The Project Gutenberg EBook of Glass, by Edward Dillon This eBook is for the use of anyone anywhere in the United States and most other parts of the world at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org. If you are not located in the United States, you'll have to check the laws of the country where you are located before using this ebook. Title: Glass Author: Edward Dillon Release Date: September 16, 2014 [EBook #46877] Language: English Character set encoding: UTF-8 *** START OF THIS PROJECT GUTENBERG EBOOK GLASS *** Produced by David Garcia, Sonya Schermann, and the Online Distributed Proofreading Team at http://www.pgdp.net (This file was produced from images generously made available by The Internet Archive)

In two instances, the letter N has been printed with a macron above it. This has been represented as [=N].

Some presumed printer's errors have been corrected. These are listed in a second transcriber's note at the end of the text.

The Connoisseur’s Library

It is now nearly thirty years since the late Mr. Nesbitt wrote the introduction to the catalogue of the glass at South Kensington. Some years previously the description of the glass in the Slade collection had been intrusted to the same gentleman. Since that time many works treating of special departments of the history of glass have been published in France, in Germany, and in Italy. Much fresh light has been thrown upon the primitive glass of the Egyptians; our knowledge of the glass of both the Near and the Far East has been revolutionised; abundant fresh material has been provided for the history of Byzantine glass, and the wanderings of the glass-workers from L’Altare and Murano have been traced in full detail. Mr. Hartshorne, in his Old English Glasses, has exhaustively told the story of our native glass from the documentary side, and has described with the minutest detail the wine-glasses of the eighteenth century. Apart, however, from the introductory chapters of the last work, I know of no attempt of recent years to give a general account of the history of glass—using that term in the narrower sense—as viewed from the artistic side.

We have at hand in the British Museum a collection of glass that has no rival elsewhere; only second to it is the collection at South Kensington. It is in these collections that the history of glass must be studied. I have from time to time in the following pages called attention to the most remarkable examples. I hope that what I have said may assist the student in threading his way through what is a rather complicated history.

vi My best thanks are due to Mr. C. H. Read, who has charge of the glass in the British Museum, for the facilities that he has afforded me in the photographing of the examples in his department; not less to Mr. A. B. Skinner, director of the Victoria and Albert Museum, for similar facilities at South Kensington.

I am indebted to Professor Church for much valuable information and for some hitherto unpublished analyses of glass; to Lord Rothschild and to Mr. Vincent Robinson, C.I.E., for photographs of examples of glass in their collections; finally, to Signor Ongania, of Venice, for permission to reproduce from Passini’s great work on the Treasury of St. Mark’s some photographs of the glass there preserved.

| PAGE | |

| Preface, | v |

| List of Illustrations, | ix |

| Selected Bibliography of Works on Glass, | xxii |

| Key to the Bibliographical List, | xxviii |

| Chapter I. Introduction, | 1 |

| Chapter II. Primitive Glass of the Egyptians and Syrians, | 18 |

| Chapter III. Later Greek Glass and the Moulded and Cast Glass of the Roman Empire, | 43 |

| Chapter IV. The Blown Glass of the Roman Empire, | 59 |

| Chapter V. Early Christian Glass, Byzantine Glass, and the Glass of the Middle Ages in the East and the West, | 89 |

| Chapter VI. Glass from Anglo-Saxon and Frankish Tombs. The so-called Hedwig Glasses, | 107 |

| Chapter VII. Mediæval Treatises on Glass, | 118 |

| Chapter VIII. Glass of the Later Middle Ages in Western Europe, | 132 |

| Chapter IX. The Enamelled Glass of the Saracens, | 144 |

| viii Chapter X. The Enamelled Glass of the Saracens (continued), | 161 |

| Chapter XI. The Glass of Venice—The Origins—Beads, | 174 |

| Chapter XII. The Enamelled Venetian Glass of the Fifteenth Century, | 192 |

| Chapter XIII. Varieties of Venetian Glass—Early Literature, | 200 |

| Chapter XIV. The French Glass of the Renaissance, | 220 |

| Chapter XV. The Renaissance Glass of the Spanish Netherlands and of Spain, | 240 |

| Chapter XVI. The Glass of Germany. The Green Glass of the Rhine and the Netherlands—Enamelled Glass, | 251 |

| Chapter XVII. The Glass of Germany (continued). German Cut and Engraved Glass—The Ruby Glass of Kunckel—Milch Glass, | 276 |

| Chapter XVIII. Dutch Glass of the Seventeenth and Eighteenth Centuries, | 294 |

| Chapter XIX. English Glass of the Sixteenth and Seventeenth Centuries, | 299 |

| Chapter XX. English Glass of the Eighteenth Century, | 321 |

| Chapter XXI. The Seventeenth and Eighteenth Century Glass of Persia, India, and China, | 337 |

| Chapter XXII. Contemporary Glass, | 356 |

| Index, | 361 |

| I. | Syrian or Venetian Glass. Enamelled Beaker of slightly greenish glass with a few elongated bubbles. (H. 71⁄2 in.) The Virgin and Child enthroned between conventional lilies; on either side an angel holding a tall candle; beyond, the figures of St. Peter and St. Paul. Above, an inscription in Gothic characters—D[=N]IA MATER REGIS ALTISSIMI ORA P PA. From the Adrian Hope collection. End of thirteenth century. British Museum. | |

| (Frontispiece.) | ||

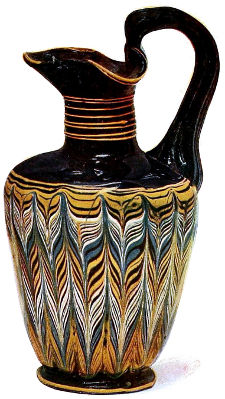

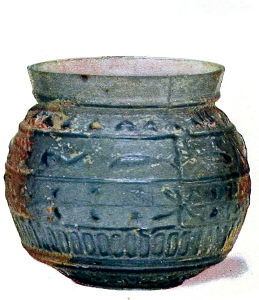

| II. | Unguentaria of Primitive Glass. British Museum. | |

| (1) From Gurob, near Illahun, Upper Egypt. (H. 4 in.) Decoration of palm-pattern formed by double drag, on a sard-coloured translucent ground. Nineteenth Dynasty. | ||

| (2) Amphora-shaped vase. (H. 53⁄8 in.) Pattern formed by simple drag, on opaque red ground. The body apparently turned on wheel. Handles of green transparent glass. Said to come from the Ionian Islands. | ||

| (3) Small Jug of Oenochoë shape. (H. 51⁄2 in.) Palm pattern formed by double drag, on dark blue, nearly opaque ground. Provenance uncertain. From the Slade collection. | ||

| (To face p. 22.) | ||

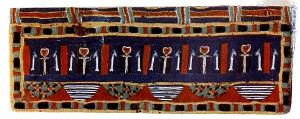

| III. | Egyptian Glass Pastes. British Museum. | |

| (1) Scarab of dark blue paste with white veins imitating lapis lazuli. (L. 31⁄2 in.) From Thebes. Later Empire. | ||

| x | (2) Vase for cosmetics, in shape of column with papyrus capital. (H. 33⁄4 in.) Slade collection. | |

| (3) Plaque of ‘fused mosaic.’ (L. 31⁄4 in., about 3⁄8 in. in thickness.) From the cemetery at Denderah. Ptolemaic period. | ||

| (To face p. 32.) | ||

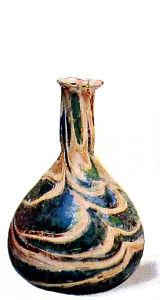

| IV. | (1) Small bottle (‘lachrymatory’). (H. 3 in.) Glass of various colours arranged in wavy lines, and now in part iridescent. Probably from a Greco-Roman tomb. Slade collection. | |

| (2) Bowl of thin white glass, finished on the lathe. (Diam. 33⁄4 in.) Probably from a late Greek tomb. | ||

| (3) Spherical vase of pale blue transparent glass. (H. 33⁄8 in.) The mark of the two parts of the mould into which the glass was blown is visible. Decoration of dolphins, fishes, etc., on bands. Probably Roman, first century A.D. Slade collection. 1, 2, and 3, all in British Museum. | ||

| (To face p. 45.) | ||

| V. | Two Bowls of Millefiori Roman Glass. Probably Roman, first century A.D. British Museum. | |

| (1) Madrepore pattern, in dark purple ground. (Diam. 5 in.) | ||

| (2) Breccia pattern, in purple ground with white scrolls. From the Durand collection. (Diam. 51⁄4 in.) | ||

| (To face p. 50.) | ||

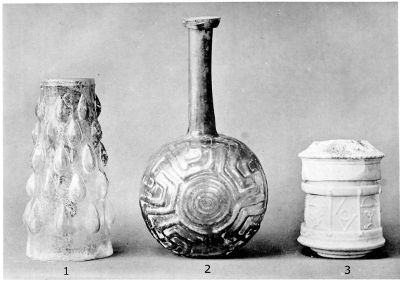

| VI. | (1) Beaker with oval bosses, formed by blowing into a mould with apertures. (H. 5 in.) Clear white glass. Said to have come from Constantinople. Greco-Roman, first century A.D. | |

| (2) Tall-necked flask of pale green transparent glass. (H. 63⁄4 in.) Maze-like pattern, formed by blowing into mould. Greco-Roman. From Melos. | xi | |

