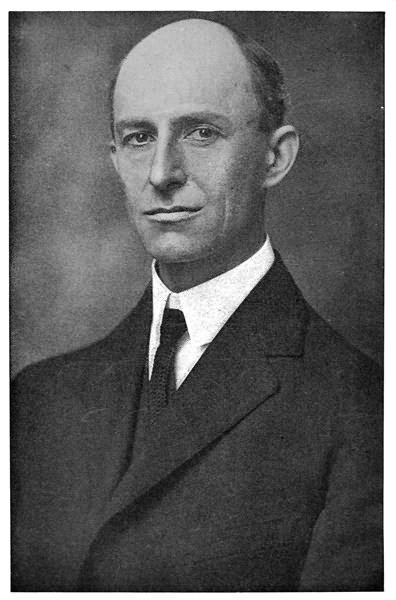

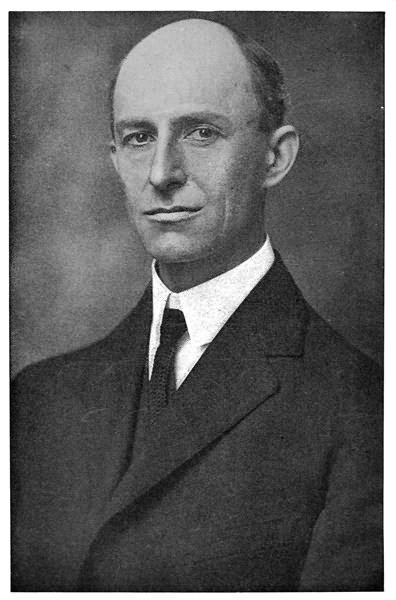

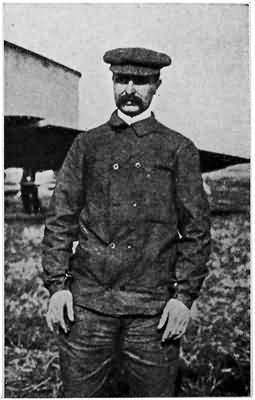

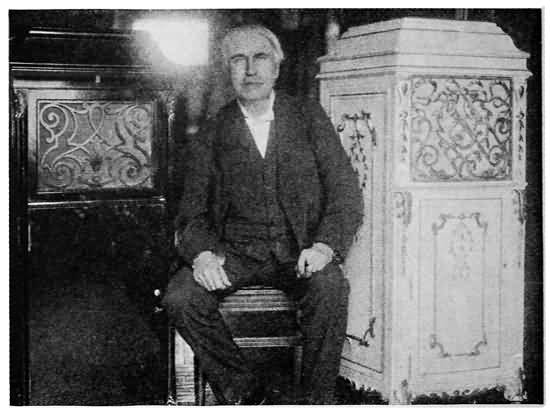

WILBUR WRIGHT

Who with his younger brother, Orville Wright, invented the first practical aeroplane. Wilbur Wright's death of typhoid fever in the summer of 1912 was an irreparable loss to aviation

Project Gutenberg's The Boy's Book of New Inventions, by Harry E. Maule This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org Title: The Boy's Book of New Inventions Author: Harry E. Maule Release Date: July 9, 2014 [EBook #46232] Language: English Character set encoding: ISO-8859-1 *** START OF THIS PROJECT GUTENBERG EBOOK THE BOY'S BOOK OF NEW INVENTIONS *** Produced by Chris Curnow, Mary Akers and the Online Distributed Proofreading Team at http://www.pgdp.net (This file was produced from images generously made available by The Internet Archive)

WILBUR WRIGHT

Who with his younger brother, Orville Wright, invented the first practical aeroplane. Wilbur Wright's death of typhoid fever in the summer of 1912 was an irreparable loss to aviation

BY

HARRY E. MAULE

MANY ILLUSTRATIONS

Garden City New York

DOUBLEDAY, PAGE & COMPANY

1912

Copyright, 1912, by

Doubleday, Page & Company

All rights reserved including that of

translation into foreign languages,

including the Scandinavian

To My Mother

In Appreciation of Her Broad Interest

In All the Activities of the World

The thanks of the publishers and author are due a great many individuals and publications for aid in securing photographs and data used in the preparation of this volume.

Although space prevents giving the names of all, opportunity is here taken to express to each the heartiest appreciation of their generous help and valuable suggestions.

More than to all of these are my thanks due my wife, Edna O'Dell Maule, for her constant aid and co÷peration.

IN THE preparation of this book the author has tried to give an interesting account of the invention and workings of a few of the machines and mechanical processes that are making the history of our time more wonderful and more dramatic than that of any other age since the world began. For heroic devotion to science in the face of danger and the scorn of their fellowmen, there is no class who have made a better record than inventors. Most inventions, too, are far more than scientific calculation, and it is the human story of the various factors in this great age of invention that is here set forth for boy readers.

New discoveries, or new applications of forces known to exist, illustrating some broad principle of science, have been the chief concern of the author in choosing the subjects to be taken up in the various chapters, so that it has been necessary to limit the scope of the book, except in one or two instances, to inventions that have come into general use within the last ten years. In vi "The Boy's Book of Inventions," "The Second Boy's Book of Inventions," and "Stories of Invention," Mr. Baker and Mr. Doubleday have told the stories of many of the greatest inventions up to 1904, including those of the gasoline motor, the wireless telegraph, the dirigible balloon, photography, the phonograph, submarine boats, etc. Consequently for the most part the important developments in some of these machines are treated briefly in the final chapters, while the earlier chapters are devoted to new inventions, which, if made before 1904, did not receive general notice until after that time.

Although the subjects treated in the earlier chapters are here spoken of as new inventions, all of them are not recent in the strictest sense of the word, for men had been working on the central idea of some of them for many years before they actually were developed to a stage where they could be patented and sent out into the world.

H. E. M.

| CHAPTER | PAGE | |

| I. | The Aeroplane How a Scientist Who Liked Boys and a Boy Who Liked Science Followed the Fascinating Story of the Invention of the Aeroplane. |

3 |

| II. | Aeroplane Development How the Inventors Carried On the Art of Aviation Until It Became the Greatest of All Sports and Then a Great Industry. |

49 |

| III. | Aeroplanes To-day Our Boy Friend and the Scientist Look Over Modern Aeroplanes and Find Great Improvements Over Those of a Few Years Ago. A Model Aeroplane. |

91 |

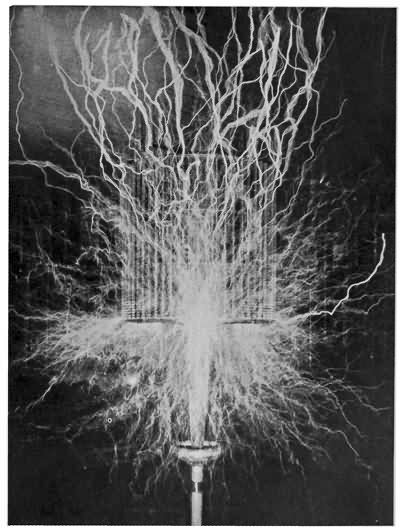

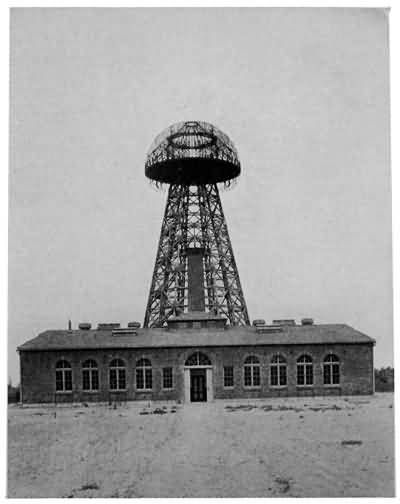

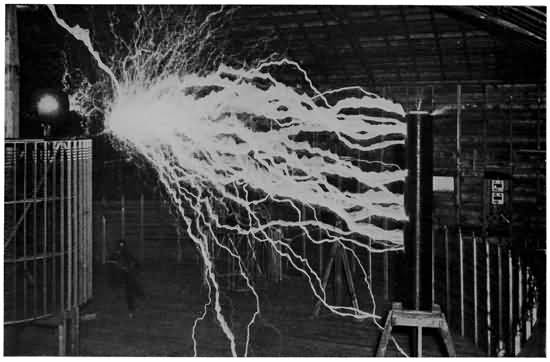

| IV. | Artificial Lightning Made and Harnessed To Man's Use Our Friends Investigate Nikola Tesla's Invention for the Wireless Transmission of Power, by Which He Hopes to Encircle the Earth With Limitless Electrical Power, Make Ocean and Air Travel Absolutely Safe, and Revolutionize Land Traffic. |

129 |

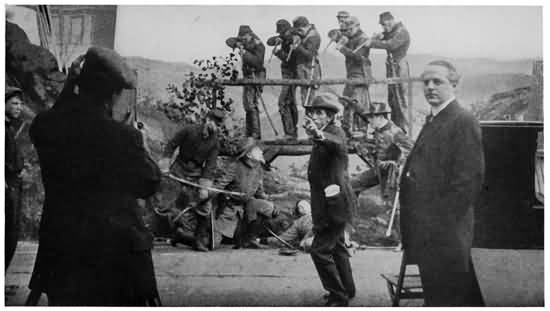

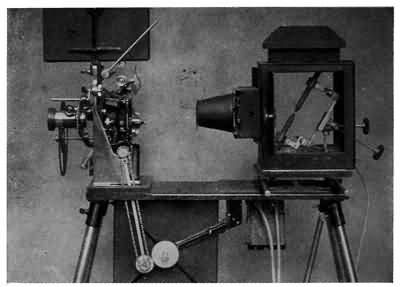

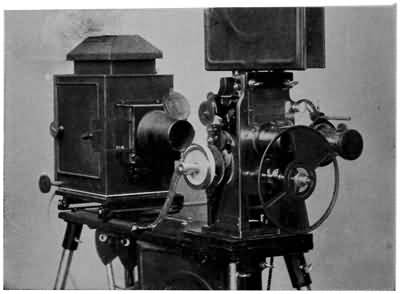

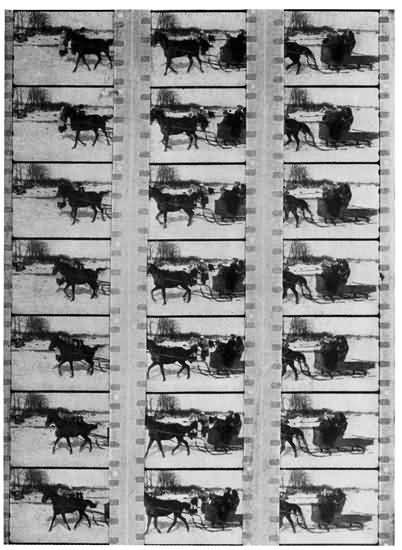

| V. | The Motion Picture Machine Machines That Make Sixteen Tiny Pictures Per Second and Show Them at the Same Rate Magnified Several Thousand Times. Motion Pictures in School. Our Boy Friend Sees the Whole Process of Making a Motion Picture Play. |

164 |

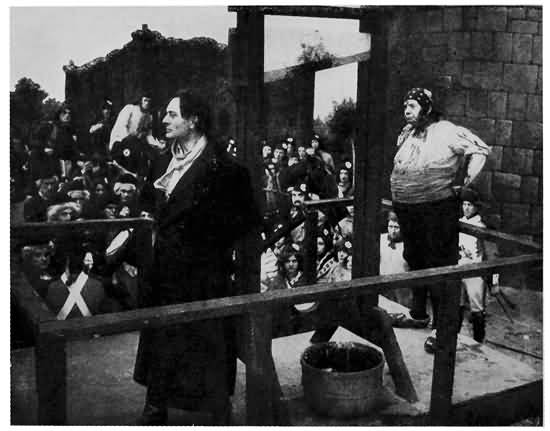

| viii VI. | Adventures With Motion Pictures Perilous and Exciting Times in Obtaining Motion Pictures. How the Machine Came to Be Invented and the Newest Developments in Cinematography. |

195 |

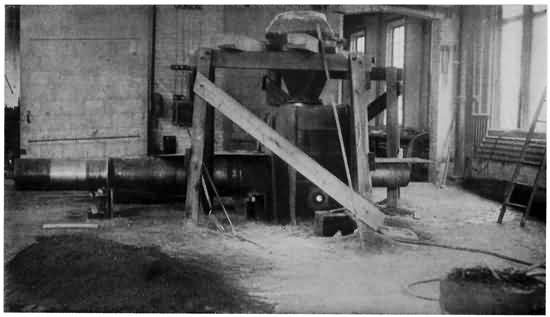

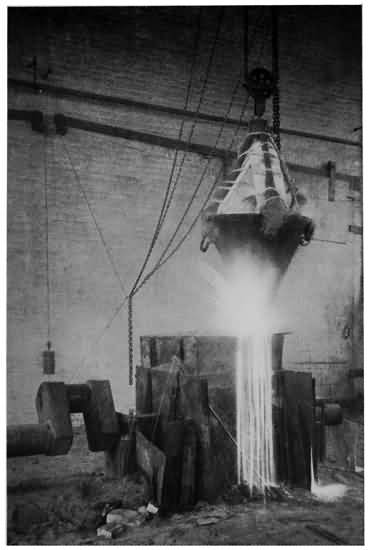

| VII. | Steel Boiled Like Water and Cut Like

Paper Our Boy Friend Sees How Science Has Turned the Greatest Known Heats to the Everyday Use of Mankind. |

224 |

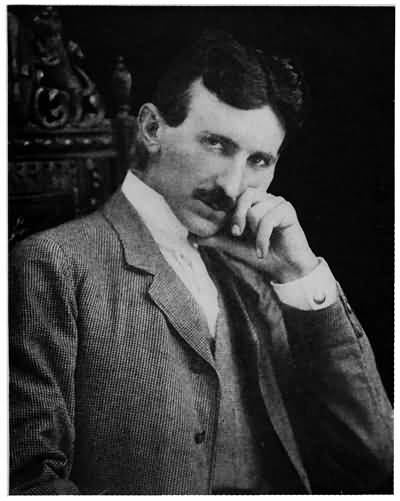

| VIII. | The Tesla Turbine Dr. Nikola Tesla Tells of His New Steam Turbine Engine, a Model of Which, the Size of a Derby Hat, Develops More Than 110 Horse Power. |

