The Project Gutenberg EBook of Printing Telegraphy... A New Era Begins, by Edward Ernst Kleinschmidt This eBook is for the use of anyone anywhere in the United States and most other parts of the world at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org. If you are not located in the United States, you'll have to check the laws of the country where you are located before using this ebook. Title: Printing Telegraphy... A New Era Begins Author: Edward Ernst Kleinschmidt Release Date: November 9, 2016 [EBook #53481] Language: English Character set encoding: UTF-8 *** START OF THIS PROJECT GUTENBERG EBOOK PRINTING TELEGRAPHY *** Produced by Stephen Hutcheson, MFR and the Online Distributed Proofreading Team at http://www.pgdp.net

Edward E. Kleinschmidt

1967

Having been associated with the printing telegraph for more than sixty years, I have felt the urge to write a résumé of the problems and the progress made during my time toward today’s wonderful achievements in the art of telegraphic communications.

It is interesting to note that of all the old-time electric telegraph systems, it appears that only those using the Morse dot-dash code invented in 1837 and the permutation code devised by Gauss and Weber in 1833 (now known everywhere as the Baudot code) have survived today.

Samuel Morse’s code, which was modified somewhat in several letter code compositions to facilitate its use anywhere in the world, has become an audible, easily learned international language, loved by its users everywhere. It will no doubt continue to be used for some time to come, as long as we have our railroad telegraph operators, radio amateurs, police CW systems, certain branches of the Armed Forces, and any others who converse in dits and dahs.

The permutation code has taken hold firmly, too. Its use of five pulses transmitted in varying combinations of on and off, or positive and negative, conditions has wide application in today’s printed communications systems. As in the Morse system, alphabets for the five-unit permutation code system have been modified as to letter code compositions for international correspondence. The permutation code uses the powers of two in progressively selecting a letter printing position.

The binary code uses the same selective stops by yes or no designation in a system of counting by the powers of two. It is used where larger groups of yes or no positions are required, as in data processing and computer systems.

This writing, then, is a bit of history that will put together the constructive developments that brought about the present era of the worldwide, telegraphically-transmitted printed word.

I wish to acknowledge with great appreciation the informative material sent to me by my friends, both here and in foreign lands, who are associated with the telegraph industry.

For assembling information we have gathered from various sources and for the most helpful assistance given me in writing this story, I also want to thank my secretary, Mrs. Doris Pompilio.

Edward E. Kleinschmidt

It is a major effort today to keep pace with the rapid advances in the field of printed communications. Hardly a day passes that we do not read of a new development in equipment that is more complex, farther reaching, more rapid in operation....

This electrical, or electronic, transmission and interchange of the printed word might be said to be an evolvement of the old printing telegraph systems. Such systems, over the years, while not so rapidly as today, were also improved upon, modified, speeded up, but could be used only in the point-to-point transmission of messages.

While the railroads had been using the Morse code system (key and sounder) satisfactorily, they would have preferred a system whereby a printed record could be obtained. In the industrial world, too, there was need for a businessman’s printing telegraph—a means to type out messages, directly and interchangeably, to far-off associates. And there was always that dream, starting with the earliest telegraph experimenters, of being able to correspond instantly with one another anywhere in the world. Indeed, the need for all this had been known for many years, but not the way.

It was after the turn of the century that telegraph engineers began in earnest to think about a system of telegraphy that would permit direct intercommunication by the printed word, and direct circuit connection to any outlying subscriber as in the telephone communication system.

Up until then, apparatus for transmitting telegrams, such as that of Wheatstone & Cooke, Morse, Hughes, Barclay, etc., also the step-by-step stock tickers and bulletin printers, used various types of code-signaling devices in which the code varied in length as to the transmission of more frequent or less frequent letters.

Now in order to provide a practical telegraph system permitting the interconnection of apparatus throughout the world, the first basic requisite is a standard signaling code; this code, moreover, must be of such nature as to use the simplest form of electrical signaling (such as make and break signals, or positive and negative signals), and the code should be of equal length for all characters.

The permutation code, where combinations of five plus and minus pulses will give thirty-two selective positions, was suggested as far back as 1833 by Gauss and Weber. Whitehouse, in 1854, and Barnett, in 1860, experimented further, using the permutation code to operate a recording mechanism. However, no practical means for actually printing letters and figures was found until 1882 when Jean Maurice Emile Baudot designed a multiplex system to permit the transmission of four messages in each direction over a single line circuit. Later, Baudot designed a tape printer in which the selecting and printing mechanisms comprised an ingenious arrangement of cooperating parts, including a rotating typewheel associated with a coded combiner wheel and five stationary elements selectively movable to received code positions, each element having an extending finger to be brought into contact with the periphery of the coded combiner wheel upon the completion of a selective code setting. When the code combination of the set fingers matched a code on the wheel, a print roller was released to press the recording tape against the typewheel and print the selected letter.

Although the Baudot Multiplex was used extensively in Europe, engineers and inventors in the United States had not produced a practical 5-unit permutation-code teleprinter system. They were constantly searching for a unit code system requiring a minimum number of electrical impulses to operate a telegraph printer. Various types of relay systems using distinctive signal pulses were proposed. A three-unit-code system that showed promise, and did not require synchronism, used four different electrical pulse conditions: a high voltage positive or negative pulse, and a low voltage positive or negative pulse. Records show that many inventors played with this code and that John Burry, C. L. Krum, G. A. Cardwell, and J. C. Barclay, among others, built operable equipment using such a code arrangement. The following excerpt from Cardwell’s patent No. 905,497 of December 1, 1908, may be of interest. It describes the code arrangement of four different line conditions in three signal groups to produce 36 different code combinations.

3In order to energize the controller magnets in proper sequence to position the type wheel for printing a desired letter, a predetermined code or system of sending in the impulses is essential. In an instrument constructed by me in accordance with the present invention I have used the following:

1-2-1 letter space 1-2-3 carriage return 1-2-4 line space 1-3-1 type wheel shift 1-3-2 type wheel release 1-3-4 A 1-4-1 I 1-4-2 O 1-4-3 D 2-1-2 E 2-1-3 H 2-1-4 N 2-3-1 W 2-3-2 R 2-3-4 S 2-4-1 T 2-4-2 V 2-4-3 U 3-1-2 - 3-1-3 , 3-1-4 ? 3-2-1 Y 3-2-3 C 3-2-4 F 3-4-1 G 3-4-2 Q 3-4-3 L 4-1-2 M 4-1-3 J 4-1-4 B 4-2-1 X 4-2-3 Z 4-2-4 . 4-3-1 K 4-3-2 P 4-3-4 The numerals in the above code or system indicate the sequence of the impulses through the relay contacts 1, 2, 3 and 4.

Cardwell’s backers formed the American Telegraph Typewriter Company and sold shares, claiming a great profitable future for their apparatus. A few printers were built, but, on extended service tests, the high-low-voltage feature proved to be impractical and the company folded.

J. C. Barclay of the Western Union Telegraph Company designed printing apparatus and perforated tape transmitting equipment for this type of system, but, after limited use of the high-low-voltage principle, he changed this feature to long and short pulses with discriminating relays. With later improvements, this system was put into service on a number of Western Union message circuits.

Note: Today, in the 1960s, the techniques of frequency division and electronics could be used for transmitting three different line conditions from a group of four different frequencies. In such a system, synchronism between send and receive terminals, or the start-stop method to control correct timing, is not needed. The transmission of any selected group of three, when received in succession at a teleprinter, will cause printing of a letter when the third receiving relay completes a circuit to the selected printing magnet. Transistor circuits with associated control elements could replace the relays.

Telegraph companies in the United States were mostly using the Morse and increased its efficiency through development of quadruplex operation and high-speed transmission systems. However, the quest for a more efficient printing telegraph system persisted and various types were proposed and tried. All made use of codes that were impractical for intercommunicating systems and, while some were used in message service 4 by the telegraph companies, they did not appear to have any great advantage over the Morse telegraph.

In 1911, Western Union began investigating systems used in Europe. The first to be tested was the Creed, a system for transmitting and printing Continental or Morse code signals at high speed. After observing several other systems, the Murray Multiplex, an improved and modernized version of the Baudot Multiplex, was found to show better operating features and, due to the use of the five-unit permutation code, more efficient use of telegraph lines.

By agreement with Donald Murray, and with his cooperation, the so-called Western Union Multiplex was developed, using Murray’s phonic wheel drive and synchronous correction. Western Union engineers designed tape transmitters and an autocontrol device for transmitting service signals. A keyboard-operated, five-unit-code, tape punch was supplied by the Morkrum Company. A page printer, which was later converted to print on gummed tape, was supplied by the Kleinschmidt Electric Company. The Western Union Multiplex was effective in increasing operating efficiency and came into extensive use throughout the system.

From that time on, development of the Baudot permutation-code printing telegraph apparatus was furthered by various companies, such as Bell Laboratories, Western Electric, the Morkrum Company, the Kleinschmidt Electric Company, as well as the companies of J. E. Wright, L. M. Potts, and others.

It appears that all of these inventors experimented with the idea of operating all transmitting and receiving apparatus at identical speeds to transmit a five-unit-code combination by first transmitting a pulse to start both transmitter and the distant receiver at the same time. Synchronous operation was obtained by electric motors equipped with governors to maintain correct speed; some used tuning-fork-controlled impulse motors. A system of five relays with progressive contact arrangements to cause cascade operation was also used to provide correct timing. Later, when correctly-timed, 60-cycle alternating current became available (see page 27), synchronous motors did the job.

Teleprinter apparatus using this synchronous method worked very well for point-to-point transmission as was used by the telegraph companies and news-distributing organizations to carry local traffic. It did not, however, solve the sought-for plan for a teleprinter intercommunicating 5 system. When attempts were made to connect printers at different distant points in a telegraph intercommunicating circuit while using the synchronous principle, false reception and printing errors would occur, due to variation in line circuit conditions and to a variation of the mechanical start operation at outlying teleprinters. This required frequent overline adjustment to keep the connected apparatus in phase.

