheny Observatory, is still in use at that institution. It appears from his account book that Fitz made many telescopes, and some have turned up in strange places. The lens of one of his refractors was located a few years ago in South Carolina, in use as substitute for the lens in an automobile headlamp![8] At an eastern university in 1958 the writer saw another of his refractors incorporated into apparatus used in graduate student experimentation.

Among the others who began telescope-making about 1845 was the portrait painter who was to become one of the world’s foremost telescope-makers, Alvan Clark. Clark is supposed to have become first interested in lens and mirror making about 1844, and, as a resident of Cambridge, Mass., to have been inspired three years later by the great 15-inch refractor installed at Harvard. His first encouragement came from the British astronomer W. R. Dawes, with whom he had a correspondence on their respective observations and to whom he sold a 7½ inch refractor in 1851. The following year he established, with his sons, the firm of Alvan Clark and Sons, a name which was later to become one of the most famous in the field of telescope making. Whereas Holcomb had demonstrated that telescopes could be made in this country, and Fitz that American instruments were adequate to the needs of the professional astronomer, Clark was to prove that American instruments could compete commercially with the finest made in Europe. In 1862 Alvan Clark and Sons completed an 18½-inch refractor which was long to serve the[159] Dearborn Observatory. It is now in the Adler Planetarium. The famous Lick Observatory 36-inch refractor was completed in 1887, the year of Clark’s death, and his sons went on to build the 40-inch Yerkes refractor, (1897) still the largest refractor ever built. It is no reflection on Clark to note that he was more fortunate than Fitz, in his longer life, his association with Warner and Swasey in the construction of mountings, and in the continuity given to his work by his sons.

Let us return for a moment to the 1840’s and John Brashear, the 9-year-old Pennsylvania boy who, was given his first opportunity of looking through a small refractor telescope by its maker, Squire Wampler of McKeesport. Brashear became a professional machinist, but retained an interest in astronomy which led him to make a 5-inch achromatic refractor in 1872 and subsequently to show the instrument to Samuel Pierpont Langley,[9] then director of the Allegheny Observatory. With Langley’s encouragement Brashear went on to construct a 12-inch reflector and in 1880 decided to make a business of telescope-making. He subsequently made, among other telescopes, a 30-inch refractor in 1906 for the Allegheny Observatory and in 1918 a 72-inch reflector, at Victoria, British Columbia. Brashear’s greatest fame, however, came from his accessory instruments—spectroscopes and the like.

Not the least thrilling aspect of the story of the spectacular ascendancy of American-made telescopes is the story of their financing—of the big-telescope era in American philanthropy and the financial giants (Lick, Hooker, Thaw, Yerkes, and others) who peopled it. In the biography of our third telescope-maker, John Peate, we see at once the persistence of the amateur and the difficulty of his position at the end of the 19th century.

Peate, too, may have acquired his interest in astronomy during the years just before 1845. It has been surmised that he was inspired by the sensation created by the comet of 1843, but it is more likely that his interest resulted from visits to European observatories while he was on a walking tour in 1859. Unlike our other amateurs, he did not change his profession (he was a Methodist minister), being certainly at less liberty to do so, but he adapted his hobby to it in an interesting way. Peate was something of a poor man’s philanthropist, and his fame would have been no greater than that role customarily brings had he not undertaken in 1893 the astonishingly audacious project of making the largest glass reflector that had ever been built. In this project he assumes, like his English contemporary A. A. Common, a position intermediate between the makers of giant metallic specula, Herschel and Rosse, and the makers of the California glass reflectors of the 20th century.[10] In a professional telescope-maker of the end of the 19th century, Peate’s accomplishment would have been remarkable. In an amateur it is amazing. It detracts nothing from Peate to reveal, as does the sketch printed here, that the accolade which this project deserves (but has never received) belongs in part to George Howard and the Standard Plate Glass Company. His example and theirs encourage us to hope that the day of the amateur in science may not be at an end.

Amasa Holcomb was born in 1787, the year John Fitch demonstrated his steamboat before the Constitutional Convention assembled at Philadelphia, and three years before the death of Benjamin Franklin. Two of Holcomb’s telescopes remained in the attic of the family home in Southwick, Massachusetts, until 1933, when they were offered by his descendants to the Smithsonian Institution.[11] With them came a manuscript book of meteorological and astronomical notes, and the following short sketch of the life of Holcomb, unsigned but almost certainly autobiographical. It appears to have been written when the subject was about 80 years old (1867).