263 |

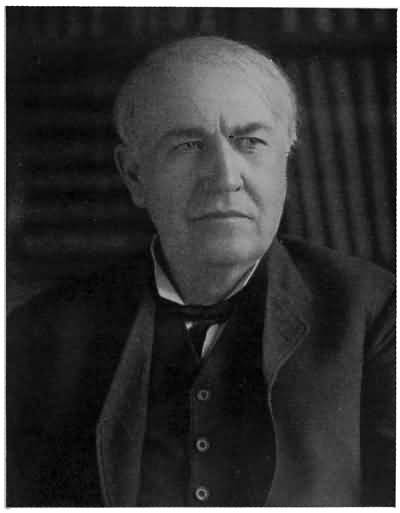

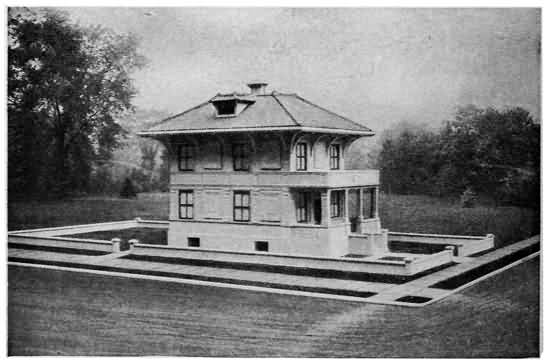

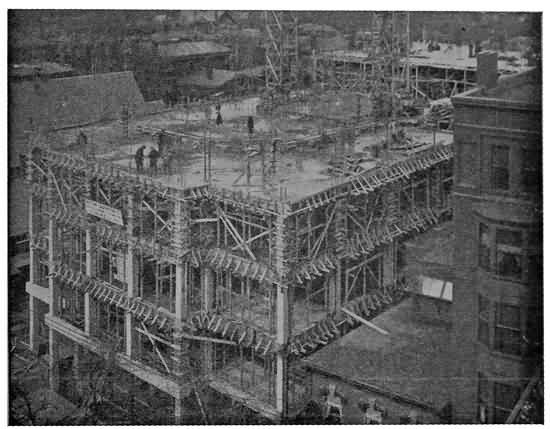

| IX. | The Romance of Concrete The One Piece House of Thomas A. Edison and Other Uses of the Newest and Yet the Oldest Building Material of Civilized Peoples, Seen By the Boy and His Scientific Friend. |

288 |

| X. | The Latest Automobile Engine Our Boy Friend and the Scientist Look Over the Field of Gasoline Engines and See Some Big Improvements Over Those of a Few Years Ago. |

320 |

| XI. | The Wireless Telegraph Up To The Minute The Scientist Talks of Amateur Wireless Operators. The Great Development of Wireless That Has Enabled It to Save Three Thousand Lives. Long Distance Work of the Modern Instruments. |

332 |

| XII. | More Marvels of Science Color Photography, the Tungsten Electric Lamp, the Pulmotor, and Other New Inventions Investigated by Our Boy Friend. |

352 |

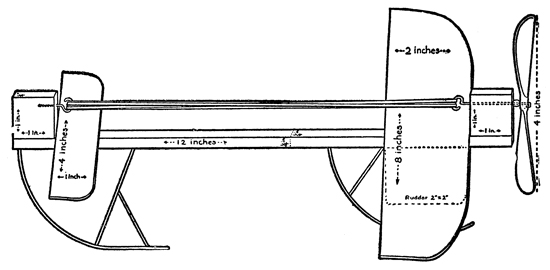

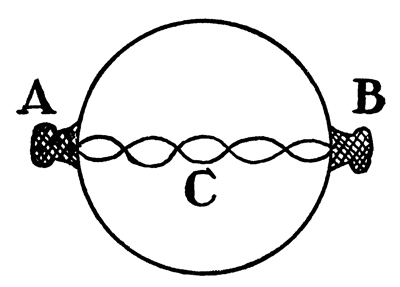

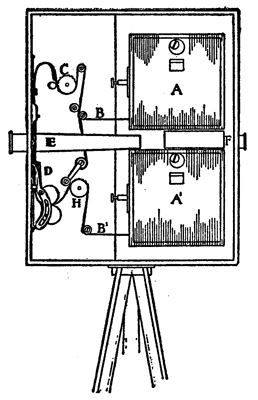

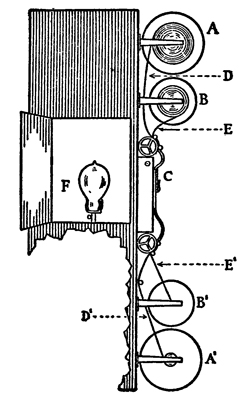

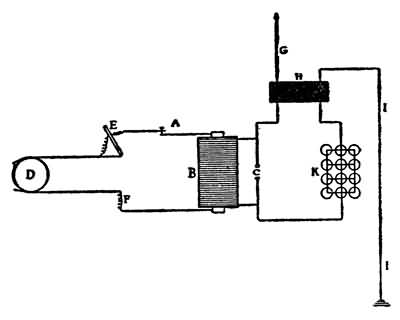

LIST OF DIAGRAMS

THE BOY'S BOOK OF NEW INVENTIONS

HOW A SCIENTIST WHO LIKED BOYS AND A BOY WHO LIKED SCIENCE FOLLOWED THE FASCINATING STORY OF THE INVENTION OF THE AEROPLANE.

WHEN, with engine throbbing, propellers whirling, and every wire vibrating, the first successful aeroplane shot forward into the teeth of a biting December gale and sailed steadily over the bleak North Carolina sand dunes for twelve seconds, the third great epoch in the age of invention finally was ushered in. First, man conquered the land with locomotive, electricity, steam plow, telegraph, telephone, wireless and a thousand other inventions. Almost at the same time he conquered the ocean with steamship, cable, and wireless. Now, through the invention of the aeroplane, he is making a universal highway of the air.

Such was the way the real beginning of aviation was summarized one day to a bright young man who spent all his spare time out of school at the laboratory of his good friend the scientist. Always in good humour, and with a world of knowledge of things that 4 delight a boy's heart, the man was never too deep in experiments to answer any questions about the great inventions that have made this world of ours such a very interesting place

The laboratory was filled with models of machines, queer devices for scientific experiment, a litter of delicate tools, shelves of test tubes, bottles filled with strange smelling fluids, and rows upon rows of books that looked dull enough, but which the scientist explained to the boy contained some of the most fascinating stories ever told by man.

Coming back to aeroplanes the boy said, "But my father says that aviation is so new it is still very imperfect."

"That is true," answered the scientist, taking a crucible out of the flame of his Bunsen burner and hanging it in the rack to cool, "but it has seen a marvellous development in the last few years.

"It was less than ten years ago—the end of 1903, to be exact—that Orville and Wilbur Wright first sailed their power-driven aeroplane," he continued, "but so rapid has been the progress of aviation that nowadays we are not surprised when a flight from the Atlantic to the Pacific is accomplished. It seems a tragic thing that Wilbur Wright should have been called by death, as he was in May, 1912, by typhoid fever, for he was at the very zenith of his success and probably would have carried on his work to a far, far greater development."

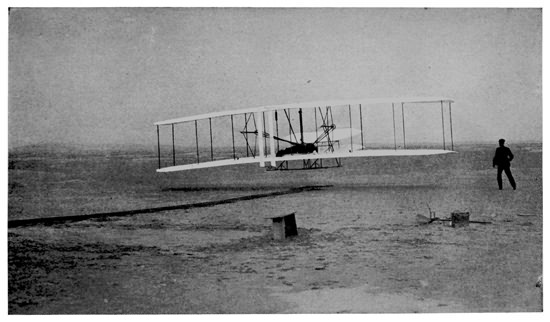

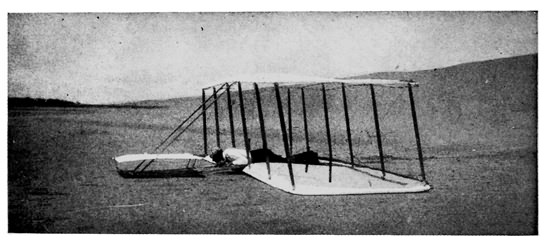

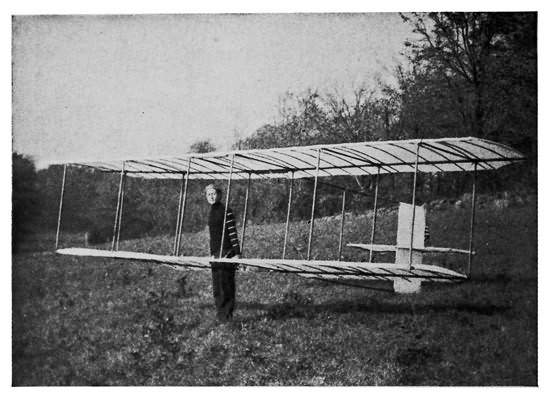

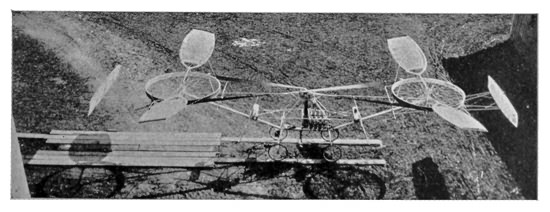

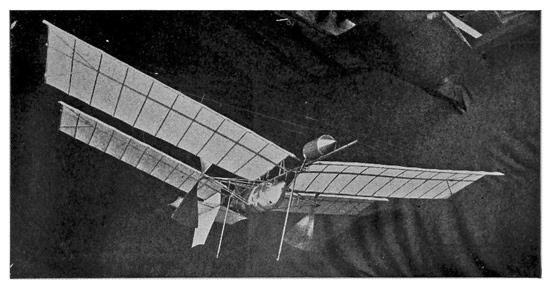

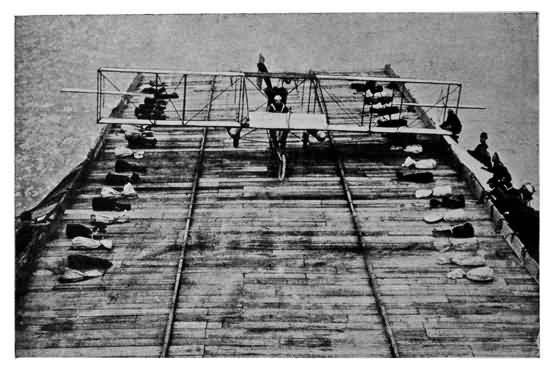

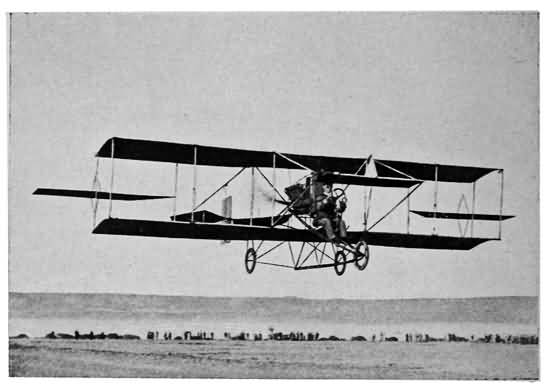

THE FIRST WRIGHT AEROPLANE

This was the machine that made the first successful flight in the history of the world, of a power-driven, man-carrying aeroplane

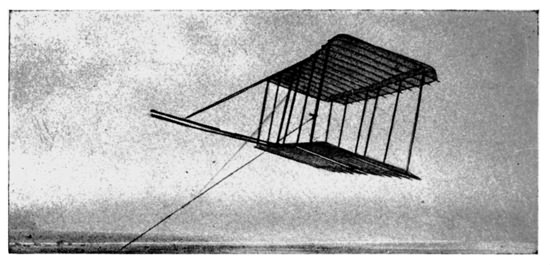

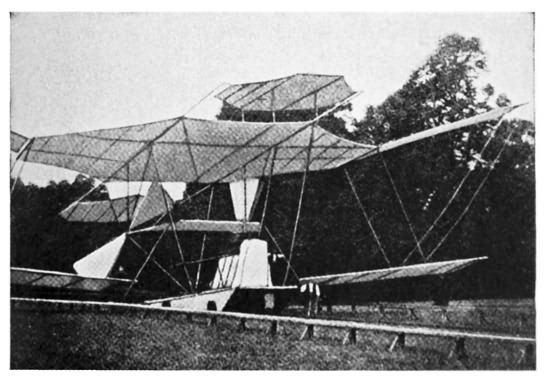

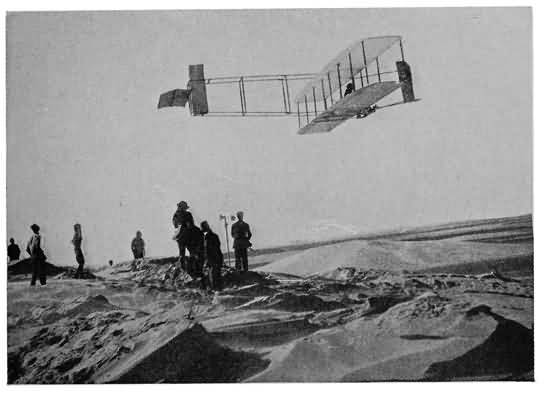

THE FIRST WRIGHT GLIDER

This device was first flown as a kite without a pilot, and the levers worked by ropes from the ground, to test the principles

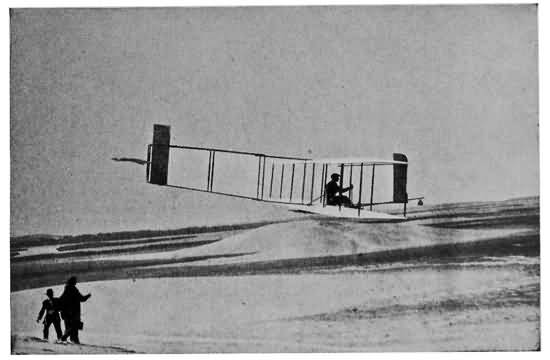

THE SECOND WRIGHT GLIDER

The machine was launched into the air from the top of a sand dune against a high wind, and proved a great success

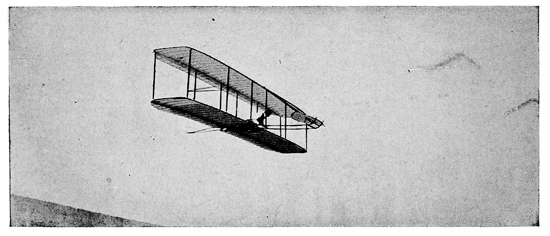

A LONG GLIDE

Wright glider in full flight over Kill Devil Hill, N. C.