The following is an excerpt from a patent application of Dr. Louis M. Potts (later to become research engineer for the Morkrum-Kleinschmidt Corporation), filed June 17, 1909, giving his idea for achieving a teleprinter intercommunicating system on the synchronous principle. Dr. Potts was a very capable telegraph engineer. His early association was with the telegraph system of the Rowland Telegraphic Company which had limited use in the early 1900s.

In those synchronous telegraph systems wherein the sending and the receiving commutator brushes constantly rotate, it is necessary to adjust these brushes so that they will approximately simultaneously engage corresponding segments. To effect this adjustment there is usually provided a special device embodying an additional segment on each commutator, and the adjustment consists in causing the brushes to arrive approximately simultaneously on this segment at the two ends of the line. Such adjustment is known as “finding the letter” and has to be made every time synchronism has been interrupted. According to the present invention, the necessity of providing additional means for performing the so-called operation of “finding the letter” is rendered unnecessary, since the transmitting and receiving commutator brushes at the two ends of the line start up afresh as it were for each signal.

In a later patent application, filed October 11, 1913, Dr. Potts stated:

This machine has also the advantage of being able to operate with a very short code. In order to adapt it to Morse circuits, it should be capable of operating with a code at least as short as the Morse code. In the present machine, I preferably employ a five unit code which, together with the starting impulse and the lag between signals, is actually shorter than the Morse code. Counting the five code impulse periods, the starting impulse period and the period of lag between impulses, each signal in my case, may be considered in comparison with the Morse code as being seven units long, whereas the Morse code is 8.5 units long. The average signal being shorter than the Morse, the delicacy of adjustment will be less and the distance of operation greater than a Morse telegraph for the same rate of transmission in words per minute.

Dr. Potts, however, still depended on like synchronous operation at both terminals, and dual start, so he did not have the answer after all!

John E. Wright, who in the 1890s designed and built step-by-step printing apparatus, including the Wright-Negron bulletin printer, also turned his thoughts toward the five-unit permutation code for printer operation and built several variations using the synchronous principle. The Superintendent of Telegraphs for the Delaware, Lackawanna and Western Railroad thought well of Wright’s apparatus and placed some in operation. But, here again, reliable operation could be maintained only in point-to-point operation. As will be noted in Chapter 2, Mr. Wright’s patents were purchased by the Kleinschmidt Electric Company in 1922.

A paper issued by Siemens-Halske of Germany in January of 1917[1] states that the Siemens Pendel Telegraph “is among the forerunners of the eventual worldwide start-stop system for intercommunication by the printed word.” The following excerpt translated from that description briefly explains the operation:

The Pendel Telegraph uses the five-unit permutation code to select characters, and operates on a start-stop principle. It is intended for station-to-station, one-way operation, the line current normally being closed to the positive side of the line battery. Transmission is under control of a keyboard with keys arranged as in a typewriter. Upon the depression of a key, the line battery is reversed, thereby transmitting a negative pulse to line which effects the start of both transmitter and receiver at the same time. Thereafter, five-code-combination pulses are transmitted, followed by positive current to line, thus restoring the circuit system to a normally closed line condition.

The name “Pendel Telegraph” would make one think that the timing of the transmitter and receiver were under control of a swinging pendulum. This is not the case. However, it does have a plan for simulating the action of a pendulum by an arrangement of springs and semi-rotating weights to effect synchronism for each printing cycle; and energy is derived from a motor which intermittently winds a power mainspring to an even tension. This arrangement is started in operation at both terminals at the same time and provides isochronal motion at both transmitter and receiver for each transmitted character. Due to multiple operations of the springs and weights used to provide synchronous action, the operating speed is limited to four or five letters per second.

In England, too, there was work being done along these same lines. Mr. H. H. Harrison, who is so well known for his contributions over the years in the telegraph field, devised printer apparatus using the five-unit 7 code which is described in Herbert’s Telegraphy,[2] as follows:

The instrument is provided with a Baudot 5-key keyboard, and has a step-by-step distributor which is mounted inside the casing. The standard Baudot alphabet is used, but each letter or character is prefixed by a positive starting impulse. Every time a key is depressed a universal bar is actuated which closes contacts giving the starting impulse and the distributors at both ends of the line step through six spaces. The combiner is of the electrical type invented by Baudot, and is similar to that used in Siemens’ new automatic printing telegraph. Five relays of the class used for telephone purposes are set at the receiving end, according to whether some of the stepping impulses are positive or negative. The distributor is a trunk hunting switch as used in automatic telephony, and consists of a ratchet wheel and stepping electromagnet. On the shaft of the ratchet wheel is fixed a wiper which sweeps over a semi-circular bank of contacts in response to the stepping impulses. Two-way working is secured by means of the differential balance.

(The article ends with the statement that a typewriter keyboard is being constructed to replace the five keys.)

It appears that all of these telegraph engineers and inventors envisioned a start-stop system and experimented with the idea of operating all transmitting and receiving apparatus at identical speeds by inserting a start signal before each group of letter code signals, to start both transmitter and distant receiver at the same time, and a stop condition between code groups.

In the following chapters will be shown the contributions made by both the Kleinschmidt and the Morkrum companies in the printing telegraph field, and finally their joint efforts which were to lead up to the establishment of that now worldwide intercommunicating system, the TELEX.

Edward E. Kleinschmidt’s first direct contact with telegraph apparatus was during his employment as a young man, in 1893, by John E. Wright, whose firm had developed and was then manufacturing printing telegraph equipment known as the Wright-Negron bulletin printer for the Havas News Agency in Paris. These printers operated on the step-by-step principle at 30 words per minute. (To attest to their ruggedness, as late as 1951 some of these machines were reported to be still in use!)

Five years later, in 1898, Kleinschmidt started an experimental shop at 122 Fulton Street in New York City. A sign over the door read, “Inventions Developed,” and he did experimental and developmental work for various customers (individuals as well as companies—including Western Union) on a time-and-material basis. In the beginning he had a project of his own going—a facsimile telegraph system. He submitted the system to Western Union in 1900 with the suggestion that it might be valuable for customer services, since a customer could write his telegram in longhand and insert the written message in the transmitting unit for transmission in facsimile to the telegraph central. The idea, however, was rejected. At that time the photoelectric cell for scanning the written message and electronic means for amplifying signals had not yet been developed; while the apparatus operated quite well over short circuits, evidently the time had not arrived for commercial facsimile telegraphy.

The first telegraph apparatus job for the shop was brought in by Dr. George A. Cardwell, a dentist by profession. It was a partially developed printing telegraph using a three-unit code made up of combinations of plus-minus-high-and-low-voltage pulses (the code we have already discussed). The work for Dr. Cardwell was carried on until 1903 when a working model was completed. It had a typewheel for printing and stops arranged in a circle; magnets under control of relay selection were used to set the stops according to the received code combinations. This arrangement operated well, and on a test over a Western Union circuit from New York to Baltimore it gave satisfactory results. As we have seen, 9 however, the code arrangement proved unsatisfactory for general telegraphic use.

Many customers came to the experimental shop with every type of idea imaginable; vacuum cleaners (The “Vacuna”), elevator signals, some early designs for Elmer Sperry’s gyrocompass were only a few. Kleinschmidt also set up a couple of side-line businesses, one for manufacturing automatic fishing reels under the trade name “Kelso,” another, the Aseptuloid Company, for making vaccination shields (some readers may well remember their childhood vaccinations being protected by a bubble of celluloid).

Another customer was George M. Seely, who later was instrumental in bringing Kleinschmidt’s work to the attention of Charles B. Goodspeed and W. S. Moore (they were to become his financial backers—see page 14). Mr. Seely came to the shop in 1906 with a partially developed block system for electric trolley car railways. His plan was to use special devices attached to the trolley pole which would cooperate with stationary electrical controls at certain fixed points along the road.

After working along these lines for awhile it became apparent that some inventive work would be required on Kleinschmidt’s part. Seely, in addition to time and material, then offered him a retainer for the assignment of any resulting patents.

As plans and studies progressed, a number of railway signaling devices were developed, tested, and patented. A major item was the development of a telephone train dispatching system. A complete set of apparatus was exhibited in operation at the American Association of Railroads Communications Convention held in Los Angeles in 1910. The company name given this venture was the “National Telephone Selector Company,” located at 235 Greenwich Street, New York City. The telephone train dispatching system was installed on the Long Branch Railroad with 30 stations connected with dispatcher headquarters at Red Bank, New Jersey. Another installation was made on the Baltimore and Ohio Railroad in West Virginia, connecting 38 stations with dispatcher headquarters at Fairbanks, West Virginia.

Most of the patents assigned to Mr. Seely were eventually sold to the Hall Signal Company.

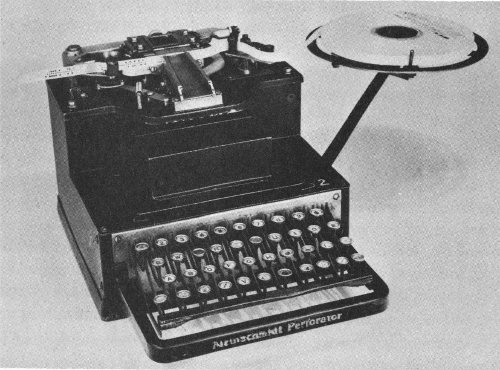

Doing development work for others and assigning patents for a retainer 10 did not satisfy Kleinschmidt’s ambitions. His interests being mainly in the telegraph, he set out to design and build a piece of apparatus that the telegraph companies could use. A keyboard-operated perforator to punch the Morse code in a tape for automatic transmission at high speed looked like a promising subject, since the tape punches in use at that time had a three-key arrangement—one each for dot, dash, and space.

Kleinschmidt’s first keyboard-operated, Morse-code perforator was constructed in 1911 and exhibited to the Western Union Telegraph Company. Mr. G. R. Benjamin, their chief engineer, and Mr. Emmett R. Shute, a vice president, thought well of the machine and, after testing it, gave Kleinschmidt an order for fifty. This order spelled success. To celebrate the event, Kleinschmidt invited his brothers, Bernard, Fred and William, and their families to a dinner party at a distinguished restaurant. Soon thereafter (1913), the Kleinschmidt Electric Company was organized, with the brothers as incorporating officers.

