Project Gutenberg's The Pyrotechnist's Treasury, by Thomas Kentish

This eBook is for the use of anyone anywhere at no cost and with

almost no restrictions whatsoever. You may copy it, give it away or

re-use it under the terms of the Project Gutenberg License included

with this eBook or online at www.gutenberg.org

Title: The Pyrotechnist's Treasury

Or, Complete Art of Making Fireworks

Author: Thomas Kentish

Release Date: September 29, 2012 [EBook #40892]

Language: English

Character set encoding: UTF-8

*** START OF THIS PROJECT GUTENBERG EBOOK THE PYROTECHNIST'S TREASURY ***

Produced by Paul Clark and the Online Distributed

Proofreading Team at http://www.pgdp.net (This book was

produced from scanned images of public domain material

from the Google Print project.)

Transcriber's Note:

Every effort has been made to replicate this text as faithfully as possible, including some inconsistencies in hyphenation. Some changes of spelling and punctuation have been made. They are listed at the end of the text.

Crown 8vo, cloth extra, profusely Illustrated, price 4s. 6d. each.

Art of Amusing. A Collection of Graceful Arts, Games, Tricks, Puzzles, and Charades, intended to amuse everybody. By Frank Bellew. With nearly 300 Illustrations.

Hanky-Panky. A Wonderful Book of Very Easy Tricks, Very Difficult Tricks, White Magic, Sleight of Hand; in fact, all those startling Deceptions which the Great Wizards call "Hanky-Panky." Edited by W. H. Cremer. With nearly 200 Illustrations.

Magician's Own Book. Ample Instructions for Performances with Cups and Balls, Eggs, Hats, Handkerchiefs, &c. All from actual experience. Edited by W. H. Cremer. With 200 Illustrations.

Magic No Mystery: Tricks with Cards, Dice, Balls, &c., with fully descriptive working directions; How to train Performing Animals; the art of Secret Writing, &c. Numerous Illustrations.

Merry Circle (The), and How the Visitors were Entertained during Twelve Pleasant Evenings. A Book of New Intellectual Games and Amusements. Edited by Mrs. Clara Bellew. With numerous Illustrations.

Secret Out; or, One Thousand Tricks with Cards, and other Recreations; with Entertaining Experiments in Drawing Room or "White Magic." Edited by W. H. Cremer. With 300 Engravings.

⁂ The above Series of Books contain Explanations of all the most startling feats of legerdemain performed by the celebrated Prestidigitateurs, Robert Houdin, Frikell, Dr. Lynn, Professor Anderson, and others.

CHATTO & WINDUS, Piccadilly, W.

THE PYROTECHNIST'S TREASURY;

OR,

COMPLETE ART OF MAKING FIREWORKS.

BY

THOMAS KENTISH.

Flammas Jovis, et sonitus imitatur Olympi.

Virgil, Æn. vi. 586.

London: CHATTO & WINDUS, PICCADILLY. 1878.

[All rights reserved.]

LONDON:

PRINTED BY J. OGDEN AND CO.,

172, ST. JOHN STREET, E.C.

Until within the last few years there was scarcely any work in English, that I am aware of, on the subject of Pyrotechny, worth reading, with the exception of an Article in "Brewster's Cyclopædia," by MacCulloch; and this, besides being accessible to only a few, having been published in 1830, made no mention of colours, which form the most beautiful part of the art.

In the first year of the present century a treatise was written by a Captain Jones, which has been copied, in whole or in part, into almost every work since published. The greater portion of it is absurd and impracticable, and shows that it was written by a person who undertook to teach what he had not learnt.

The first work of any real utility that came under my notice was a series of papers by "Practicus." This was soon followed by another, varied by the new chemical nomenclature.

The subject is far from being treated exhaustively in either of these works, so that I trust the reader will find in the following pages a fund of information, both in the repertory of recipes and the methods of manipulation.

To Chertier belongs the great improvement in colours. He was, as I was informed by the late Mr. Southby, who knew him personally, and who derived much information from him while in Paris, a retired French Artillery Officer, who made colours "his study and theme." His "New Researches," published in 1856, nearly thirty years after his first pamphlet, is an excellent work, that leaves little to be desired in the way of colours. Gunpowder attracted but little of his attention.

Tessier, of Paris, has written, since, his "Pyrotechnic Chemistry," and a new edition of the "Firework-Maker," by Hutstein and Websky, was published three or four years ago at Breslau.

I have neglected none of these sources of information, but do not know that I have been able to learn much from them with which I was not previously acquainted.

Gibbon's "Artillerist's Manual," and Ben[Pg vii]ton's "Ordnance and Gunnery," published at New York, have furnished me with a hint or two; also Owen's "Practice of Modern Artillery," Scoffern's "Projectile Weapons of War," and his "New Resources of Warfare;" but as all these works are on Military Pyrotechny, they have not been available to any great extent. I mention their names, that anyone desirous of a knowledge of Rockets and Shells, as instruments of destruction, may know the books from which to gain the information.

It is possible that, as Chemistry advances, a few new substances may be discovered; meanwhile, nearly every shade of colour may already be produced.

The extensive use of these colours, from their beauty and variety, for stars and lancework, has very materially altered the class of fireworks, and necessitates the employment of an enormous quantity of quick-match. The preparation of this is one of the most disagreeable parts of Pyrotechny, besides demanding a great amount of manipulative skill. Most amateurs are deterred from attempting to manufacture it, and so have to content themselves with only the simplest pieces.

I have, therefore, set myself sedulously to work to devise a different plan of preparing it; and have succeeded—not till after many years, however, and numerous failures, simple as it now seems—in discovering a process of producing a splendid and perfect match, that leaves nothing to be desired; which is easy and expeditious, and does not even soil the hands. Amateurs will now find no trouble in making any pieces they may desire.