| (3) Small octagonal pyx, or case for cosmetics. (H. 61⁄4 in.) White opaque glass (but probably originally transparent); blown into mould. From Sidon. Probably first century B.C. 1, 2, and 3, all in British Museum. | ||

| (To face p. 56.) | ||

| VII. | Sepulchral Glass From the Syrian Coast (said to come from Mount Carmel). Probably about first century B.C. Pale green glass, with iridescence. British Museum. | |

| (1) Vase for cosmetics in shape of double column. (H. 51⁄4 in.) | ||

| (2) Vase with six handles. (H. 41⁄4 in.) | ||

| (3) Vase with handles and stringings of cobalt-blue. (H. 8 in.) | ||

| (To face p. 60.) | ||

| VIII. | Bowl of Olive-Green Glass, carved in high (detached) relief. Mounted on metal stand and with metal rim. Deep red by transmitted light. Subject—The Madness of Lycurgus. Probably Roman, about third or fourth century A.D. From the collection of Lord Rothschild. | |

| (To face p. 73.) | ||

| IX. | Roman Glass from Graves in Britain. British Museum. | |

| (1) Jug of pale olive glass, with iridescence. (H. 83⁄8 in.) From Colchester. | ||

| (2) Vase of olive-green glass, with two handles, each ending in quilled attachments. (H. 9 in.) From Bayford, near Sittingbourne. | ||

| (To face p. 86.) | ||

| X. | Gilt Glass of the Cemeteries. Fifth century A.D. British Museum. | |

| (1) Part of a bowl, the sides ornamented with xii small medallions of gilt glass. Subjects—Adam and Eve, Sacrifice of Isaac, Jonas, the Three Children, Daniel, etc. (Max. dimension, 61⁄2 in.) Found near the Church of St. Severinus, Cologne. | ||

| (2) Disc from base of bowl. (Diam. 33⁄4 in.) Below, Christ, between Timothy and Hippolytus; above, St. Paul, St. Sixtus, and St. Laurence, standing between torque columns. | ||

| (3) Portraits of Bride and Bridegroom—Orfitus and Constantia; with figure of Hercules and congratulatory inscription. (Diam. 4 in.) | ||

| (To face p. 91.) | ||

| XI. | Byzantine Glass, from the Treasury of St. Mark’s, Venice. (Reproduced from Passini, Tesoro di S. Marco.) | |

| (1) ‘Balance-pan’ lamp of clear glass for suspension. On the silver rim, an invocation to St. Pantaleone by the Bishop of Iberia. (Diam. 101⁄2 in.) | ||

| (2) Ellipsoid lamp, for suspension. Common glass, carved in high relief with shells, fishes, etc. Silver rim, with cloisons for jewels and sockets for candles. (Chief diam. 8 in.) | ||

| (3) Paten, or more likely ‘balance-pan’ lamp. Greenish glass, incised with a series of concentric rings. (Diam. 7 in.) | ||

| (To face p. 96.) | ||

| XII. | Cantharus-shaped Vase of sky-blue, bubbly glass. (H. 61⁄4 in.) Probably a chalice. Circa fifth century A.D. Found at Amiens. From the Pourtalès collection. British Museum. | |

| (To face p. 98.) | ||

| XIII. | Byzantine or Early Saracenic Glass, from the Treasury of St. Mark’s, Venice. (Reproduced from Passini, Tesoro di S. Marco.) | |

| Pear-shaped vase, set with ‘false’ metal spout and handle, to resemble an ampulla. Carved in xiii low relief, in imitation of rock-crystal—design of two sheep-like animals amid conventional foliage. (Glass alone 4 in. in H.) | ||

| (To face p. 101.) | ||

| XIV. | Byzantine or Late Roman Glass, from the Treasury of St. Mark’s, Venice. (Reproduced from Passini, Tesoro di S. Marco.) | |

| Situla of greenish glass, carved in high (detached) relief with a hunting scene. Below, a raised grating, supported on rods of glass (diatretum work). H. 11 in. | ||

| (To face p. 102.) | ||

| XV. | Glass Beads. British Museum. | |

| (1) Cylindrical beads with white and yellow pellets: (i) Blue glass with satyr-like mask; (ii) opaque greenish glass. Probably from Cyprus. Greek or Phœnician. | ||

| (2) Two Chevron beads. Provenance uncertain. Slade collection. | ||

| (3) Three chains of beads, from Frankish tombs in the Rhine-Moselle district. | ||

| (To face p. 108.) | ||

| XVI. | Anglo-Saxon Glass. Prunted Beaker of olive-green glass. (H. 111⁄8 in.) From burial-mound, Taplow. British Museum. | |

| (To face p. 111.) | ||

| XVII. | Anglo-Saxon Glass. (1) Conical cup of pale green glass, with applied threadings. (H. 101⁄4 in.) From Kempston, Bedfordshire. British Museum. | |

| (2) Drinking-cup of olive-green glass. (H. 81⁄2 in.) From Faversham, Kent. British Museum (Gibbs Bequest). | ||

| (To face p. 112.) | ||

| XVIII. | Hedwig Glass (so-called). Two views of a cup of nearly colourless glass (H. about 4 in.), carved in relief with lion, griffin, and shield. German or Oriental; thirteenth century, or perhaps earlier. xiv Now mounted on Gothic metal stand, which is not shown. Germanic Museum, Nuremberg. | |

| (To face p. 114.) | ||

| XIX. | Mediæval Glass Furnace. Reproduction of a coloured miniature from a manuscript, written probably in 1023, of Rabanus Maurus (De Originibus Rerum), preserved in the library at Monte Cassino. | |

| (To face p. 124.) | ||

| XX. | German Glass, Fourteenth and Fifteenth Century. Dark bluish-green glass, from the Germanic Museum, Nuremberg. | |

| (1) Prunted cup for holding relics. | ||

| (2) Wax cover to above, with seal of the Abbey to which it belonged. | ||

| (To face p. 137.) | ||

| XXI. | Do. do. | |

| (1) Small cup with pap-shaped prunts. | ||

| (2) Cup with conical cover, containing relics. | ||

| (To face p. 137.) | ||

| XXII. | Saracenic Glass. Pilgrim bottle; brownish, amber-coloured thick glass, enamelled and gilt. (H. about 8 in.) On the flattened back a rose-wheel design. Long preserved at Würzburg; said to come from Mesopotamia. Circa 1300 A.D. British Museum. | |

| (To face p. 153.) | ||

| XXIII. | Saracenic Glass. Tall-necked bottle; decorated with enamelled and gilt medallions, Chinese phœnix, etc. (H. 171⁄2 in.) The inscription has been read ‘Glory to our Lord the Sultan, the wise, the just, the warrior King.’ Bought in Cairo. Circa 1300 A.D. Victoria and Albert Museum (Myers Bequest). | |

| (To face p. 154.) | ||

| XXIV. | Saracenic Glass. Victoria and Albert Museum. | |

| (1) Small lamp of clear white glass, a little decayed xv on surface. (H. 81⁄4 in.) Enamels of white, red, and yellow with gold, sparingly applied—horsemen with falcons; gold frieze on rim and foot. Stated to have come from a Christian monastery in Syria. Late thirteenth or early fourteenth century. Myers Bequest. | ||

| (2) Vessel for oil. Probably to be suspended in a large mosque lamp (lantern). (H. 61⁄2 in.) Pale greenish-blue glass, with remains of the gilding that formerly covered it. | ||

| (To face p. 156.) | ||

| XXV. | Saracenic Glass. Beaker enamelled with frieze of three polo-players, between two bands with inscription in Arabic, both in praise of ‘our Lord the Sultan’ (without date or proper name). About 1300. The silver-gilt foot and cover are probably Augsburg work of the early sixteenth century. From a reproduction in water-colours of the original in the Grüne Gewölbe, Dresden. | |

| (To face p. 162.) | ||

| XXVI. | Saracenic Glass. Mosque lamp (H. 16 in.) from Cairo. Clear white glass with many bubbles. Eight handles for suspension. Design of lotus-blossom, etc., outlined in opaque red, and the interstices filled with translucent blue enamel. Early fourteenth century. Victoria and Albert Museum (Myers Bequest). | |

| (To face p. 168.) | ||

| XXVII. | (1) Drinking-cup (Diam. 51⁄2 in.) of honey-coloured glass. In centre, enamelled figure of ‘the angel who serves the wine to the faithful.’ Angel’s wings and surrounding band, gold upon a lavender-blue ground. Persian in style, but according to M. Schefer, possibly made at Ermenas and enamelled at Aleppo. Probably fifteenth century. British Museum. xvi | |

| (2) Hollow Sphere of honey-coloured enamelled glass. (Diam. 4 in.) Ornament of chain of mosque lamp. Provenance unknown, but probably from Northern Syria. British Museum. | ||

| (To face p. 172.) | ||

| XXVIII. | Venetian Glass. The Aldrevandini Beaker. (H. 51⁄8 in.) Thin clear glass with black specks, enamelled with three shields bearing the arms of South German towns: (1) Three stag-horns in fesse, azure; (2) argent, three keys in fesse, gules; (3) per fesse argent and sable, in chief a bar. Between, apple-green leaves outlined in white. Some enamelling also inside. Inscription in Gothic letters. About 1300 A.D. British Museum. | |