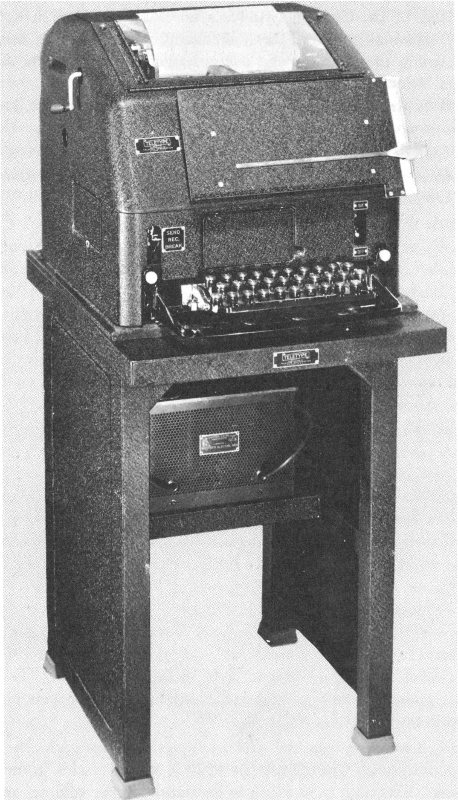

The Kleinschmidt Keyboard Perforator came into use by telegraph and cable companies throughout the world where Morse, Wheatstone, or Cable codes were used to transmit telegrams. It was also used with Western Union’s Barclay system which had its own code. The device was later manufactured by Teletype Corporation under the name “Teletype Perforator” and used by the U. S. Government where it served its purpose for high-speed Morse transmission during the war period (see figure 1).

In the years 1911 and 1912, the Western Union Telegraph Company, in looking toward higher operating efficiency over their trunk circuits, decided to test the Creed high-speed Morse and the Murray Multiplex, and invited both companies to bring their apparatus to New York. It was on this occasion that Kleinschmidt became acquainted with Mr. F. G. Creed, who, upon observing the Kleinschmidt keyboard perforator at Western Union, was impressed by its performance and said that there would be a good market for it in England, especially as a keyboard punch for the Creed high-speed Continental-Morse-code system. As a result of that conference he asked for ten as a trial order. These perforators were shipped to London in due time and gave satisfactory service. The British Post Office Telegraph evidently had heard about this new perforator and sent a letter to the Kleinschmidt company asking for a demonstration at their London headquarters.

Now it happened at that time that Kleinschmidt was extremely busy with the development of a five-unit-code typebar printer for the new Multiplex—and this was urgent since the first model was to be put on competitive test with a typewheel printer submitted by L. M. Potts and the Western Electric typewheel printer which was then in use. Therefore, he felt he should not lose a month or two in this developmental work for a trip to London. So, his answer to this important invitation was that he could not personally bring one of his perforators for exhibit but that he would ask Mr. F. G. Creed to do so. Mr. Creed agreed and set up a formal exhibit for the Post Office engineers; he consequently received an order for twenty Kleinschmidt perforators. Further correspondence with Creed resulted in an order for one hundred and a request that Kleinschmidt come to London the next year (1914) to negotiate a contract to supply his keyboard perforators for the Creed high-speed Morse and to set up a sales agency with Creed for certain territories.

While in London in the summer of 1914, Kleinschmidt visited the Managing Director of the Post Office Telegraph at his office to apologize for having had Mr. Creed exhibit the Kleinschmidt perforator instead of bringing it personally as had been requested. The Managing Director replied that Mr. Creed had indeed given a very good operating exhibition of the device and that an order for twenty had been placed with him. “However,” he added, “you know, we sent you an official invitation and expected your appearance with your machine!”

To continue: Upon observing the change in systems at Western Union (switching from the Barclay to the Murray Multiplex), the Kleinschmidt Electric Company, who had been experimenting in the development of a telegraph typewriter, built a receiving teletypewriter for the multiplex. It was a magnet-operated, five-unit-code typebar page printer, using the Underwood typewriter mechanisms as a basis; and it was completed in time for test and evaluation at Western Union in competition with the typewheel printers of both L. M. Potts and Western Electric.

The Western Electric machine was given the number 1A, Mr. Potts’s, 2A, and the Kleinschmidt printer was 3A. The final outcome of the tests was the selection of the Kleinschmidt model, and the company received an order for five machines, to include a spare, to equip the New York terminal of a New York-to-Boston, four-channel multiplex system. The order was filled in a short time and the machines were put on test.

Fig. 1 Kleinschmidt Keyboard-Operated Morse-Code Perforator (this machine returned to author by a customer after being used thirty years!)

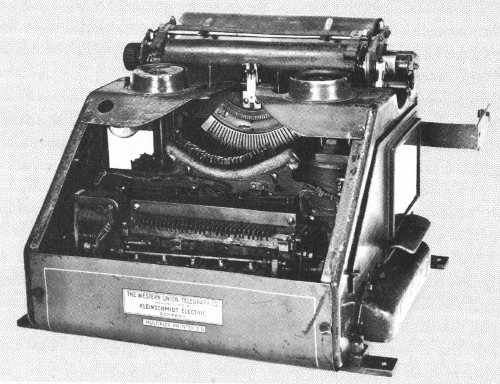

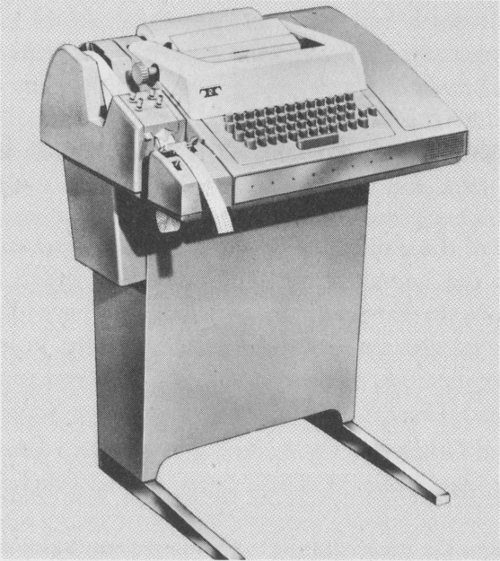

Fig. 2 3B Typebar Page Printer of Kleinschmidt Electric Companyfrom Museum of Kleinschmidt Division of SCM Corporation

Kleinschmidt watched the operation of his machines in service almost every day and was continually on the lookout for possible ways to improve and simplify the apparatus. The tests ran through to completion satisfactorily, and, upon submitting an improved design, numbered the 3B, the Kleinschmidt Electric Company received an order for one hundred typebar page printers. The 3B thereafter became standard apparatus and additional orders were placed as the multiplex system at Western Union expanded (see figure 2).

Several years later, Western Union efficiency engineers found that, due to circuit failures, certain parts of messages would have to be repeated. Because this meant retyping the message, they felt, and for other reasons as well, that printing the received messages on tape would be more economical, since corrections could be inserted without repeating the entire message. To meet this requirement, the typebar page printer was redesigned for printing on tape. This was accomplished by using the same selection controls and operating the typebars to print downward on the tape instead of upward against the platen as in the page printer. A tape gummer to attach the tape to a message blank was also designed. The 21A, later No. 22, tape printer was ordered in quantity thereafter.