5 After a little pause the scientist continued, saying that, at the time the Wright brothers made their first flight they were experimenting with what we now know as a biplane, or Chanute type glider, at Kill Devil Hill, near Kitty Hawk, N. C. It is a desolate wind-swept spot on the coast where only a little rank marsh grass grows on the sheltered sides of the great sand dunes. The brothers chose this barren place for their experiments because here the winds were the most favourable for their purpose.

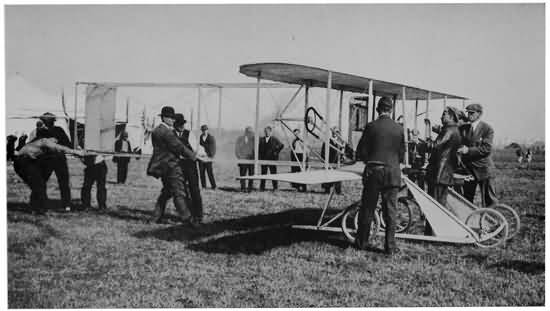

They were not ready for their first attempt to fly in a motor-propelled machine until December 17th, and though they sent out a general invitation to the few people living in that section, only five braved the cold wind. Three of these were life savers from the Kill Devil Hill station near by. Doubtless the other people had heard of the numerous failures of flying machines and expected the promised exhibition of the silent young men who had spent the autumn in their neighbourhood, to be just another such. They were sadly mistaken, for they missed a spectacle that never before had been seen in all the history of the world. Nowadays we are familiar with the sight of an aeroplane skimming over the ground and then soaring into the sky, but to the five people who, besides the inventors, were present it undoubtedly was almost beyond belief.

The brothers had installed a specially constructed gasoline engine in their glider, and after thoroughly 6 testing it they carried the machine out on to a level stretch of sand, turned it so that it would face the wind, and while the life savers held it in place the brothers went over every wire and stay. They felt perfectly confident that the machine would fly, but they made no predictions, and in fact spoke but few words between themselves or to the five men gathered about the aeroplane. The machine was not the smoothly finished one we know to-day as the Wright biplane. The operator lay flat on his face on the lower plane, the elevating rudder composed of two smaller planes stuck out in front, instead of behind, and there were several other important differences in design, but in principle it was the same machine that has carried the fame of the American inventors around the world.

Finally the operator took his place, the engine was started, the signal was given, the men holding the machine dropped back and it started out along the rail from which it was launched. It ran along the track to the end, directly against the wind, and rose into the air.

It meant that the air had been turned into a highway, but the Wright brothers were very modest in setting down an account of their achievement.

"The first flight," they wrote, "lasted only twelve seconds," a flight very modest compared with that of birds, but it was, nevertheless, the first in the history of the world in which a machine carrying 7 a man had raised itself by its own power into the air in free flight, had sailed forward on a level course without reduction of speed, and had finally landed without being wrecked. The second and third flights (the same day) were a little longer, and the fourth lasted fifty-nine seconds, covering a distance of 853 feet over the ground against a twenty-mile wind.

"After the last flight the machine was carried back to camp and set down in what was thought to be a safe place. But a few minutes later, when engaged in conversation about the flights, a sudden gust of wind struck the machine and started to turn it over. All made a rush to stop it, but we were too late. Mr. Daniels, a giant in stature and strength, was lifted off his feet, and, falling inside between the surfaces, was shaken about like a rattle in a box as the machine rolled over and over. He finally fell out upon the sand with nothing worse than painful bruises, but the damage to the machine caused a discontinuance of experiments."

"Thus," said the scientist, we see the record aeroplane flight for 1903 was 853 feet while in 1911 a Wright biplane flew more than 3,000 miles from the Atlantic to the Pacific. In ten years more we may look back to our monoplanes and biplanes of to-day in the same way we do now on the first cumbersome 'horseless carriages' that were replaced by the high-powered automobiles we know now. Some experts in 8 aeronautics say that we may even see the complete passing of the monoplane and biplane types in favour of some now unknown kind of aeroplane."

Who knows but that the man to invent the perfect aeroplane will be one of the boy readers of this! Everywhere the making and flying of model aeroplanes by boys is looked upon, not only as play, but as a valuable and instructive sport for boys and young men of any age. One of the indications of this may be seen in the public interest taken in the tournaments of boys' model aeroplane clubs. Not only do crowds of grown people with no technical knowledge of aeroplanes attend the tournaments, but also older students of aviation who realize that among the young model fliers there may be another Orville or Wilbur Wright, a BlÚriot, or a Farman.

So important is this knowledge of aviation considered that the principles and the practical construction of model aeroplanes are taught in many of the public schools. Instead of spending all their school hours in the study of books, the boys now spend a part of their time in the carpenter shop making the model aeroplanes which they enter in the tournaments. Of course, dozens of types of models are turned out, some good and some bad, but in the latter part of Chapter III is given a brief outline for the construction of one of the simplest and most practicable model aeroplanes.

Not only the schools but the colleges also have 9 taken up aviation, and nearly every college has its glider club, and the students work many hours making the gliders with which they contest for distance records with other clubs. As a consequence aviation has become a regular department of college athletics, and intercollegiate glider meets are a common thing.

The epochs of invention go hand in hand with the history of civilization, for it has been largely through invention that man has been able to progress to better methods of living. In the olden days, when there were few towns and every one lived in a castle, or on the land owned by the lord of the castle, war was the chief occupation, and the little communities made practically everything they used by hand. When they went abroad they either walked or rode horses, or went in clumsy ships. Pretty soon men began to invent better ways of doing things; one a better way of making shoes, another a better way of making armour, and the people for miles around would take to going to these men for their shoes and armour. Towns sprang up around these expert workmen, and more inventions came, bringing more industries to the towns. Inventions made industry bigger, and war more disastrous because of the improvement invention made in weapons. Then came inventions that changed the manner of living for all men—the machines for making cloth, which did away with the spinning-wheels of our great-grandmothers, and created the great industry 10 of the cotton and woollen mills; the inventions for making steel that brought about the great steel mills, and enabled the armies of the world to use the great guns we know to-day, and the battleships to carry such heavy armour plate; the steam locomotive that enabled man to travel swiftly from one city to another; the steamship that brought all the nations close together; the telegraph, cable, telephone, and wireless, that made communication over any distance easy; the submarine that made war still more dangerous; and finally the aeroplane that makes a highway of the air in which our earth revolves.

But even from the time of the ancient Greeks and Romans man had tried to fly. Every nation had its list of martyrs who gave their lives to the cause of aviation. In modern times, too, many attempts had been made to discover the secret of flight. Otto Lilienthal, a German, called the "Flying Man," had made important discoveries about air currents while gliding through the air from hills and walls by means of contrivances like wings fitted to his person. Others had made fairly successful gliders, and Prof. Samuel Pierepont Langley of the Smithsonian Institution in Washington actually had made a model aeroplane that flew for a short distance. Also, Clement Ader, a Frenchman, had sailed a short way in a power flier, and Sir Hiram Maxim, the English inventor, had built a gigantic steam-driven aeroplane that gave some evidences of being able to fly. But these men 11 were laughed at as cranks, while the Wrights kept their secret until they were sure of the success of their biplane. However, the question as to who first rode in a power-driven flier under the control of the operator still is the subject of a world-wide controversy.

It was as boys that the Wright brothers first began experiments with flying, and though they have received the highest praises from the whole world, Orville still is, and until his death Wilbur was, the same quiet, modest man who made bicycles in Dayton, and the surviving brother of the pair is working harder than ever. In telling the story of their own early play, that later proved to be one of the most important things they ever did, the Wright brothers wrote for the Century Magazine: "We devoted so much of our attention to kite-flying that we were regarded as experts. But as we became older we had to give up the sport as unbecoming to boys of our age." As every boy knows, kite-flying was one of the early methods of experimenting with air currents and greatly aided the scientists in their exploration of the ocean of air that surrounds the world, eddying and swirling up and down, running smoothly and swiftly here, coming to a dead stop there—but always different from the minute before.

But before the Wright brothers gave up flying kites they had played with miniature flying machines. 12 They were known then as "helicopteres," but the Wright brothers called them "bats," as the toys came nearer resembling bats than anything else the boys had seen about their home in Dayton, Ohio. Most boys probably have played with something of the kind themselves, and maybe have made some. They were made of a light framework of bamboo formed into two screws driven in opposite directions by twisted rubber bands something like the motors on boys' model aeroplanes of to-day. When the rubber bands unwound the "bats" flew upward.

"A toy so delicate lasted only a short time in our hands," continues the story of the Wright brothers, "but its memory was abiding. We began building them ourselves, making each one larger than that preceding. But the larger the 'bat' the less it flew. We did not know that a machine having only twice the size of another would require eight times the power. We finally became discouraged."

This was away back in 1878, and it was not until 1896 that the Wright brothers actually began the experiments that led to their world-famous success.

Strangely enough it all started when Orville, the younger of the two, was sick with typhoid fever, the same disease that caused Wilbur Wright's death. According to all accounts, the elder brother, having remained away from their bicycle factory in order to nurse Orville, was reading aloud. Among other 13 things he read to Orville the account of the tragic death of Otto Lilienthal, the German "Flying Man" who was killed while making a glide.