Dangerous chemicals, that might produce spontaneous combustion, have been rigidly excluded; the fullest information throughout has been furnished for preparing the mixtures with safety; the mode of projecting balloons, and the manner of constructing steelyard scales, and every kind of tool used in the art, has been added; and no pains have been spared to make the work as complete and comprehensive as possible.

In conclusion, I may say that I have had thirty-five years' experience; and there is nothing I have not tried repeatedly: the reader may, therefore, place the greatest confidence in everything recommended. He has only to imitate to succeed.

T. K.

| Page | |

| Roman Candles: | |

| To Make a 5⁄8 Roman Candle | 1 |

| To Make a Roman Candle Star | 5 |

| To Damp Stars | 7 |

| To Make Lac Solution | 9 |

| To Make Wax Solution | 10 |

| To Make Stearine Solution | 10 |

| To Make Gum Solution | 11 |

| To Make Dextrine Solution | 11 |

| To Make Paste | 13 |

| Roman Candle Scoops | 15 |

| To Charge Roman Candle Cases | 19 |

| To Make Touchpaper | 23 |

| To Make Slowmatch | 24 |

| To Make Quickmatch | 24 |

| A New Method | 26 |

| Rockets: | |

| To Make a 6⁄8 Rocket | 34 |

| To Charge Rocket Cases | 39 |

| Rocket Stars | 53 |

| To Make Cut Stars | 54 |

| Dry Pill-box Stars | 54 |

| To Fill the Boxes with Dry Colour | 56 |

| Another Way | 56 |

| Bottomless Pill-boxes | 57 |

| Enveloped Stars | 58 |

| Rocket Heads | 59 |

| Wheel and Fixed Cases | 66 |

| Gerbes | 69[Pg x] |

| Flower Pots | 72 |

| Port Fires and Shell Fuses | 73 |

| Tourbillions: | |

| To Make a Tourbillion | 75 |

| Saxons | 81 |

| Five Pointed Stars | 83 |

| Squibs | 84 |

| Serpents | 90 |

| Pinwheels | 91 |

| Crackers: | |

| To Make a Cracker | 98 |

| Leader Pipes | 103 |

| Maroons: | |

| To Make a Maroon | 105 |

| Another Method | 106 |

| Gold and Silver Rains | 107 |

| Peacock's Plumes | 108 |

| Saucissons | 109 |

| Pearl Streamers | 111 |

| Blue Lights and Star Candles, or Star Lights | 111 |

| Prince of Wales' Feathers | 112 |

| Lances: | |

| To Make a Lance | 112 |

| To Form a Device, or Design | 115 |

| To Preserve Steel Filings, or Cast-iron Borings | 116 |

| Shells: | |

| To Make the Shells | 119 |

| Cylindrical Shells | 125 |

| Asteroid Rockets | 131 |

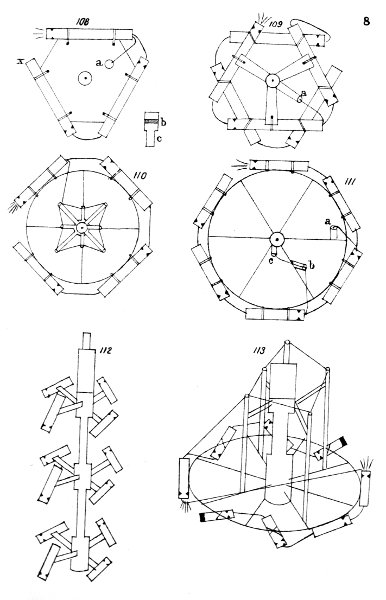

| Compound Fireworks: | 135 |

| To Fire a Girandole of 100 Rockets at once | 153 |

| Tools | 154 |

| To Construct a Steelyard Scale | 155 |

| Montgolfier Balloons: | |

| To Cut the Gores | 161 |

| To Join the Halves Together | 161[Pg xi] |

| To Paste Two Gores Together | 161 |

| To Paste the Pairs Together | 162 |

| To Make the Last Joining | 162 |

| To Wire the Balloon | 163 |

| Winged Rockets: | |

| To Make Winged Rockets | 168 |

| To Construct a Slot-Tube, or Rocket-Guide | 170 |

| List of Prices | 172 |

| Concluding Remarks | 173 |

| Fuses: | |

| Roman Candle | 185 |

| Rocket | 185 |

| Bursting Fire | 185 |

| Starting Fire | 185 |

| Wheel and Fixed Case | 186 |

| Squib and Serpent | 186 |

| Pinwheel | 186 |

| Saxon | 187 |

| Five-Pointed Star | 187 |

| Spur-Fire, for Flower-Pots and Star-Candles | 187 |

| Tourbillion | 187 |

| Bengal Light | 188 |

| Blue Light | 188 |

| Wasp Light | 188 |

| Portfire | 188 |

| Shell Fuse | 188 |

| Gerbe | 188 |

| Tailed, Streamer, or Comet Stars, for Rockets, Shells, and Roman Candles | 189 |

| Oiled Tailed Stars for Rockets and Shells | 189 |

| Steel Stars for Rockets and Shells | 190 |

| Pearl Streamer | 190 |

| Gold Rain | 190 |

| Silver Rain | 191 |

| White or Bright Stars and Lances | 191[Pg xii] |

| Sugar Blues for Stars and Lances | 191 |

| Blue Stars and Lances without Sugar | 192 |

| Crimson and Scarlet Stars and Lances | 193 |

| Green or Emerald Stars and Lances | 194 |

| Deep and Pale Yellow Stars and Lances | 195 |

| Mauve and Lilac Stars and Lances | 196 |

| Purple and Violet Stars and Lances | 196 |

| Magnesium Colours for Stars and Lances | 197 |

| Slow Fires, to be Heaped upon a Tile in the shape of a Cone, and Lit at the Top | 197 |