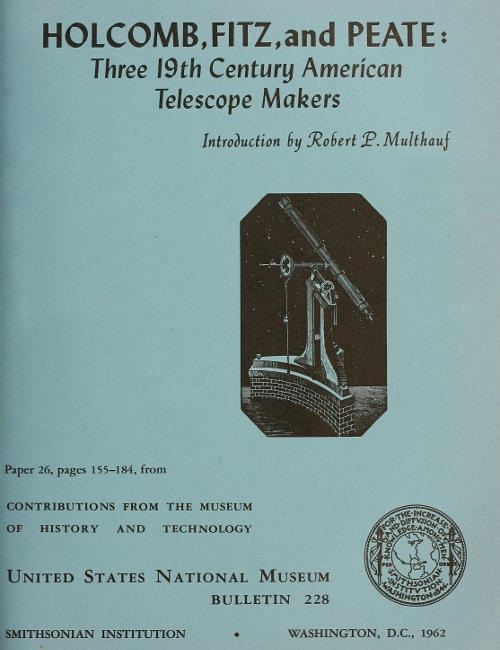

The subject of this notice was born June 18, 1787. The place was Simsbury Connecticut previous to 1768. That year Simsbury was divided and his birth place fell in Granby Con. that being the name of the new town. It remained so until 1804 when the line between Connecticut and Massachusetts was moved further south and his birth place fell in Southwick Massachusetts. The house was about a quarter of a mile north of the new state line, and on a road about half a mile west of the main road from Westfield to Simsbury and Hartford. Here his father and mother lived and died, having lived in three different towns and two different states without changing the place of their residence. Here Amasa was born and past his early youth. His grand father and grand mother on his fathers side lived and died in a house about thirty rods further south, on the same road. His grandfather’s name was Elijah, and was a son of Nathaniel Holcomb 3d, and married Violet Cornish of Simsbury Con. daughter of Capt. James Cornish. His fathers name was Elijah Holcomb Junr. He was a farmer and cooper. In the latter part of his life his father became involved in debt, and mortgaged the farm. His son Amasa paid the debt and the father Elijah Holcomb Junr occupied the farm until he died Oct 5th 1841. The grandfather on the mothers side was Silas Holcomb a son of Judah Holcomb 1st and grandson of Nathanial Holcomb 2d. He lived in the northwest part of Granby, near Hartland line, where he owned a large farm and beautiful home. He kept a park for deer and cultivated fruit, and made raisins. He married Mary Post of Hebron Connecticut, and in this beautiful place they lived and died. There Lucy Holcomb the mother of Amasa was born in 1767. During her short life, she was one of the excellent ones of the earth, and labored for the welfare of her children by instruction and example, until she died August 31 1800. In a very hot day in 1797, she attempted to get some cattle out a field of wheat. The men were at work in a distant field, too far off to know about it. She became heated, and never recovered, though she lived three years. During the last year of her life she became so reduced, that for a long while she could not speak a loud word, but she could and did whisper some good advice to her children. Her son Amasa never forgot it, and he always remembered his mother with affection and gratitude. She had two sisters but no brother. The house where she was born is still standing, but has passed out of the family. The house where his father and mother [lived and died][12] spent their married life, and where he was born, has been taken down, and a new house built on the same place by his brother Newton Holcomb who now owns the old home stead. Here Amasa spent his early youth and school days. There was not a schoolhouse in the district where he lived, until he was past having any use for a common school. The schools were kept in dwelling houses, one part was occupied by the family, and the other part by the school. In these schools were taught, reading, spelling, writing and the first rules of arithmetic. In some of them a little English grammar was taught. Climena Holcomb, Lois Gains, Bethuel Barber, Samuel Frasier, and James L. Adair, in the order in which they are named, were his teachers. At the age of fifteen he was asked to take a school in Suffield Connecticut. He was inspected and passed and[161] took the school. A large portion of the pupils were older and stouter than he was, but they had the good sense to submit to be governed and taught, and good progress was made. But before this a great impulse had been given to his mind. He had an uncle Abijah Holcomb that went to sea about 1798 and never returned. Abijah had fitted for college and left a valuable collection of books. Some of them were classical, and some scientific. Here he found books on Geometry, Navigation, and astronomy. Amasa had free access to these books, and they opened a brighter world before him. He went into these studies with great pleasure, and a mind fully awake, but alone. None of these branches were taught in any school to which he had access. He had so far progressed without help, in Geometry, Surveying, navigation, Optics and Astronomy, that at the great Solar eclipse in June 1806 he could make astronomical computations, and was prepared to observe the eclipse with instruments of his own making. The stars were visible during about four minutes of total darkness. He computed, and published, an almanac for the next year 1807, and also for the year 1808. He went into the business of surveying land about this time. He loved to climb the mountains, and enjoyed fine[162] health. In the year 1808 he married Miss Gillet Kendall, a daughter of Noadiah Kendall of Granby Connecticut. She was one of the best of women, and had no enemies, but was beloved by every body who was acquainted with her. For a while he took students into his own house, and taught them such branches as each one had engaged to be instructed in. Julius M. Coy of Suffield, studied surveying—Levi —— also from Suffield studied Navigation, and soon went to sea, and after a while command[ed] a vessel. Benoni B. Bacon of Simsbury, studied Surveying and astronomy, Joseph W. King of Suffield, studied surveying—Henry Merwin of Granby studied Surveying, Jefferson Cooley, a graduate of Yale College, studied surveying and civil engineering. He had also students from Granville Mass. But the school interfered with his other business, and he discontinued it. He manufactured about this time a good many sets of surveyors instruments—compasses, chains, scales, protractors, and dividers, some for his pupils and some for others. He also manufactured, magnets, electrical machines, leveling instruments, and some others. He was greatly attached to the business of surveying, and had more applications than he could attend to. He was compelled to leave it in 1825, and go into the business of civil engineering, which also in a few years, gave way for the business of manufacturing telescopes. At the commencement, he never thought of its ever becoming a business of profit. About the year 1830 he had completed an achromatic telescope, which he took to New Haven, and asked Prof. Benjamin Silliman to look at it. He did so, and at once took an interest in it, and published a notice of it in the American Journal of science, of which he was editor. He manufactured principally Reflecting[163] telescopes, of the Herschelian kind. About the year 1833, he began to have orders for telescopes. Among these orders was one from William J. Young, a celebrated Philosophical instrument maker of Philadelphia, who wanted two small diagonal metallic reflectors for two Transit instruments that he was making. Mr Holcomb made the articles wanted, and thought he would take them and a telescope and visit Philadelphia. Mr Young introduced him to the late Sears C. Walker, and Mr Walker introduced him to Mr Hamilton, Actuary of the Franklin Institute of the State of Pennsylvania, and the Actuary appointed a committee to examine the telescope. He selected the committee from the standing committee on Science and the Arts of the Institute. Mr Patterson of the Mint, Alexander D. Bach superintendent of the Coast survey, Dr Robert Hare the chemist, James P. Espey, Sears C. Walker, Isiah T. Lukens and some others. These were among the first scientific men of America. The committee examined the telescope, and compared it with others of European manufacture. The Report of that committee may be found in the Journal of the Franklin Institute Vol. 14 p. 169. The next year 1835 he took a larger telescope to Philadelphia, and offered it to the same committee for examination and comparison with European telescopes. That Report may be found in the Journal of the Franklin Institute Vol 16 p. 11. The next year 1836 he presented a Telescope 14 feet long to the same committee. Their report may be found in the Journal of the Franklin Institute Vol. 18 p. 312. These Reports furnish the best information in regard to the performance of these telescopes. The committee gave them a high character, and they were sold in almost every state in the Union. One went to Seramp in the East indies, and one to one of the Sandwich islands in the Pacific ocean. While he was pursuing his labors as Engineer, and manufacturing Telescopes, and other instruments, in 1839 the news reached this country from Paris, of Daguerre’s great discovery of taking pictures on silver plates by solar light.[164] The discoverer had not then succeeded in taking likenesses from life. Holcombe immediately commenced experimenting and soon succeeded in taking portraits, on silver plates, made sensitive to light by Iodine. There was soon a great demand for instruments to take portraits. He had for a considerable time as much as he could do to supply the applications he received for these instruments, from 1839 to 1845. As the calls for these instruments lessened he continued the manufacture of telescopes. He was the first that sold a telescope of American manufacture. All the telescopes used in this country before 1833, had been obtained in Europe. It had been said that they could not be made in this country. He had been greatly assisted in his sales, by the influence and recommendation of scientific men. It was soon discovered that telescopes could be made in America and about 1845, one after another went into the business, and there is now no further need of going to Europe for telescopes, as good ones can be made in the United States as can be made in Europe. The whole market was in his hands during thirteen years. During this time the business was good and paid well. The competition afterward reduced the profit. In 1816 he was chosen select man and assessor in his own town, which office he held during four successive years, and held the office occasionally by subsequent elections. In 1832 he was chosen to represent the town in the Legislature of Mass and he was reelected three successive terms. In 1852 he was elected to the State senate. In 1833 he was appointed a Justice of the Peace for the county of Hampden, which office he has held every year since, and his last commission does not expire until May 1875, at which time, if he should live to see it, he will be but a few days less than 88 years old. In 1837 he received from Williams College the Honorary degree of A.M. In 1831 he was ordained a minister in the Methodist Episcopal church. He preached constantly on the sabbath during many years, and afterward occasionally until he was eighty years old.

Figure 1.—Page from manuscript sketch of the life of Amasa Holcomb, now in the collections of the U.S. National Museum.

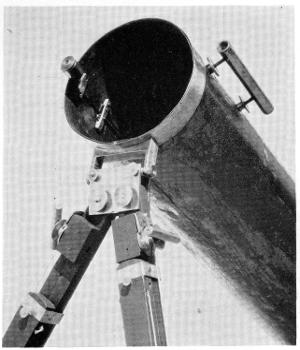

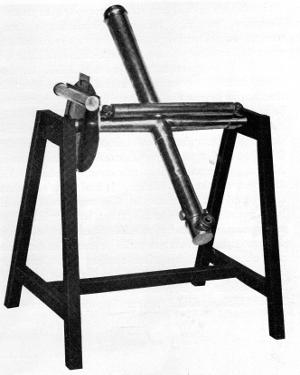

Figure 2.—Herschelian reflecting telescope (USNM 310598) built by Amasa Holcomb and shown by him at the Franklin Institute, Philadelphia, in 1835. The Institute’s report of the demonstration is given in the appendix (p. 182). (Smithsonian photo 11000-a)

Figure 3.—Eyepiece and tripod head of the Holcomb reflecting telescope shown in figure 2. (Smithsonian photo 11000)

Figure 4.—Transit telescope (USNM 310599) made by Amasa Holcomb. The aperture is 1½ inches, length 21 inches, and axis 14 inches. It lacks the original support. (Smithsonian photo 43472-c)

Julia Fitz Howell

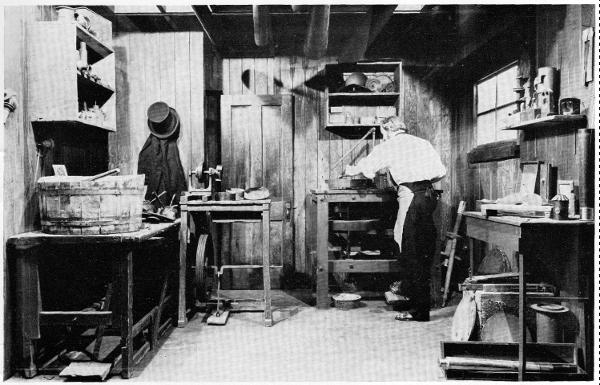

Henry Fitz died suddenly through an accident in 1863, when he was in his 55th year. His widow closed his shop in New York City and moved the equipment to Southold, Long Island, where it was used by his son to complete certain contracts in progress. Thereafter it remained essentially as it was until nearly the present time, when the shop was offered to the U.S. National Museum of the Smithsonian Institution by Mrs. Julia Fitz Howell, granddaughter of Fitz. The decision to construct a new Museum of History and Technology made it possible to accept this generous offer, and the complicated project of transferring the shop and reassembling it was accomplished in 1957 through the assistance of Mr. L. C. Eichner.[13]

Although a few duplicate items were eliminated, the shop is essentially complete, including such items as Fitz’s account books, the small rouge box he used to polish lenses in the course of a walk, and his door key. Through the assistance of Mr. Eichner and Mr. Arthur V. A. Fitz the Smithsonian has obtained a comet-seeker telescope and Fitz’s first instrument, a small draw telescope.