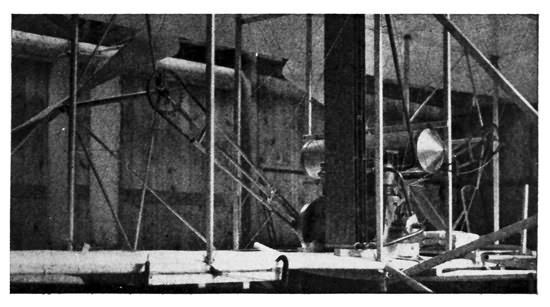

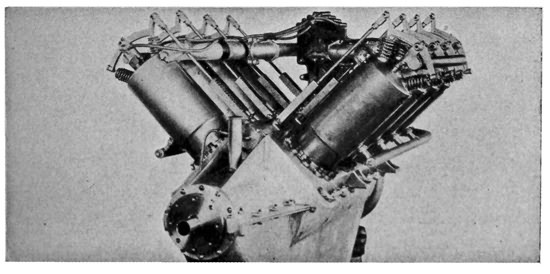

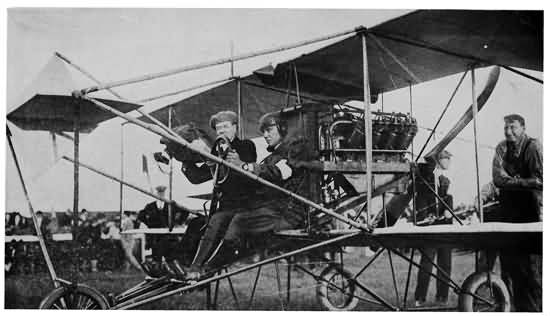

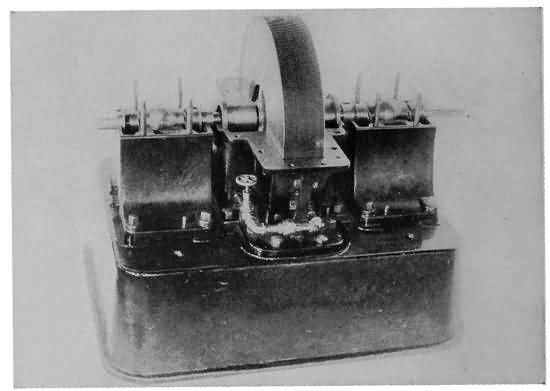

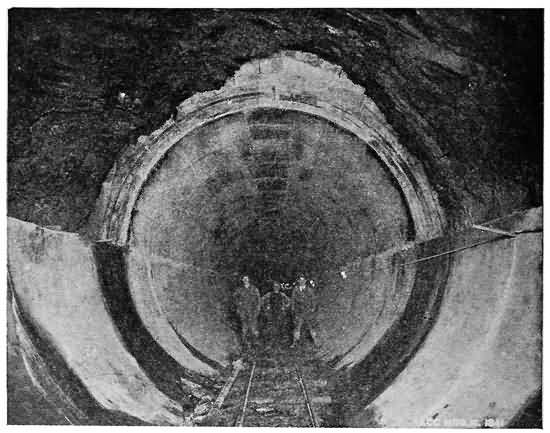

MOTOR OF THE WRIGHT BIPLANE

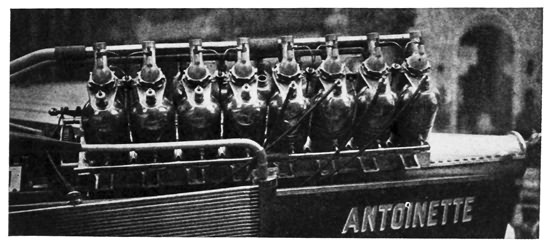

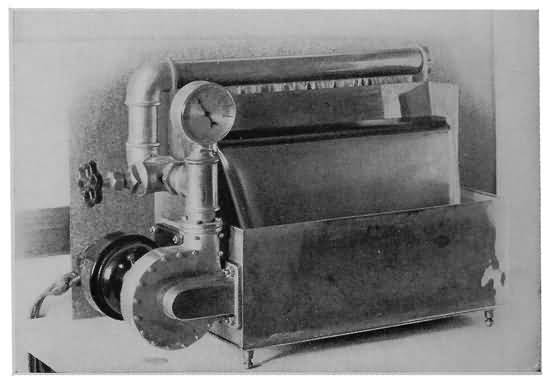

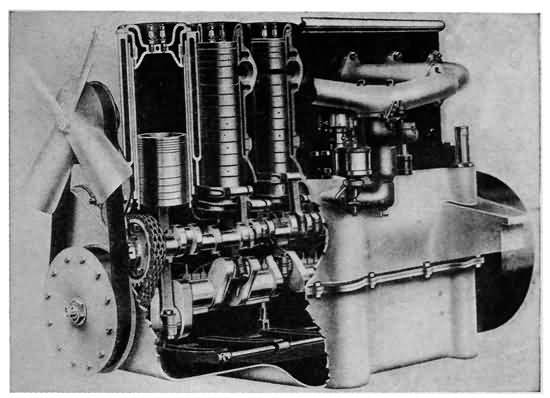

A 16-CYLINDER 100-HORSEPOWER ANTOINETTE MOTOR

A frequent prize winner

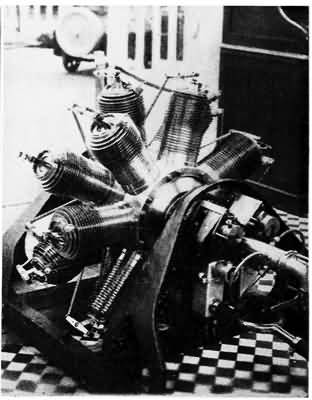

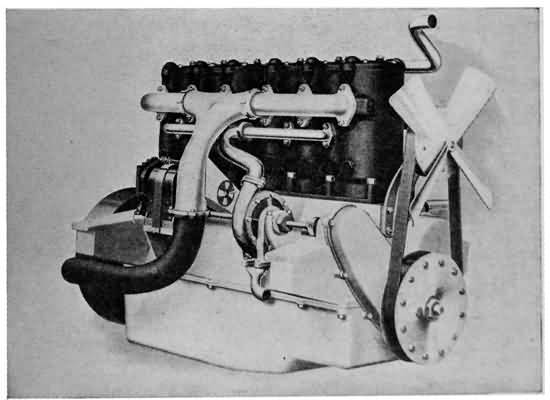

AN 8-CYLINDER 5O-HORSEPOWER CURTISS MOTOR

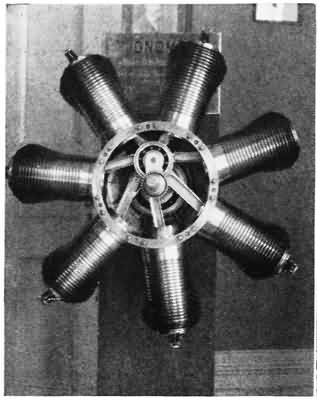

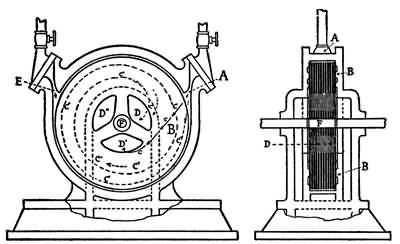

THE GNOME MOTOR

Standard Gnome aeroplane motor, showing interior.

Photo by Philip W. Wilcox

Fourteen-cylinder 100-horsepower Gnome motor. Used on many racing aeroplanes.

Courtesy of the Scientific American

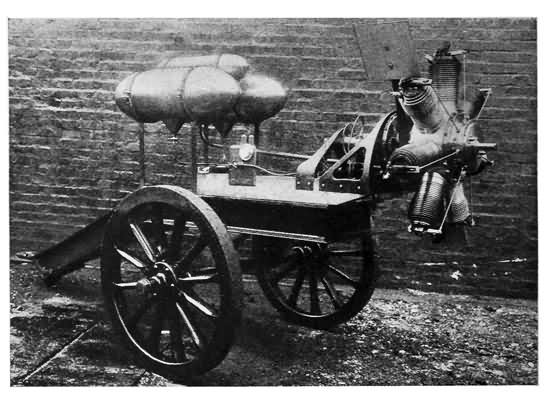

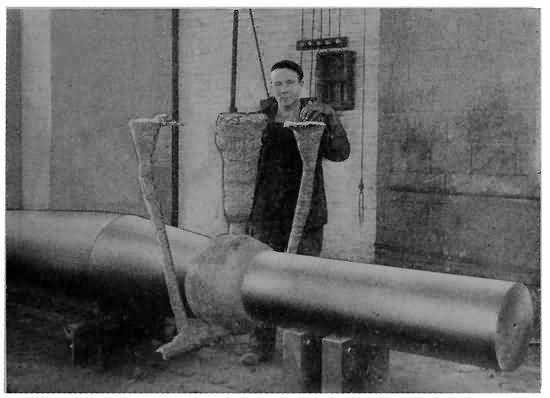

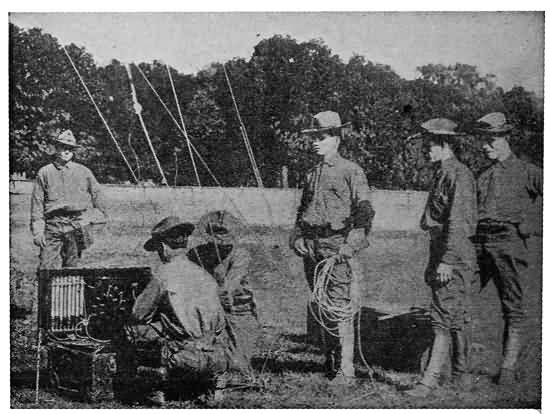

Testing a Gnome motor on a gun carriage. So great is the power of the engine that the tongue of the heavy carriage is buried in the ground to hold it in place

"Why can't we make a glider that would be a success?" the brothers asked each other. They were sure they could, and they got so excited in talking it over that it nearly brought back Orville's fever. When he got well they studied aeronautics with the greatest care, approaching the subject with all the thoroughness that later made their name a byword in aviation for care and deliberation.

Neither of these two young men was over demonstrative, and neither was lacking in the ability for years and years of the hardest kind of work, but together they made an ideal team for taking up the invention of something that all the scientists of the world hitherto had failed to develop. Wilbur was called by those who knew him one of the most silent men that ever lived, as he never uttered a word unless he had something to say, and then he said it in the most direct and the briefest possible manner. He had an unlimited capacity for hard work, nerves of steel and the kind of daring that makes the aviator face death with pleasure every minute of the time he is in the air.

No less daring is Orville, the younger of the two, who is a little bit more talkative and more full of enthusiasm than was Wilbur. He was the man the reporters always went to when they knew the elder 14 brother would never say a word, and his geniality never failed them. He also is a true scientist and tireless in the work of developing the art of aviation.

First, the brothers read all the learned and scientific books of Professor Langley, and Octave Chanute, the two first great American pioneers in aviation, and the reports of Lilienthal, Maxim, and the brilliant French scientists.

They saw, as did Professor Langley, that it was out of the question to try to make a machine that would fly by moving its wings like a bird. Then they began with great kites, and next made gliders—that is, aeroplanes without engines—for the brothers knew that there was no use in trying to make a machine-driven, heavier-than-air flier before they had tested out practically all the theories of the earlier scientists.

They fashioned their gliders of two parallel main planes like those of Octave Chanute. The width, length, distance between planes, rudders, auxiliary planes and their placing were all problems for the most careful study. It was very discouraging work, for no big thing comes easily. As their experiments proceeded they said they found one rule after another incorrect, and they finally discarded most of the books the scientists had written. Then with characteristic patience they started in to work out the problem from first principles. "We had taken aeronautics merely as a sport," they wrote 15 later. "We reluctantly entered upon the scientific side of it. But we soon found the work so fascinating that we were drawn into it deeper and deeper."

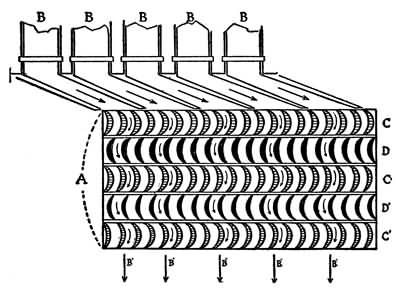

The Wrights knew that an oblong plane—that is, a long narrow one—driven through the air broadside first is more evenly supported by the air than would be a plane of the same area but square in shape. The reason for this is that the air gives the greatest amount of support to a plane at the entering edge, as it is called in aviation—that is, the edge where it is advancing into the air. A little way from the edge the air begins to slip off at the back and sides and the support decreases. Thus, it will be seen that if the rear surface, which gives little support because the air slips away from under it, is put at the sides, giving the plane a greater spread from tip to tip and not so much depth from front to rear, the plane is more efficient—that is, more stable, less subject to drifting, and better able to meet the varying wind currents. Scientists call this proportion of the spread to the depth the aspect ratio of planes. For instance, if a plane has a spread of 30 feet and a depth of 6 feet it is said to have an aspect ratio of 5. This is a very important consideration in the designing of an aeroplane, because aspect ratio is a factor in the speed. In general, high speed machines have a smaller aspect ratio than slower ones. The aspect ratio also has an important bearing on the general efficiency of an aeroplane, but the lifting power of 16 a plane is figured as proportionate to its total area. In order to hold the air, and keep its supporting influence, aviators have tried methods of enclosing their planes like box kites, and putting edges on the under sides. This latter was found a mistake because the edge tended to decrease the speed of the flier and did more harm than the good obtained through keeping the air.

In aviation, as we know it to-day, aeroplane builders believe in giving their planes a slight arch upward and backward from the entering edge, letting it reach its highest point about one third of the way back and then letting it slope down to the level of the rear edge gradually. This curve, which is called the camber, is mathematically figured out with the most painstaking care, and was one of the things the Wright brothers worked out very carefully in their early models. Also, planes are driven through the air at an angle—that is, with the entering edge higher than the rear edge—because the upward tilt gives the air current a chance to get under the plane and support it. This angle is called by the scientists the angle of incidence and is very important because of its relation to the lifting powers of the planes.

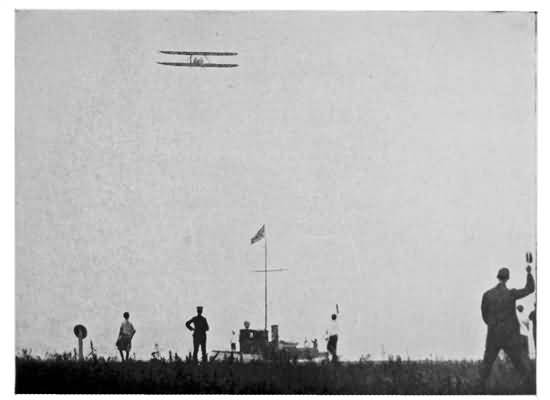

MODEL AEROPLANE FLIERS

Every fair Saturday the model makers and fliers spend in the parks either practising for or holding flight tournaments

A MODERN COLLEGE MAN'S GLIDER

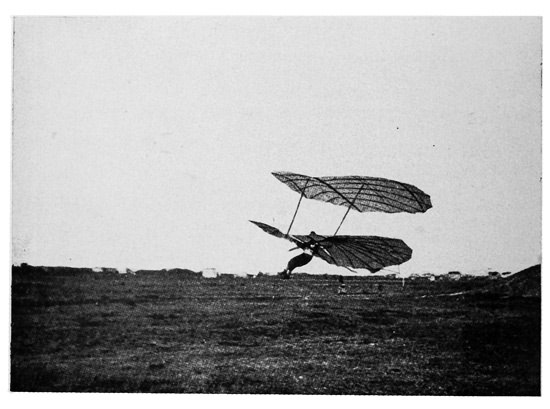

OTTO LILIENTHAL MAKING A FLIGHT IN HIS GLIDER

Another one of the difficult problems the inventors had to struggle with was the balance of their fliers. Before the Wright brothers flew, it was thought that one of the best ways was to incline the planes upward 17 from the centre—that is—make them in the shape of a gigantic and very broad V. This is known in science as a dihedral angle. The idea was that the centre of gravity, or the point of the machine which is heaviest and which seeks to fall to earth first through the attraction of gravitation, should be placed immediately under the apex of the V. The scientists thought that the V then would keep the machine balanced as the hull of a ship is balanced in the water by the heavy keel at the bottom. The Wrights decided that this might be true from a scientific point of view, but that the dihedral angle kept the machine wobbling, first to one side and then righting itself, and then to the other side and righting itself. This was a practical fault and they built their flier without any attempt to have it right itself, but rather arched the planes from tip to tip as well as from front to rear.

The winglike gliders of Lilienthal and Chanute had been balanced by the shifting of the operator's body, but the Wrights wanted a much bigger and safer machine than either of these pioneers had flown. In their own words, the Wrights "wished to employ some system whereby the operator could vary at will the inclination of different parts of the wings, and thus obtain from the wind forces to restore the balance which the wind itself had disturbed." This they later accomplished by a device for warping or bending their planes, but in their first glider there 18 was no warping device and the horizontal front rudder was the only controlling device used. This latter device on the first glider was made of a smaller plane, oblong-shaped and set parallel to, and in front of, the main planes. It was adjustable through the system of levers fixed for the operator, who in those days lay flat on the front plane.

Thus the two main planes and the adjustable plane in front with stays, struts, etc., made up the first Wright glider.

The Wright brothers took their machine to Kitty Hawk, N. C., in October, 1900, presumably for their vacation. They went there because the Government Weather Bureau told them that the winds blew stronger and steadier there than at any other point in the United States. Also it was lonely enough to suit the Wrights' desire for privacy. It was their plan to fly the contrivance like a boy does a huge box kite, and it looked something like one. A man, however, was to be aboard and operate the levers. According to the Wright brothers' story the winds were not high enough to lift the heavy kite with a man aboard, but it was flown without the operator and the levers worked from the ground by ropes.

A new machine the next year showed little difference of design, but the surface of the planes was greater. Still the flier failed to lift an operator. At this time the Wright brothers were working with Octave Chanute, the Chicago inventor, engineer and 19 scientist whom they had invited to Kitty Hawk to advise them. After many discussions with Chanute they decided that they would learn the laws of aviation by their own experience and lay aside for a time the scientific data on the subject.

They began coasting down the air from the tops of sand dunes, and after the first few glides were able to slide three hundred feet through the air against a wind blowing twenty-seven miles an hour. The reason their glider flights were made against the wind was because the wind passing swiftly under the planes had the same effect as if the machine was moving forward at a good clip, for the faster the machine moves, or the faster the air passes under it, the easier it remains aloft. In other words, no one part of the air was called upon to support the planes for any length of time, but each part supported the planes for a very short time. For instance, if you are skating on thin ice you run much less danger of breaking through if you skate very fast, because no one part of the ice is called upon to support you for long.

In 1902 the Wright brothers were approaching their goal. Slowly and with rare patience they were accumulating and tabulating all the different things different kinds of planes would do under different circumstances. In the fall of that year they made about one thousand gliding flights, several of which carried them six hundred feet or more. Others 20 were made in high winds and showed the inventors that their control devices were all right.