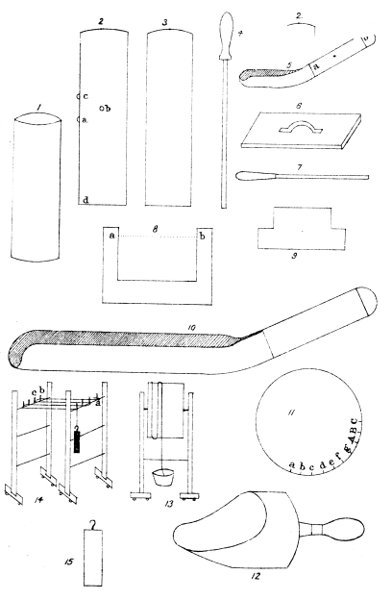

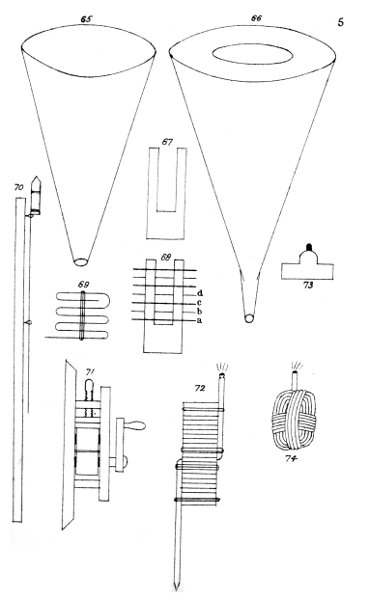

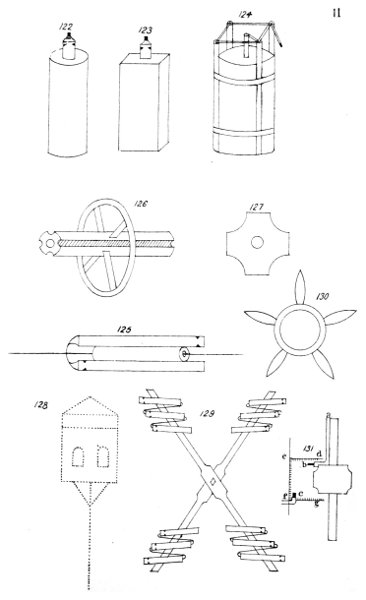

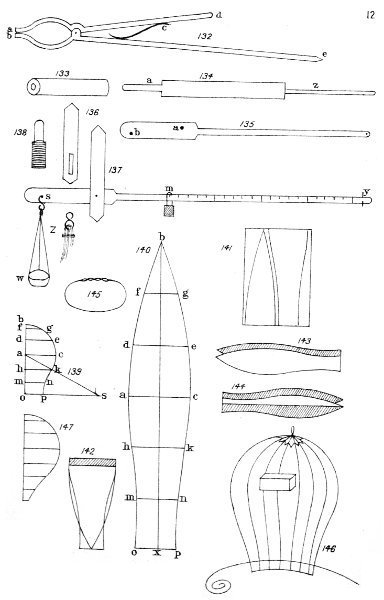

Procure a straight piece of brass tube, 6⁄8 of an inch external diameter, and 161⁄2 inches long. Saw or file off a piece, 11⁄2 inch long, fig. 1. This is for the star former, and is drawn of the correct size.

In the other piece, of 15 inches, fix a handle, as shown, in diminutive, in fig. 7. This is for the case former. It should be filed smooth at the end.

Take another piece of brass tube 41⁄2/8 or 9⁄16 of an inch external diameter, and about 161⁄2 inches long. In this also fix a handle, or fix it into a handle, fig. 4. Invert it, and set it upright in a flower-pot, filled with sand or loose mould. Melt some lead in a ladle, and pour it slowly into the tube, leaving room for the air to escape up the side, till it is full. If the lead is poured in rapidly, the confined air, expanding, jerks the metal[Pg 2] up, and may cause serious injury. A pound or more of lead will be required. When cold, drive the end of the lead in with a hammer, and file it smooth. This is for a rammer.

Take a piece of deal, fig. 6, about 12 inches long, 6 broad, and 3⁄4 thick; and, on the top, screw a handle, like one on a copper-lid, or black-lead brush. This is for a rolling-board. An iron door-handle would serve, and may be obtained at any ironmonger's, for about 2d. or 3d. A wooden one, however, about an inch thick, not cylindrical, but slightly flat, and rounded at the edges, is preferable, as it gives more purchase for the hand.

Cut a piece of tin, or zinc, or thin board, into the shape of fig. 8, in which the distance between the arms a and b, across the dotted line, shall be 7⁄8 of an inch. This is for a gauge, with which to measure the external diameter of the case. Write upon it, "7⁄8 space."