The following biographical sketch was written by Mrs. Howell on the basis of papers in the possession of the family.

Henry Fitz, inventor and telescope maker, was born in Newburyport, Massachusetts, on December 31, 1808. Little is known of his mother, Susan Page Fitz, except that she was probably of Scottish ancestry. His father, Henry Fitz, Sr., was a hatter[165] by trade and the youngest son of Mark Fitz, who for several years represented his city in the Massachusetts General Court.

Figure 5.—The telescope-maker’s shop of Henry Fitz as reconstructed in the U.S. National Museum. (Smithsonian photo 46545)

Newburyport was then a prosperous and fast growing maritime community and the Fitzes, though not among its wealthy citizens, were a public spirited and reasonably prosperous family. As in other sections of New England, the War of 1812 made great changes in this pleasing picture. The town’s shipping and ship-building had been brought almost to a standstill and all its business suffered disastrously. After the war recovery was very slow. Since few needed or could afford new beaver hats, Henry Fitz in 1819 took his wife and three small children first to Albany, New York, where he worked at his trade for awhile, and later to New York City.

To young Henry, aged eleven, New York was an exciting and stimulating place and he watched all its activities with eager interest. The father found the city stimulating in a different way. An enthusiastic Universalist, he met in New York many persons with similar leanings. He soon established a religious weekly, The Gospel Herald, which he edited for several years. It is therefore not surprising that young Henry was set to learning the printer’s trade, but although he rapidly became skilled, he didn’t especially like the trade. What he most enjoyed about it was tinkering with the machinery of the shop. In this his mechanical ability soon became evident. When his father relinquished his editorship, Henry, then nineteen, gladly turned to different work.

He chose locksmithing, which he learned speedily and well in the shop of William Day of New York. The years 1830 to 1839 found him travelling between[166] New York, Philadelphia, Baltimore, and New Orleans, following the activities of the building trades and trying by long hours and austere living to save money for a locksmith shop of his own. For the sake of both health and pocketbook, he never rode if he could walk, neither drank nor smoked, ate little meat, and lived chiefly on graham bread and water.

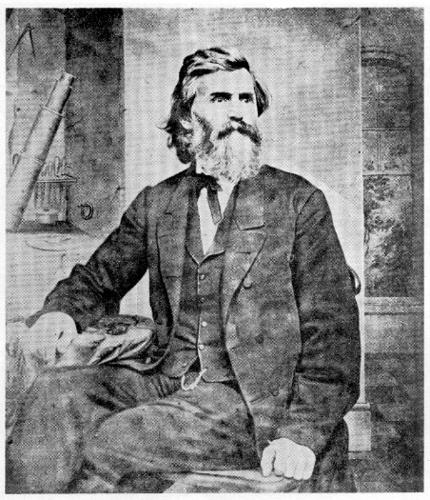

Figure 6.—Henry Fitz, from a photograph in the collections of the U.S. National Museum. (Smithsonian photo 44594-b)

Evenings were spent in reading, study, and the pursuit of hobbies, chief of which was astronomy. His diaries and letters of this period show him buying telescopes and lenses and carrying them with him on his travels. He first made a telescope in 1838, a reflector, with which he delighted to show the stars and planets to his friends. The well-known Reverend Clapp of New Orleans referred to him in a public address as “the young locksmith who knew more about the heavenly bodies than anyone else in the United States.” Henry was pleased with this compliment, even while deprecating the enthusiasm which prompted it.

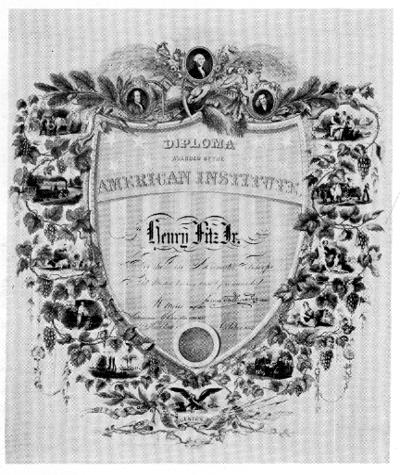

Figure 7.—Certificate of award to Henry Fitz, Jr., by the American Institute, 1852, “For the best achromatic telescope.” (Smithsonian photo 46815-a)

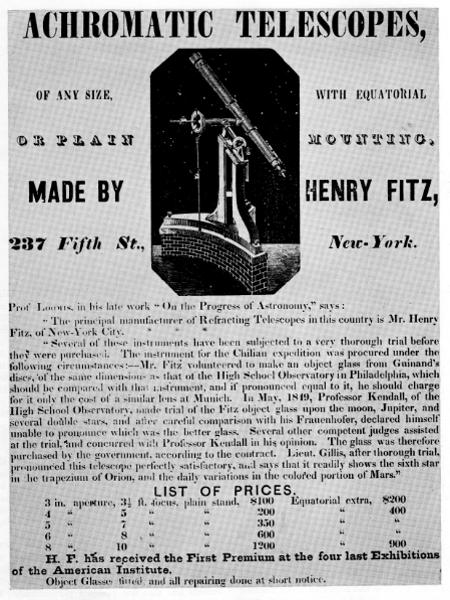

Figure 8.—Advertisement of Henry Fitz, about 1850. (Smithsonian photo 44594-a)

Figure 9.—Refracting telescope, comet seeker, (USNM 317027) by Henry Fitz, 8¼-inch aperture, 61-inch tube, fitted for equatorial mounting. The stand is lacking. (Smithsonian photo 46815)

Although he saved money, his work did not bring him the financial or other rewards that he had hoped for. In spring of 1839 he appears to have worked as a speculum maker with Wolcott and others—one of them may have been his acquaintance John Johnson—and to have read of Daguerre’s work in photography. To learn more of these experiments, as well as to inquire into optics and optical glass, he sailed to Europe in August of that year, taking passage by steerage.

He returned to New York in November 1839 and in that month, according to the testimony of his son Harry, made a portrait with a camera invented by Wolcott. This camera portrait he believed to be the first ever made. In 1840, after more experimenting, he set up a studio in Baltimore, where his father was then living, and spent several years there “taking likenesses.” At the same time he continued to work with telescopes and lenses. His first refractors were built there, instruments he later referred to as crude affairs.

While in Baltimore he took a step which marks the beginning of the final phase of his career. In June 1844 he married Julia Ann Wells of Southold, Long Island, whom he had known for about a decade and with whom he had long corresponded. Julia was a woman of unusual ability and personality, less scientific than he but more literary and artistic, and no less intelligent. With her to encourage him, he continued his experiments in telescope building. A year after their marriage they moved to New York, where he was to spend the remainder of his life.

That summer he prepared a 6-inch refracting telescope for exhibition at the Fair of the American Institute, held annually in New York. This carefully constructed instrument, with its ingenious tripod and its achromatic objective—which he had made himself, correcting the curves by a process of his own invention—won the highest award of the Fair, a gold medal. It was the first of many such medals he was to earn. His telescope also received favorable notice from scientists and astronomers, among them Lewis M. Rutherfurd, a wealthy New Yorker and trustee of Columbia College. Rutherfurd immediately ordered a 4-inch refractor for his own observatory. His interest and example soon brought orders from others.

From this time on, Henry Fitz devoted most of his energies to building telescopes. Cameras were not altogether abandoned. He continued to make them and to instruct others in their use. He invented a camera lens that was patented posthumously. He was one of the founders of the American Photographical Society and remained interested in it all his life. But from 1845 on, cameras became secondary; he built them between telescope orders.