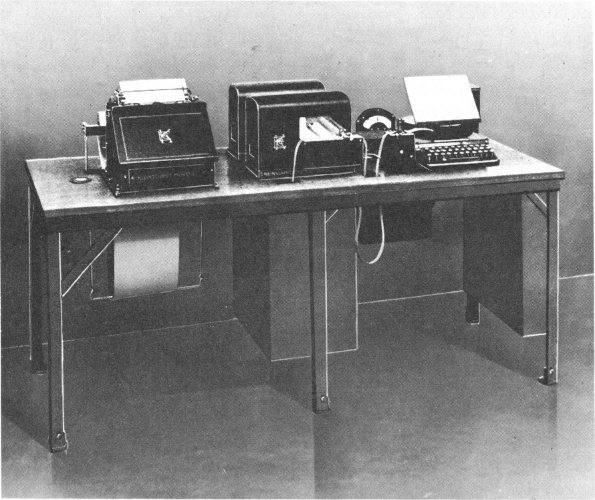

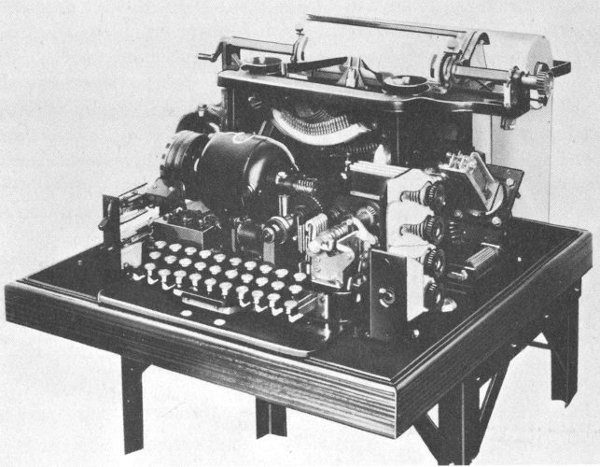

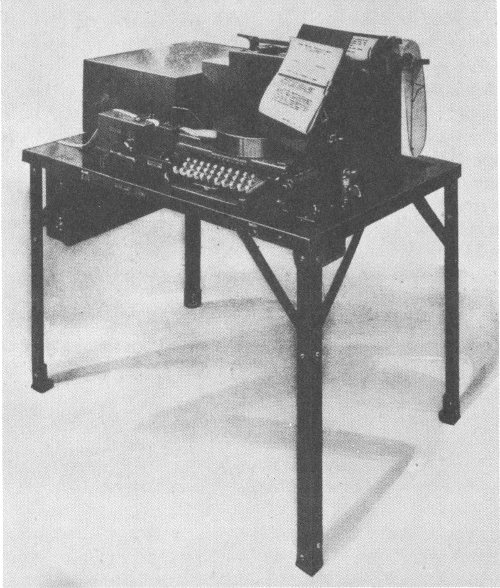

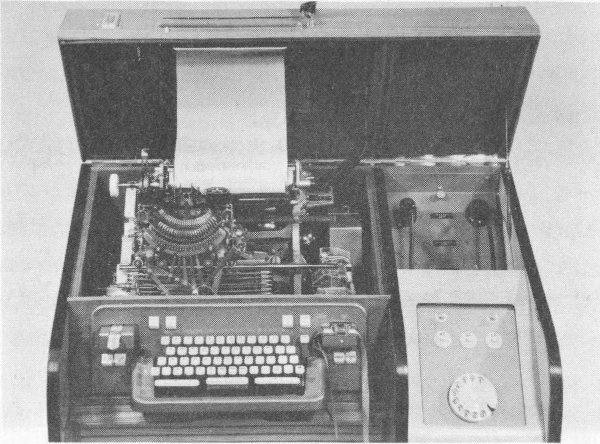

Seeing the possibility of using their typebar page printer for direct-line service, the Kleinschmidt company built a motor-driven send-receive unit having a single contact transmitter which operated under control of a code-perforated tape to transmit seven signals in succession: one start, five code, and a stop signal. The receiving unit had a seven-segment commutator, one segment for start, five for code, and one for stop, and a rotating brush to pick up and transmit the received code signals to the printing unit. This apparatus was installed at the United Press for news distribution to their connected newspapers. Another set was installed at the Louisville and Nashville Railroad for station communications, and still another in New York City at the Equitable Life Assurance Society between their downtown and uptown offices. In connection with the latter installation, the Equitable people asked permission to install the printing apparatus on the telephone line and there was objection from the telephone company. However, after some consideration they finally agreed that the apparatus could be installed but warning that should it create interference with the telephone line it would be removed immediately. As it turned out, the printer operation over this telephone circuit 14 did not create any interference and the apparatus remained in service a long time (figure 3).

Fig. 3 Kleinschmidt Electric CompanyTeletypewriter Apparatus for Direct-Line Service

The Kleinschmidt Electric Company now began to have financial difficulties. Edward Kleinschmidt was borrowing wherever he could. There was no large quantity production and evidently his charges for the apparatus delivered were too low. At any rate, early in 1917, Mr. Seely suggested that he get financial help to carry on and it was here that the following gentlemen entered the picture: Charles B. Goodspeed of the Buckeye Steel Casting Company; Paul M. Benedict, assistant to the president of the C. B. & Q.; Edward Moore, son of Judge Moore of the American Can Company; Eldon Bisbee, a New York lawyer; and one of Mr. Bisbee’s clients, Albert Henry Wiggen, who was then president of the Chase National Bank. With their financial backing, the company was able to continue with further developmental work on simplified and 15 more efficient apparatus. Orders for various types of equipment for the Western Union Multiplex and for the Morse code keyboard perforator came along, but developmental costs were high and still more capital investment was required; Kleinschmidt would then borrow from the Chase Bank. Every so often at the Kleinschmidt company’s directors’ meetings, Mr. Holly, cashier of the bank and also a director of the company, would state that the Kleinschmidt loan “stood out like a lighthouse,” so a vote for an additional stock issue was carried and the loan paid.

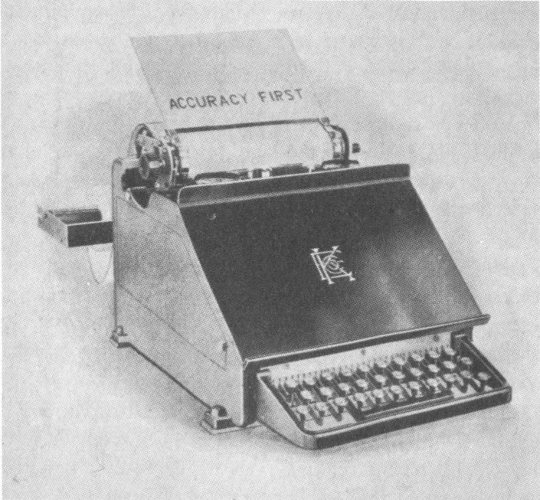

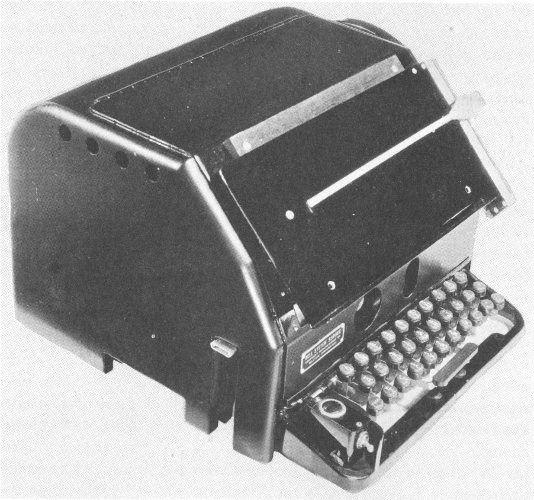

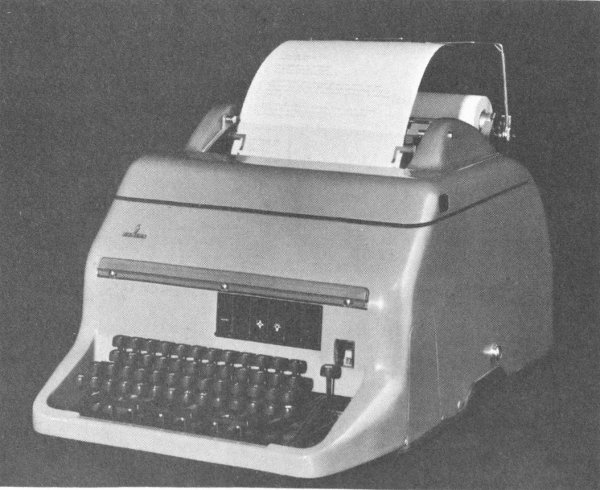

Along about 1919 the Kleinschmidt company had completed a satisfactory keyboard-operated typebar teleprinter for intercommunication systems (see figure 4). The Kleinschmidt Telegraph Typewriter, as it was called, was installed at the New York City News, the Panama Canal, and at the Brooklyn Union Gas Company (fig. 5).

In 1922, Edward Kleinschmidt, having learned that Mr. J. E. Wright had discontinued further developments in the telegraph field, proposed the purchase of his patents, stating that this acquisition would broaden the Kleinschmidt company’s patent situation. The proposal was carried, and, after negotiations, Mr. Wright’s patents were bought for 100 shares of the Kleinschmidt Electric Company’s common stock.

In 1923, the Kleinschmidt Telegraph Typewriter was exhibited at the 20th Annual Business Show in New York and created a great deal of interest. In 1924, a complete telegraph system was engineered and set up for the Mexican government. (An engineer from Western Union was borrowed to help with this job.)

One day, in 1923, after some correspondence with Samuel Samuel & Co., Ltd., through whom the Kleinschmidt company received orders from Japan for the Morse code keyboard perforator, the Japanese Telegraph Administration sent one of their telegraph engineers, Mr. Y. Okomoto, to the company’s headquarters to assist in working out a keyboard arrangement of Japanese characters for a simplified alphabet consisting of 88 characters which the Japanese Telegraph Administration had devised. The five-unit code could not be used since only 64 selective positions could be had. So the telegraph typewriter mechanisms were changed to six-unit-code operation, which worked out very well. The Kleinschmidt company, and later Morkrum-Kleinschmidt, received continuing orders for the six-unit-code telegraph typewriters.

Fig. 4 Kleinschmidt Electric Company Telegraph Typewriter(keyboard-operated typebar teleprinter)

Fig. 5 Kleinschmidt Telegraph Typewriters(installation at Brooklyn Union Gas Co.)

Mark Morton, head of the Western Cold Storage Company in Chicago, and cold-storage engineer Charles L. Krum, the vice president of the firm, entered the telegraph field quite by accident. A young electrical engineer named Frank Pearne, in 1902, had some ideas for a printing telegraph machine and needed financial backing to carry on his experiments. One of his contacts happened to be Joy Morton, the founder of the Morton Salt Company. Joy Morton became interested enough to become Pearne’s backer, and prevailed upon brother Mark to set up a laboratory in the attic of the cold-storage plant for Pearne’s experiments.

It seems that after a year or so, Pearne lost interest in his invention and went into the teaching field. He proved to be a very successful professor at Armour Tech where he remained until his death.[3] But Pearne’s work was not in vain, for Charles L. Krum had become intensely interested and carried on the work with further inventions of his own. Indeed, he filed his first patent application on August 20, 1903, which proposed the use of a code comprising four signals: a positive pulse or a negative pulse of low voltage, and a positive or negative pulse of a higher voltage. Four additional patents were filed, the last in 1906.

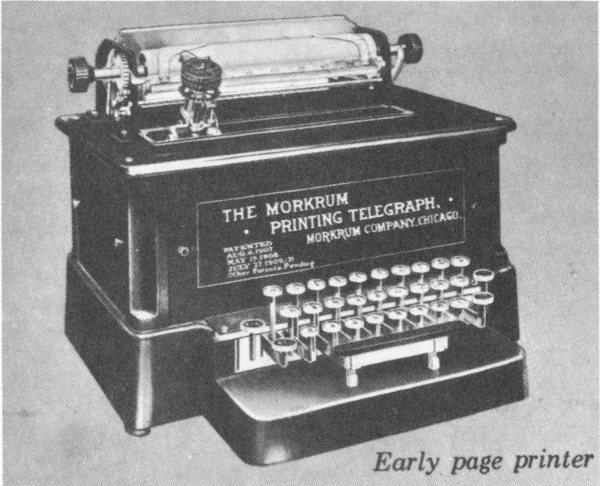

C. L. Krum then set about building a machine which was demonstrated in 1906 and looked promising enough to form a company to further develop it. This company was made up of the Mortons (brothers Joy and Mark) and the Krums (Charles L. and his son Howard who had just finished college). The combination of their names, of course, resulted in “The Morkrum Company,” which was incorporated in the State of Maine on October 7, 1907. The charter stockholders were Joy Morton, who shouldered the greatest financial burden; Charles Krum; Joy Morton’s secretary, Daniel Peterkin (he later became an officer of the Morkrum Company); Mark Morton; and Sterling Morton (Joy’s son, of whom we 18 shall be hearing more later on). The working capital of the new company amounted to $150,000.00.