Procure some 60 lb., 70 lb., or 84 lb. imperial brown paper: the size of a sheet will be 29 inches by 221⁄2. Cut a sheet into 4 equal parts, each 141⁄2 by 111⁄4: paste the 4 pieces on one side, and lay them one on another, with the pasted face upwards, putting the fourth[Pg 3] piece with the pasted side downwards, upon the pasted side of the third piece. Turn them over: take off the now top piece, and lay it flat on the near edge of a table, pasted side upwards. Take the former, fig. 7, and paste the tube all over. Lay it along the edge of the paper, bend the paper over with the fingers of both hands, and roll it tightly up, until the external diameter of the case about fits the gauge, fig. 8. If the paper should be too long, of course a piece must be cut off; if it should not be long enough, more must be added, taking care to bind in the second piece with 3 or 4 inches of the first piece; for if the whole of the first piece be rolled up before beginning the second, the latter, when dry, will probably slip off, and spoil the case. The case having been rolled up, take the handle of the former in the left hand, lay the case flat on the near side of the table, take the rolling-board, fig. 6, in the right hand, press the front part of it on the case, and drive it forwards 5 or 6 times, like a jack-plane, letting the handle of the former slip round in the left hand. This will tighten the case, and render it, when dry, as hard as a book-cover.

The former must always be pasted, before rolling a case, to prevent its sticking. It should, likewise, be wiped clean with a damp sponge, before being laid aside. Brass tubes keep clean a much longer time if lacquered. To lacquer them, clean them with very fine glass-paper; make them hot by the fire, till you can just bear them on the back of the hand; then, with a camel's-hair pencil, wash them over with thin lac solution. The cases may be either 141⁄2 or 111⁄4 inches long; but 111⁄4 is the best, for when the cases are too long, the fuse, as it approaches the bottom, is apt, if slow, to smoke; if fierce, to set the top of the case in a flame. If the learner decides upon 111⁄4 inches, the former and rammer may each be 2 or 3 inches shorter.

After the first case has been rolled up to fit the gauge, it may be unrolled, and the paper measured. Future pieces of the same quire of paper can then be cut of the right size at once, so that the case will fit the gauge without further trouble.

A large slab of slate is convenient for rolling upon; but a smoothly planed board will answer every purpose.

When a number of cases are finished, hitch a piece of flax two or three times round each of them, and hang them up to dry, in a place free from draught, that they may not warp.

Flax is sold in balls; the thick yellow, at 2d., is the best. It is named, indifferently, flax, or hemp. It is much used by shoe-makers; and is sold at the grindery, or leather shops. Two or three thicknesses of this, waxed, or drawn through the hand with a little paste, is very convenient for passing round the necks of small choked cases, tying cases on wheels, &c.

Take the former, fig. 1, which, as said before, is 11⁄2 inch long; have a cylindrical piece of turned wood, box, beech, or mahogany, fig. 2, about 2 inches long, and of a diameter to just fit easily into fig. 1. At a point a, at the distance of about 7⁄8 of an inch from the end d, with a bradawl, or very small gimlet, or nosebit, make a hole, and drive in a piece of brass wire, to project just so much as to prevent the tube slipping over it. A piece of a brass rivet, such as used by shoe-[Pg 6]makers, is convenient for the purpose. The part with the head on is best; a quarter of an inch length will be sufficient, filed or cut off with the nippers. It is evident that upon inserting fig. 2 into the tube fig. 1, a vacant space of 5⁄8 of an inch will be left at the bottom. Fig. 3 is a piece of turned wood, or, better still, of turned brass, exactly like fig. 2 without the side-pin a. Now to pump a star, insert fig. 2 in fig. 1; press the tube into damped composition, turn it round, and withdraw it. Rest the tube on a flat surface, insert fig. 3, and give it two or three taps with a small mallet, like fig. 26. A convenient size for the mallet is 11⁄2 inch square, 3 inches long, with a turned handle. The mallet is best made of beech or mahogany. The slight malleting consolidates the star, and prevents it from getting broken in charging; it will compress it to about 41⁄2/8 or 9⁄16 of an inch in height. Push it out and set it by to dry.

Stars are best made in summer, and dried in the sunshine; when dry they should be put into clean pickle-bottles, furnished with tight-fitting bungs. A piece of wash-leather[Pg 7] passed over the bottom of the bung, gathered up round the sides, and tied at the top like a choke, makes a good stopper. Shot, shaken up in bottles, with water, soon cleans them.

Stars containing nitrate of strontian must be damped, either with lac solution, or wax solution; anything containing water destroys the colour. Nitre stars may be damped with gum water, dextrine solution, or thin starch. Most other stars with either of the solutions. Crimsons and greens will mix with boiled linseed oil, but they cannot then be matched, as oil renders meal-powder almost uninflammable. With all stars, not a drop more of the solution should be used than is sufficient to make the composition bind; and it is advisable not to damp more than half an ounce at a time; this is particularly the case in using the lac solution, as it dries rapidly; and if a large quantity of composition is damped, and gets dry, and has to be damped over and over again, it becomes clogged with the shellac, and the colour is deteriorated. If it should get dry, and require a second[Pg 8] damping, it is best to use pure spirit only, the second time.

Before mixing compositions, every article should be as fine as wheaten flour, and perfectly dry. Nitrate of strontian, if purchased in the lump, should be set over the fire, in a pipkin; it will soon begin to boil in its water of crystallization; it must be kept stirred with a piece of wood, till the water is evaporated, and a fine dry powder left. A pound of crystals will yield about 11 ounces of dry powder, which should be immediately bottled. Even then, if used in damp weather, it is best dried again, and mixed with the other ingredients while warm. This second drying may be in a 6-inch circular frying-pan.

Articles, separately, may be reduced to powder, with the pestle, in a mortar. See that it is wiped clean every time, as there is danger of ignition with chlorates and sulphurets. When the articles are to be mixed, they may be put into the mortar, and stirred together with a small sash-tool. A 3⁄8 inch is a convenient size. The mixture must then be put into a sieve, and shaken in the usual way; or it may be brushed through with the[Pg 9] sash-tool. Return it to the sieve, and brush or shake through again. As it lies in a heap, level or smooth it with the blade of a table knife, or any straight-edge; if thoroughly mixed it will present a uniform colour; if it appears darker in one part than in another, it must be sifted again. A sieve with a top and receiver is very desirable, as nearly all mixtures are either black or poisonous; the dust from star mixtures is very injurious to the lungs. If a top and receiver cannot be readily purchased, both may easily be constructed out of a sheet of millboard, fastened with a bradawl and waxed yellow flax, and neatly covered with paper.