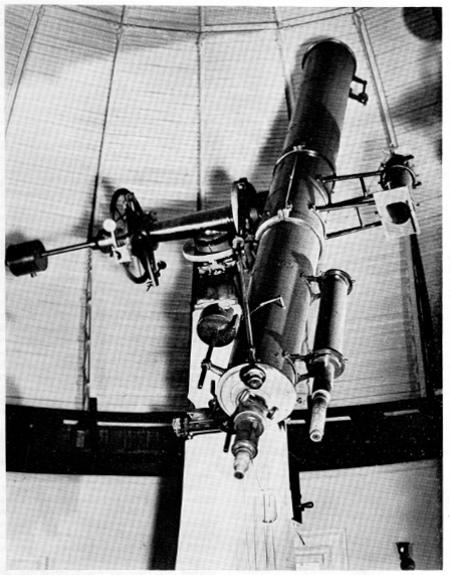

Figure 10.—Henry Fitz made this 13-inch equatorial refractor in 1861 for the Allegheny Observatory. It is still in use. The University of Michigan has in use a Fitz refractor of similar size. (Photo courtesy Allegheny Observatory)

During the years that followed he constantly improved the quality of his lenses and the accuracy and speed with which he could “execute the true curves,” as he expressed it. He used better and better glass. In his early experiments he had taken what came to hand—ordinary tumbler bottoms, for instance. In his 1845 prize winner he combined Boston-made flint with French plate glass. But the Boston flint proved too veiny for any but small lenses and he soon was importing both crown and flint. He designed and built machines, run by foot power, on which he could train employees to do much of the labor of lens making, always reserving the final polishing for himself. He increased the size as well as the quality of his lenses. By 1856, he was making 12½-inch refractors, which according to Prof. Loomis, were as large as any that had then been made in Munich. He built later, still larger ones, of which one was a 16-inch instrument made for Mr. Van Duzee of Buffalo. It was his ambition to make a 24-inch one, but this project, for which he had made careful plans, he did not live to complete.

One of his early successes was a 3¾-inch telescope for the Government of Haiti. By a happy accident the objective for this instrument proved to be exceptionally fine and provided a standard which he tried to meet in all his work. The telescopes of European opticians became another measuring stick. It was a matter of both personal and patriotic pride to him that he, an American locksmith untrained in optics, had been able to invent his own process for making so complex and difficult a thing as an achromatic lens, and that he was able to manufacture telescopes to compete with those of European make. He sometimes contracted to make a telescope equal in performance to an imported one of similar size, usually at a lower price. The 6¾-inch telescope made in 1849 for Lt. J. M. Gilliss to use on an astronomical expedition to Chile passed such a test and greatly enhanced Henry Fitz’s reputation. Another that met such a test was the 13-inch instrument made for the Allegheny Association at Pittsburgh in 1861.

His telescopes were procured by private observatories not already mentioned, among them that of Van Arsdale, in Newark, and of Campbell, in New York. For Rutherfurd he made several, including a 9- and a 12-inch instrument. The latter is now at Columbia University. Among the telescopes made for colleges were a 12-inch one for Vassar and another for the University of Michigan. Besides these and other important instruments he made many of smaller size—4, 5, 6, and 8 inches.

Most of the time, he was handicapped by lack of capital with which to develop his business. The savings from locksmithing days he had, on his father’s advice, invested in Baltimore real estate, but found it difficult to raise cash on this property when he needed it. With the many orders that came in, this situation gradually improved, though he always continued to supervise all phases of the process and to work 12 to 16 hours a day himself. As soon as his eldest son, Harry, was old enough, he taught him all he knew. The boy proved an apt pupil and a great help. By 1863 Henry Fitz felt secure enough to give up renting, and had a house built for his family and business in 11th Street, not many blocks from his friend and patron, Mr. Rutherfurd. Plans for the future looked bright. However, the family had hardly moved into the new home when disaster befell. A heavy chandelier fell on the master of the house, causing injuries which in a few days proved fatal. Henry Fitz died on October 31, 1863, at the height of his career, leaving to carry on his work a widow and six children, the oldest a girl of eighteen, the youngest an infant.

His son Harry, not yet seventeen, was able satisfactorily to fulfill the outstanding contracts. In this he had the backing and advice of Mr. Rutherfurd. In fact, Harry continued the business, though on a smaller scale, for some twenty years. Eventually he became a teacher of drawing, pursuing this occupation for over forty years more.

As soon as possible the widow, Julia Ann Wells Fitz, sold the city house and bought a farm in Peconic, Long Island, near her birthplace, where she managed to raise her family. All the children showed marked ability. Louise, the only daughter, married Silas Overton of Peconic, and used her talents in home and community. The second son, Benjamin, became a noted painter before his early death in 1890. Robert’s reputation as a fine mechanic was county-wide. Charles was a prominent business and civic leader in Suffolk County. George became a physician and inventor and was for a time Professor at Harvard. All married, and there are now living in the United States about fifty descendants of Henry Fitz, telescope maker.

A number of his instruments, though made a century ago, are still in use.

F. W. Preston and William J. McGrath, Jr.

Although John Peate was born when Holcomb was only 33, and before that pioneer telescope-maker had produced his first instrument, he lived well into the time when American telescope-making had come of age. Before Peate’s death George Ellery Hale had begun his career as a promoter of large telescopes; indeed, the Yerkes 40-inch refractor was completed a year prior to Peate’s delivery of his own magnum opus, a 62-inch reflector, to The American University. For 34 years the University sought funds to finance the installation of this mirror, until it finally became obsolete as a result of advances in the technology of glass mirror making.

In 1934 it was sent by the American University to the Smithsonian Institution. About this time Dr. F. W. Preston undertook the difficult task of reconstructing Peate’s career and particularly the story of the great mirror. His results were published in the Bulletin of the American Ceramic Society in 1936.

With the gracious permission of Dr. Preston and the Bulletin, this article has been condensed, and augmented, for publication here by William J. McGrath, Jr., of the United States National Museum staff.

John Peate, bricklayer, Methodist minister, and amateur extraordinary in the art of telescope making, was the first born of Thomas and Mary Peate.[14] He was born on May 6, 1820, in the small northern Irish town of Drumskelt. When John was seven, his father, a mason, emigrated to Quebec, Canada, the first of several moves to cities in Canada and the United States, terminating in 1836 in Buffalo, New York, where the father was to spend the last seven years of his life.[15]

Nothing is known of the circumstances of John’s life during these early years, nor of his education. In 1836, at the age of 16, he entered his father’s trade as an apprentice bricklayer. He worked at this trade for about sixteen years, apparently intermittently, for he seems to have been a student at Oberlin College part of the time between 1842 and 1845.[16] In the latter year he married Mary Elizabeth Tilden of Buffalo.

Peate’s career as a bricklayer ended in 1851, when he became a full-time minister, having been converted to his mother’s religion. This came about in consequence of his attendance, when he was about 20 years old, at a Methodist revival. There he was “converted,” and, with characteristic energy and enthusiasm, plunged into his new religion. His attendance at Oberlin may have been connected with his preparation for the ministry. In any case, he started to preach in 1849, on trial with the Methodist Erie Conference, was ordained a deacon in 1851, and an elder two years later. From this time until he was made a supernumerary in 1894 he worked full-time as a minister.

The mobility which marked his early life was repeated in his ministerial career. Including his probationary term he held 19 different appointments in 14 cities and towns in northwestern Pennsylvania, northeastern Ohio, and southwestern New York. He was a successful and popular minister, and is said to have converted some 500 persons at one revival[172] in Jamestown, New York. J. N. Fradenburgh, historian of the Erie Conference, begins his sketch of Peate’s life with the phrase, “Who has not heard of John Peate?”[17]

In 1859 Peate journeyed to Europe, visiting England and Ireland, and making a walking tour of western Europe and the Middle East. His biographer Fradenburgh hints that his interest in astronomy was aroused on this trip. In any event, upon his return home, he took up the study of the science. His fellow minister, R. N. Stubbs reported that “his library reveals that difficult and abstruse works became his delight.” At some point in the perusal of these “abstruse works,” Peate decided to concentrate on that basic tool, the telescope. It is possible that he first made a telescope, as many amateurs do, to advance himself in the study of astronomy, and only after completing it realized that his primary interest lay in the instruments rather than in the theoretical science. His natural aptitude for craftsmanship probably exerted a strong influence in this decision.