Charles Krum’s son Howard, after graduation, joined with his father in the developmental work of this new company and, due to his studies in electrical engineering, was able to help his father considerably. His first love and intended career was music, but he put this aside in favor of his father’s telegraph printer. However, a tune on the piano which he always kept in the laboratory would help him solve many a difficult problem.

In 1908 the Krums developed and produced a working model of the four-unit-code, plus-minus, high-low-voltage system, which was applied to operate the mechanism of an Oliver typewriter. The system was then given an operative test on the wires of the Chicago and Alton Railroad, of which Joy Morton was a director.

As their research work progressed, Howard studied the various systems in current use and, with his father, decided to abandon the plus-minus, high-low-voltage system. They turned instead to a system using the five-unit permutation code as employed by Baudot in his multiplex telegraph in which synchronized terminal apparatus with periodic correction was the controlling feature.

Their first joint patent describes a plan for accomplishing synchronized reception with transmission using a system of five relays interconnected to operate in successive cascade form; thus, when the relays at both terminals are correctly timed for successive operation, they will transmit and receive the five pulse combinations of the Baudot code. For transmitting and receiving the code pulses, each of the five relays has an additional contact. To start the relay cascade operation, a start relay is added at both terminals and operated by a start pulse which precedes each code transmission. It seemed natural for the Krums to turn to a relay system at first, since, from his work with the three-unit-code, high-low-voltage system, C. L. Krum was experienced with the possibilities of relay operation.

The system of the relay chain in cascade operation was employed to operate a page printer using the mechanisms of the Blickensdoerfer typewriter which had a three-row typewheel. The Postal Telegraph Company became interested and bought a number of these printers in 1910. This was the first sale of Morkrum apparatus and provided enthusiasm for the 19 Krums for further research, which led to the substitution of a governed-motor-driven brush distributor to replace the relay cascade system. For this new plan the motor at the receiving printer operated at a slightly higher speed and was held in continuously synchronous operation with the transmitter by the periodic transmission of a correcting pulse. The new code selecting and printer control system was also adapted to operate the mechanism of the Blickensdoerfer typewheel typewriter. The idea worked out better than the cascade relay system, and a number of printers using this method were constructed and named the “Morkrum Blue Code.” A few were put in service at the Postal Telegraph Company.

The Associated Press (AP) became interested in the Morkrum “Blue Code” printer system as a replacement for the low-speed Morse system which was being used to transmit news items to newspapers in many cities. Here, continuous transmission under control of a code-punched tape, as used in the Morse code system, was a requirement, so Messrs. Krum set to work and designed a keyboard-operated, five-unit, Baudot-code perforator and an automatic punched-tape-controlled transmitter. This apparatus was installed at the New York headquarters in 1915 and receiving printers were gradually installed throughout the Associated Press system. The following excerpt and picture (fig. 6) from Oliver Gramling’s book, AP—The Story of News,[4] describes the introduction of the system to the Associated Press:

The tide of news by telegraph had continued with the years. Facilities had been improved, the Morse clicked into virtually every town in the country, but the old method was the same. Day in and day out, sending operators took dispatches, translated them into the dash-dot of code, and the telegraph keys sent the signals on the circuits at a rate of twenty-five to thirty-five words a minute. In member newspaper offices along the line the Morse sounders clack-clacked busily and receiving operators translated the code symbols back into words, copying the stories in jerky spurts. The news of more than half a century had been handled that way.

For some time, however, Charles L. Krum, a Chicago cold-storage engineer, and his son Howard had been working to perfect an automatic machine which would send the printed word by wire at greater speed without the intermediary of code. They called their invention the Morkrum Telegraph Printer—coining the word Morkrum by combining the inventor’s name with the first syllable in the last name of Joy Morton, a Chicago businessman who financed them.

Fig. 6 A SENDING OPERATOR SAT AT A KEYBOARD LIKE THAT OF A TYPEWRITER.Reproduced from AP—The Story of News, by permission of Associated Press.

21Several other automatic telegraphic devices were being promoted, but (Kent) Cooper and engineers in the Traffic Department decided Krum’s machine held the most promise for their purposes. Tests got under way. In the Associated Press headquarters, which had been moved seven blocks from the old Western Union building to 51 Chambers Street, a sending operator sat at a keyboard similar to that of an ordinary typewriter. As he struck the keys, copying the dispatches before him, the machine perforated a paper tape with a series of holes, each combination representing a letter. The tape fed into a box-like transmitter which transformed the tape perforations into electrical impulses and sent them along the wires into the receiving machines in newspaper offices. These impulses actuated telegraph relays and set the receiving Morkrum machines automatically reproducing the letters which the sending operators were typing miles away.

The tests demonstrated that the Morkrum could transmit news hour after hour at the rate of sixty words a minute and the copy was delivered clean and uniform. Thus began the slow extension of Morkrum transmission to the whole leased wire system, replacing the “brass pounding” Morse keys. It was a transition that required years and until it was completed both Morse and Morkrum worked side by side in many places.

An interesting story appeared recently in “The AP World,”[5] giving some recollections of AP’s first field maintenance man, Royal (Roy) Bailey, then aged 71 and living in retirement in California. He still remembers the AP’s first printing telegraph machines, the article says; in fact, he helped make them, for he was a mechanic in the Morkrum Company’s factory in Chicago. When the Morkrum Company shipped the first machines to AP headquarters, Bailey went along with the machines to install and maintain them, although he remained on the Morkrum Company’s payroll. He eventually installed AP printers all over New York City and Connecticut, in Newark, Philadelphia, Baltimore and Washington, and in Chicago, St. Louis and Kansas City. He recalls that Morse telegraphers “used to groan when they first saw him.” The early teleprinters were hard to keep synchronized, Bailey further recalls, and copy boys had to check the speed frequently by sighting the striped motor flywheel through a tuning fork. (Many of those copy boys, he says, including Mickey Burt and Henry Elling, became AP engineers.)

As the experimental and developmental work continued at the Morkrum plant, Howard Krum studied all types of start-stop systems and found that synchronous control was the basis of all systems. After experimenting with various ideas his thoughts turned to a plan to make the start of the 22 receiving unit somewhat independent of the transmitting unit start, thus avoiding irregularities then present in transmitter start devices. This idea led to the construction of a permutation-code, start-stop system, using segmented commutators with rotating brush distributors at both transmitting and receiving units and a start magnet for each to control start-stop operation.

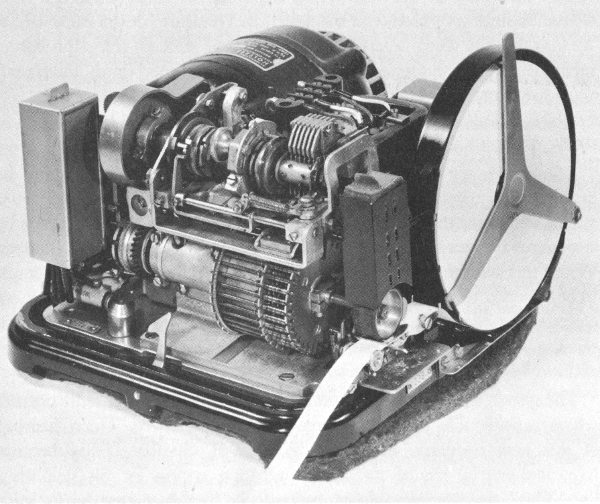

In this system the transmitter start magnet, when energized, releases the transmitting brush, which immediately contacts the first segment to transmit a start pulse to operate the receiver start magnet; the five-unit-code signal combination follows and both transmitting and receiving units are stopped. The apparatus was applied to control the selecting and printing mechanism of the Blickensdoerfer typewheel typewriter and named the “Morkrum Green Code.” This improved apparatus soon replaced the Blue Code printer at Associated Press and other installations (see figs. 7 and 7A).

In this connection the following additional comments of Mr. Bailey may be of interest:[6]

In 1919 I installed the New York-Washington circuit, with drops at Philadelphia and Baltimore. This was a new type of printer using what we called the Green Code. This was considered an improvement over the old Blue Code, which meant a rearrangement of the receiving mechanism, but still the machines made use of a typewheel....

Our biggest job of all came in 1923 when we changed over all the old Blue Code typewheel printers in the New York area to the new style L. C. Smith typebar printers using Green Code. (Morkrum bought L. C. Smith typewriters and added new machinery to them. Those printers became the famous Model 12.)

As we have seen, a number of inventors had patented ways and means to adopt the five-unit code for operating a telegraph printer system by the transmission of a start pulse to start both transmitting apparatus and the distant receiving apparatus at the same time, followed by transmission of a selected code and a stop pulse. To achieve successful operation, very close speed adjustment was required. At first, this was achieved by the use of governed motors and, later, when accurately timed, 60-cycle alternating current became available, the problem of synchronous operation of send and receive stations was solved by the use of synchronous motors.

Fig. 7 Morkrum Company’s Blue Code Typewheel Page PrinterPicture through courtesy of Teletype Corporation

Fig. 7A Morkrum Company’s Green Code Typewheel Page PrinterPicture through courtesy of Teletype Corporation

Telegraph printer systems of this type were used by telegraph companies for city-to-city transmission of telegrams and by news-gathering and -distributing organizations to transmit the news from headquarters to newspapers in different cities. While start-stop systems of this type were used successfully on press circuits and on telegraph message station-to-station circuitry, trouble was experienced when a number of printer send-receive units were set up in an intercommunicating system. Here it was found that the receiver start was not always in time with the transmitter start, due to varying line circuit conditions and a variation in the start release mechanism at connected stations.