The next year, 1903, which always will be remembered as the banner one in the history of aviation, the brothers, confident that they were about to succeed in their long search for the secret of the birds, continued their soaring or gliding. Several times they remained aloft more than a minute, above one spot, supported by a high, steady wind passing under their planes.

"Little wonder," wrote the Wright brothers a few years, later, "that our unscientific assistant should think the only thing needed to keep it indefinitely in the air would be a coat of feathers to make it light."

What the inventors did to keep their biplane glider in the air indefinitely, however, was to add several hundred pounds to the weight in the shape of a sixteen-horsepower gasoline motor. The total weight of the machine when ready to fly was 750 pounds. Every phase of the problem had been worked out in detail—all the calculations gone over and proved both by figures and by actual test. The planes, rudders, and propellers had been designed by mathematical calculations and practical tests.

The main planes of this first machine had a spread from tip to tip of 40 feet, and measured 6 feet 6 inches from the entering edge to the rear edge, a total area of 540 square feet. This will show how 21 great is the spread of the main planes as compared to their length from front to rear. The two surfaces were set six feet apart, one directly above the other, while the elevating rudder was placed about ten feet in front of the machine on a flexible framework. This elevating rudder was composed of two parallel horizontal planes which together had an area of eighty square feet. The elevating planes could be moved up or down by the operator just as he desired to fly upward or downward. The machine was steered from right to left or left to right by two vertical vanes set at the rear of the machine about a foot apart. They were a little more than six feet long, extending from the upper supporting plane to a few inches below the lower supporting plane. These also were turned in unison by the operator, according to the direction toward which he wished to fly.

The most intricate device of their machine, however, was not perfected on their first biplane. This is the one for maintaining a side to side balance, or lateral equilibrium, as the scientists say. In watching the flights of gulls, hawks, eagles, and other soaring birds, the brothers had observed that the creatures, while keeping the main part of their wings rigid, frequently would bend the extreme tips of their wings ever so slightly, which would seem to straighten their bodies in the air. The inventor decided that they needed some such device as nature had given to these birds.

22 The system was called by the scientists the torsional wing system, which means that the tip ends of the wings were flexible and could be warped or bent or curled up or down at will by the operator. Only the rear part of the tips of the wings on the Wright machines could be bent, but this was enough to keep the machine on an even keel when properly manipulated. How the Wright modern machines are operated is fully described on page (99). The whole machine was mounted on a pair of strong light wooden skids like skiis or sled-runners.

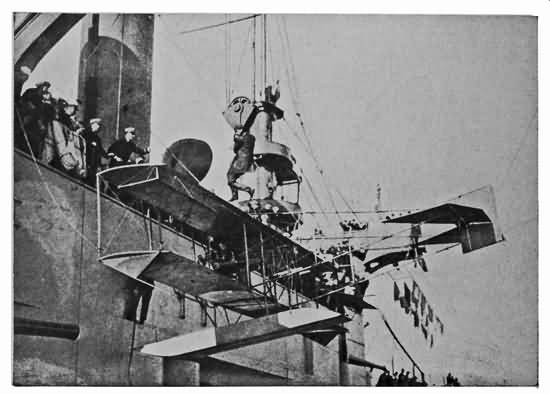

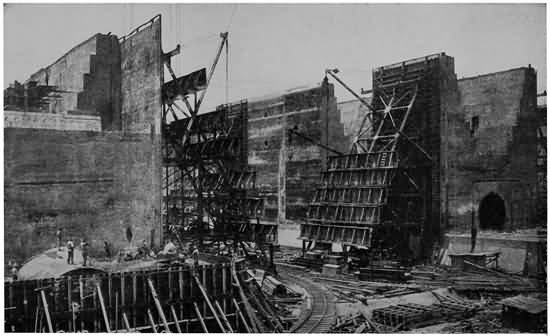

To start the early Wright biplanes, the machines were placed on a monorail, along which they were towed by a cable. The force for towing them at sufficient speed was obtained by dropping from the top of a derrick built at the rear of the rail a ton of iron which was connected with the cable. The later Wright biplanes were equipped with rubber-tired wheels mounted on the framework, which still retained the skids. Heavy rubber springs were provided to absorb the shock. With the wheels the machine could run over the ground of its own power and thus the cumbersome derrick and monorail were done away with.

The operator was supposed to lie on his face in the middle of the lower plane, but in the later machines a seat was provided for him alongside the engine, and in still later ones seats for one or two passengers.

The engine which was designed by the Wright 23 brothers themselves for this purpose, was a water-cooled four-cylinder motor which developed sixteen horsepower from 1,020 revolutions per minute. The engine was connected with the propellers at the rear of the biplane by chains. The propellers were about eight feet in diameter and the blades were six to eight inches wide. The materials used in the biplane were mostly durable wood like spruce pine and ash, the metal in the engine and the canvas on the planes. There was not one superfluous wire. Everything had a use, and even the canvas was stretched diagonally that it might fit more tightly over the framework of the planes and offer less wind resistance, and also stretch more easily for the wing warping.

Finally on December 17, 1903, everything was in readiness for the first attempt of these two patient men—then unknown to the world—to fly in a power-driven machine. That first flight, made practically in secret amid the desolate sand dunes of the North Carolina coast, lasted only twelve seconds. However, it was the first time, but one, in the history of the world that a machine carrying a man had lifted itself from the ground and flown entirely by its own power.

The two succeeding flights were longer, and the fourth covered 853 feet, lasting fifty-nine seconds.

The inventors were not heralded as the greatest men of their time. There were no medals or speeches. The five men—fishermen and life savers—who saw 24 the flights agreed that it was wonderful, but they kept the Wrights' secret and the brothers calmly continued their studies and experiments.

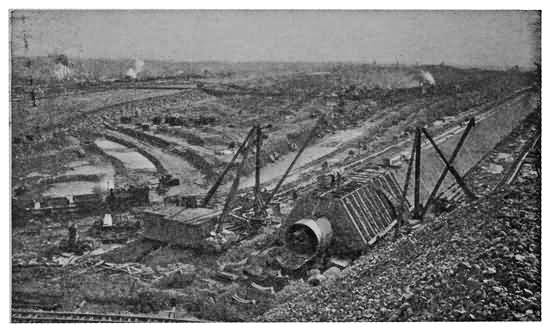

The spring of 1904 found them at work on Huffman Prairie about eight miles east of Dayton. The first trials there were not very successful and the brothers, who had worked seven long years in secret, had the unpleasant experience of failing to show satisfactory results to the few friends and reporters invited to see an aeroplane flight. Their new machine was larger, heavier, and stronger, but the engine failed to work properly.

Of course this was no great disappointment to those two silent, determined young men. "We are not circus performers," they said. "Our aim is to advance the science of aviation."

And advance it they did.

Their experiments continued, and in 1904 they made a record of three miles in 5 minutes 27 seconds. The next year, 1905, they made a record flight of 24.20 miles and remained in the air 38 minutes 13 seconds at heights of from 75 to 100 feet.

All this time the brothers were solving problems and correcting faults, but in 1904 and 1905 their chief endeavour was to keep their machines from tipping sidewise when they turned. Only the most technical study and the final development of their wing-warping device solved the problem.

Perhaps the strangest part was the lack of interest 25 shown in their work by the world and even by their own townsmen, for, though there had been several newspaper accounts of their test flights, no great enthusiasm was aroused.

They were not wealthy and they had spent more on their experiments than they could afford, so all this time they had proceeded without attracting any more attention than necessary. They desired to perfect their patents before letting the world know the secret of their inventions, and spent the next two years in business negotiations. Meanwhile, the French inventors were making much progress and soon brought out several successful aeroplanes.

Why was this?

Why was it that the art of air navigation sought by man since the earliest times should have been discovered and mastered so quickly?

The answer lies in the putting together of two things by the Wright brothers—that is, their discovery of the kind of a plane that would stay aloft with the air passing under it at a swift enough clip to give it support, and their adaptation of the gasoline engine to the use of driving the plane forward with enough speed.

When they began work, the gasoline engine was just coming to its real development. It was light, developed a high power, and its fuel could be concentrated into a small space. These things were essential to the success of the aeroplane—light weight, 26 high power, and concentrated fuel. And these were things that the early inventors lacked. Sir Hiram Maxim equipped his machine with a steam engine, while Langley used steam engines in most of his models. These were very heavy, cumbersome, gave slight power in comparison to their weight, and could carry only a little fuel with them.

Undoubtedly the adaptation of the gasoline engine to the use of the aeroplane marked the difference between mechanical flight and no flight, but it also is not to be doubted that those aviators, who are more mechanical than scientific, have overrated the importance of the engine in aeroplane construction. Before engines ever were used, the Chanute type of biplane had to be worked into a state of reliability, if not perfection. Now the scientific leaders in aviation are giving every bit as much attention to the perfection of their planes, their gliding possibilities, and the scientific rules governing their action as they are to their engines.

Most boys understand, at least generally, how an automobile or motor-boat engine works. Scientists call gasoline engines "internal combustion motors," and that means that the force is gathered from the explosion of the gasoline vapour in the cylinder. Enough gasoline to supply fuel to run an aeroplane motor for as much as eight or nine hours can be carried in the tank. From the tank a small pipe carries the gasoline to a device called the carbureter. 27 The carbureter turns the gasoline into gas by spraying it and mixing it with air, for gasoline turns into a very inflammable and explosive gas when mixed with the oxygen in the air. So this gas, if lighted in a closed space, will explode. The explosion takes place in the motor-cylinder by the application of an electric spark, and the force pushes the piston, which turns the crank and drives the aeroplane propeller, automobile wheels, or motor-boat screw.

Thus we have the piston driven out and creating the first downward thrust, but the thrusts must be continuous. The piston must be drawn back to the starting place, the vapours of the exploded gas expelled, and the new gas admitted to the cylinder ready for the next explosion. On the ordinary four-cycle motor two complete revolutions of the flywheel are necessary to do all the work. First, we must have the explosion that causes the initial thrust; second, the return of the piston rod in the cylinder by the momentum of the flywheel as it revolves from the initial thrust, thus forcing out the burned gas of the first explosion; third, the next downward motion to suck in a fresh supply of gas; and, fourth, the next upward thrust to compress it for the second explosion. It sounds simple enough, but it isn't, as every one knows who has tried to run a gasoline motor for himself.

The carbureter must do its work automatically 28 and convert the air and gasoline into gas in just the right proportions. A slight fault with the feed of gasoline or air would cause trouble. Also the electric-spark system that ignites the gas and causes the explosions must be in perfect running order. The explosions cause great heat, so some system of cooling the cylinders either by air or water must be used.

Only one cylinder has been explained here, but most engines have several, each working at a different stage, so that the power is exerted on the shaft continuously. For instance, take a four-cylinder engine; on the instant that the first cylinder is exploding and driving the shaft, the second cylinder is compressing gas for the next explosion, the third is getting a fresh supply of gas, and the fourth is cleaning out the waste gas of the explosion of a second before. Thus it will be seen why the explosions are almost constant.

Now think of the aeroplane motor that has fourteen cylinders and develops 140 horsepower! This is probably the most powerful aeroplane engine in the world, although there are many motor boats that have engines developing 1,000 horsepower.

In the early days when scientists were groping for the secret of air navigation the best that the clumsy steam engines they had at their disposal would do was to generate one horsepower of energy for every ten pounds of weight. These days the light powerful aeroplane engines we hear roaring over our heads 29 are generating one horsepower of energy for every three or three and a half pounds of dead weight, and engines have been constructed weighing only one pound to every horsepower, though they are impractical for general use.

The first engines that were used in aeroplanes were simply automobile engines adapted to air navigation. The main question in those days was lightness and power. This was achieved by skimming down the best available automobile engines so that they were as light as safety would allow.

Although lightness is still an important factor in aeroplane engine construction, many authorities declare that it is growing less so as the science advances and aeroplanes are able to carry heavier loads.

There were many intricate and difficult problems, however, that attended taking a motor aloft to drive an aeroplane. The motor had to run at top speed every second, for it could not rest on a low gear as an automobile engine could. First one part and then another would give out and the motors were constantly overheating. Experience taught the makers how to make their machines light enough and yet strong enough to do the required work.

It was in cooling that the greatest difficulties were met, and it was this that brought about the great innovations in motor building. The system of cooling the engine with water required much heavy 30 material, such as pipes, pumps, water, water jackets, and radiator.

On account of the general efficiency of a water-cooled engine many builders of aeroplanes stuck to it and developed it to a very high standard. At present many of the prize-winning engines are water cooled, as, for instance, the Wright and Curtiss.

All of these water-cooled engines and several standard air-cooled makes are of the reciprocating type that have stationary cylinders and crankcase while the crankshaft rotates like that of the motor boat.

The famous Curtiss, Anzani, Renault, and others are all engines of this type. They all differ, but all have a high capacity, as we know from the records they have broken. The Anzani and R. E. P. makers, whose motors are air cooled, have used to great advantage the plan of making their motors star-shaped—that is, with the cylinders arranged in a circle around the crankshaft.

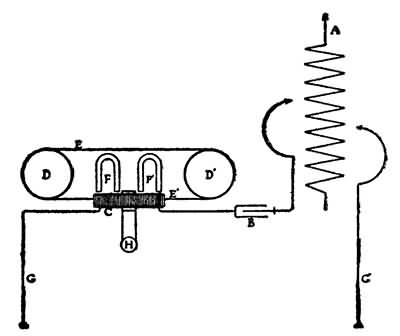

This is the shape taken by the famous air-cooled rotary engines of which the much-discussed Gnome is the best known make. In this rotary motor the cylinders and crankcase revolve about the crankshaft which is stationary. Authorities are divided over the Gnome, which has many severe critics as well as many enthusiastic supporters. Its lightness is certainly an advantage. The ordinary Gnome has 31 seven cylinders and develops fifty horsepower while the newest models have fourteen cylinders and develop 100 and 140 horsepower.

A brief description of the motor here will suffice to show the general principle of the rotary engine. The stationary crankshaft is hollow, and through it the gasoline vapour passes from the carbureter at the rear to the cylinders. Of course the inlet valves in the pistons are made to work automatically. The magneto is also placed behind the motor and the segments revolve on the crankcase. Wires extend from the segments to the spark plugs in the cylinders, and revolve with them. The cylinders are turned out of solid steel and the whole engine is conceded by experts to be one of the most wonderfully ingenious ever built. The cylinders and crankcase themselves serve as flywheel, thereby eliminating the dead weight of the usual heavy flywheel in the other types of motors, and the rotation serves to cool the engine perfectly. Again, the rotary motor is light and small, while it develops a tremendously high power. Aviators also claim for it other advantages too technical for consideration here.