His first instrument was a 3-inch refractor which he made and mounted for his own use. This was about 1870. He next made either a 6-inch refractor or a 6-inch reflector, or perhaps both. One of these, if there were two, was mounted by Peate for use at Chautauqua and Jamestown, New York, and then used in his own observatory at Greenville. After his death it was taken to Salina, Kansas, by W. F. Hoyt, for a small observatory there.[18]

Thereafter Peate made reflectors exclusively. It is possible that he was influenced by the treatise on the making of silvered glass reflectors, by Dr. Henry Draper, published by the Smithsonian Institution in 1865, a work which led to a great improvement in the construction of reflectors in this country.[19]

Attempts to trace Peate’s mirrors have been singularly inconclusive. A 7-inch reflector sent to India was still in use in 1903.[20] A 12-inch reflector made for “Harriman University, Tennessee,” was evidently mounted, but no record even of the observatory has been found at the present time [1936].[21] A 15-inch mirror in a reflector located at Allegheny College in 1935 was probably made by Peate, although the College records do not show its origin, nor do they mention a 30.5-inch mirror which Peate was making for Allegheny College in 1891, according to an article in The Scientific American.[22] Definitely Peate’s was a 22-inch reflector found in about 1935, still in its packing case, at Thiel College, Greenville, Pennsylvania.[23]

Altogether, 10 lenses and mirrors (sometimes also described as “lenses”) have been traced. As many as 20 were ascribed to him by some sources at the time of his death. Of these only his magnum opus, the 62-inch mirror now in the Smithsonian Institution, can now be found. Most of them seem never to have been used, but this is not necessarily an indication of defects in the instruments. As our consideration of the 62-inch mirror will show, Peate was a competent maker. Nor is it a consequence of his being an amateur. Many of the large telescopes in the world in the mid-nineties had lenses and mirrors made by two other Americans, John Brashear and Alvin Clark, who, like Peate, entered telescope making as amateurs.[24] But they had the fortune to become associated with well known professional astronomers. Peate may have erred in presenting his reflectors to institutions unable to finance their installation. Perhaps his error was in presenting rather than selling them.

We come now to Dr. Peate’s greatest mirror, the 62-inch reflector. In September 1893 the annual meeting of the Erie Conference was held at Dubois, Pennsylvania. This was to be Dr. Peate’s last meeting as an active minister. In 1894 he would become a supernumerary, a position of semiretirement, after which he would retire. In order to honor the old minister and to mark the opening of a new Methodist university, American University, at Washington, D.C., it was decided to commission Peate to make a telescope mirror for the school. This was to be no ordinary reflector but the largest in the world.

While the facts surrounding this commission and its accomplishment are astounding in themselves it has inspired an even more remarkable legend, which, although rather unjust to the ability and good sense[173] of Dr. Peate, indicates the impression his hobby had made on his contemporaries. According to this legend, John suddenly realized at the age of seventy-three that he must have something to occupy his time while retired.

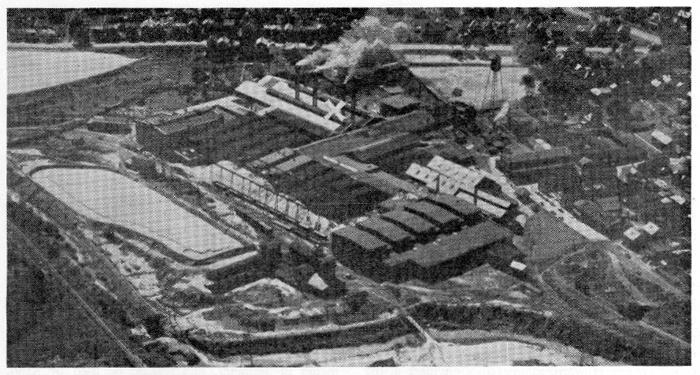

Figure 11.—Standard Plate Glass Company, Butler, Pennsylvania, with x marking building where Peate’s 62-inch disc was cast. (From Preston, fig. 1.)

“What am I to do all the rest of my life?” he asked of the presiding officer of the meeting, Bishop Hurst, who was also chancellor of the newly founded University.

“Oh, study astronomy,” said the Bishop.

“Make a big telescope lens,” said Dr. Wythe.

Dr. Wythe, whose doctorate was in medicine, was a minister well known in the conference as an inventor and technologist. The legend continues that, urged on by Wythe, Peate announced to the conference, “I will make for the new University the largest telescope lens in the world, if you will defray the out of pocket expenses.”

“Well, how big a lens can you make?” asked the Bishop.

“Oh, as big as that chart on the wall,” said Peate.

“Get a rule and measure the chart.”

The chart was 62 inches across.

“Offer accepted. One 62-inch reflecting telescope from Dr. Peate,” ordered the Bishop.[25]

The minutes of the conference state:[26]

Proposition of John Peate … John Peate made a proposition to manufacture a large reflecting lens for the University providing material for the same was furnished him … a committee of 5 was appointed to take the same into consideration. R. N. Stubbs, G. H. Humason, N. T. Arnold, G. P. Hukill, and G. B. Chase were appointed to that committee.

Although he was 73 years old Peate was in good health and had tremendous vitality for one his age. He had already made a number of large mirrors, so that he could estimate the amount of time and energy he would expend in this work. He knew that if he retained his health for the next few years he could complete it.

With his typical planned enthusiasm he started his preparations. He wrote to his usual supplier St. Gobain of France asking the price of a glass blank[174] large enough for a mirror of this size.[27] They quoted a price of $18,000—more, obviously, than he could afford. He then canvassed the glassmakers of Pittsburgh, the center of American glassmaking. However, the Pittsburgh firms had little experience in optical glass, especially of this size, and none would consider making the blank.

Having been rebuffed in Pittsburgh, he approached the Standard Plate Glass Company of Butler, Pennsylvania. Plate glass making, at least profitable plate glass making, was new in America and the Standard was one of the newer companies. Moreover, it was reputed one of the best plate glass makers in the country. Peate wrote to H. C. Tilton, general manager of the plant, asking him for a disc of glass without bubble or flaw 62 inches in diameter and 7 inches thick. He further advised him that he would see him in a few days. Tilton’s experience and that of his top supervisors was limited to the business of making ordinary plate glass. Therefore, he sought advice as to the feasibility of this fantastic project. He consulted George Howard, maintenance engineer of the plant, who had graduated from Cornell only a year before. George Howard, later to become noted as an inventor of glassmaking machinery, was at this time simply an optimistic young engineer.

“Howard, here’s a man at Greenville who wants us to cast him a disc 62 inches in diameter and 7 inches thick. Is that possible?”

Howard calculated the cubical contents of the proposed disc and replied that it was just barely possible. He didn’t see any particular difficulty in it. He thought the first few attempts might fail but felt that they could cast it successfully. Howard was later to ascribe his success more to his optimism and ignorance, rather than to any particular innovation he made. After being reassured by Howard, Tilton continued “Well, this Dr. Peate is coming down here tomorrow and he wants a quotation. How much do you think we ought to ask?”

“We’ll have some special apparatus to make and some experimenting to do. Then we’ll probably lose two or three pots of glass. I think you’d better ask him $800.” Howard thought that this was plenty. Tilton, however, was more cautious and doubled the price. Peate arrived in Butler on schedule. When Tilton named his price, Peate, of course, agreed instantly. Tilton was somewhat shocked and probably would have been more so had he known what St. Goubain had asked. At any rate the contract was placed with Standard, apparently in October 1894.

Having obtained a maker for his disc Peate immediately began making arrangements to prepare the disc. He contracted with the machine shop of a John Hodge for the tools with which the mirror would be worked. This small firm, The Hodge Manufacturing Co., employed only four men besides the owner. Among these was Frank A’Hearn, then just a boy, who became the prime source for details of the tools used by Peate in this work. Starting in November 1894 notes such as, “worked for Dr. Peate 3½ hours” begin to appear in his workbook.[28]

Figure 12.—Hodge’s method of cutting the checker grooves. (From Preston, fig. 6.)