Mixtures may be damped on a Dutch-tile, a marble slab, or a slate without a frame. They may be stirred about with a dessert knife, pressed flat, and chopped, or minced as it were, and again pressed flat.

Put 1⁄2 an ounce of flake shellac into a tin pot, and pour upon it a quarter of a pint, or 5 ounces of methylated spirit; or, preferably, a like quantity of wood naphtha. Let it[Pg 10] stand for about a day, stirring it occasionally till dissolved. Then half fill a basin with boiling water; set the tin containing the lac, in it, and leave it till it boils and curdles. If the water does not remain hot long enough to make it boil, set it in a second basin of boiling water. As soon as it has curdled, remove it; and when cold, pour it into a vial, and cork it. Spirit must never be boiled over a fire, nor near one, as the vapour might inflame. Keep the pot, therefore, while in the hot water, at a distance from a fire, or flame of a lamp or candle.

Put into a vial 1⁄2 an ounce of white wax, (bleached bees' wax), pour upon it 5 ounces of mineral naphtha, (coal or gas tar naphtha), keep it tightly corked.

Dissolve a piece of composite candle in mineral naphtha, in the same way. Mineral naphtha must not be used near a candle or fire, as it gives off an inflammable vapour, at less than 100° Fahrenheit.

There is no better way of preparing this than simply to put cold water upon gum arabic, and let it stand till dissolved. If for sticking purposes, as much water as will just cover the gum will be sufficient; but, for making quickmatch, 1 ounce or 11⁄4 ounce of gum to a pint of water. If required in a hurry, put the gum into cold water, in a pipkin, or tin saucepan, set it on the fire, make it boil, and keep stirring till dissolved. When cold, bottle, and cork it.

Take half an ounce of dextrine, and 5 ounces, or a quarter of a pint of cold water, put the dextrine into a cup or basin, add a little of the water, and mix it well with a teaspoon, rubbing it till all is dissolved; then add the remainder of the water, stir well together a second time, pour it into a vial, and cork for use. Dextrine, wetted to the consistency of honey, may be used instead of thick gum-arabic water, for pasting. For this purpose it is advisable to keep either in[Pg 12] a wide-mouthed bottle, and to set the bottle in a gallipot containing a little water; the brush, a camel's-hair pencil, or very small sash-tool with 1⁄3 of the bristles cut away on each side, to render it flat, can then be kept in the water, when not in use; this will prevent it, on the one hand, from becoming dry and hard; and, on the other, from getting clogged and swollen. It can be squeezed between the thumb and fingers, when wanted for use. The flat gum brushes now sold, bound with tin, are not pleasant to use, as the tin oxidises, and turns of a disagreeable brown colour. If there is a difficulty in obtaining a graduated water measure, one sufficiently correct for pyrotechnic purposes may be made with a vial. Paste a narrow strip of paper up the outside of the vial, weigh 4 ounces of water in a cup, in the scales: pour it into the vial, mark the height, and divide it into 4 equal parts, for ounces; of course, it can be graduated into half and quarter ounces, and increased, if large enough, to 5 or more ounces. A gallon of distilled water weighs exactly 10 pounds. Consequently, a pint of pure water weighs a[Pg 13] pound and a quarter. This is also near enough for spirit, though, of course, spirit is a trifle lighter. Doctors' vials are often marked with ounce divisions.

Paste is most economically made in a zinc pot, which may be 4 inches deep, and 31⁄2 inches diameter. Any zinc worker will make one to order for about 6d. Put into it 2 ounces of wheaten flour, add a little cold water, rub the two together with a spoon till smooth and free from lumps; pour in more water till the pot is full within about an inch; set the pot in half a saucepanful of water, put it on the fire; make the water boil, and keep it and the paste boiling for 4 or 5 minutes, stirring the paste the while. Remove it from the fire, and set it by to cool. The paste is to remain in the zinc pot, in which it will keep good for a length of time, and beautifully white.

Some recommend alum in paste, I think it best avoided, especially in cases intended to receive coloured fires. Alum is a double salt, a sulphate of alumina and potassa; it has an acid[Pg 14] reaction; and, coming in contact with chlorate of potash and sulphur, may cause spontaneous combustion. A drop of sulphuric acid instantly ignites stars containing them. At theatres, the clown sometimes fires a cannon, with what appears to be a red hot poker; but which, in reality, is only a piece of wood, painted red. A mixture is made of chlorate of potash and sulphur, or sugar, a glass bead is filled with sulphuric acid, and the hole stopped up with wax. This is laid in the mixture, and when it is struck with the poker, the liquid escapes, and inflames the potash and sulphur. Sulphate of copper is a particularly dangerous salt, and must never be used, as it is almost certain to cause spontaneous combustion. Chertier, to whom pyrotechny otherwise owes so much, introduced an empirical preparation, by dissolving sulphate of copper in water, together with chlorate of potash, drying it, and wetting it with ammonia: but this, however dried, when again wetted, turns litmus paper red. Practicus has named it Chertier's copper. I discommend its use.

Two paste brushes will be sufficient for an amateur, sash-tools, one about an inch[Pg 15] diameter, the other smaller for light purposes. Let them stand in the paste. If they get dry, the bristles fall out. For convenience, one may be kept in the paste, and one in water.