Many authorities, in fact, declare that the rotary engine is the aeroplane motor of the future. It is very popular among the French aviators and at present holds a great many speed records. It was with one of these high-power Gnomes that Claude Grahame-White, the English flier, won the Gordon Bennett race 32 at Belmont Park in the fall of 1910, and Weyman again in England in 1911.

While this high state of development in the aeroplane motor has been attained comparatively within a few years, the art of flying has occupied the mind of man since it was described in Greek mythology. The Chinese for thousands of years have used kites and balloons. The ancient Greeks watched the wonderful flights of the birds and invented myths about men who were able to fly. Then Achytes, his mind fired by these stories, invented a device in the form of a wooden dove which was propelled by heated air. Other inventors made devices that were intended to fly, and during the reign of Nero, "Simon the Magician" held the world's first aviation meet in Rome. According to the account, he "rose into the air through the assistance of demons." It further states that St. Peter stopped the action of the demons by a prayer, and that Simon was killed in the resultant fall. Simon made another record that way by being the first man to be killed in an aeronautical accident. Other records show that Baldud, one of the early tribal kings in what later was named England, tried to fly over a city, but fell and was killed. A little later, in the eleventh century, a Benedictine monk made himself a pair of wings, jumped from a high tower and broke his legs. These wings really were rude gliders and the principle remained in the minds of men, even in those days when their chief occupation was war. 33 According to the legends, a man named Oliver of Malmesburg, who lived during the Middle Ages, built himself a glider and soared for 375 feet.

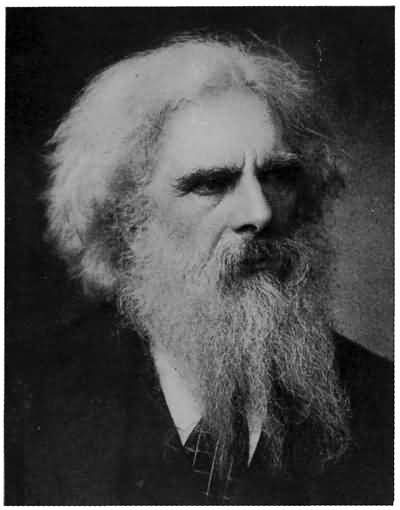

Courtesy of the Smithsonian Institution

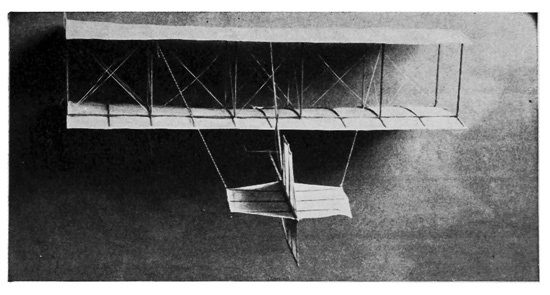

THE CHANUTE TYPE GLIDER

Upon this machine was based the invention of the biplane.

Courtesy of the Smithsonian Institution

THE HERRING GLIDER

Based on the idea of the Lilienthal gliders.

AN EARLY HELICOPTER

An idea that was abandoned before the aeroplane became a reality.

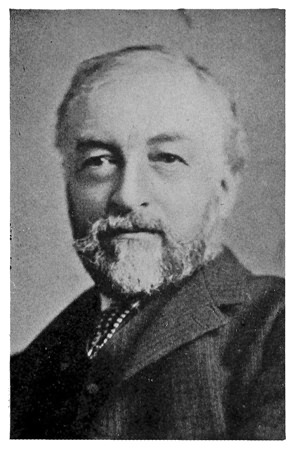

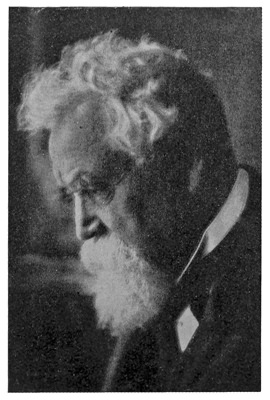

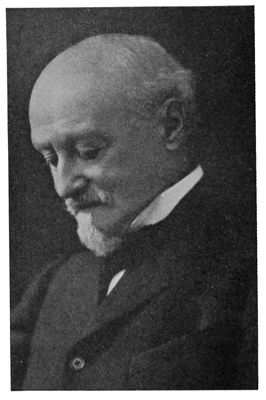

THE THREE GREAT PIONEERS IN AVIATION

Courtesy of the Smithsonian Institution

Prof. Samuel Pierpont Langley

Courtesy of the Scientific American

Sir Hiram Maxim

Courtesy of E. L. Jones, N. Y.

Octave Chanute

It was in the fifteenth century that men first began to make flying a scientific study by making records and, in part at least, tabulating the results of their experiments.

Among these early students of the science were Leonardo da Vinci, who is best known to the world as a painter and sculptor, but who was a great engineer and architect of his time, and Jean Baptiste Dante, a brother of the great poet. Although Da Vinci was the more scientific in his experiments, Dante made greater progress, and it is on record that he made many wonderful flights with a glider of his own construction over Lake Trasimene. He launched his glider from a cliff into the teeth of the wind, showing thereby his knowledge of the fact that a glider works best when flown against a high wind, because in that way the air is passing under it at greater speed. In one flight he made about 800 feet, which would be a fine record for any glider manipulated by an expert to-day. Finally Dante attempted an exhibition at Perugia, at the marriage festival of a celebrated general, fell on the roof of the Notre Dame Church and broke one of his legs.

Da Vinci had three different schemes for human flight. One was the old idea of bird flight, first dreamed of by the Greeks when Ovid wrote the poem 34 of "DŠdalus and Icarus." Scientists called the machine that Da Vinci proposed an orthopter and the operator was supposed by the movement of both arms and legs to fly by flapping the wings. Needless to say it did not work, and we know to-day that bird flight by wing flapping is probably impossible for man. Another of Da Vinci's ideas is still being worked upon by some inventors. This was a machine known as the helicopter, which was supposed to fly upward by the twisting of a great horizontal screw ninety-six feet in diameter. The idea was just the same as that of the toy that started the Wright brothers to thinking. The trouble with Da Vinci's machine was that he had no power to run it. Boys in playing with toy helicopters to-day can run them with rubber bands, but Da Vinci had to turn his screw by human power. Little was accomplished with this machine, although Da Vinci showed its practicability with models. The third scheme of this Italian scientist is one that many years later was perfected and demonstrated at every county fair—that is, the parachute. The first parachute was very crude, but it soon was developed to a fairly high stage of effectiveness and men came down from the tops of towers in them without much injury.

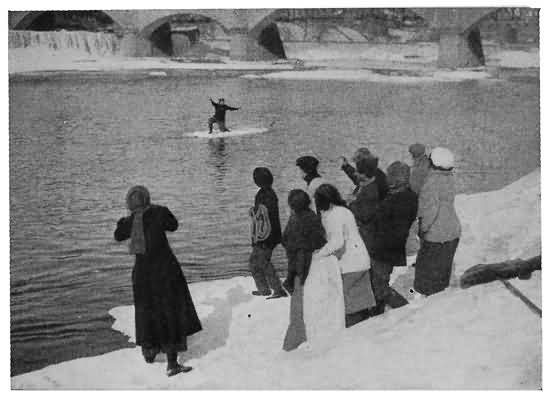

Again, in 1742, the Marquis de Bacqueville, then sixty-two years old, made a contrivance with which he flew about nine hundred feet before he fell into 35 a boat in the Seine River and broke his leg. The Marquis had announced in advance that he would fly from his great house in Paris, across the Seine River and land in the famous Garden of the Tuileries. A crowd assembled and marvelled when the nobleman sailed into the teeth of the wind supported by what apparently were great wings. Something went wrong after a flight that would be considered remarkable by a scientific glider to-day, and his fall resulted in a broken leg for the experimenter. According to the authorities, all these experiments were not very valuable to science, because while the flights were accurately described the construction of the fliers (except in the case of Leonardo da Vinci) was not given, or only indicated in the most uncertain and unscientific language.

In 1781 a French scientist named Blanchard attempted to make a flying machine of which the man driving it was to be the power. He was still working with it when ballooning became known, and he took up that sport with avidity.

At that point came the true division between heavier-than-air and lighter-than-air machines. Before 1783 many scientists had hinted at the practicability of a hot air or gas balloon, but all successful flying experiments had been made with what we suppose to have been some form of gliders. However, in 1783 Tiberius Cavallo, an Italian scientist living in London, made a small hydrogen balloon, 36 and was followed by the manufacture of fairly successful balloons by the Montgolfier brothers, two French inventors.

From that time ballooning, with which this chapter has no concern, made rapid strides, until to-day the balloon has reached the stage where great motor-driven balloons are used by the European armies, and also to carry passengers.

The next step in the heavier-than-air machine, known these days as the aeroplane, was taken in 1810, by Sir George Cayley, an Englishman and a true scientist, who constructed a glider and tabulated much valuable information. It was this scientist who made the first conclusive demonstrations looking toward the proof that man can never fly like a bird, but must proceed upon the principle of sustained planes. Sir George set down many laws of equilibrium governing the control of flying machines, estimated the power necessary to carry a man, and even hinted at the possibility of a gas engine more powerful and lighter than the then crude steam engine. He declared that a plane driven through the air, and inclined upward at a slight angle, would tend to rise and support a weight, and also that a tail with horizontal and vertical vanes would tend to steady the machine and enable the pilot to steer it up or down.

Courtesy of the Smithsonian Institution

LANGLEY'S STEAM MODEL

This tandem monoplane made several successful trial flights.

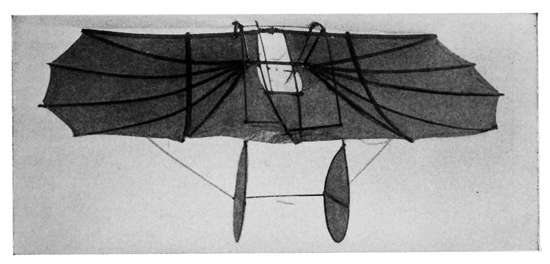

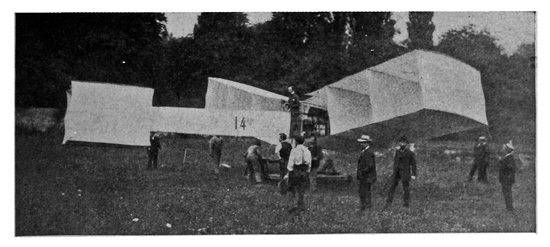

THE MAXIM AEROPLANE

Maxim's great machine was claimed as the first successful aeroplane. In trials it rose a few inches off the ground.

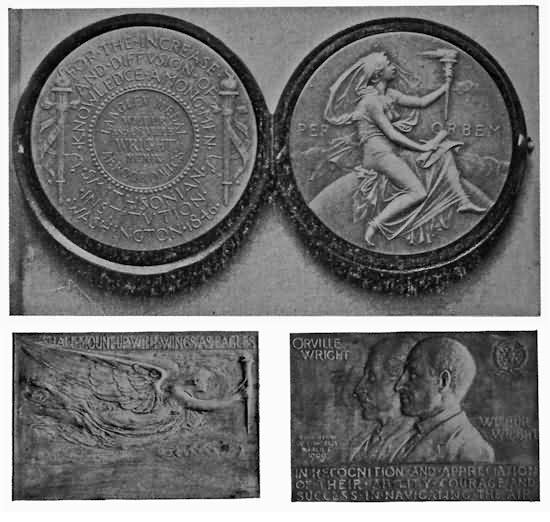

MEDALS WON BY THE WRIGHT BROTHERS

Top, Langley medal bestowed by the Smithsonian Institution; bottom, medal authorized by Act of Congress.

This, it will be seen, was a very close approach to the idea of the aeroplane as we know it to-day. It 37 remained for another British inventor, by the name of Henson, to carry these ideas to a further development, and with his colleague, F. Stringfellow, he worked out a model that embodied most of the principles of the present-day flier of the monoplane type. They decided the proper proportion for the width and length of the plane and steadied their machine with both horizontal and perpendicular rudders. In 1844 Henson and Stringfellow built a model of their aeroplane and equipped it with a small steam engine. A subsequently constructed steam-propelled model made a free flight of forty yards. This is claimed to be the first flight of a power-driven machine, although it was only a model. In 1866 F. H. Wenham, another Englishman, took out a patent on an aeroplane made up of two or more planes, or, as the scientists call it, two or more superposed surfaces. Immediately following this, Stringfellow constructed a steam-propelled model of triplane type, but it was no more successful than his monoplane. This latest model may be seen in the Smithsonian Institution at Washington to-day along with other models marking the progress of aeroplanes.

In the years following other inventors contributed much valuable information to the data concerning aviation. Among these was Warren Hargrave, the Australian, who had discovered the box kite, and who had seen in it the principle for the aeroplane. Hargrave even built a small monoplane weighing 38 about three pounds and propelled by compressed air, which flew 128 feet in eight seconds.

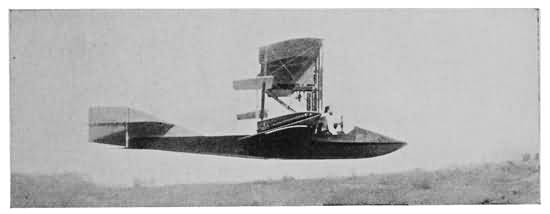

Though the Wright brothers were the first to make a practical man-carrying, power-propelled aeroplane, they were not the first men to be carried off the ground by such a machine. The first man admitted by most authorities to have flown in a power-driven aeroplane was Clement Ader, a Frenchman, who had spent his life in the study of air navigation. His first machine was of monoplane type driven by a forty-horsepower steam engine. It was called the Eole and it had its first test before a few of the inventor's friends near the town of Gretz on October 9, 1890, making, according to witnesses, a free flight of 150 feet. Ader built two more machines in subsequent years and succeeded in interesting the French military authorities. In October of 1897 he made several secret official tests of his last machine, the Avion. It had a spread of 270 square feet, weighed 1,100 pounds, and was driven by a forty-horsepower steam engine. The day for the trial was squally but he persevered. The flier ran at high speed over the ground, several times lifted its wheels clear off its track and finally turned over, smashing the machine. The officials did not consider the exhibition successful, and the support of the army was withdrawn. Ader in disgust gave the Avion to a French museum and abandoned aviation, with success almost within his grasp.