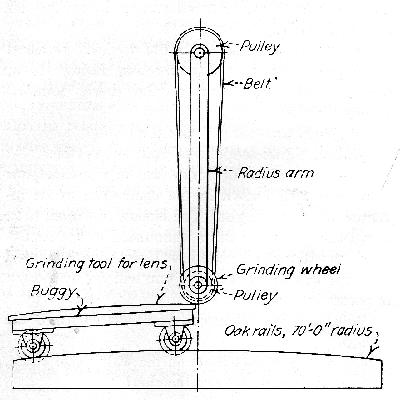

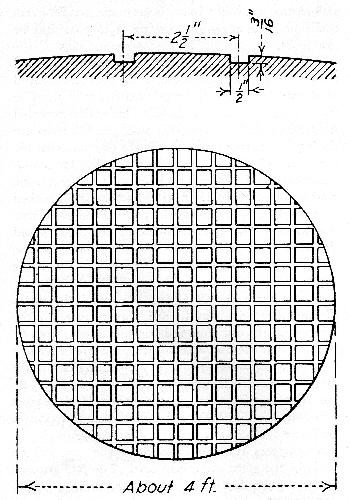

The Hodge company made several (probably three) grinding tools for Peate. One was about 12 inches in diameter, and was to be used by hand. Two of the larger tools were provided with the male member of a ball and socket joint and were to be[175] power driven. They were 30 and 48 inches in diameter, respectively. The largest was grooved to a waffle-like surface on its convex face. These grooves were about ½ inch wide and 3/16 inch deep. This pattern was ground by placing the tool face up on a wheeled buggy, which rode on cambered oak rails. As it was pushed along the length of the rail the grinding wheel on the radius arm cut one groove. When the groove had been cut, the radius arm was moved 2 inches along a line shaft and another groove cut. When all the grooves had been cut in one direction the tool was turned 90 degrees on the buggy and the other set of grooves was ground. The grinding of this tool took many weeks, and making the tools and apparatus for Peate may have kept Hodge busy for nearly six months.[29]

Figure 13.—Face of largest grinding tool made by Hodge for Peate. (From Preston, fig. 5b.)

The history of Peate’s 62-inch mirror probably would have remained as obscure as that of his others except for the furor which arose over casting the disc. The Erie Conference made no attempt to publicize this project, and both Hodge Manufacturing and Standard Plate Glass accepted Dr. Peate’s contracts as somewhat unusual but hardly newsworthy jobs. But when the glass trade became aware of Standard’s intention to cast this disc, a mighty outcry arose. Instead of encouraging Standard to complete this novel task the National Glass Budget, one of the leading trade journals, reviled them as “bumpkins” for attempting something that even the great glassmakers of Europe would not do.

It is hard to imagine why the trade journal so strenuously objected to Standard’s attempt. It has been suggested that it derived from the fact that Standard Plate Glass just previous to that time had refused to join in a combination of Pittsburgh companies which had set up a glass trust.[30] Or it is possible that the young industry was afraid that an overly ambitious project doomed to failure might open American glassmaking to European ridicule and so harm the entire American industry. Whatever the reason, the Budget ridiculed Standard Plate Glass, and later Dr. Peate, for the attempt. They argued that it could not be done, but that if it were possible Pittsburgh would be the logical place to try it. Criticism and unfavorable comment came from other sources also, including “university professors from Meadville” (evidently Allegheny College).[31] Nonetheless, Standard Plate Glass started the project.

George Howard was in charge of the casting operation. He planned to use the glass from a pot regularly used in the routine manufacture of plate glass. However, certain modifications were introduced in the procedure. The glass was to be poured on the traveling casting table, upon which was placed a circular mold made up of two semicircles of a special charcoal iron obtained from Philadelphia. This iron was not apt to generate bubbles of gas when in contact with the molten glass.

The iron mold was hinged at one joint of the semicircles, and the other joint was bolted. After[176] the cast was poured it would be allowed to cool somewhat. When it was judged cool enough, it would be pushed into a kiln to be annealed. After it had remained in the kiln a certain length of time—again based simply on judgement—a quantity of pre-heated sand was to be poured over the mold as insulation. A further innovation was the use of a zinc sheet placed on the underside of the mold to avoid the possibility of trouble from grease on the casting table. This was the initial plan of operation.

Sometime early in 1895 the first attempt was made. It was an immediate failure. The zinc sheet, intended to protect the cast from grease, volatilized when the molten glass was poured on it, bubbled up through the glass, and, of course, ruined the cast.

The second attempt was evidently made sometime in March. The casting itself was successful. Sand had been substituted for the zinc sheet. The cast was placed in the kiln, and when it was thought to be set the insulating sand was poured over it. After a time variously estimated at from 4 to 11 days, the cast was considered sufficiently annealed, and was examined.

When the sand was removed, the disc was found in fragments. There was also a large concavity in what would have been the face of the disc. The sand had been poured over it before the glass was sufficiently set. However, the disc had been destroyed by its iron mold. The mold had contracted against the disc, bending the bolt and deforming the hinges, and this tremendous pressure had shattered the glass. The next issue of the trade paper jubilantly noted the failures. They also included Dr. Peate in their derision. They said in effect that at least this experience would save the old preacher the waste of many years of time and effort.[32]

This slur on their most esteemed citizen brought the Greenville papers into the battle. The Budget had also made the mistake of implying that any number of Pittsburgh manufacturers were willing and able to make the disc. John Morrison, at that time editor of the Greenville Advance Argus, and source of much of our information regarding this controversy, immediately called the bluff of the trade paper, which was able to supply but one name, that of a George A. McBeth Company. This firm promptly declined without qualification. Later the name of the Phillips Semner Co. was given, and this firm guaranteed a perfect disc within 60 days for a “remunerative price,” but would not state what this price was.[33] Therefore Dr. Peate could not deal with the firm.

Although the hue and cry continued for a few more weeks, the battle was really over, for Howard was soon to cast his disc. He had replaced the iron bolts in his mold with bolts of red oak dipped in nitric acid and then charred. The purpose of this was to relieve the strain on the glass by having the wooden pegs break as the mold contracted.

The third cast was in the kiln and in process of being annealed when Howard read in the Budget an article that set forth the difficulties of successfully casting optical glass. This article was anonymous and was obviously the work of an expert; it is thought to have been written by John Brashear.[34] Although Howard was thoroughly discouraged by this article, the cast had already been made and no harm could be done now by allowing it to cool and be examined.

In May 1895 Howard, with the workmen, opened the kiln. The mold was loose, so the pegs had sheared as expected. When the sand was removed the disc was found to be whole. A close inspection revealed no obvious faults. The disc was gently carried to an inspection room and Dr. Peate was immediately sent for. He arrived, examined the disc for a moment, then said, “Give me a hammer.” Before anyone could move he seized a nearby hatchet and knocked off the sprue, or tail left as the pot was removed from the mold. The onlookers feared the lens would “explode,” as predicted by its detractors, but the only result was the removal of the tail, as Dr. Peate expected.[35]

The Budget was still saying it couldn’t be done. Commenting on a May 1, 1895, announcement of the removal of the disc from the kiln, the paper seized on the fact that the disc was still warm to predict that it would be shattered before Peate could examine it, and reiterated its low opinion of Standard Plate. By the time this issue was in the hands of its readers however, the disc had been inspected and approved by Peate.

Newspapers in Pittsburgh and elsewhere carried the news of the great American disc. The embarrassed Budget replied that it was not talking about the mere[177] casting of the disc but the completion of the mirror. It feigned surprise that this was all that was to be done in Butler. Even as late as May 24, 1895, the Butler Democratic Herald was still defending its town. It concluded an editorial on the issue thus:

… we have a feeling he [The Budget] has set his foot in it when he goes to poke fun at the Standard about casting the biggest mold on earth, and the end of it may be a repetition of the old saw “he who laughs last laughs best.”

A week before this, however, the success of this casting had been made more or less official by an announcement to that effect in the May 17, 1895, issue of Science, a publication of the American Association for the Advancement of Science and probably the most highly regarded scientific paper of the time.