| (To face p. 179.) | ||

| XXIX. | Venetian Glass. The Berovieri Cup. (H. c. 81⁄2 in.) Coppa Nuziale (marriage cup) of deep-blue glass, enamelled and gilt. The heads of bride and bridegroom in medallions. Between, (1) a procession of knights and ladies approaching a fountain; (2) bathing in fountain. Attributed to Angelo Berovieri. About 1440. Museo Civico, Venice. | |

| (To face p. 194.) | ||

| XXX. | Venetian Glass. (1) Lamp for suspension, enamelled with studs of white on coloured ground. (H. 11 in.) Shield with stemma of Tiepolo family. Early sixteenth century. Museo Civico, Venice. | |

| (2) Stemless cup of thin clear glass. (H. 51⁄2 in.) Decorated with scrolls, lions, and birds, in ‘painted’ enamel. About 1450. Dug up while excavating the foundations of the new Campanile. Museo Civico, Venice. | ||

| (To face p. 199.) | ||

| XXXI. | Venetian Glass. Flower-vase. (H. 11 in.) Transparent, colourless glass, slightly greyish, xvii with tendency to deliquescence on surface: threading and studs of cobalt-blue. Probably sixteenth century. British Museum. (Slade, ex Bernal collection.) | |

| (To face p. 200.) | ||

| XXXII. | Venetian Glass. Spherical vase (H., with ‘made-up’ foot, 91⁄2 in.) of opaque white glass, decorated with gilt scrolls and bosses and a pair of rudely drawn mermaids. Sixteenth century. British Museum. (Slade, ex D’Azeglio collection.) | |

| (To face p. 203.) | ||

| XXXIII. | Venetian Glass. Pilgrim’s bottle. (H. 61⁄2 in.) Design (Cupid fishing, and Venus and Anchises) painted in blue on opaque white (lattimo) ground. Early sixteenth century. Museo Civico, Venice. | |

| (To face p. 204.) | ||

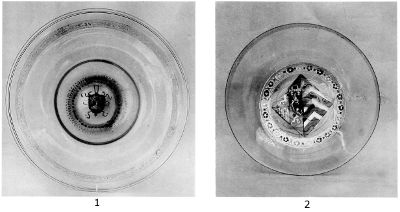

| XXXIV. | Venetian Glass, enamelled and gilt. Early sixteenth century. British Museum. | |

| (1) Plate of thin glass. (Diam. 7 in.) In centre a shield with oak tree, green and gold on blue ground. (? Rovere arms.) Round margin a ring of delicate pattern in powder gold. Early sixteenth century. (Slade collection.) | ||

| (2) Tazza of thin glass. (Diam. 6 in.) Coat of arms in lozenge in centre, surrounded by ring with flowers in oval medallions—apple-green, dull red, blue and yellow enamels. Powder gold band round margin. (Slade, ex Bernal collection.) | ||

| (To face p. 214.) | ||

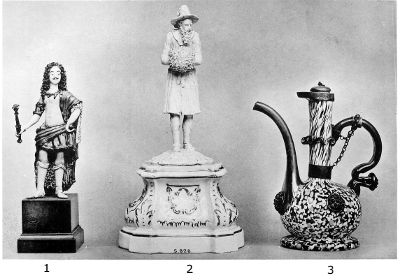

| XXXV. | French Glass of Renaissance. British Museum. (Slade collection.) | |

| (1) Statuette of Louis XIII. or XIV. (H. 41⁄4 in.) Opaque white glass with coloured enamels. Probably made at Nevers. Seventeenth century. | ||

| xviii | (2) Statuette of man with muff. (H. of figure, 5 in.) Opaque white, porcelain-like glass, on a copper base. On stand of white Dresden china, partly gilt. | |

| (3) Small burette (H. 5 in.) of dark greenish-blue transparent glass; the body and neck splashed with green, white, and red enamels. Gilt berry-like bosses on body. Probably sixteenth century. | ||

| (To face p. 233.) | ||

| XXXVI. | Spanish Glass. Victoria and Albert Museum. | |

| (1) Vase of pale bottle-green glass; four handles with quilled edges. (H. 61⁄2 in.) From the South of Spain. Sixteenth or seventeenth century. | ||

| (2) Jug of white transparent glass (H. 81⁄2 in.), made at S. Ildefonso. | ||

| (3) Vase of transparent glass, slightly greenish. (H. 6 in.) Two handles with quilled edges. From the South of Spain. Sixteenth or seventeenth century. | ||

| (To face p. 245.) | ||

| XXXVII. | German Glass. Roemer of green glass; berry prunts on waist; the foot built up of glass stringing. Circa 1600. Germanic Museum, Nuremberg. | |

| (To face p. 254.) | ||

| XXXVIII. | German Glass Furnace. Sixteenth century. From Agricola, De Re Metallica, Basle, 1556. | |

| (To face p. 260.) | ||

| XXXIX. | German Glass. Willkomm Humpen, enamelled in colours with the Reichs-adler. On the wings, as recorded by an inscription on the back, the arms of the various members of the Holy Roman Empire. Dated 1656. Greenish glass; below margin, a ring of ‘powdered’ gold, between beading of white and blue enamel. British Museum (Henderson Bequest). | |

| (To face p. 264.) | ||

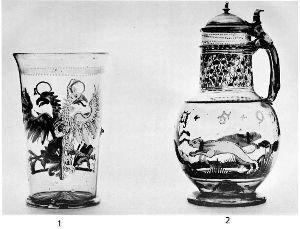

| XL. | xix German Glass. British Museum. | |

| (1) Beaker of clear white glass. (H. 51⁄2 in.) Enamelled with double eagle, white and blue, with yellow beaks and claws; at the back a sprig of lily-of-the-valley. Dated 1596. From the Bernal collection. | ||

| (2) Jug of pale purple glass (H. 8 in.) with pewter lid. Enamelled with a white dog pursuing a red stag and fox. In addition green, blue, and yellow enamels. Dated 1595. From the Slade collection. | ||

| (To face p. 267.) | ||

| XLI. | German Glass. Willkomm Humpen. Enamelled in colours with hunting scene, the game being driven into net. About 1600. British Museum. | |

| (To face p. 268.) | ||

| XLII. | German Glass. Covered beaker of clear white glass. (H. with cover 63⁄4 in.) Engraved with design of amorini dancing among vines. The metal knob of cover is enamelled and gilt, and on the interior button are enamelled the arms of the Archbishop of Trèves, with the following inscription:—Joan Hugo D.G. Arc. Trev. PR. EL. EP. SP. Early eighteenth century. | |

| (To face p. 283.) | ||

| XLIII. | Dutch Glass. Beaker in the form of a roemer. (H. 9 in.) On the bowl, in medallions, heads symbolising the four seasons, scratched with the diamond. The waist, decorated with berry prunts, showing remains of gilding. On this part is scratched (in English) ‘August the 18th, 1663,’ and the letters W.H.E. between bay branches. On the foot a landscape with hunting scene. British Museum. | |

| (To face p. 296.) | ||

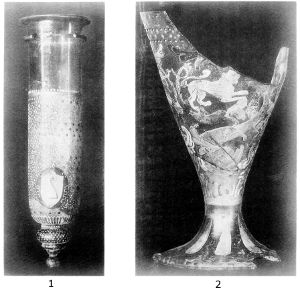

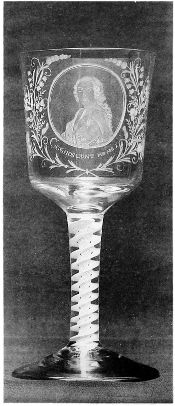

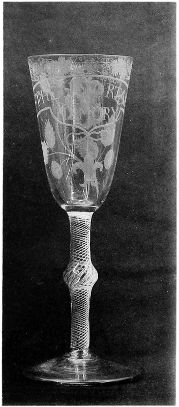

| XLIV. | English Wine-Glasses. British Museum. | |

| (1) Wine-glass, early eighteenth century. (H. xx 83⁄4 in.) The hollow knop of the moulded stem is decorated with prunts and encloses a sixpence of Queen Anne (dated 1707). | ||

| (2) Jacobite wine-glass with opaque twisted stem. (H. 73⁄4 in.) On the bowl is engraved a portrait of the Young Pretender, inscribed ‘Cognoscunt me mei’; at the back are the words Premium Virtutis under a crown. | ||

| (3) Jacobite wine-glass with air-twisted stem. Round the bowl are engraved the words ‘Immortal Memory’; above, a band of vine-leaves, and below, fleurs-de-lis and roses. Presented by Mr. A. Hartshorne. | ||

| (To face p. 327.) | ||

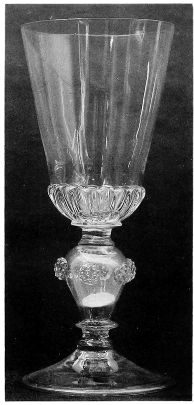

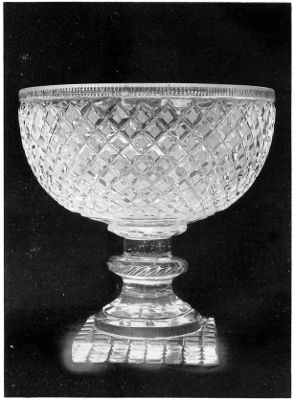

| XLV. | English Flint Glass. Victoria and Albert Museum. | |

| (1) Standing cup and cover (H. 12 in.) on square, stepped foot. Carved in relief with gadroons descending spirally. End of eighteenth century. Presented by Mr. H. B. Lennard. | ||