It seems odd that synchronous systems, where both transmitter and receiver were started at the same time (requiring both transmitter and receiver to maintain synchronism), held the field for so long a time, thus limiting telegraph transmission to one-way operation.

It evidently took a mind not bound or hampered by the standard and accepted way of operating synchronous systems to discard such old ideas and to set forth boldly on a new pattern which, in reality, differed but slightly from the then-established synchronous systems, and to sow the seed for starting further developments leading to the present telegraph typewriter, TWX, and TELEX intercommunicating systems. Such a man was Howard L. Krum, who, in further thinking on the subject, came upon the almost simple idea of having the transmitter start the receiver rather than having them both start at the same time. This arrangement required higher speed operation of the receiver and therefore the receiving code pulse positions were spread over a shorter area, which meant progressively decreasing the angular division of the receiving members. Then, to set the received start pulse in the most favorable position with relation to the following code signal reception, an orientation adjustment of the receiver start position was provided.

(Note: On June 20, 1961, Kleinschmidt wrote to Howard Krum—then in retirement in California—giving a short description of the Morkrum Company activities, including the wording of the above last two paragraphs, and asking him to write the Morkrum story. Howard Krum replied on July 3, 1961, indicating his approval and saying that he would be glad to put together some notes for Kleinschmidt. It was quite a shock, therefore, when a letter was received from Howard Krum’s son, Charles, in September of 1961, telling of his father’s sudden serious illness. Then, regretfully, it was not long afterwards that 25 word was received of Howard Krum’s death on November 13, 1961.)

Fig. 8 Morkrum Company No. 12 Typebar Page PrinterPicture through courtesy of Teletype Corporation

Howard Krum’s improved method for operating start-stop, permutation-code telegraph systems was first applied to the Morkrum Green Code apparatus to control the selecting and printing operations of the Blickensdoerfer typewheel typewriter.

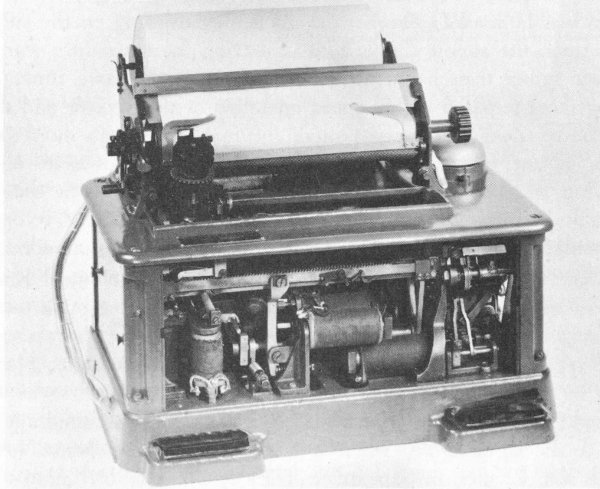

At this time the Kleinschmidt company and other manufacturers were starting to produce permutation-code, start-stop telegraph printers using typebar printing like the more modern typewriters which began rapidly to replace the Blickensdoerfer, the Hammond, and the other typewheel printing typewriters. Observing this situation, the Morkrum Company started intensive development work to produce the No. 12 typebar page printer, using the typebars and operating mechanism of the L. C. Smith typewriter and platen of a Woodstock typewriter (fig. 8).

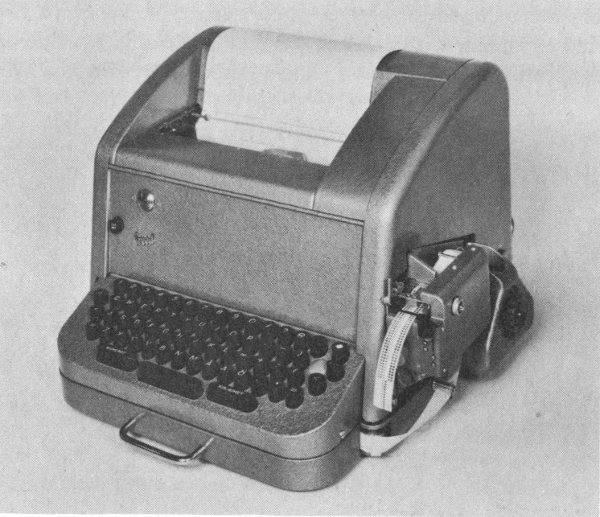

Further developments produced the Morkrum No. 11 tape printer which used the Baudot combiner method for selecting and printing 26 characters under control of start-stop, send-receive devices. The No. 11 was a small, compact tape printer operating at fifty words per minute. Quite a number were put into service at hotels and elsewhere for local message service (fig. 9).

Fig. 9 Morkrum Company No. 11 Tape PrinterPicture through courtesy of Teletype Corporation

The new No. 12 typebar page printer found numerous applications. It replaced the Green Code and the earlier Blue Code wherever used. The new No. 12 was installed at Western Union, on some railroads, and in the Chicago Police telegraph system. The No. 12s were also installed by Postal Telegraph on intercity circuits and used as receiving units for the Postal Multiplex. The Postal Multiplex had been designed by Morkrum and Postal engineers with the consultant assistance of Donald Murray who was a friendly associate and had a license agreement with the Morkrum Company covering some of his patents. A few No. 12 Morkrums were shipped abroad for use with the Murray Multiplex; the British Post Office Telegraph and the Australian Telegraph Administration were customers.

Late in 1924 the Morkrum Company and the Kleinschmidt Electric Company joined to form the Morkrum-Kleinschmidt Corporation. A story telling of the union of these two companies was published by Fortune magazine in March of 1932.[7]

Before going to that story, it may be of interest to describe an important event concerning the change in the supply of electric power from direct current to 60-cycle alternating current and the final timing to exactly 60 cycles per second of all A.C. power supplies so that our electric clocks may be connected to an A.C. outlet and give correct time.

The advent of correctly timed, 60-cycle A.C. electric power, available throughout the nation, was a great boon to the designers of printing telegraph apparatus and some types of facsimile telegraph and picture transmitting systems. In prior years, overline synchronization of send and receive apparatus was always a problem and never perfect. Today, synchronizing apparatus between terminals becomes the simple matter of providing 60-cycle A.C. synchronous motors. Just plug into a power outlet and you have “sync”!

Henry Ellis Warren, a clock maker, noting the change in electric power service from direct current to 60-cycle alternating current, set about to build a motor to operate at 60-cycle speed but found that the 60-cycle frequency did not always hold to form, and when applied to running a clock, did not hold correct time.

The following excerpt, from The Romance of Time,[8] tells of Warren’s activities which led to synchronizing 60-cycle alternating current to exact time:

Synchronous Electric Time

One of the most important of all contributions to horology is the work of an American who has earned the title, “Father of Electric Time.”

Henry Ellis Warren was graduated from Massachusetts Institute of Technology in 1894. In 1907 he married and settled in Ashland, Massachusetts. Here it was that he began to work out his idea for electrically operated timepieces.

His first product was an ingenious battery-operated clock. In 1914 he organized the Warren Clock Company and set up production in a barn on his farm. Yet he knew the battery clock was not his goal, for direct current offered no means of accurate regulation. Direct current flows constantly 28 in one direction only, like water down a river or like the passage of time. On the other hand, alternating current changes direction regularly, like the oscillation of the balance wheel in a watch. But instead of the usual five times a second of the balance wheel, most alternating current completes its trip forward and backward sixty times a second. Obviously, a clock “geared” to such a frequency would run as reliably as the current.

In 1916, after several years of extensive experimentation, Warren developed a motor which would start by itself, run on alternating current, and carry without difficulty the load of reduction gears driving the clock hands. It could also handle the cams and contacts of an alarm clock or set in motion a striking or chiming mechanism.

Then came the test. He plugged the clock into the power socket. It commenced to run. Weeks of observation and checking showed an irregular error of as much as ten to fifteen minutes a day.

Convinced that his clock was right, Warren discovered that the alternating current frequency delivered to his barn factory was off half a cycle per second—59½ and not 60 cycles. This slight deflection would produce that much time loss in a 24-hour run. When he informed the electric company of this error, he was met at first with polite disbelief. Yet he showed such a comprehensive knowledge of the subject that the company began to recheck their standards.

Warren built several more synchronous clocks and a master regulator of his own design for power-station use. On one dial of his master clock there were two hands, black and gold. The black hand was connected to an accurately adjusted pendulum clock, beating seconds. The gold hand was driven by the gear train of one of his electric clocks. As long as the two hands revolved together, the current cycles were exactly 60 per second. Set up in a power station, this allowed the operator to adjust the turbine generators as needed to keep the two hands of the master clock together. Thus all other properly set electric clocks on the same system would keep the same time automatically.

The Edison Electric Illuminating Company of Boston tried out the master clock on October 23, 1916. Since then this regulation has continued.

Other power companies adopted Warren’s master clock. Today virtually all alternating current furnished in America is similarly checked. Practical electric time is available at the light socket almost everywhere. But there are additional benefits.

Standardizing the frequency expanded the market for current to run the increasing number of clocks in use. Yet, from the consumer’s point of view, each clock draws little current, costing but a few pennies a month. Uniform frequency also gave more even speeds in motor-driven machinery, with a resultant improvement in product. It made easier the joining of 29 one power station to another. Synchronous motors used in certain meters and recorders produced better, more accurate records at lower cost.

The Warren enterprise expanded rapidly. The battery clock was discontinued. The red barn was no longer large enough, and new space was acquired. The trade mark “Telechron,” meaning “time from a distance” (from two Greek words), was used to identify all products of the company. The firm name was changed to stress the name Telechron, and in 1952 a merger was made with the General Electric Company. Plants are now operated in Worcester as well as in Ashland, Massachusetts.