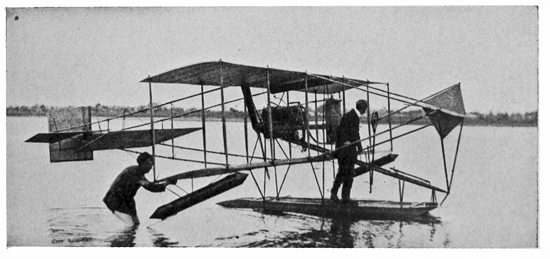

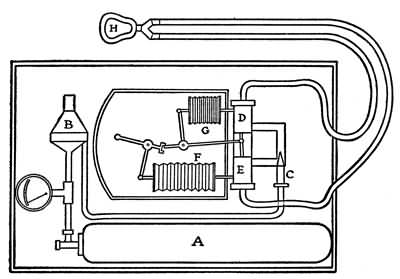

39 Shortly before this time Prof. Samuel Pierpont Langley of the Smithsonian Institution and Octave Chanute, the great American pioneers in aviation, were making their early experiments. Professor Langley experimented with numerous kinds of model fliers, and finally, on May 6, 1896, launched a steam-propelled model over the Potomac River. According to the scientist Dr. Alexander Graham Bell, who was present, it flew between 80 and 100 feet and then "settled down so softly and gently that it touched the water without the least shock, and was in fact immediately ready for another trial." The second test was equally successful. The speed was between twenty and twenty-five miles an hour and the distance flown about 3,000 feet. Professor Langley's first aerodrome, as he called it (the word is now used to mean aviation field), was made in the form of a tandem monoplane about sixteen feet long from end to end and with wings measuring about thirteen feet from tip to tip. The steam engine and propellers were placed between the forward and aft planes. The whole machine weighed about thirty pounds and of course was too small to carry a pilot.

Langley next made a model which took the form of a tandem biplane, and which had some success in flights. When the Government appropriated $50,000 for him to build an aerodrome that would carry a man, Langley began to experiment with a gasoline engine. He used his tandem biplane and a motor 40 that developed two and a half to three horsepower. The whole machine weighed fifty-eight pounds, and the planes, which were set at a dihedral angle, had sixty-six square feet of surface. A successful test without a pilot was made on the Potomac River below Washington on August 8, 1903, and while the spectators and reporters were lauding him the inventor merely remarked: "This is the first time in history, so far as I know, that a successful flight of a mechanically sustained flying machine has been seen in public."

The man-carrying machine was ready for its tests a few months later. Ever since having been financed by the Government, Langley had been at work, and the result was a tandem monoplane much like his early models. It was driven by a gasoline motor placed amidships which acted on twin screw propellers, which also were between the tandem planes. The whole machine with the pilot weighed 830 pounds, and had 1,040 square feet of wing surface. It was fifty-two feet long from front to rear and the wings measured forty-eight feet from tip to tip. The wings were arched, like those of modern aeroplanes, and the double rudder at the rear had both horizontal and vertical surfaces to steer the machine up or down, or from right to left. The aerodrome did not have any device for keeping it on an even keel, such as the ailerons we know to-day, or the wing-warping system of the Wright machine. This was a serious drawback, according to the present-day 41 scientists, but Professor Langley had set his wings in a dihedral angle—that is, like a broad V, to give what is called automatic stability. This dihedral angle, it will be remembered, is one of the principles discarded by the Wright brothers early in their experiments as one that tended to keep the machine oscillating from side to side. Professor Langley realized this, it is said, and to offset it had already advanced several ideas along the line of wing warping, for keeping his machine on an even keel when buffeted by the wind.

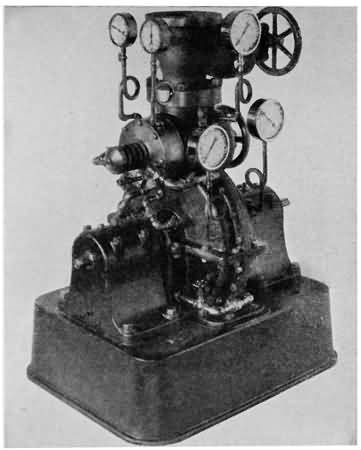

The aerodrome also lacked the wheels now used on aeroplanes for starting and alighting, and even the skids that were used on the first Wright machines. His motor was remarkably well adapted to the work. It developed 50 horsepower with a minimum of vibration, and with its radiator, water, pump, tanks, carbureter, batteries, and coil weighed twenty pounds, or about five pounds per horsepower. The arrangement of the five cylinders around the shaft like the points of a star was one that has become very popular in modern aviation motors.

The first trial took place at Widewater, Va., on September 7, 1903. The machine was placed on a barge on the Potomac River; the pilot, Charles M. Manley, Professor Langley's able young assistant, took his seat in the little boat amidships, and a catapult arrangement, like the early Wright starting device, sent it into the air. To the bitter disappointment 42 of Langley and his friends the machine dived into the water. It came up immediately, the daring Manley undaunted and uninjured. Investigation showed that in launching it the post that held the guys which steadied the front wings had been so bent that the forward planes were useless.

At the next trial, December 8, the rear guy post was injured in a similar accident and the machine fell over backward. This ended the experiments, as the Government appropriation had been spent, and the machine was repaired and stored in the Smithsonian Institution, where it is yet.

Professor Langley died a few years after this, feeling that his great work had never been appreciated or understood by the world. Many have declared that he died of a broken heart as a result of the frequent ridicule of the public and press. Although he never saw the triumph of aerial navigation, he died firm in the belief that it was only a matter of time and the working out of theories then laid down until man could fly. His last hours were cheered by the receipt of a copy of resolutions of appreciation passed by the Aero Club of America.

In the meantime, the Frenchman Ader had actually flown in a power-driven machine of his own construction, at private tests, while Captain Le Bris and L. P. Mouillard, Frenchmen, and Otto Lilienthal, a German, had been carrying on important glider flights. Also Sir Hiram Maxim, the American-born 43 inventor who was knighted in England, made a great aeroplane that was tested with some success. The machine was built in 1889 and was mounted on a track. It was called a multiplane—that is, it had several planes, one above the other, and was driven by a powerful steam engine. The whole machine weighed three and a half tons and had a total surface of 5,500 square feet. During its tests on the track it lifted a few inches off the ground. Thus Maxim claimed that his was the first machine that had ever lifted a man off the ground by its own power.

It was Otto Lilienthal, however, the "flying man," who established a systematic study of one phase of aviation which became general enough to be called the Lilienthal School. This was the system of practising on gliders before attempting to go into the air with power-driven machines. As will be remembered, this was exactly the system the Wright brothers followed out.

Lilienthal's first experiments were made in 1891 with a pair of semicircular wings steadied by a horizontal rudder at the rear. The whole apparatus weighed forty pounds and had a total plane surface of 107 square feet. He would run along the ground and jump from the top of a hill. He made many good flights, and in 1893 with a new glider averaged 200 to 300 yards and steered up or down or to either side at will. Lilienthal found that the air flowing along the earth's surface had a slightly 44 upward current, as science tells us it does, and that it would carry him upward if the wind was blowing strong enough. Hence he could go forward either up or down in about the same way that a yacht tacks against the wind. But Lilienthal had the same trouble in balancing that the Wright brothers had at first, so he kept an even keel as best he could by swinging his legs and body from side to side as he hung underneath the glider.

The "flying man" made about 2,000 flights and then constructed a still more successful biplane glider for which he built an engine. He was killed while making a glide on August 9, 1896, however, and the motor was never used. Several authorities who were in touch with Lilienthal declared that the machine had become wobbly and unreliable. This, they said, was the cause of its collapsing in midair under the heavy strain.

Lilienthal's death, though mourned by scientists all over the world, did not interfere with the great work he had started, for his system had many disciples both in Europe and America. Among these, besides the Wrights, were the Americans Octave Chanute and A. M. Herring, and Percy S. Pilcher of the University of Glasgow. Pilcher was killed three years after Lilienthal, September 30, 1899, while trying to make a glide in stormy weather.

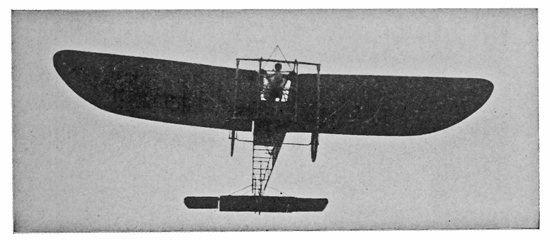

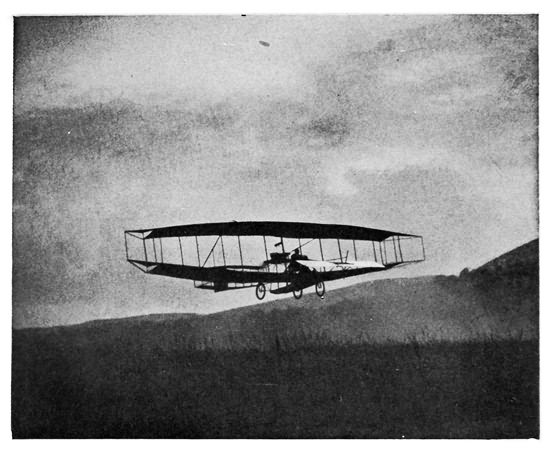

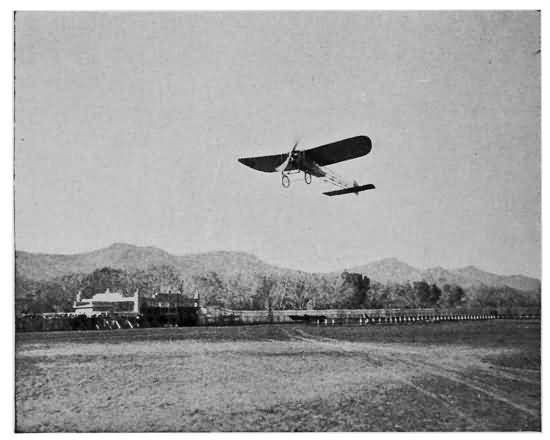

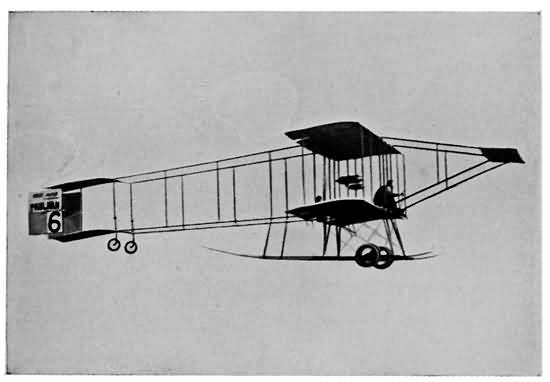

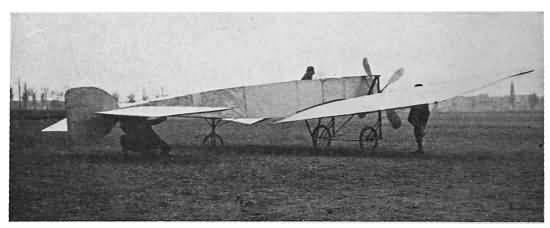

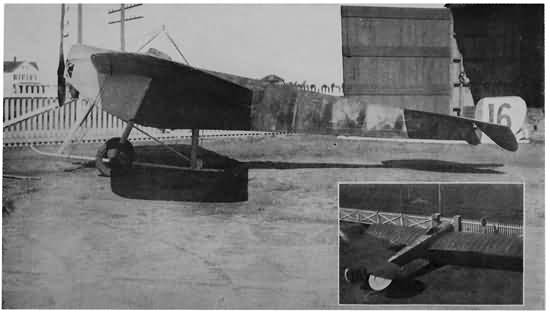

THE FIRST SANTOS-DUMONT AEROPLANE

This was the first successful aeroplane to be flown in Europe, and was quickly followed by others.

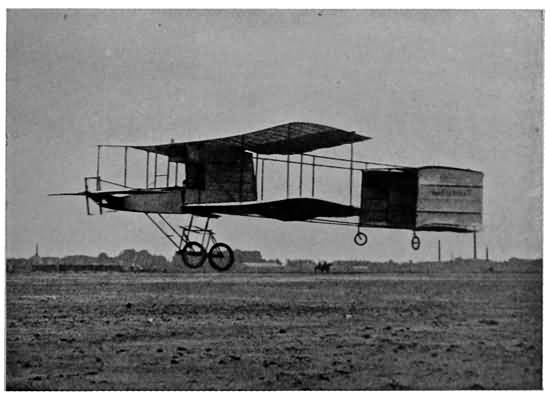

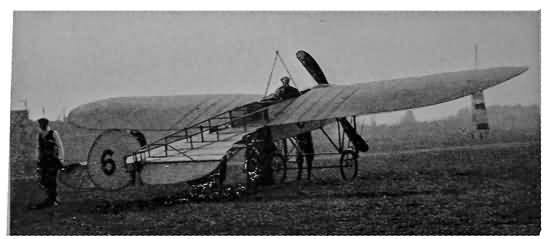

THE CROSS-CHANNEL TYPE BL╔RIOT MONOPLANE

The BlÚriot monoplane was the first of the monoplane type to make a success in Europe.

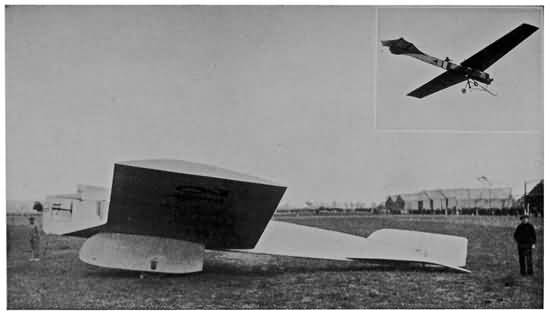

A VOISIN BIPLANE

The Voisin brothers perfected the first permanent aeroplane used in Europe. Henri Farman made his first wonderful flights in a Voisin.