Dry clay, powdered and sifted as fine as possible, is used for plugging, or stopping up the bottoms of cases. I have, for some time, discontinued its use, and employ plaster of paris in preference. Directions will be given for each, so that the learner can adopt which he pleases: but plaster is infinitely preferable. It is an American improvement.

No species of fireworks require greater care in their construction than roman candles. In the first place the stars must be fierce, that they may light thoroughly: next, they must not be driven out with too great velocity. For this purpose the blowing-powder must be carefully adjusted. The stars, also, must be of so easy a fit that when put into the case they may fall to the proper depth of their own accord. If they require pushing, they are too tight, and will probably be blown out blind. When made as directed they will,[Pg 16] necessarily, be of an easy fit, as they will be of the inner diameter of the brass tube, while the bore of the case is equal to its external diameter.

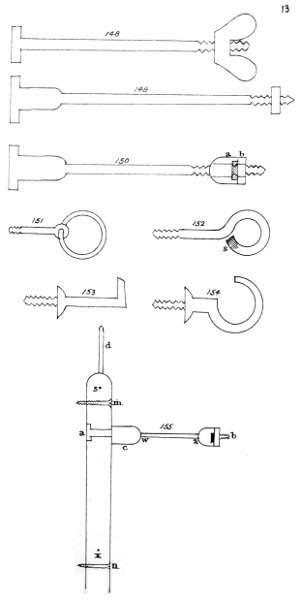

To regulate the blowing powder, prepare a number of little scoops, like fig. 5, which is about the right size for the bottom star. They are formed of pieces of tin, zinc, or copper. Cut a long strip of tin, 1⁄2 an inch broad; cut this across into 7 pieces, of the following lengths, 15⁄8, 16⁄8, 17⁄8, 2, 21⁄8, 23⁄8 and 4 inches. Round off the corners. Take a piece of brass wire, or stair-rod, about 1⁄4 inch diameter, and with the wooden mallet, before mentioned, fig. 26, bend each of the pieces round the rod into a half cylinder, or gutter. Take up the smallest, and hold 5⁄8 of an inch of the end of the stair-rod in the end of the semicylinder, to keep it open; put the other part from a to b, fig. 5, in a vice, and pinch it up; it will assume the form represented; the bowl part will be 5⁄8 long, and the handle 1 inch long. Make the bowl of the next scoop 6⁄8 of an inch long, the next 7⁄8, and so on; the handle will always be 1 inch long. The last, for the top star,[Pg 17] will have a bowl of 3 inches. The smallest scoop ought to hold as much grain powder as will weigh about 1⁄12 of the star; but to have the scoops accurate, it will be necessary to charge a roman candle, fire it, and observe whether the stars go a uniform height. For measuring the interval fuse, or fuse between the top of one star and the bottom of the next, a large scoop of the size of fig. 10 will be required. The tin may be an inch broad, and the bowl part 21⁄2 inches long, bent round the rammer, fig. 4. To adjust it, take a roman candle case, fit it on the foot, fig. 9, which is a piece of wood, or brass, turned with a tenon to fit tight in the bottom of the case. Fill the scoop, and strike it level, with a straight-edge; empty it into the case, rest the foot on a flat surface; insert the rammer, fig. 4, and jolt it up and down, a dozen times, or more, lifting it about 1⁄2 an inch at a time; put in another scoopful, and jolt it in like manner. If the 2 scoopfuls, thus compressed, fill an inch of the case, the scoop will be correct. If more or less, the scoop must be shortened, or lengthened, accordingly.

A piece of writing-paper may be pasted and wound twice round the handle of each scoop, as from a to b, fig. 4. One dot can be put upon the scoop, for the first, or bottom, star; two dots, for the second scoop, &c., or any memorandum can be written upon them, for future guidance. Should they get soiled, they may be cleaned with a soaped damp piece of sponge.

Gunpowder, for fireworks, is used in two forms; meal-powder, and grain-powder. Meal-powder is a fine black dust, and is employed in all cases of mixing. Grain-powder is of three kinds, F, FF, and FFF, fine, double fine, and treble fine. FFF is best for crackers, simply because it runs rapidly down the pipes: for driving stars, shells, &c., F will be sufficient; but FFF may be employed: FF need not be purchased. All kinds of powder may be obtained of Pinnell, 214, Whitechapel Road. If, in any place, there should be a difficulty in obtaining meal-powder, F grain-powder may be crushed in a leather bag, by laying the bag on a hard surface, and beating it with a hammer. The leather should be of the same kind as shoes are made of.

Pour some F grain-powder into a wooden bowl, or platter, represented by fig. 11. Round the edge lay the little blowing-powder scoops, side by side, beginning with the smallest at a, the next at b, and so on to g. Put some roman candle fuse into a large tin scoop, made to stand on a flat bottom, like fig. 12, the same, in shape, as used by tea-dealers; and, on the right-hand of it, lay the charging-fuse scoop, fig. 10. If the roman candle is to contain different-coloured stars, set seven in a row, in the order desired. When the cases are intended to be fired in threes or fours, the stars in one may be all blue, in another crimson, in another green, in another white. Fit the foot, fig. 9, in the bottom of the case, put in a scoopful of clay, insert the rammer, fig. 4, and jolt it till the clay is well compressed. The clay should fill 1⁄2 an inch. This being done, invert it, and shake out any little dust that may remain. Put in the little scoopful a, of F grain-powder; then lay the scoop at A. Now put in a star. As previously stated it ought to fall of its own[Pg 20] accord; but make sure that it has reached the blowing-powder, by putting in the rammer. Having ascertained this, put in a scoop of fuse, fig. 10; lay the scoop on the left of fig. 12; insert the rammer and jolt it; put in another scoop of fuse, fig. 10; lay the scoop on the right of fig. 12; insert the rammer and jolt it, as before. Then proceed with the scoop b of grain-powder, and lay it at B, and so on, till the case is filled. The fuse on the top star is best driven in with a short solid rammer and mallet, as it is difficult to jolt the long rammer in so small a space. The last 1⁄8 of an inch, near the mouth of the case, should be fine meal-powder, as it binds better than the roman-candle fuse, and also blows off the leader pipe.