| (2) Bowl standing on square base. (H. 81⁄2 in.) The whole of the surface facetted; the under surface of the foot cut into square compartments. End of eighteenth century. Presented by Mr. H. B. Lennard. | ||

| (To face p. 332.) | ||

| XLVI. | Persian Glass. Tall-necked vase of colourless glass; body shaped in a mould; appliqué stringings on foot. Taken from a tomb at Baku. Vincent Robinson collection. | |

| (To face p. 338.) | ||

| XLVII. | Persian Glass. Victoria and Albert Museum. Seventeenth or eighteenth century. | |

| (1) Tall-necked, pear-shaped vase, the surface spirally ribbed, of deep blue transparent glass. (H. 11 in.) | ||

| xxi | (2) Cruet-shaped vase of clear white glass. (H. 9 in.) From the Richard collection. | |

| (3) Perfume sprinkler, with curved neck and barnacle-shaped lip. Blue transparent glass, the surface spirally ribbed. (H. 12 in.) | ||

| (To face p. 340.) | ||

| XLVIII. | Indian Glass. Indian Museum. Vase or basin with wide-spreading lip. (H. 53⁄4 in.) Milky, semi-transparent glass; the ground gilt, surrounding white flowers, with pistils of red enamel. Provenance unknown. (Delhi district?) | |

| (To face p. 343.) | ||

| XLIX. | Chinese Glass. Victoria and Albert Museum. | |

| (1) Bowl of mottled green glass with purple markings, imitating jade. (H. 27⁄8 in.) Eighteenth century. From the Bernal collection. | ||

| (2) Spindle-shaped vase of orange, ‘tortoise-shell’ glass. (H. 71⁄2 in.) The stopper of silver, inlaid with Chinese characters; the base European. | ||

| (3) Small tripod vase of mottled yellow glass, in form of incense-burner. (H. 33⁄4 in.) Eighteenth century. | ||

| (To face p. 350.) |

Agricola (Georg): De Re Metallica (last chapter of work). Basle, 1556.

Appert (L.) et Henrivaux: Verre et Verrerie. Paris, 1894.

Appert (L.): Notes sur les verres des Vitraux Anciens. Paris, 1896.

Bapst (A.): Chinesische Glasarbeiten; Zeitschrift für Bildende Kunst, 1885.

Bate (Percy): English Table-Glass. No date. (1904?)

Biringuccio (V.): De la Pirotechnia. Venice, 1540.

Blancourt (Haudicquer de): L’Art de la Verrerie. Paris, 1697.

Bontemps (G.):—

Guide du Verrier. Paris, 1868.

Exposé des moyens employés pour la fabrication des Verres Filigranés. 1845.

Bordoni: L’Arte Vetraria in Altare. Savona, 1884.

Bosc d’Antic (P.): Mémoires sur l’Art de la Verrerie. Paris, 1780.

Boutellier (L’Abbé): Histoire des Gentilshommes Verriers de Nevers.

Brent (John): ‘On Chevron Beads.’ Archæologia, vol. xlv.

Brinckmann (Justus): Various Catalogues, etc., of the Hamburg Museum.

Bucher (B.): Die Glassammlung des K.K. Oesterreich. Museum. Vienna, 1888.

xxiii Bushell (S. W.):—

Oriental Ceramic Art. New York, 1899.

Chinese Art, vol. ii. (South Kensington Art Handbooks). 1906.

Busselin (D.): Les Célèbres Verreries de Venise. Venice, 1846.

Cecchetti:—

Delle Origini dell’ Arte Vetraria Muranese. R. Institute Veneto, 1872.

Monographie dell’ Arte Vetraria. Venice, 1874.

Czihak (E. von): Schlesische Gläser. Breslau, 1891.

Dalton (O. M.):—

Catalogue of Early Christian Antiquities in the British Museum—Cemetery Glasses. 1901.

‘Gilded Glass of Catacombs.’ Archæological Journal, 1901.

Deville (A.): Histoire de l’Art de la Verrerie dans l’Antiquité. Paris, 1873.

Dobbs (H. C.): ‘Glass-blowers of North-west Provinces.’ Journal of Indian Art, vol. vii.

Eraclius: see Heraclius.

Fillon (B.): L’Art de Terre chez les Poitevins. Niort, 1864.

Fioravanti (L.): Dello Specchio di Scienza Universale, Bk. vii. cap. 29. Venice, 1567.

Fourcaud (L. de): Émile Gallé. Paris, 1903.

Fowler (J.): ‘On the Process of Decay in Glass.’ Archæologia, vol. xlvi.

Franks (Sir A. W.):—

Guide to Glass Room in British Museum, 1888.

Art Treasures of United Kingdom. Vitreous Art. 1858.

Friedrich (C.): Die Altdeutschen Gläser. Nürnberg, 1884.

xxiv Froehner (W.): La Verrerie Antique. Collection Charvet, 1879.

Garnier (E.):—

Histoire de la Verrerie et de l’Émaillerie. Tours, 1886.

Spitzer Catalogue, vol. iii. ‘La Verrerie.’

Garrucci (P. R.):—

Storia dell’ Arte Christiana, vol. iii. 1876.

Vetri ornati di Figure in Oro. 1858 and 1864.

Garzoni (T.): Piazza Universale di tutte le professioni del Mondo. Discorso lxiv. Venice, 1585.

Gerspach: L’Art de la Verrerie. Paris, 1885.

Griffith (F.): Egypt Exploration Fund. Tanis, Part ii. 1888.

Hallen (Rev. A.): ‘Glass-making in Sussex, etc.’ Scottish Antiquary, 1893.

Hartshorne (Albert): Old English Glasses. 1897.

Havard (H.): Les Arts de l’Ameublement. La Verrerie. Paris, 1894.

Heraclius or Eraclius: De Artibus et Coloribus Romanorum. Eitelberger von Edelberg: Quellenschriften für Kunstgeschichte, vol. iv.

Hirth (F.): Chinesische Studien; Zur Geschichte des Glases in China. Leipsic, 1890. And other papers.

D’Holbach (Baron)?: Art de la Verrerie, de Neri, Merret et Kunckel. Paris, 1752.

D’Hondt (P.): L’Art de la Verrerie. Liége, 1891.

Houdoy (J.): Verrerie à la façon de Venise. Paris, 1873.

Kunckel (J.): Ars Vitraria Experimentalis. 1679.

Labarte (J.):—

La Collection Debruge Duménil. Paris, 1847.

Histoire des Arts Industriels, vol. iv. Paris, 1866.

xxv Lacroix (P.): Les Arts au Moyen Âge et à l’Époque de la Renaissance. Paris, 1869.

Lane-Poole (S.):—

The Art of the Saracens in Egypt. London, 1886.

Arabic Glass Weights in British Museum. 1891.

Layard (Sir A. H.): Nineveh and its Remains. 1853.

Lazari (V.): Notizia delle Opere d’Arte della Raccolta Correr. Venice, 1859.

Lobmeyr (L.): Die Glas-industrie. Stuttgart, 1874.

Loysel (C.): Essai sur la Verrerie. Paris, 1800. (Written earlier.)

Mathesius: Sarepta oder Bergpostil (Sermon xv.). Nürnberg, 1562.

Merret (C.): The Art of Glass of Neri translated into English. London, 1662.

Milanesi (G.): Tre Trattatelli dell’ Arte del Vetro per Mosaici. (Fifteenth century MSS.) 1864.

Minutoli (H. de): Ueber der Anfertigung der farbigen Gläser bei den Römern. Berlin, 1836.

Molinier (E.): La Peinture sous Verre. Spitzer Catalogue, vol. iii.

Naples: Description of Museo Borbonico. Glass, vols. v., xi., and xv.

Neri (A.): L’Arte Vetraria. 1612.

Nesbitt (A.):—

Catalogue of Slade Collection of Glass. Privately printed, 1871.

Catalogue of Glass Vessels in South Kensington Museum, 1878.

Glass (South Kensington Art Handbooks), 1875.

‘Opus Sectile in Glass.’ Archæologia, vol. xlv.

Encyclopædia Britannica, article ‘Glass.’ 1879.

Owen (H.): Ceramic Art in Bristol (chapter on Bristol Glass). 1873.

xxvi Passini (A.): Il Tesoro di San Marco. Venice, 1886.

Peligot (M. E.): La Verre, Histoire et Fabrication. 1876.

Pellat (Apsley):—

Curiosities of Glass-making. London, 1849.

Memoir on the Origin, etc., of Glass-making. London, 1821.

Pelletier: Les Verriers du Lyonnais. 1887.

Petrie (Flinders):—

Burlington Fine Arts Club; Introduction to Catalogue of Egyptian Exhibition, 1895.

Tell-el-Amarna. Egypt Exploration Fund. 1894.

Pinchart (A.): Les Fabriques des Verres de Venise, d’Anvers et de Bruxelles au XVIe. et au XVIIe. siècles. Bulletins des Commissions Royales. Bruxelles, 1882.

Plinius Secundus (Caius): Historia Naturalis, Bk. xxxvi. caps. 44-47.

Porter (G. R.): ‘Glass and Porcelain.’ Lardner’s Cabinet Encyclopædia. London, 1832.

Powell (H. J.):—

Principles of Glass-making. London, 1883.

Encyclopædia Britannica, article ‘Glass.’ 1902.

Read (C. H.):—

‘Glass in South Saxon Graves.’ Archæologia, vol. lv.