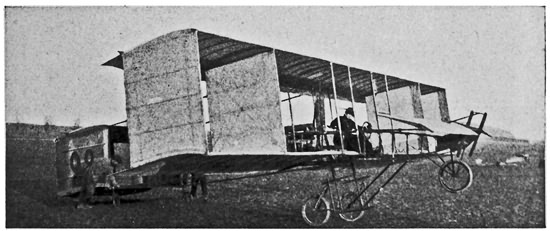

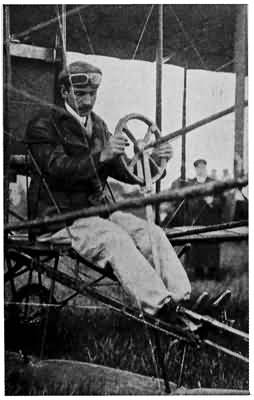

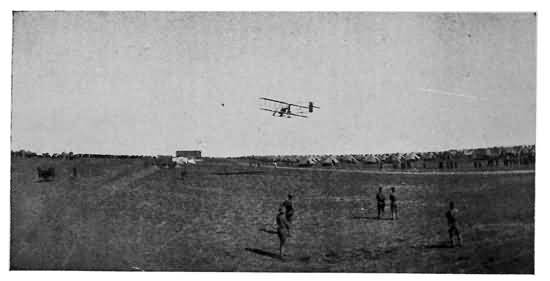

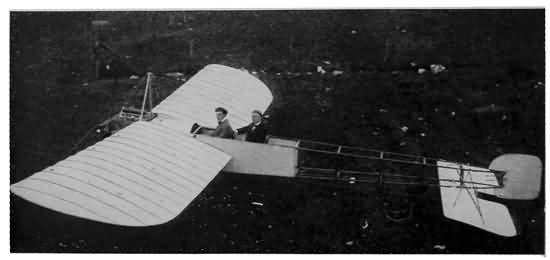

GLENN CURTISS ABOUT TO MAKE A FLIGHT

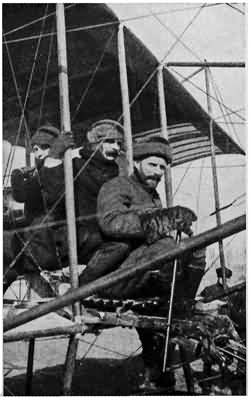

HENRI FARMAN STARTING ALOFT WITH TWO PASSENGERS

LOUIS BL╔RIOT SHORTLY AFTER COMPLETING HIS TRANS-CHANNEL FLIGHT

Great credit must be given to Chanute because it was in great part through his advice that the Wright 45 brothers achieved final success, and all biplanes to-day are known to the technical side of the aviation world as Chanute type machines. Chanute and Herring started experiments with gliders among the sand dunes on the southern shore of Lake Michigan, and, after some indifferent success with the Lilienthal monoplane type of glider, made a flier of five surfaces one above the other. The rudder was in the rear and the pilot hung below the machine. One by one experiments pared down the number of planes to three and then to two. The planes were arched, as they are in modern aeroplanes. The rudder extended behind the contrivance and had both horizontal and vertical blades. The whole machine weighed 23 pounds and had 135 square feet of plane surface.

The biplane was eminently satisfactory and Herring decided to make an engine for it and sail in a power-driven flier—or a dynamic aeroplane, as the scientists call it. His motor was a compressed air machine and he proposed to go into the air as if for a glide and then start the engine. According to newspaper accounts, he accomplished this and his compressed air engine drove him forward seventy-three feet in eight or ten seconds against a strong breeze. The flight was not given very much consideration, however, for lack of authoritative witnesses.

This brings us around again to the activities of 46 the Wright brothers, who started their work with the glider built along the lines laid down by Octave Chanute. They had the active support and aid of this inventor throughout their three or four years of experiments, although many other scientists were inclined to discredit their work.

While the brothers were going ahead with their practical flier the European scientists were developing with rapid strides and Prof. John J. Montgomery of Santa Clara College, Santa Clara, Cal., who was killed in a glider accident in 1911, was astonishing the far West with gliding experiments of great importance.

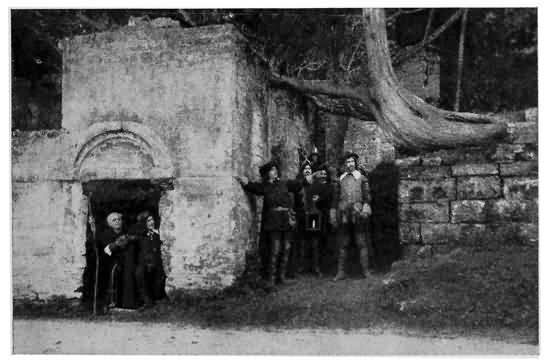

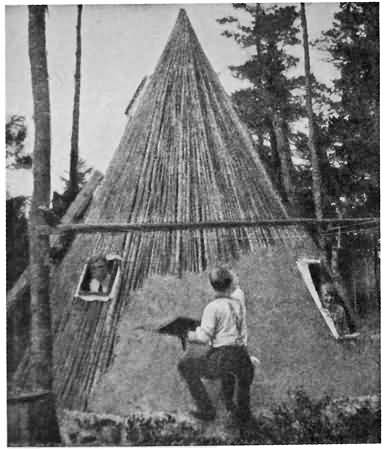

Montgomery's best glider was a tandem monoplane with a device by which the pilot could change at will the amount of curvature of any of the wings. This gave him the tremendous advantage of being able to vary the lifting power of the wings independently of each other and hence a means of maintaining side to side balance. Professor Montgomery made his own flights until injuring his leg in alighting, and then he hired trained aeronauts to glide from great heights. As it turned out it would have been better had he never resumed flying himself. He used balloons to carry up the gliders and when they reached the required altitude the operator cut the cable. Daniel Maloney, a daring parachute jumper, and two other aeronauts, named Wilkie and Defolco, carried on these hair-raising experiments.

Flights were made at Santa Clara, Santa Cruz, 47 San JosÚ, Oakland, and Sacramento, in 1905. The balloon would take up the aeroplane, and aviator, who sat on a saddle like a bicycle seat between the tandem planes and manipulated the wing control and rear rudder with hand levers and a pair of stirrups for his feet. In April of that year a forty-five-pound glider, such as the one described, with Maloney in the seat, was taken up four thousand feet. When the aviator cut loose he glided to earth, making evolutions never before made by man in the air, and finally landed as lightly as a feather on a designated spot.

Shortly afterward Maloney while making a sensational glide was killed. As the balloon was rising with the aeroplane, a guy rope switched around the right wing and broke the post that braced the two rear wings and which also gave control over the tail. Those below shouted to Maloney that the machine was broken, but he probably did not hear, and when he cut loose the machine turned turtle.

One of the saddest of all the many aeroplane fatalities was the accident early in the fall of 1911, in which Professor Montgomery was killed while experimenting with his glider.

Thus we see that the pioneers whose work has counted for the most in the early history of aviation were Americans—that the science can almost be claimed as a development of American genius. True, Ader was the first man to fly in a power-propelled machine, and Lilienthal led the way in the science 48 of gliding, but it remained for Chanute, Langley, Montgomery, and the Wright brothers to gather all this scientific data together and put it to practical use so that the motor could be installed and power flight, or dynamic flight, as the scientists call it, begun.

HOW THE INVENTORS CARRIED ON THE ART OF AVIATION UNTIL IT BECAME THE GREATEST OF ALL SPORTS AND THEN A GREAT INDUSTRY

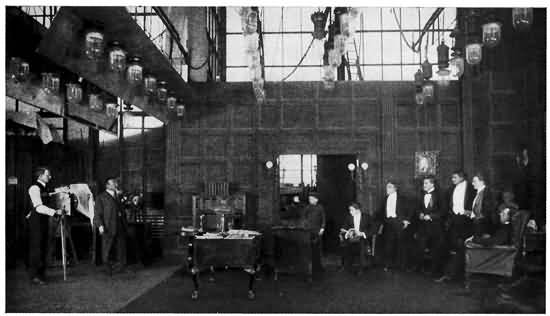

SO INTERESTED in aviation had our young friend become that he forgot all other inventions in his enthusiasm for flying. He never missed a chance to go to the aviation field, and sometimes his scientist friend would go with him. These days were rare treats indeed, for the boy always learned some new and important points from their conversations.

With them we have seen how the science of aeronautics has been divided into two great departments: balloons, or lighter-than-air fliers, and all other machines that are not maintained in the air by hot air or gas. We have seen also the three great divisions of heavier-than-air aviation—that is, orthopters or wing-flapping machines; helicopters or machines that fly upward through the operation of horizontal screws; and aeroplanes. Lastly we see the three divisions of aeroplanes: gliders; dynamic aeroplanes, 50 or the machines we know to-day; and true bird soaring, the art of flying without artificial power and without the flapping of wings.

But on every side the boy heard people talking of great feats of flying that he knew nothing about.

"Who was Santos-Dumont? What was that first trans-Channel flight? Why do they always talk about the first Rheims meet?" he asked one afternoon as he was returning home from the field with the scientist.

The man could not answer the questions all in one breath, but we will follow his explanation, which extended over many pleasant hours, and see how aviation developed into a mighty sport and industry.

For several years following 1905 the world of aviation was led by Europeans—mostly Frenchmen who readily grasped the principles of the science and made the best and lightest motors that the world has ever seen. The United States, however, was the first nation to experiment with aeroplanes for military purposes, although at present the country is far behind France, England, and Germany in the development of aeroplanes for use in war.

Alberto Santos-Dumont, a daring young Brazilian who a few years earlier had astounded the world with his achievements with dirigible balloons, was the first of the aviators working in Europe to construct a practical man-carrying power flier. Scores of brilliant foreigners were working on the principles 51 for gliders laid down by Lilienthal, but Santos-Dumont, working along the ideas of the scientists who had built power-propelled models, made himself a clumsy biplane equipped with a 50-horsepower motor and actually inaugurated public flights, considering that all done by the Wrights up to that time was experimental and practically in secret.

On August 22, 1906, he made his first flight near Paris. It was brief, but authorities agree that it was the first time in Europe that a power-propelled flier had risen in free flight with a man at the steering wheel since Ader's secret flight in 1892. Two months later he made a public flight of 221 metres in 21 seconds, winning the world's first regularly offered aviation prize. This was the Archdeacon Cup of 2,000 francs authorized by the Aero Club of France for a flight of 100 metres.

Scientists gave these flights more attention than they did the flights of the Wright brothers the year before because they were viewed by many thousands of people and also by men who had studied the science of aviation for years. Besides this, Santos-Dumont made no secret of the construction or workings of his machine as the Wright brothers did. He was already a popular idol through his work with dirigible balloons, and being very rich—the son of a millionaire plantation owner in Brazil—he did not have the same financial incentive for keeping his plans secret.

52 His flights gave the aviators of France tremendous encouragement and it was but a short time until half a dozen aeroplanes, the makes of which are all well known now, were making successful flights and breaking records.

Santos-Dumont called his biplane an aeromobile. The two main planes had perpendicular surfaces enclosing them so that the wings of each side looked like two box kites hitched together side by side, as shown in the picture. The rudder extended to the front and it also looked like a box kite. The pilot sat just in front of the wings and could manipulate his rudder from side to side or up and down. Thus he could steer his machine from right to left, upward or downward. The Brazilian had not solved the problem of keeping his aeromobile from tipping sideways, so he arranged its wings in a dihedral angle, which balanced it fairly well. The starting and alighting device was a set of wheels which we know so well to-day. The biplane contained 65 square feet of plane surface and the total weight was 645 pounds.

Perhaps the most important factor in this machine was an eight-cylinder 50-horsepower Antoinette gasoline motor. This was the first time that this now famous motor was used in an aeroplane and it gave promise at that time of the prize-winning capabilities it later developed. The propeller, which was made of aluminum, was about six feet in diameter, 53 or about two feet less than the diameter of the twin screws in the early Wright biplanes.

Copyright H. M. Benner, Hammondsport, N. Y.

THE JUNE BUG

Glenn Curtiss making a flight in one of his first aeroplanes.

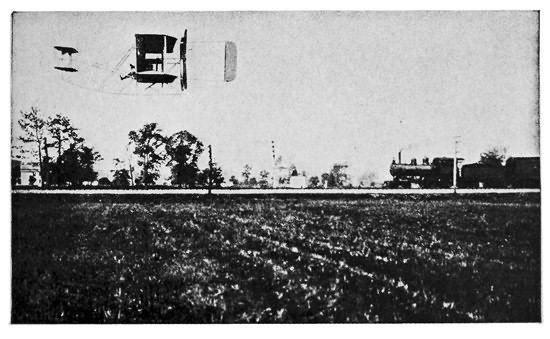

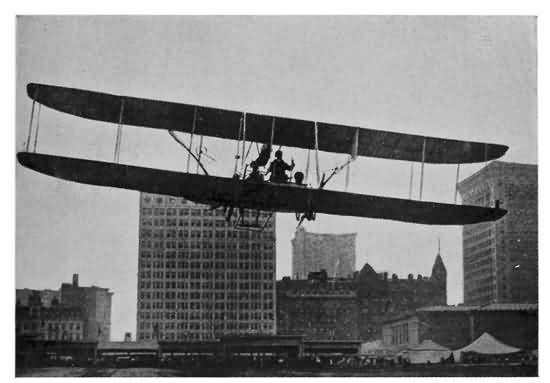

ORVILLE WRIGHT MAKING A FLIGHT AT FORT MYER

The aeroplane first became well known in this country when the Wright brothers carried on their Fort Myer tests.

Courtesy of the Scientific American

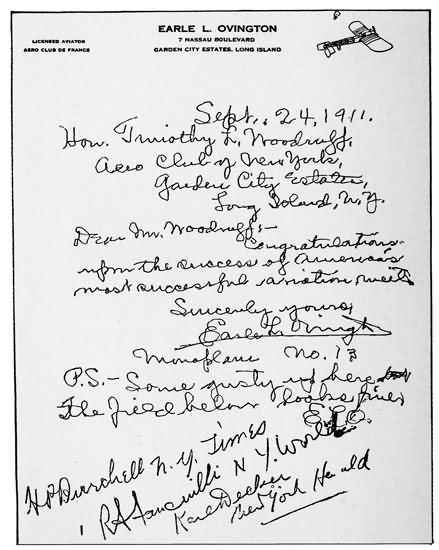

THE FIRST LETTER EVER WRITTEN ABOARD AN AEROPLANE IN FLIGHT

This was written at the time Ovington was carrying aeroplane mail from Garden City to Mineola, by aeroplane.