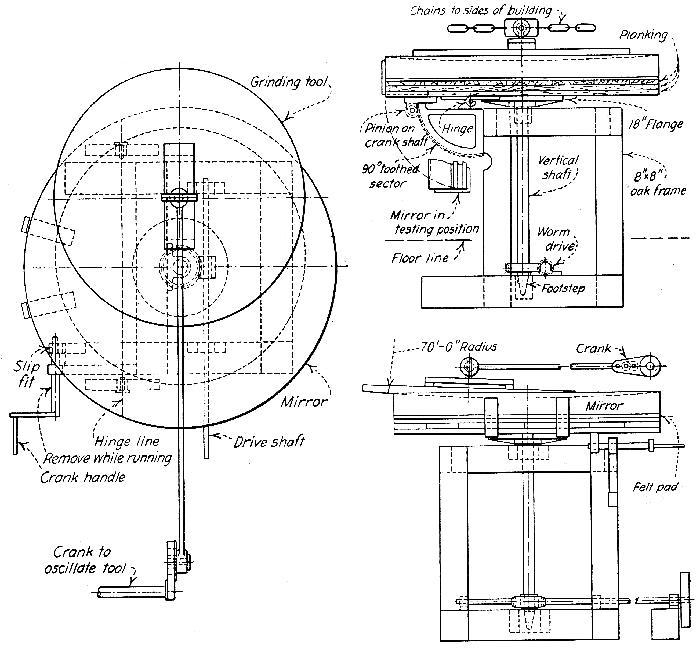

Figure 14.—Surfacing machine used by Peate. (From Preston, fig. 4.)

On June 1, 1895, Standard Plate rendered Peate an invoice, not for $1600, but for $450. Evidently their work was done at cost. The disc was now removed to Greenville where Dr. Peate had erected a shop to grind, polish, and figure it. As the disc was slightly out of round the first operation was to make it perfectly circular. Peate did this roughly by spalling off[178] pieces of the edge with his bricklayer’s hammer. The final rounding was done with the aid of the iron hoops that had made the mold. Dr. Peate fed steel shot between the edge of the disc and the iron semicircles. He rotated the disc on the turntable and thus rounded it off.

After this had been done he commenced the rough grinding. Using the large checkerboard tool, steel shot, and levigated emery Dr. Peate ground out a rough hollow. This took only a few days. George Howard stated that the depth of the concavity was about ⅝ inch and the shape correct to within about 1/10,000 inch. The calculated concavity of the mirror would be 6/10 inch. Peate evidently used the usual method in polishing the large mirror, that is, he covered the tool face with pitch and used rouge (iron oxide) as the abrasive. This method had been used for many years before this time and is still in use today.

The figuring, which consists of removing high spots to achieve a truly parabolic contour, probably took the longest time to complete. A mirror must be continually tested as this polishing is being done, and since the polishing warms the glass and distorts its shape, it is necessary to allow a long time for the glass to cool before it can be tested. Peate estimated that polishing and figuring the mirror took 750 hours.[36]

We do not have a really accurate account of how he tested the mirror. Unfortunately none of the eyewitnesses to these tests had any knowledge of optics or of standard testing procedure. The information of those who had such knowledge is all at least secondhand and sometimes even more remote. J. W. Fecker, successor to Brashear,[37] who was one of a group that examined the mirror in 1923, states that Peate did not use the knife edge test but that he did use a pin with a hole in its head in one of the tests used at that time.

A variety of different tests and diversions with the mirror have been reported. Dr. Peate would entertain visitors in various ways. One of these was to train the mirror on an apple orchard in a valley a few miles away. In another Peate would pull out one of his whiskers and hang it on a fence nearly a quarter of a mile away. Peate himself tells of the time spent in testing the mirror, but does not go into detail about the procedure. He does mention a testing table that stood about 75 feet away from the revolving table on which the mirror rested. He says further that the mirror was tested “in all ways known, in the shop and on a pin and a watch dial a thousand feet distant.” Of these only the pin test seems to have been a conventional one.[38]

After the polishing, the mirror was silvered. Said Peate: “It was silvered and tried on the heavens in the starless region under Corvus, and under the very imperfect management of the mirror on telescopic stars, the report was as good as could be expected.”[39] Dr. Peate must have spent some time testing it on the stars. The mirror was evidently completed sometime late in summer of 1897, and when Peate was satisfied that it was as perfect as possible, he made arrangements to send it to American University. He also designed the shipping case to protect it on the trip to Washington. It is described in the University paper as follows:[40]

This consists of a box in which the glass is packed and a wheeled truck in which it is swung. It is swung on its edge by iron bands, which go around it over an iron belt which encircles it.

After waiting for the case, he encountered a further delay by reason of the fact that the express company had no office at Greenville. However the great glass finally was loaded on the train, and on August 24, 1898, it arrived safely at American University.

Although all parties concerned in this project seemed optimistic, no provision for mounting the mirror had yet been made. The University paper which announced the safe arrival of the glass hoped, at a later date, that—

some day, we trust before long, a noble and generous giver will appear, who will provide for the proper mounting of this mirror and also build a worthy housing.

This donor was never to appear. Five years later, in announcing the death of Peate, the Courier was still appealing for funds to mount the mirror. Late in 1903 it announced that a gentleman in Pennsylvania would contribute $100,000 to defray the cost of an observatory to house the mirror, but nothing further was ever heard of this gentleman. Earlier, before the mirror had been made, the Reverend H. G.[179] Sedgwick of Nashville, Tennessee, had offered to mount and equip the mirror on the same terms under which Peate had made it. That is, he would do the work if someone would donate the cost and the material. But of this offer, too, nothing further was heard. Possibly he died before the mirror was completed.

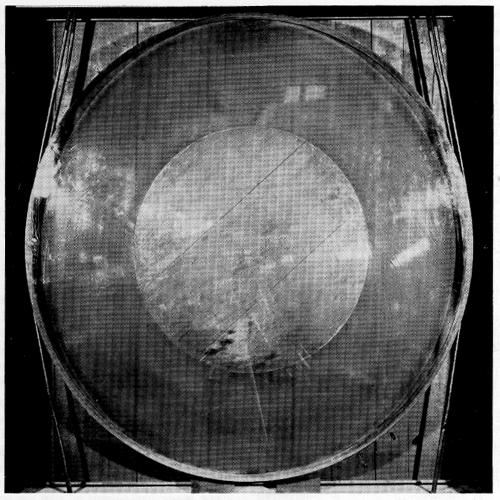

Figure 15.—The 62-inch telescope reflector disc (USNM 310899), cast by Standard Plate Glass Company, April 20, 1895, and figured by John Peate. It weighs 2500 pounds. Shown here as it hangs in its protective crate, this clear green glass mirror will be a feature of the exhibit of optics and astronomy now being prepared for the Smithsonian’s new Museum of History and Technology, scheduled to open soon after 1962. (Smithsonian photo 41172)

The mirror was to remain untouched for some 24 years. In 1922 the “Greenville Roundtable,” a group reportedly founded by Dr. Peate, allocated $90 to the Reverend H. G. Dodds to investigate the disposition of the mirror. In that same year the Erie Conference appointed Dodds a committee of one to report on the same matter. Dodds visited American University and conferred with the chancellors. They checked the mirror and it seemed to be in good shape. Dodds then went to Warner and Swasey, in Cleveland, Ohio, where he attempted to discover what it would cost to mount the mirror and provide an observatory. But he learned nothing there. Dodds knew nothing either of astronomy or of glass and his lack of knowledge did not inspire confidence in his mission. He did note a peculiar phenomenon, that people seemed suspicious of the mirror in itself without knowing anything about its actual condition.[41]

Shortly after Dodds’ failure to secure a user for the mirror the Perkins Observatory at Ohio Wesleyan University, which planned to add a large reflecting telescope, became interested in it. Dr. Clifford C. Crump, director of the Perkins Observatory, J. W. Fecker, then president of the J. W. Fecker Company, and A. N. Finn and A. Q. Tool, of the National Bureau of Standards, inspected the glass at American University. They found it remarkably free of bubbles and similar defects. Due to a lack of facilities they were unable to test the mirror optically, so that no comment was made on either the polishing or the correctness of the figure. It was, however, found badly strained due to poor annealing, and Fecker advised against using it, as it would have to be re-annealed. If this were done, some refiguring would also be necessary. After this rather expensive renovation it would remain a rather thin, flexible glass and not equal to modern standards. The Perkins Observatory consequently decided rather to use a mirror cast and finished under the supervision of the Bureau of Standards.[42]

This was the last attempt to use the mirror. It remained at American University until the mid 30’s, when it was placed in the Smithsonian Institution. It was still, in February 1935, the largest mirror ever cast and polished in the United States.

Let us return now to Dr. Peate. After seeing the mirror safely stored at American University he returned to Greenville, Pennsylvania. Then 78 years old, still in good health and very active, he was to live for 5 more years.