‘On a Saracenic Goblet of Enamelled Glass.’ Archæologia, vol. lviii.

Riaño (J. F.): Industrial Arts in Spain, Part ii. (South Kensington Handbooks). 1879.

Santi (M.): Origini dell’ Arte Vetraria in Venezia e Murano.

Sauzay (A.):—

La Verrerie depuis les Temps les plus reculés. Paris, 1868.

xxvii Sauzay (A.):—

Marvels of Glass-making. (Translation of above.) London, 1870.

Schebek (E.): Böhmens Glasindustrie und Glashandel. Prague, 1878.

Schmoranz (G.): Old Oriental Gilt and Enamelled Vessels. German and English Editions. Vienna and London, 1899.

Schuermans (H.): The Wanderings of the Muranese and Altarist Glass-workers. Eleven Letters. Bulletins des Commissions Royales. Bruxelles, 1883-1891.

Spitzer Catalogue. See Garnier and Molinier.

Theophilus: Diversarum Artium Schedula. Eitelberger von Edelberg. Quellenschriften für Kunstgeschichte, vol. viii. Vienna, 1874.

Ure (A.): Dictionary of Arts, article ‘Glass.’ 1853.

Vopel (H.): Die Altchristlichen Goldgläser. Freiberg, 1899.

Zanetti (V.):—

Monographia della Vetraria Veneziana. Venice, 1873.

Museo Civico di Murano; Guida di Murano. Venice, 1866.

Egyptian, etc. Griffith, Layard, Petrie.

Greco-Roman and Roman. Deville, Froehner, Fowler, Minutoli, Naples Museum, Nesbitt, Pliny.

Early Christian, Byzantine, Anglo-Saxon, etc. Brent, Dalton, Garrucci, Heraclius, Passini, Read, Theophilus, Vopel.

Saracenic and Perso-Indian. Lane-Poole, Dobbs, Read, Schmoranz.

Venetian (Murano and Altare). Biringuccio, Bontemps, Bordoni, Busselin, Cecchetti, Fioravanti, Garzoni, Houdoy, Labarte, Lazari, Neri, Pinchart, Santi, Schuermans, Zanetti.

French and Spanish. Boutellier, Fillon, Fourcaud, Gamier, Gerspach, Pelletier, Riaño.

German. Agricola, Brinckmann, Von Czihak, Friedrich, Kunckel, Lobmeyr, Mathesius, Schebek.

English. Bate, Hallen, Hartshorne, Merret, Owen, Pellat.

Chinese. Bapst, Bushell, Hirth.

Technical. Appert, Blancourt, Bontemps, Bosc d’Antic, D’Holbach, Kunckel, Lobmeyr, Loysel, Merret, Neri, Peligot, Pellat, Porter, Powell, Ure.

General and historical. Brinckmann, Franks, Garnier, Gerspach, Havard, Labarte, Lacroix, Nesbitt, Sauzay.

Glass is a substance in so many ways connected with the conveniences and amenities of our daily life, and the word calls up so many varied associations, that I must here at the very beginning make clear with what a comparatively small proportion of the manifold applications of the substance I have to deal.

In the first place, this is an art history, so that with methods of manufacture and practical uses we are only concerned so far as they may influence or help to explain points of artistic interest. Again, even on the artistic side, it is not with every branch of the varied applications of glass that we shall be occupied in this work. By an anomaly of the English language, whose vocabulary for matters connected with the arts is so strangely deficient, we have come to understand by the term ‘glass,’ when used without further explanation, what is called in the trade ‘hollow ware,’ the verrerie of the French; in other words—vessels of glass. The term may also be extended to include various minor applications of the material—beads, small ornaments, etc., what the French call verroterie. But the application of glass to windows, especially when coloured and stained glass is in question, to say nothing of work in mosaic, is usually, although not always, held to lie outside this narrower connotation of the word.

Now it happens that for us this restriction is in every 2 way convenient. For though the material basis is the same, it is evident that both the artist who works in mosaic and the designer of stained windows are concerned, each in his department, with artistic problems only incidentally connected with the material in which they work. In other words, the art element in both these crafts only becomes prominent at a stage when the actual preparation of the glass is completed. It is, however, certainly a pity that there is no English word which would not only clearly connote the class of objects with which I have here to deal, but which would at the same time distinctly comprise nothing beyond.

I have now explained the somewhat restricted and artificial sense of the word glass that I propose to accept in this work. But for a moment let us pass to the other extreme, and going beyond the ordinary connotation of the term include in it the glazes of pottery—the word ‘glaze’ is in its origin the same as glass—as well as the many forms of enamel. In all these cases we are dealing with substances of similar composition. They may all probably be traced back to a common origin, so that from an evolutionary point of view we have here an instance of the development of the complex and varied from the simple and single. Looking at the question in another way, the art of the enameller, using the term in a restricted sense, may be held to be subsidiary both to that of the potter and of the glass-worker; while many of the problems that arise in treating of the glazes of fictile wares—questions as to fusibility, or as to the colours employed and the changes of these colours during the firing—turn up again in the manufacture of glass. We shall see that experience gained in following the processes of one art may serve to throw light upon the difficulties and problems of the other.

Historically the connection between glass and pottery is not so close. In some degree the prevalence of one art has tended to oust the other, or to relegate it to an inferior position. The Greeks, who carried the potter’s 3 art to such perfection, knew little about glass—it was long an exotic substance for them. The Romans, on the other hand, who in the first centuries of our era first fully appreciated and developed the capacities of glass, produced little pottery of artistic interest. In the sixteenth century, in Umbria and Tuscany, where the finest majolica was made, we hear nothing of the manufacture of glass, while on the other hand the fayence of Venice, at this time pre-occupied with her glass, was of subsidiary importance. If we turn to the home of porcelain, in China glass has always held a subordinate position, while in Japan it was until recent days practically unknown.

Were a comparison to be made between the development of the various minor arts, it would be difficult to find a wider contrast than that between the history of porcelain and that of glass. The knowledge of porcelain was confined for nearly a thousand years to China, the country where it was first made, and where it was slowly brought to perfection. Let loose, as it were, in the West early in the eighteenth century, it had then a short period of glory, but before the end of the century the art had already fallen upon evil days. The manufacture of glass, on the other hand, had long been carried on in Egypt, and perhaps in other Eastern lands, by a primitive process, although it only became an article of general use after the discovery of the blowing-iron. When and where this discovery was made we do not know—perhaps somewhere in Syria or Mesopotamia, in the third or second century before Christ. The art of blowing glass was known, no doubt, if not fully developed, at the time when the kingdoms of the Ptolemies and of the Seleucidæ fell under the rule of the Romans. By them it was before long brought to perfection and carried into every corner of the West, so that by the second or third century of our era the production of glass in Europe was probably greater than at any subsequent time, at least until quite recent days. Nor was the art of glass-making completely extinguished by ‘the advance of the 4 barbarians.’ Indeed, some of the Germanic tribes not impossibly brought with them a knowledge of the process not only of preparing but also of blowing glass, picked up on their journeyings through East Europe, or perhaps even learned in Western Asia. This was an instance of the passage to the North and West of the arts of civilisation, by what we may call the back-road of Europe, in opposition to the high-roads that led directly from Italy by way of the Rhone and the Rhine.

But in the West the manufacture, though continuously carried on in many spots, was after the fall of the Western Empire relegated to the woods,—for nearly a thousand years little glass was produced of any artistic interest. Indeed, but few examples of this forest or green glass of the Middle Ages have survived to our time. During all this long interval, in one direction only, in the West, was any advance made. Within this period falls the great development of stained glass: we must turn to the glorious windows of the cathedrals of France and other Western lands, to see what the glass-workers of the time were capable of producing. In the East, on the other hand, in the lands ruled from Constantinople or influenced by Byzantine civilisation, what we know of the glass of the early Middle Ages is almost confined to the mosaic coverings of the walls of the contemporary churches. But just as distinctly as the glass in the windows of the Gothic churches, this mosaic work, for the reason we have already given, falls outside our limits.

It was not till the end of the twelfth century that any important advance was made in our narrower department of ‘hollow ware.’ Among the many beautiful things made during that glorious season of artistic production that had its start about this time in Egypt (or perhaps, rather, in the lands between the Persian Gulf and the Mediterranean)—except it be the inlaid metal work—there is nothing that now interests us so much as the enamelled glass, the beautiful ware that culminated in the magnificent Cairene mosque lamps of the thirteenth 5 and fourteenth centuries. The art of enamelling on glass passed over to Venice in the fifteenth century, perhaps earlier, and there in the next century the manufacture of the famous cristallo was finally achieved, and complete mastery was obtained in the working of this pure white glass. A fresh start was now given to the industry in the north by means of the Venetian glass-workers, who were sought for in every country to teach their new methods.

In Germany alone did some of the traditions of the old forest-workers of ‘green-glass’ survive. By the end of the seventeenth century the German glass, in some respects to be regarded as a compromise between the old and new, had become the most important in Europe. For a hundred years the products of ‘the mountain fringe of Bohemia’ held the premier position, but towards the end of the eighteenth century this place was taken by the facetted flint-glass of England. It is certainly remarkable that it is only of quite recent years that any such prominent position could be claimed for France, which heretofore had been content to follow in the wake first of Venice and then of Germany and of England. At the present day, however, this at least may be said—that France is almost the only country where any really artistic work in glass, apart from the reproduction of old patterns and old methods, is being produced.