And now back to the telegraph field....

During and after the first world war, both the Morkrum Company and the Kleinschmidt Electric Company were progressively developing and producing telegraph apparatus and bringing out new and improved operating devices to a point where conflicting patents were at issue. This meant infringement litigation which might destroy both companies. Neither company could obtain orders in sufficient quantity to make the manufacturing of apparatus profitable, and, with costly development work at hand, more capital investment was a continuous requirement.

The following excerpts from the March 1932 issue of Fortune[9] tells of the final joining of the two companies.

The Morkrum Co. had no profits to show for its efforts, and one can be fairly safe in assuming that no other maker of telegraph printers made profits. There were competitors, of course. Even the first telegraph invented by Samuel Morse had a printer, but it printed in dots and dashes instead of in letters of the English alphabet. That original Morse printer was abandoned as far back as 1844 because a man who could be trained to read dots and dashes could just as easily be trained to listen to them. The problem of getting a printer to print the alphabet was faced by inventors more than half a century ago, and it was not really a difficult problem. The difficulty was to invent a printer that was not too complicated and delicate to be reliable, that was simple enough to be manufactured for a few hundred instead of a few thousand dollars.

This difficulty occupied many minds other than the Morton-Krum intelligences. The most noteworthy of Morkrum Co.’s rivals in printer-making was Edward Kleinschmidt, an inventor who had all the inventor’s legendary devotion to his task and to nothing else. His creations included a vaccination shield, an automatic fishing reel, and the perfection of the Wheatstone perforator. He had been tinkering with a telegraph printer in one form and another since the beginning of the century. In 1917 his project was revamped. It had the financial backing of Charles B. Goodspeed, of the Buckeye Steel Casting Co.; Paul M. Benedict, assistant to the president of the C. B. & Q.; Edward Moore, son of Judge Moore of American Can fame; 31 Eldon Bisbee, a New York lawyer; and one of Mr. Bisbee’s legal clients, Albert Henry Wiggin, then president of the Chase National Bank. It was Mr. Goodspeed, a quiet, retiring gentleman, who supplied most of the corporate (as distinct from inventive) energy of the Kleinschmidt Electric Co....

In the years from 1917 to 1924 the Kleinschmidt and the Morkrum companies became the leading makers of telegraph printers, but they did not have an easy row to hoe. Their only possible customers were the two great telegraph companies, the Telephone company, the railroads, and an occasional outside business such as a press association. The competition was disheartening, and it became keener with the elevation of Sterling, son of Joy Morton, to the presidency of the Morkrum Co., an elevation that was mainly a War-time accident, for Sterling Morton had resigned from his father’s company to enlist in the Army, had been rejected because of a small steel plate in his anatomy, and had chosen the Morkrum Co. as an alternative. Engineering progress was made, sometimes under ludicrous circumstances.

There was one occasion when Sterling Morton, about to sail for Europe, heard that the Kleinschmidt Co. was about to bring out a simplex printer. Up to that time both companies had been making printers for use with multiplex machines. Mr. Morton was afraid that Mr. Kleinschmidt was about to anticipate him in the simplex development which was the forerunner of the present teletypewriter. This was a contingency which Mr. Morton could not well permit. On the spur of the moment, he called on Howard Krum, who happened to be in New York. They bought a drawing board, hired a room at the Princeton Club, and worked for twenty-four hours trying to design such a machine. Completely baffled by one small detail, they gave up and took a bus for Coney Island. On the way, Howard Krum doubled up in sudden ecstacy and inspiration. They rushed from the bus at Coney Island, entered a soda fountain, and on the spot designed the machine on the back of an envelope. This simplex machine of the Morkrum Co. and the one developed by Kleinschmidt at the same time are the machines which make Teletype commercially important, the substance of the business today.

But engineering progress was not business progress. Both companies from the standpoint of profits were failures. Their few customers played them off against each other. In despair, they were both willing to sell out. At one point Mr. Goodspeed offered the Kleinschmidt company to Mr. Newcomb Carlton of Western Union for $412,000, the amount invested in it. Mr. Morton sold his company in all but fact to Mr. Charles G. du Bois, then president of Western Electric, but Mr. du Bois went off to Europe, and his substitute refused to see any merit in the deal. So it fell through. Unable to sell themselves to their customers, they tried selling themselves to each other. In 1923 Messrs. Goodspeed and Morton came to terms. The Morkrum Co. signed the agreement and, everything arranged, Mr. Goodspeed 32 went off to bicycle with his wife in South Africa—whereupon his company suddenly changed its mind.

That was the situation of these two unfortunate companies in 1924 when Mr. Morton started a suit for patent infringement against his rivals. A counter suit was promptly filed. Mr. Goodspeed was quite right when he said the suits would ruin both—there was every prospect that by the time the courts had settled things, the patents would have been in such a snarl that neither could do anything. The suit, in fact, was Sterling Morton’s way of bringing matters to a head. So, figuratively speaking, on the courthouse steps they merged.

The terms of the merger as embodied in the six-line agreement (it was later made over into a twenty-five-page legal document which concluded by saying that in case of dispute the six-line agreement should be the final authority) were these: each of the old companies received a half interest in the common stock (10,000 shares) of the new company; 15,000 shares (callable at 105) of the new company’s preferred stock should be divided according to the assets of the old companies. Actually, 13,979 shares of preferred were issued, the majority going to the Morkrum group.

And so it was that the agreement to join both companies under the name Morkrum-Kleinschmidt Corporation was consummated and chartered in the State of Delaware on December 29, 1924, with Sterling Morton as President, Howard L. Krum as Vice President in charge of manufacturing, and Edward E. Kleinschmidt as Vice President in charge of development, patents and foreign sales.

One of the first decisions to make was whether the Kleinschmidt plant in Long Island City or the Morkrum plant in Chicago would be the headquarters for the new company. The Kleinschmidt company was on a 27,000-foot leased floor in a building which R. H. Macy Company had just purchased to use for a warehouse, and negotiations had been going on for some time for the purchase of the Kleinschmidt lease—the sum of $25,000.00 having been offered. When the union of the two companies was decided upon, an agreement to vacate on the terms offered was signed, and the Kleinschmidt firm moved to the Morkrum-owned plant in Chicago.

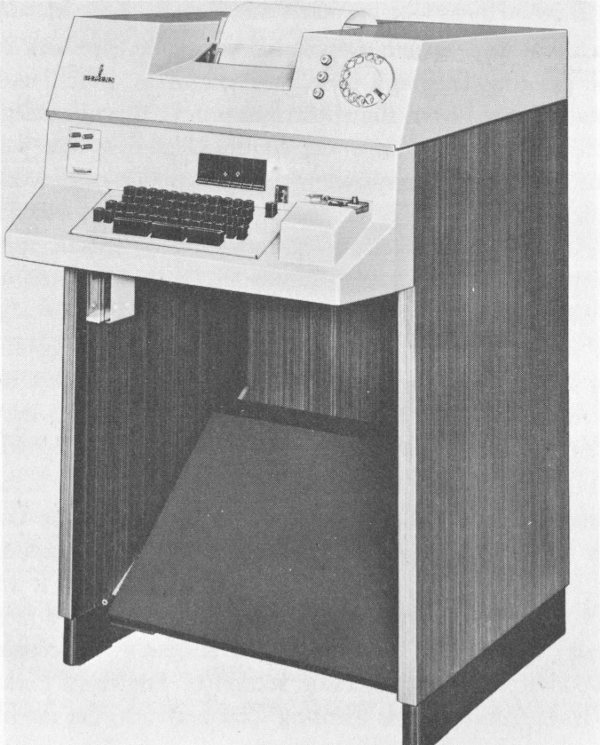

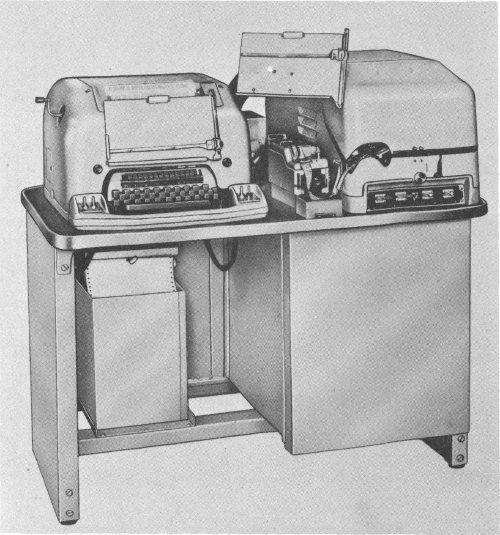

Fig. 10 Morkrum-Kleinschmidt Corporation No. 14 Start-Stop Typebar Tape PrinterPicture through courtesy of Teletype Corporation

Bringing together the engineering talent and patents of the two companies had an immediate effect toward further progress. The first thing the new company set out to do, through consolidation of their past efforts, was to perfect a satisfactory start-stop-operated tape printer for the Western Union Telegraph Company to use for circuit extension to customers who were extensively using the telegraph for immediate, written communication. (This was to speed up telegraphic communication and eliminate the need for messenger service which had been the custom.) The Morkrum company had submitted their start-stop-operated Baudot tape printer, and the Kleinschmidt company had proposed the Western Union No. 22 tape printer in a redesign to start-stop operation. Now, the new company was able to combine both plans and as a result came up with their first development, a typebar, start-stop-operated, tape printer, the No. 14 (see figure 10). In the final design, Howard Krum and his production engineers took a large part. After tests and evaluation, Western Union’s first order was for 10,000 machines at $317.00 each. This amounted to a total of $3,170,000.00. No such quantity had ever been heard of before!

It is quite evident that while the two companies were separated, each coming up with improved and new designs of telegraph apparatus, there was a lack of decision by telegraph companies as to which type of apparatus to adopt in expanding their operations, and therefore they did not buy in quantity. The largest previous order to the Kleinschmidt Electric Company was for 800 No. 22 typebar tape printers for the Western Union Multiplex.