To the end of his life he maintained his interest in astronomy, and was optimistic about the possibility of his great mirror eventually being mounted and used. In 1900 at the age of 80 he decided to see Europe once again. His prime objective on this trip was undoubtedly the Paris Exposition of 1900, where one of the main attractions was a huge telescope made by Gautier. It had a refracting objective of 49.2 inches, mounted horizontally, the largest refractor yet made. Strangely enough this much publicized telescope was never used either. After the exposition was over the backers became bankrupt and the instrument was dismantled and sold for scrap.

Dr. Peate with his wide range of knowledge and his conversational ability delighted and puzzled his fellow passengers on the boat to and from Europe. They guessed that he was an educator, a scientist, or statesman but he denied all this saying, “no, I’m only a bricklayer.”

Dr. Peate lived three years after this trip, dying on March 24, 1903. His good health and physical vigor never left him till almost the moment of his death; as shortly as a week before, he had conducted a funeral service.

It would be rather easy to dismiss him as a harmless fanatic except that everything known of him indicates that he was not. It is reasonable to believe that his mirrors were made more in the hope than in the certain expectation that they would stimulate the study of astronomy in the institutions receiving them. He was probably well aware of the difficulties of establishing so large a telescope at a newly founded institution such as American University, and, content in the knowledge that he had done his part, could only hope that others might be inspired to do likewise.

Dr. Peate’s great mirror will shortly be put to use in a manner that could hardly have been predicted by its maker. It has been in the Smithsonian Institution for over 20 years. The huge glass will form a part of the exhibition of optics and astronomy in the new Museum of History and Technology that the Smithsonian Institution will open to the public about 1962. There it will be seen by some millions of persons each year. Because of its spectacular size it should catch the attention of most museum visitors. Surely it will awaken in more than one potentially able worker an interest in astronomy. If so, it will have accomplished Dr. Peate’s purpose.

[1] Instruments surviving from 18th-century America are almost exclusively of European origin, products of the numerous and famous shops which sprang up, particularly in England and France, to meet the demand occasioned by the popularity of the telescope among amateurs and dilettanti.

[2] U.S. National Museum catalog nos. 152078 and 152079.

[3] W. I. Milham, Early American Observatories, Williamstown, Mass., Williams College, 1938.

[4] Mechanics Magazine, 1830, vol. 13, pp. 114-115 and frontispiece.

[5] See p. 184 for a list of Holcomb’s instruments in the U.S. National Museum.

[6] H. C. King, The History of the Telescope, London, Charles Griffin, 1955, pp. 246-248. Milham op. cit. (footnote 3), p. 10.

[7] As reported in the Journal of the Franklin Institute for July 1834, new ser. vol 14 (whole no. 18), pp. 169-172; July 1835, new ser. vol. 16 (whole no. 20), pp. 11-13; and August 1836, new ser. vol. 18 (whole no. 22), p. 110. The first two of these are given in the appendix, pp. 181-184.

[8] Reported by “R. K. M.” in Sky and Telescope, March 1942, vol. 1, p. 21. The “Catalog of Objectives Made by Henry Fitz,” the time span of which is unspecified, lists 428 objectives up to 13 inches and only 6 mirrors. It is not clear, however, that these represent finished units.

[9] Langley’s work at the Allegheny Observatory, particularly his invention of the bolometer, brought him international reknown as a scientist. In January 1887 he was appointed assistant secretary of the Smithsonian Institution, and later in that year became its third Secretary, serving from 1887-1906.

[10] The giant mirrors of Herschel (1789) and Rosse (1842) were made of an alloy of 71% copper and 29% tin, and 68½% copper and 31½% tin, respectively. This alloy was known as “speculum metal.” The silvered glass mirror was pioneered by Steinhill and Foucault in 1856. In England Dr. A. A. Common made considerable use in the 1870’s of silvered glass mirrors made by George Calver. About 1892-97 Common himself made, but never finished, a 60-inch mirror. It was later refigured and is still in use.

On these matters see King, op. cit. (footnote 6).

[11] For a list of these, see appendix, p. 184.

[12] Words crossed out in manuscript. See figure 1.

[13] For a list of Fitz material in the U.S. National Museum, see appendix, p. 184.

[14] F. W. Preston, “The first big American telescope mirror, John Peate, his lens,” Bulletin of the American Ceramic Society, 1936, vol. 15, pp. 129-152. Hereafter cited as Preston.

[15] The circumstances of Peate’s life and ministerial career are from Preston, supplemented by Dr. Peate’s service record, provided by the Erie Conference of the Methodist Church. Dr. Preston’s prime sources are: J. N. Fradenburgh, History of the Erie Conference, Oil City, Pa., 1907, vol. 2, pp. 204-211; obituary notice by R. N. Stubbs in Minutes of the Erie Conference, pl. publ. 1903, p. 90. Other data were obtained by Preston through interviews and letters, all cited in detail in the article.

[16] From information provided by Robert Barr, acting secretary of Oberlin College, February 15, 1960. The college records show a John Peate from Buffalo enrolled in the preparatory department in 1842-43 and 1844-45. The Encyclopedia Americana (1924 ed., vol. 21, p. 460) states that Peate attended Oberlin about this time. The Doctorate was an honorary one conferred by Allegheny College.

[17] Fradenburgh, op. cit. (footnote 2), p. 204.

[18] Preston, p. 130, n. 10; p. 131, n. 19; p. 148.

[19] “On the Construction of a Silvered Glass Telescope, Fifteen and a Half Inches in Aperture, and its Use in Celestial Photography,” Smithsonian Contributions to Knowledge, vol. 14, art. 3, iv+55 pp., 1865 (reprinted in vol. 34 as art. 2, 1904).

[20] Preston, p. 148. From an article in the Greenville, Pa., Record Argus, December 17, 1903.

[21] Preston, p. 148. In 1960 it was further learned that an “American Temperance” college or university once existed at Harriman.

[22] Scientific American, October 24, 1891, vol. 65, p. 260.

[23] Communication from Thiel College, Preston, p. 131, n. 17.

[24] Popular Astronomy, July 1898, vol. 6, p. 310.

[25] Preston, p. 129, notes 2 & 3. Based on recollections of George Lambert (1895) and John Morrison (1903). That the decision to make the mirror 62 inches in diameter may have had another origin is suggested by the fact that Common, in England, had made two mirrors of 60 and 61 inches in 1886-91.

[26] Minutes of the Erie Conference, 1893, p. 29. Preston, p. 130, n. 4.

[27] Preston has reconstructed the story of the making of the 62-inch mirror from contemporary journals, which will be cited below, and from personal communications with some of the participants, notably George Howard and George Lambert. Detailed citation of these communications are given in Preston. He has also used a brief manuscript account by Peate himself (Preston, p. 142, n. 62).

[28] Communication with Frank A’Hearn and John Hodge. Preston, p. 135.

[29] Peate’s workshop and apparatus is described in detail by Preston, pp. 135-138.

[30] Preston, p. 139.

[31] Advance Argus, Greenville, Pa., May 9, 1895. Preston, p. 139.

[32] Clipping of uncertain date from the Pittsburgh Leader, quoting the National Glass Budget. Preston, p. 139 and n. 55.

[33] Preston, p. 140.

[34] Preston, p. 139.

[35] Preston, p. 140.

[36] Preston, p. 142.

[37] The Brashear Instrument Company, after the death of its founder John Brashear, became the J. W. Fecker Company, Inc. This concern is now a division of the American Optical Company.

[38] Preston, pp. 142-143.

[39] The mirror is no longer silvered. The silver surface was apparently removed during the inspection by the Bureau of Standards in the 1920’s.

[40] Preston, p. 144. Various notices were published in the American University Courier in 1898.

[41] Preston, pp. 145-146.

[42] Preston, p. 146.

[From Journal of the Franklin Institute, July 1834, new ser. vol. 14 (whole no. 18), pp. 169-172.]

The Committee on Science and the Arts, constituted by the Franklin Institute of the State of Pennsylvania for the promotion of the Mechanic Arts, to whom was referred for examination a Reflecting Telescope, manufactured by Mr. Amasa Holcomb, of Southwick, Hampden county, Massachusetts,

REPORT:—

That the following is the description of the instrument as given by Mr. Holcomb.