The blowing-powder scoops, having been laid at A, B, &c., all that is required is to turn the bowl or platter, a little round to the left, and they will come in rotation, ready for the next case. Also, by putting the scoop, fig. 10, alternately to the left and right of the scoop, fig. 12, it will always be known whether the proper quantity of fuse has been put in.

Coloured stars, from their fierceness, have[Pg 21] a tendency to burn in the cases. This defect may be remedied by putting upon each star a small scoopful of Starting Fire, No. 1, before putting in the interval fuse; as much as will fill round the sides of the star. This composition is somewhat fiercer than would suit for the regular fuse, so catches the blowing-powder sooner.

A roman candle is well charged when the stars isochronise, or come out at equal intervals of time: they should, also, theoretically, ascend to equal heights; but, with coloured stars, this cannot be perfectly insured, as some shrink more than others in drying, and, of course, fit more loosely; some are heavier, some fiercer than others.

The interval fuse must always be driven in at twice, never at once. Each star, with its blowing-powder and fuse, occupies about an inch and a half; perhaps a trifle more.

Instead of driving in clay at the bottom, plaster of paris may be used, and then the foot, fig. 9, will not be required. Have some plaster of paris in a wide-mouthed bottle; a glass of cold water with a salt-spoon in it; and a number of pieces of paper, about 4[Pg 22] inches square. Put a small quantity of the plaster on one of the pieces of paper; indent the middle with the finger; put to it a little water, and work it up with a dessert-knife. Just as it gets to the consistency of mortar, and is about to set, mould it with the fingers, to the shape of a cork; push it into the end of the case; rest the case on a flat surface; insert the rammer, and give it two or three slight jolts; turn it round a few times, and withdraw it. If the plaster sticks to the end of the rammer, it shows, either that you have used the plaster too wet, or have not turned the rammer round a sufficient number of times.

No more plaster must be mixed at a time than will suffice for one case. When plaster has once set, it cannot be mixed up a second time; therefore take a fresh piece of paper, and let the knife be cleaned every time. It is advisable to have two dessert-knives, then one can be used with which to scrape the other. As much plaster should be used as will fill the case up about 1⁄2 an inch. They must be set by to dry; their not requiring the use of the foot will be found a great convenience.

Roman candles are usually made from 3⁄8 to[Pg 23] 6⁄8; but 5⁄8 is a very satisfactory size. If a roman candle is intended to be fired singly, twist a piece of touchpaper round the mouth. If the cases are intended to be fired in threes, fours, &c., to form a bouquet, or to be placed round a mine, jack-in-the-box, or devil-among-the-tailors, omit the touchpaper, and envelope the case in double crown, made to project an inch beyond the mouth, to receive the leader, or quickmatch.

A steel-pen inserted, nib backwards, in the end of a small paper tube, rolled round the end of a penholder, makes a neat little scoop. It may be fastened in with a little plaster of paris. A scoop may also be made with a quill.

Cracks in wooden bowls may be stopped with the same material; and, if painted over with linseed oil, after getting dry, will remain waterproof for a long time. A screw may be made to hold in brickwork, by drilling a hole in the brick, and pushing in the screw, covered with plaster.

Dissolve 1⁄2 an ounce of nitre in 1⁄2 a pint of hot water. Procure some 12 lb. double crown[Pg 24] blue; cut each sheet into four equal parts, 15 by 10. Lay them smooth upon each other, and, with a sash-tool dipped into the nitre solution, wash them over on one side, and hang them up to dry.

Dissolve 1 dram of nitrate of lead in 1⁄2 an ounce of boiling water. Cut a sheet of blotting paper into six equal parts, and wet them on both sides, with a sash-tool, with the solution. When dry, paste a piece all over, and upon it smoothly press another piece; upon this, pasted, put a third piece; and so on, till all the six form a stiff board. Lay them under a heavy weight; and, when dry, with a sharp knife and straight-edge, cut the whole into strips 1⁄4 of an inch broad. Four inches will burn about a quarter of an hour. Narrow tape, boiled in the solution, makes excellent slowmatch.