At Morkrum-Kleinschmidt more space was needed. The corner property on Wrightwood Avenue adjoining the Morkrum plant was purchased, and a four-story building was erected.

The design of a telegraph typewriter that would be more efficient and require a minimum of maintenance service was the most important project, and Morkrum-Kleinschmidt was working with Bell Laboratories engineers endeavoring to meet all the requirements of the Bell Telephone system. A typebar printer with a stationary printing platen and moving typebar printing unit was specified. These requirements were finally met with the design of the No. 15 page printer to operate at 60 words per minute, and manufacture of this apparatus was started in 1927 (see figure 11). The No. 15 page printer became the standard for nationwide intercommunicating telegraph service for many years.

In 1926, soon after the No. 14 tape printer was put into service, Morkrum-Kleinschmidt received a request from the police department of Berlin, Germany, for detailed information, stating that they were interested in the purchase of about sixty No. 14 printers. The letter asked if Morkrum-Kleinschmidt was represented by an agent in Germany whom they could contact. At an executive meeting, Mr. Morton and Mr. Krum asked Mr. Kleinschmidt to take care of this matter since his company, before joining them, had sold apparatus in some foreign countries. After further correspondence with the Berlin police officials, Kleinschmidt decided personally to take a No. 14 printer to Germany and arrange for a representative there. After visiting and conferring with several companies experienced in the telegraph and associated apparatus field, a satisfactory arrangement was consummated with the C. Lorenz Company, on October 25, 1926, for the manufacture and sale of Morkrum-Kleinschmidt equipment in Germany, on a royalty-licensing basis. At that time the Lorenz company manufactured telegraph and telephone equipment and railway signaling apparatus. Their engineering department was under the supervision of Dr. Gerhard Grimsen who took the matter in hand for further exploitation toward an intercommunicating printing telegraph system, using the No. 15 page teletypewriter. Siemens & Halske, the principal manufacturers of telegraph equipment in Germany, were also licensed by the Morkrum-Kleinschmidt Corporation, on June 1, 1929, with the consent of the Lorenz company.

Fig. 11 Morkrum-Kleinschmidt No. 15 Page PrinterPicture through courtesy of Teletype Corporation

(As may be seen in the following chapter, it was these licensing arrangements which led to the establishment of the TELEX intercommunicating teleprinter system in Europe.)

In early 1927 the well-known newspaper publisher, Mr. Frank E. Gannett, came to Morkrum-Kleinschmidt, bringing his company’s engineer, Mr. Walter Morey, who had heard of various attempts to operate a typesetting machine, such as Linotype or Intertype, directly from the telegraph. Mr. Gannett said, “We have telegraph typewriters in our news rooms that record the news as transmitted from the Associated Press and the United Press, and that is fine. Now, why not go a step further and operate our typesetting machines directly from the telegraph circuit? If you can develop such a device, I will help finance the project.”

Indeed, after some study of the matter, the possibility of devising such a system seemed entirely feasible and the development of suitable apparatus was turned over to the research and development department. A workable plan was soon put together and a separate company, the Teletypesetter Company, was organized, with Mr. Gannett joining financially. Edward Kleinschmidt was elected president. Development proceeded and a complete set of apparatus was set up and publicly demonstrated for the first time on December 6, 1928, at one of Mr. Gannett’s newspapers, The Times Union of Rochester, New York. Teletypesetter equipment was subsequently manufactured for several installations. After the Western Electric Company purchased the Teletype Corporation in 1930, the Teletypesetter Company was sold to the Fairchild Company. Teletypesetter equipment is now in universal use by most newspapers and the larger printing companies.

During the period that the United States’ business cycle was on a continuous upswing (during the late 1920s), securities sales on the New York Stock Exchange were going to constantly higher volume, and the old step-by-step stock ticker did not, by large margins, keep pace in recording stock share transactions. There was a cry for a higher speed stock 37 ticker; in fact, the Stock Exchange officials told Morkrum-Kleinschmidt that they would be happy to convert the entire system if they could get higher speed.

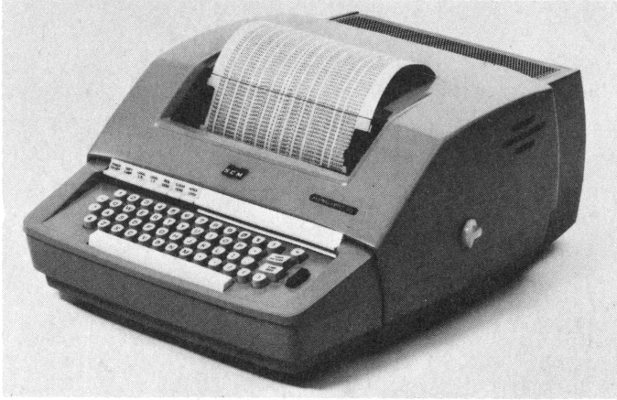

An adaptation of the five-unit-code, start-stop system seemed the solution and the Research and Development department set out to develop suitable apparatus. Several ideas were studied and, because of the frequent changes from letters to figures, requiring printing in separate rows on the tape, a six-unit code was adapted instead in which combinations for a figure included the sixth selecting pulse to operate the figures print hammer and block the letters print hammer.

Fig. 12 Morkrum-Kleinschmidt Corporation Stock TickerPicture through courtesy of Teletype Corporation

The Morkrum-Kleinschmidt company was soon able to show the Stock Exchange people a stock ticker operating on a telegraph system that 38 worked at twice the speed of the step-by-step-operated tickers then in use. A speed of 500 printing operations per minute could be obtained, thus attaining a one-hundred-percent increase in the transmitting and recording of stock quotations on the tape (see figure 12). The Stock Exchange ticker service company ordered 15,000 of these high-speed tickers and the Western Union Telegraph Company also ordered a quantity for their national stock quotations distributing systems.

As business of the combined Morkrum and Kleinschmidt companies went along, it was thought that the name “Morkrum-Kleinschmidt Corporation” was a pretty big mouthful and that a simpler name more characteristic of its products would be better. The name “Teletype” was suggested, and in the year 1928 the name change to “Teletype Corporation” was made. The exact origin of the word “teletype” is not known but it is no doubt one of the abbreviated forms of the words “telegraph typewriter” which were used over the years. In literature, in the early 1900s, we find that the word “teletype,” in speaking of printing telegraph equipment, and other shortened forms, such as “telewriter” and “teletyper,” were used interchangeably.

Kleinschmidt’s son, Edward F., who studied electrical engineering at Steven’s Institute and at Northwestern University, was employed as development engineer by the Morkrum-Kleinschmidt company where he assisted in the design of projects at hand, and, during 1929, produced a system and apparatus for transmitting and recording printed characters by the successive transmission of dots arranged in a pattern to form letters. While this system required a higher signaling frequency, it was thought to be superior to permutation-code transmission over radio circuits where electrostatic interference is experienced, since, in the dot pattern transmission, electrostatic interference up to a degree will not change the readability of a transmitted letter.

The system was in test operation to prove its efficiency over radio circuits where considerable static interference was experienced. Upon hearing of this new telegraph for the radio, Mr. R. Stanley Dollar became interested in the use of this communicating system for his steamship line. There was considerable correspondence in this matter during mid-1930, just prior to the sale of Teletype; however, neither AT&T nor Western Electric was interested in further promoting this new radio telegraph, so the matter was dropped.

Business activities of Teletype Corporation were now growing rapidly and with good profit. The capital structure of 10,000 shares was wholly inadequate, so by a 15-to-1 stock dividend the capital structure was raised to 150,000 shares, and dividends on an annual basis of $12.00 were paid.

The successful development of apparatus for different applications useful in the telegraph field was largely due to the close cooperation between the research-development and the manufacturing departments of the organization. Howard Krum had expert engineers and designers in his department, Kleinschmidt brought his leading engineers and designers from the Long Island City plant, and there was a definite spirit of cooperation all around.

To quote again from the Fortune magazine story:[10]

As the years up to 1925, when the Kleinschmidt-Morkrum merger took place, were wanderings in a profitless desert, so the years from 1925 to 1930 found the teletype in a land of milk and honey. Mr. Morton, however, was inclined to think that a company which had only two or three major customers is not strongly placed. Furthermore (and by the spring of 1930), at least one of those customers was actively in the market as a Teletype purchaser. This buyer was Colonel Sosthenes Behn, whose International Telephone & Telegraph Co. includes Postal Telegraph at home in addition to many communication and manufacturing companies abroad. With Colonel Behn wanting to buy and Mr. Morton wanting to sell, negotiations rapidly proceeded to a point at which Mr. Morton, at least, thought the deal was almost concluded. But while Mr. Morton and the Colonel were discussing the prospective acquisition, into the Colonel’s office walked a man who has no other place in this story except that he happened to interrupt at this moment. As this gentleman was introduced, he asked whether Mr. Morton were related to Joy or Paul Morton. When Mr. Morton admitted that they were his father and uncle, the man turned to Colonel Behn and said in jest: “Better watch your step. That’s a smart family.” Only Colonel Behn knows whether he gave that remark any weight, but the point is that the negotiations suddenly collapsed, and that the visitor’s remark about the smart family still lives vividly in Mr. Morton’s memory.

This setback was not a setback at all to such a negotiator as Mr. Morton. Two months later, in May, 1930, you find him walking into the office of Clarence G. Stoll, vice president of Western Electric, A. T. & T.’s manufacturing subsidiary. This time there had been no preliminaries. Mr. Stoll rose from his desk and said: “Good morning. What can I do for you?”

“Do you want to buy Teletype?”

40“Is it for sale?”

“Yes, at a price.”

“All right. Let’s get down to business.”

They got down to business on the spot, and they remained at it for three solid days in Mr. Stoll’s office. The agreement as reached called for A. T. & T. to pay off the preferred stock of Teletype, 13,979 shares callable at 105, and to give one share of A. T. & T. in exchange for each common share of Teletype. The A. T. & T. shares were worth about $200, so the price came to upwards of $30,000,000—plus, of course, the $1,467,795 for retiring the Teletype preferred.