This hasty sketch of the history of glass-making will help us to understand why it is that in following the development of the art in so many lands, and for a period of more than three thousand years, there is no need to linger for any time except at a few of the more important étapes. Indeed such a procedure is forced upon us, for much of the road is quite barren, other parts are unexplored, while for whole stages we pass through prosaic districts where we find little of artistic merit to detain us.

The periods, then, of real importance in the history of glass, either from the cultur-historisch or from a purely artistic point of view, are separated by long intervals, 6 during which little of interest was produced. The primitive glass of Egypt, the varied productions of the first centuries of the Roman Empire, the enamelled glass of the Saracens, and the Venetian glass of the Renaissance—this exhausts all that we find either of commanding historic interest or of superlative artistic merit. What follows—the German and the Netherlandish glass of the seventeenth and eighteenth centuries—is still of some importance under both these heads. I can hardly say so much of the English glass of the eighteenth century; but this glass must not be neglected—it is English, and it is highly prized by many enthusiastic collectors.

It will be seen that there is a long gap between the first and second of our critical periods—between the beginning of the primitive Egyptian and the earliest Roman glass. This gap will be filled, in some measure, by some account of the rare surviving specimens of glass that can claim an Assyrian origin, of the glass pastes of the Mycenæan age, and of the few examples of glass that can be strictly classed as Greek of the classical age. So again of the second long hiatus—the interval of nearly a thousand years between the period of the Roman glass and that of the Saracens,—this may be partly filled by the few scanty pieces that have come down to us from Sassanian and Byzantine times. To this period belongs also the glass of the Germanic tribes of northern Europe, above all that of our Anglo-Saxon ancestors.

Some notice must also be taken of a few districts situated on bypaths, of the glass from countries that lie away from the main centres of production—these latter centres, I may note, until comparatively recent times are mostly to be found in close connection with the basin of the Mediterranean. To these outlying districts we must finally turn to examine the glass of Persia, of India, and above all the glass of China.

An interesting chapter, nay, a separate work, might 7 be devoted to the classification and history of a class of objects of which the manufacture has been carried on continuously and with few changes from the time of the Middle Empire in Egypt—of beads, I mean, and other allied applications of glass, included in the French term verroterie. But, however great the claims to attention of such objects, their interest is rather archæological than artistic, and it will be sufficient to treat of them incidentally along with the, for us, more important class of ‘hollow ware’ produced with the aid of the glass-blower’s tube.

Christopher Merret, our earliest English writer on glass, sets down the properties of the material under twenty-six heads, ‘by which we may easily differentiate it from all other bodies.’ From these I will select some four or five which will be sufficient for our purpose. Thus, of glass, he says: ‘’Tis a concrete of salt and sand or stones. ’Tis artificial. It melts in a strong fire. When melted ’tis tenacious and sticks together.... When melted it cleaves to iron, etc. ’Tis ductile whilst red-hot, and fashionable into any form, but not malleable, and it may be blown into a hollowness’ (Art of Glass, 1662). Here we have briefly expressed the real differentiæ of glass. It is rather by these properties than by any virtue of transparency or of definite chemical composition that glass is to be distinguished from all other bodies; and it is only by duly taking advantage of these properties that the preparation of a vessel of glass is rendered possible.

In passing from a liquid to a solid state there intervenes a viscous stage when the glass may be gathered at the end of an iron rod; the ductile, tenacious mass may now be drawn out into long threads, whose length and fineness are only limited by the difficulty of maintaining the requisite temperature. Again, if the rod upon which 8 the mass is gathered is hollow, the glass may be blown out into a vesicle or bulb, the starting-point from which an endless variety of objects, bottles, cups, tubes, or even flat sheets of glass, may be subsequently formed. Until advantage was taken of this remarkable property of glass—its capability, I mean, of being blown out into a hollow vesicle when in a viscid condition—the art of the glass-maker was in a primitive stage. We may compare the glass prepared without the aid of the blowing-tube—that of the ancient Egyptians, for instance—to the pottery made by hand before the invention of the potter’s wheel.

In dealing with the practical side of our subject—the materials from which glass is made, how these materials are first fritted and then fused together, and how the fused mass is subsequently dealt with—the best plan will be to approach the questions in each case from the point of view of the time and country. But as, on the one hand, for classical times, our sources of information for these practical details are but scanty, and as, on the other, I am not concerned with the industrial developments of the nineteenth century, it will be well to postpone any fuller treatment of such matters until I come to speak of the glass of late Mediæval and Renaissance times. I shall then be able to make use of contemporary accounts which will throw light on the processes of manufacture.

A few preliminary notes on the chemical and physical properties of glass may, however, not be out of place.

Glass, Merret tells us, is ‘a concrete of salt and sand or stones.’ This, in modern scientific language, we should express by saying that it is a combination of silica with an alkali. But these substances alone are not enough. You cannot make a glass fit for practical use from a pure quartz sand with the addition of nothing else than a salt of potash or soda. Such a glass—a simple alkaline silicate—would indeed be transparent, but it would be difficult to work and very fragile. In all cases there is need of a second base, and this, to speak generally, should be either lime or oxide of lead. The latter base we may 9 for the present neglect; speaking generally, it is the presence of lime that gives the working qualities and the requisite toughness. These, then, are the essential materials for the preparation of glass. Other substances may be present; alumina, for example, or one or other of the oxides of iron, but as a rule the presence of these latter bases is not desired—the glass would be better without them.

Putting aside, then, for the present the glass in which lead is a constituent, as well as that in which the soda is replaced by potash, it is remarkable how little difference of composition we find in examples of glass of the most divergent origin. Let us compare the composition of a Roman ‘lachrymatory’ with that of a piece of modern English plate-glass. In a hundred parts we find—

| Silica. | Soda. | Lime. | Iron Oxide. | Alumina. | |

| Roman lachrymatory | 71·5 | 16·5 | 8 | 1 | 2 |

| English Plate-glass | 72 | 17 | 6 | 2 | 2 |

These examples are indeed two extreme terms of a long but continuous series. A sample of Saracenic glass of the fourteenth or of Venetian glass of the sixteenth century, would yield on analysis much the same result.[1]

This, then, may be regarded as the normal composition of such glass as I shall have to deal with in this history. The main question has generally been—How can the sand or silica, the premier element in glass, be best converted into a substance which shall in external aspect resemble as closely as possible the native rock crystal (itself pure silica), but which at the same time shall be not only fusible, but after fusing pass on cooling through a plastic condition when it may be expanded into a vesicle and otherwise worked up into various shapes? Long practical experience has shown that this can be best 10 effected by adding to the sand materials containing both soda and lime, and as far as possible nothing beyond these bases. A glass thus compounded we may take as our normal type, but, as I have said, the soda may in certain cases be replaced by potash and the lime by lead oxide.

Silica in any case is the essential element in glass, and in any normal glass there may be present from 60 to 75 per cent. If, however, the bases with which it is combined have a high combining number—and this is especially the case with lead—the percentage of silica may fall below the former figure. Thus, in a bottle glass with 12 per cent. of iron oxide and alumina[2] the proportion is reduced to 54 per cent., and in a flint glass with 43 per cent. of lead oxide there is only 45 per cent. of silica.

It was once the fashion among English writers on glass to classify the substance under the heads of crown-glass, bottle-glass, broad-glass, plate-glass, flint-glass, etc.; but such a classification, not very logical in itself, would be of no use to us.[3]

Glass, of course, varies in optical properties, in hardness, and in fusibility, but I do not think that any useful classification could be based directly on these properties. But there is one distinction of the greatest importance technically and geographically, and this is between the glass of maritime countries in which the alkali is soda, and that of inland and forest districts where the soda is replaced by potash. In the first group, by far the most important—I have indeed regarded such glass as the normal type—may, it would seem, be placed not only the ‘primitive’ glass of the Eastern Mediterranean, but probably all the glass of the Romans. To it 11 belongs also the glass of the Saracens and the greater part of the artistic glass of the Renaissance, including the Venetian glass, although in this last the soda is often in part replaced by an appreciable quantity of potash. The potash group, on the other hand, includes the old voirre à fougère of the French and the wald-glas of the Germans. In addition, almost the whole of the glass of higher quality made in later days in Germany and in the Bohemian borderlands belongs essentially to this last class. Finally, it may be mentioned that in the case of the abnormal family where the lime is replaced by oxide of lead, the alkali is invariably potash. Of this family our English flint-glass is the most important member.

With regard to the hardness of glass, Merret mentions as the thirteenth property possessed by that substance, ‘that it only receives sculpture or cutting from a Diamond or Emery stone.’ But such a statement would be likely to give an exaggerated idea of the hardness of glass. If we take the scale of hardness used by the mineralogist, it will be found that there are few kinds of glass that do not fall between the fifth and sixth divisions of that scale. In other words, it would be difficult to find a specimen of glass on which a crystal of apatite (phosphate of lime) would make any impression, whereas all glass in ordinary use is readily scratched by felspar. It is possible, however, that some kinds of Bohemian glass may equal the latter mineral in hardness; it is indeed a common statement that certain Bohemian or German ‘combustion-tubes’ will strike fire with steel. On the other hand, the presence of lead tends to make a soft glass; our cut flint is perceptibly softer than common window-glass, and perhaps the most important defect of the paste used to imitate precious stones—such paste may contain as much as 50 per cent. of lead oxide—is to be found in its comparative softness.

At the same time, the greater the amount of lead in a glass, the greater its dispersive power on the light that 12 passes through it. Hence the brilliancy and fire of flint-glass, and still more of artificial gems.

Apart from the varieties containing lead, samples of glass differ little in weight; the specific gravity may range between 2·4 and 2·8. That of flint-glass, on the other hand, varies from 3 to 3·8; indeed in some optical glasses containing a large percentage of lead, and again in the paste used for false jewellery, the specific gravity may be as high as 4·5 or even 5.

The high melting-point, or more definitely the high softening-point, of certain kinds of Bohemian and German glass, makes them invaluable in the laboratory of the chemist. On the other hand, the ready fusibility of glass containing lead was, as we shall see, one of the causes that promoted the adoption of such a glass in our furnaces.

Thus we find that the potash-lime glass of Bohemia, containing a high percentage of silica, excels in hardness and resistance to heat; on the other hand, the various kinds of glass containing lead are soft and easily fusible, and at the same time they combine a high specific gravity with a wide dispersive power. What we may call the maritime or soda-lime glass takes an intermediate place in all these respects. This is indeed an additional reason for regarding this great family of ‘Mediterranean’ glass as the normal type.

The two essential elements, then, required by the glass-maker are, in the first place, silica, and secondly an alkali, in each case as pure as possible, and in a convenient form for mixing and fusing together. I do not propose here to do more than indicate the source of these materials.

The silica has at all times been derived either from solid quartz, whether in the form of rock crystal or of the white pebbles from the beds of Alpine rivers, or more often from sand obtained either by excavation or from the seashore.

In the case of the alkali, the maritime people of the South extracted their soda, for the most part, from the ashes of certain plants growing in salt marshes near the 13 sea. Most of these maritime plants belong to the natural order of the Chenopodiaceæ, the goose-foot or spinach tribe, and we find among them various species of Salsola, Chenopodium, Salicornia, etc. These plants were all included in old days under the vague name of kali. The roughly lixiviated ashes exported from Spain were known in the trade as barilla; those from the Levant as roquetta.[4] In other instances the impure alkaline carbonates were found ready at hand—as in the case of the natron deposits not far from Cairo. In the North the principal source of soda was till recent days the varech or kelp, cast up on the west coast of France and of Scotland.

The inland folk, on the other hand, had to find the alkali for their glass in the ashes of plants. This ‘potash’ was obtained by lixiviating the ashes of various trees and bushes—in Germany the ashes of beechwood, in France those of the bracken or fougère, were most in favour.

The quality of the glass depended in great measure upon the care taken in the preparation of the soda or potash. But the more impure ashes had this advantage: the amount of lime, to say nothing of the iron oxide and alumina, that they contained, rendered unnecessary in many cases the addition of any further basic material; even the comparatively pure Spanish barilla contained as much as seven per cent. of lime. In other cases that base had to be added, generally in the form of a more or less impure limestone.

Of the furnaces and of the various operations that come into play in the preparation of the glass I shall treat as the occasion arises in the following chapters. As, however, in this book we are—at least after the ‘primitive glass’ has been dealt with in the next chapter—almost exclusively concerned with vessels of ‘hollow ware’ made by a blowing process, it may be well to indicate, 14 in this introductory chapter, the nature of this process, and to give the names of the principal tools used. These implements—apart from quite modern improvements with which I am not concerned here—are of the simplest nature, and have undergone little change during the last five hundred years—perhaps I might say since the days of the Romans.

The molten glass is collected on the extremity of the blowing-iron to form a ‘gathering.’ This gathering, while still in a soft condition, is rolled upon the ‘marver’ into a cylindrical mass. By blowing down the tube this mass is now distended to form a hollow pear-shaped vesicle, for which it will be convenient to adopt the French term paraison. It is from this paraison that a start is made to form by a ‘spinning’ or ‘flashing’ process a sheet of broad or crown glass; again, the vesicle may be made to assume a cylindrical shape, and then opened out to form larger sheets of glass; or finally—and this is for us the most important—by holding the blowing-iron to which the bulb of glass is attached in a vertical position (or sometimes by swinging it over the workman’s head), and then by shaping it by means of certain simple tools, the paraison is started on the course by which it will finally be converted into a bottle or into a bowl-shaped vessel. I will here only dwell on one point. It is evident that so long as the glass is attached to the blowing-iron, although a simple bulb-shaped vessel may be formed, there is so far no means of shaping or finishing the upper portion. Before this can be done the further extremity of the paraison must be attached by means of a small gathering of molten glass to a light tapering rod of iron, the ‘punto’ or ‘pontil.’ The vessel—for so the paraison may now be called—is at this stage removed from the blowing-iron. This is done by ‘wetting it off’ by means of a rod of moistened iron. The glass vessel, now attached by its base to the pontil, is reheated, and the further treatment taken in hand by a workman seated on a stool with long projecting arms, 15 on which (or on the knee of the workman) the pontil is rotated. The shaping is chiefly done by an iron instrument called the ‘procello,’ or spring-tool, formed like a pair of sugar-tongs by two blades connected by an elastic bow. Finally, the edges are finished off by shears and scissors of various forms, which cut the hot glass as if it were a piece of soft leather. The now finished vessel is removed from the pontil by wetting the point of attachment, and is taken to the annealing oven.

In this very summary account of the processes involved in making, say, a flask of simple shape, I have only dwelt upon such instruments and methods as have for several centuries been in general use.

Before ending this preliminary chapter, a few words may be said of the changes that take place in glass in the course of time from the action of the surrounding medium.[5] These changes are in the main due to the moisture and carbonic acid contained either in the soil or in the atmosphere. Perhaps what is most striking in this action is on the one hand the apparently capricious and irregular way in which the glass is attacked, and on the other the great beauty of the iridescent effects that so often accompany the process of decay.

As to the apparent irregularity in the progress of the superficial decay, it would seem that, apart from differences in the chemical composition of the glass, much depends upon the preservation of the original smooth ‘epidermis.’ Once this is impaired, whether by accidental scratches or by the growth of fungus or lichen, the carbonic acid or the ammonia salts contained in the air or soil find, in the presence of moisture, a secure lodgment, and the work of decay proceeds rapidly. Thus in the case of the little flasks of primitive glass of which 16 I shall have to speak in the next chapter, in one example it may be found that the smooth skin of the glass has for more than three thousand years remained absolutely intact, while in another specimen from a neighbouring tomb the glass not only on the surface, but far into the interior, has taken on a talc-like or porcelainous consistency, and the brilliant colours have for the most part disappeared.

There is no need to enter into the details of the chemical processes involved in this process of decay. Suffice to say that the action is one of the same nature as that which has played so important a part in the geological changes of the earth’s surface, especially in the disintegration of the granitic rocks. It depends upon the power possessed by carbonic acid, in the presence of moisture, of decomposing the silicates of the alkalis. The soluble carbonate of soda or of potash thus formed is then quickly washed out from the surface of the glass. There remains, in the form either of iridescent scales or of an opaque pearly crust, a layer consisting not perhaps of pure silica, but of an acid silicate of lime, alumina, or lead as the case may be.

Now a piece of clear glass may appear to the eye to be devoid of internal structure. But the ‘metal’ has, we know, in every case been subjected during the manufacture to a complicated series of involutions and doublings, to say nothing of the subsequent inflation if the glass has been subjected to a blowing process. When decay sets in—something similar may at times be seen in the case of a piece of wrought iron—this complicated formation is in part revealed, for it is evident that upon it the lines taken by the decay are in a measure dependent. On blown glass especially, the disintegration of the surface tends to result in a scaly formation resembling that of the shell of an oyster. As a result of the decomposition of light in its passage through these fine superficial films, and of the partial reflection from the back of the scales at various depths, we get those unsurpassed iridescent effects that we associate 17 above all with the glass of the Romans. That these brilliant hues are dependent entirely upon the physical structure is well shown by the total disappearance of the colours when the surface of a piece of iridescent glass is moistened, as well as by their reappearance when the glass is again dried.

Lead of glass is much less liable to such changes, but where in such glass decay has once set in, the whole mass may be converted into a white horny substance.

In other cases the surface of a piece of clear white glass will become gradually filled with a series of minute intersecting fissures, which in time may penetrate the whole mass. When this change has been fully developed we get a true crackle-glass, not to be confounded with the frosted glass of Venice mentioned in Chapter XIII. This fissuring of the glass-mass in its various stages may be traced in many of the specimens of Venetian, Netherlandish, and English glass at South Kensington. When fully developed the effect is at times very beautiful.

The tints of coloured glass may, it would seem, change in the course of time. Colourless glass also, from which the greenish shades derived from protoxide of iron have been removed by the addition of binoxide of manganese, is above all liable to assume in the course of time a purple tint under the action of sunlight. Again, if sulphur be present in glass, as is the case where sulphate of soda has been employed as a source of the alkali, the soda salt may be reduced by any protoxide of iron that is present. The sulphide of sodium and the sesqui-oxide of iron thus gradually formed will both of them tend to give a yellowish tint to the glass.[6]

Changes of this nature may occasionally have come about in the stained glass of the windows of our Gothic churches—the flesh-tints, which we know were produced in early days by manganese, may in the course of time have become of a more pronounced purple hue.

From a technical point of view the history of glass might be divided into three periods—periods, it is true, of very unequal length and relative importance.

The first of these, one more especially of archæological interest, would include all the glass made before the discovery of the process of forming a vesicle by blowing through a hollow tube. Nearly all the glass that finds its way into our collections would be classed in the second period; this would extend from the beginning of our era to the end of the eighteenth century. In the course of these long centuries, the work of the glass-maker has of course been influenced by the varying schools and fashions of different ages and countries, but technically there is no great advance to be noted in the work of the seventeenth and eighteenth centuries when compared with that of the early days of the Roman Empire; and this is still more true if we consider merely the materials employed, their preparation, and the methods of their fusion. But before the end of the eighteenth century a great change had set in. The manufacture of glass in England and France had become an important industry, and we enter upon the third or industrial period. With the general advance in mechanical processes that is so characteristic of the time, the old methods of the working of glass were swept aside, so that before the middle of the last century, whatever of interest was to be found in the manufacture and 19 in its results depended upon anything rather than upon the artistic qualities of the glass made.

Now, as I have said, the characteristic and dominant quality of glass is to be found in its capability of being blown into vessels of varying shape when in a viscous and semi-fluid state. All glass then, made at a time when advantage had not yet been taken of that essential property of the material, we may class together in a primitive group. This line of demarcation is as important, to return to a comparison I have already made, as that between hand-moulded pottery and that thrown on the potter’s wheel. The objects made in the earlier period by primitive processes were mostly small, and their merit depended chiefly upon the brilliancy and the skilful juxtaposition of a few simple colours—they may for the most part be classed as verroterie.

It has long been acknowledged that it is from Egypt that our earliest specimens of glass have come. But until quite recently the greatest misconceptions have prevailed as to the age and the methods of preparation of Egyptian glass. Misled by an erroneous interpretation of what are probably representations of metallurgical processes, on the walls of Twelfth Dynasty tombs at Beni Hassan and elsewhere, it was inferred that the art of blowing glass was known to the Egyptians at least as long ago as the days of the Middle Empire; by others the art was carried back to a still earlier period. We now have almost full assurance that glass in a true sense was practically unknown to the Egyptians before the time of the Eighteenth Dynasty (say between 1600 and 1500 B.C.),[7] and that for at least a thousand years after that period all that was made was produced by a primitive process in 20 which the blowing-iron found no part. We have, unfortunately, up to the present time absolutely no evidence to show in what country or at what date this new process—I mean the blowing of a vesicle of glass—first came into use. There is, as we shall see, some reason to look for it rather in Western Asia than in Egypt, but the important point to bear in mind is that it was only after the introduction of this process of blowing, first to Alexandria and then to the Rome of the early empire, that the employment of glass for objects of daily use became in any way general.

Glass, indeed, in these early days, whether in Egypt or in the Greek world of the Mycenæan age, was something very different from what we now understand by the term. We must ‘think away’ a great deal of the modern connotation of the word. We must, above all, think of the material in connection with the native precious or semi-precious stones that it more or less resembled, and which were used along with it for decorative purposes. We do not know the Egyptian name for glass, but probably, like the Greeks, they divided all the hard stony bodies used in the arts into such as were ‘dug up’—natural products, that is, which they found ready at hand—and such as had been artificially prepared, and above all previously melted (the Λίθος όρωρυγμένη on the one hand, and the Λίθος χυτή on the other).

If, as I have said, there is little evidence for the existence of glass in Egypt before the Eighteenth Dynasty, it is quite otherwise with regard to a very similar substance, identical almost in chemical composition—one whose history can be traced much further back. On beads of clear rock crystal, dating from the First Dynasty, and it would seem from an even earlier period in some cases, we find a coating of turquoise blue transparent glaze[8]—the very glaze, in fact, that has given a 21 prevailing tint to the vast series of smaller objects of Egyptian art that we see in the cases of our museums. A similar colour, I may observe, continued in favour in Mohammedan times, and indeed gives a dominant note to Oriental art in contrast to the ochry tints of yellow, red, and brown prevalent in the West.

The Egyptians soon learned to apply this blue glaze—essentially a silicate of soda and copper—to the surface of other natural stones, and above all to a fritty porous earthenware, the so-called Egyptian porcelain. Such an alkaline glaze, indeed, will only adhere to a porous base of this kind, with which it becomes united on firing, by a chemical reaction, or at least by the solution in it of some of the silicates of alumina and lime in the clay. This glaze differs essentially from those used on true porcelain—these last are almost of the same composition as the ground they cover—but, as in the case of the glazes on porcelain, so the materials of the Egyptian glazes were probably first incorporated together in a partially fused frit which was then ground and mixed with water to form a soup-like ‘slip,’ into which the object to be glazed was dipped. There have been brought from Egypt a few rare objects carved out of a blue frit (probably similar to that used in the preparation of glazes), for which a very early date has been claimed. But such a frit is no true glass.

The Egyptians had from the earliest periods been adepts in the carving of native minerals and rocks, and evidently found great pleasure in the strange markings and contrasts of colour found on their polished surfaces. Already in pre-dynastic times they availed themselves of their native granites, porphyries and conglomerates; from these materials they manufactured those large, carefully turned vases of which so many have lately been brought from Egypt. For smaller objects—jewellery, beads, and inlay of various descriptions—they had command of a wide scale of colours—reds and tawny yellows from jasper, purple from the amethyst, greens from root of emerald and from a special kind of felspar, and blue 22 from the turquoise and (at a very early period) from the lapis lazuli. But the stones to which they had recourse for their favourite blues and greens were rare, and they were therefore the more ready to find a cheaper substitute in glass. Again, in Egypt, no stone was in greater favour than the native alabaster,[9] with its bands and zig-zag lines of transparent crystals in an opaque base of a warm milky hue. But there was no play of colour in this latter substance, and its very softness restricted the uses to which it could be put. In glass they found a substance hard enough to allow of more delicate forms, and on it chevrons of yellow and white could be traced upon a nearly opaque ground of turquoise or dark blue. Some such origin in native stones we may perhaps find for the decorative motives of the little vases, variously known as phialæ, unguentaria, alabastra, which were in such favour not only with the Egyptians, but perhaps even more so among the inhabitants of the islands and coasts of the Mediterranean, during a period of at least a thousand years. It is indeed these little vases that are the most characteristic product of the first period of glass-making.

It is not too much to say that the little we know of the processes of these early Egyptian glass-makers is derived from notices on the subject scattered through the memoirs in which Dr. Flinders Petrie has described the results of his excavations, more especially from the report issued in 1894, on his discoveries at Tell-el-Amarna. In the introduction to the catalogue of the Egyptian Exhibition held at the Burlington Fine Arts Club in 1895, Dr. Petrie has summed up our knowledge on this subject. I will quote the description of the method by which, according to him, these alabastra were made.

2

1

3

SMALL VASES OF “PRIMITIVE” GLASS

1. EGYPTIAN, NINETEENTH DYNASTY. 2. PROBABLY FROM GREEK ISLANDS. 3. ŒNOCHOE, FROM THE SLADE COLLECTION.

‘A metal rod of the size of the intended interior of the neck, and rather conical, was coated at the end with a ball of sand held together by cloth and string. This was 23 covered with glass, probably by winding a thread of glass round it, as large beads of this age are thus made. The vase could then be reheated as often as needed for working by holding it in a furnace, the metal rod forming a handle, and the sand inside the vase preventing its collapse. Threads of coloured glass could then be wound round it and incorporated by rolling; the wavy pattern was produced by dragging the surface in different directions, the foot was pressed into shape by pincers, the brim was formed, and the handles were put on. Lastly, on cooling, the metal rod would contract and come loose from the neck, and after it was withdrawn the sand could be rubbed out from the body of the vase.’

The wavy decoration thus obtained was of two types: (i) formed simply by a succession of crescent-shape curves, or (ii) by means of a double drag, the pattern assumed a form like a frond of palm leaves, or still more like these leaves plaited into a basket. (Cf. Pl. II.)

The number of these little vases that can be definitely attributed to the Eighteenth Dynasty (say about the sixteenth or fifteenth century B.C.) is small, but it is worthy of note that for brilliancy of colour and for purity of the glassy paste, the early examples are unsurpassed in later times. This is certainly a remarkable fact, especially if we are to regard the art as a new one. I cannot enter here into the evidence that would seem to point to a foreign origin for this early Egyptian glass—it will be enough to mention the conquests of Thothmes III. in Syria, and the close relation of his successor, Akhenaten, the ‘heretic king,’ with Syria and Babylonia, as shown by his marriage, and by the famous Tell-el-Amarna tablets. As bearing on this question I may refer to certain paintings on a tomb of this age at Drag Aboul Neggah, near Thebes (reproduced in the Revue Archéologique, 1895, Pl. 15), which represent the unloading of a foreign trading-vessel. We can distinguish here the merchants offering certain objects of value to an Egyptian official; among these are certain striped vases which have been 24 doubtfully recognised as of glass. In the hieroglyphics accompanying wall paintings of this period we more than once find that vessels of rock crystal and lapis lazuli are mentioned, as well as blocks of uncut stones, and neither by the hieroglyphics used nor by the representation of the objects would it be easy to distinguish the latter material from lumps of glass. Again, Syrian workmen are known to have been employed at this time in Egypt, and nowhere would this be more likely than in the immediate neighbourhood of the palace of the king at Tell-el-Amarna, where the glass-works described by Dr. Petrie were situated.