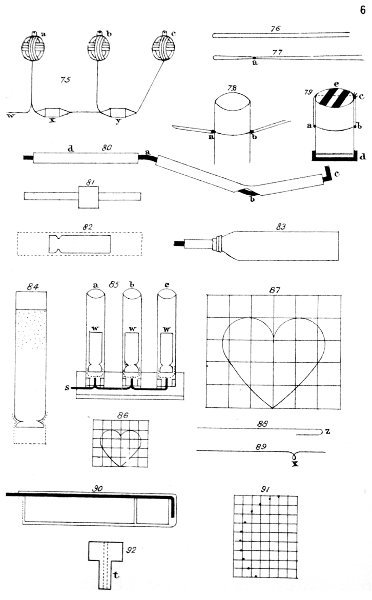

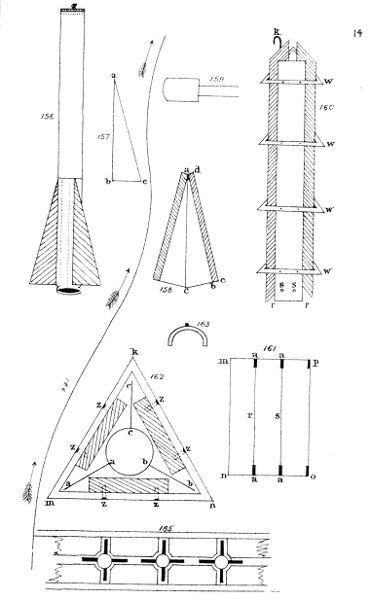

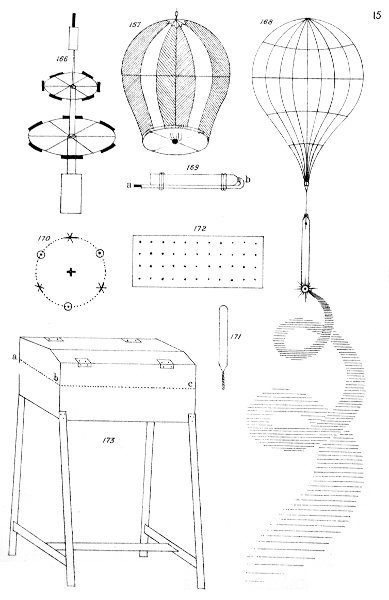

Put into a pan 1 lb. of grain-powder, or meal-powder; pour upon it some thin hot starch, and stir it well about, breaking all[Pg 25] lumps, till the mixture is of the consistency of paint. Procure some lamp-cotton, such as forms the wicks of candles. It will probably consist of sixteen or twenty-four strands. Divide it carefully into lengths of eight strands. This is not so easy a task as might appear. The best way is to act the reverse of a man spinning string. Divide the end of the cotton, say of sixteen strands, into two of eight each; fasten them to two screw-hooks, a few inches apart. Take one in each hand, and walk backwards, gently pulling them apart, and when they catch, untwist them: with care they will separate without breaking or entangling. Drop the end of one of the pieces into the pan; and, as it keeps falling, coil it round and round in the mixture, and press it down with an iron spoon, until as much is pressed in as the quantity can saturate. Be very particular that it is thoroughly soaked. Have ready a wooden frame, fig. 13, of deal, resembling a swing looking-glass, with the glass taken out. It may be 5 feet by 4. The frame is to be supported on pivots between two uprights. Fix a nail or hook at the left-hand corner of the frame,[Pg 26] and tie the end of the cotton to it which has been hanging outside the pan. Get a person to slowly turn the frame and hold it steady. Take hold of the cotton in the right hand, shut the hand, and allow the cotton to slip gradually and slowly through it, as the frame is turned; squeeze it very gently, so as to allow it to come out well coated, and contrive to make it as round as possible. When all the cotton is wound upon the frame, spread some sheets of paper—old newspapers—on the floor; at each corner place a brick; lay the four corners of the frame upon the four bricks; sift dry meal-powder all over the match, turn it over and sift over the other side. Prop the frame against the wall, and leave it to dry. One ounce of white starch will be sufficient for a pint and a half of water. Rub the starch up smooth with a little of the water, then add the rest, and boil it.

Put into a gallipot, or basin, some hot starch, made as before directed, or some cold gum-water, or cold dextrine solution; and with a small stencil-brush, or a 3⁄8 sash-tool,[Pg 27] cut across the middle to make the bristles short and stubby, stir in some meal-powder, till it is well mixed and looks like black paint. To avoid repetition, it will be convenient to refer to this under the name of Meal-paste. Take two towel-horses, fig. 14, and set them parallel 5, 10, or 20 feet apart. In the top rail of each, drive four nails 1⁄2 an inch asunder. Fix the dry cotton to the nail a, carry it across to the opposite nail b, pass it round the second nail c, bring it to the opposite second nail, and so on, till the cotton lies in four parallel lines, like the strings of a harp placed horizontally. Hitch the cotton, without cutting it, to the hook of the weight, fig. 15. This weight is made by taking a piece of brass tube, 1 inch diameter, and 4 inches long. Stop one end with a bung, fill it with melted lead; and before it sets push in a lucifer match, having previously cut off the priming. As soon as the lead is cold, pull out the match, which having been partially burnt smaller, will come out easily, and in the hole left by it screw a cup-hook, as drawn. Invert the weight, pick out the bung, and fill its place with more melted lead.[Pg 28] Now procure two pieces of planed deal board; one 4 inches square, the other 6 inches square. With the left hand hold the smaller piece close underneath the cotton; and with the sash-tool or stencil-brush, work the meal-paste well into the fibres of the threads, pressing the cotton on the board till it is thoroughly soaked, and rolling it over, laterally, to make it as round and smooth as possible. It is best to begin on the left, and work towards the right. If the wetting slackens the threads, pull them tight. Now brush some meal-powder through a fine sieve, to free it from lumps; put a tablespoonful or two upon the larger board; hold it close under the four threads, as the other, with the left hand, and move it laterally forwards and backwards, and down the whole length, at the same time brushing the meal over the threads, with a soft, dry, sash-tool, till they are smothered, and giving them an occasional jar to shake off the superfluous meal. By a little practice they may be made as smooth and as round as a piece of wire. Leave the weight hanging to them till they are dry. Instead of four nails on each rail, a dozen may be put;[Pg 29] and if the towel-horses are set 12 yards apart, 144 yards may be soon made. In this case, three or four heavier weights would be required. These contrivances, however, are by no means necessary for an amateur; four hooks or nails opposite four others, anyhow supported, will be sufficient; and six or eight feet apart is a good distance. A small quantity may thus be made one day, and a small quantity another; and for this purpose it is best to use gum-water, as it is always ready, and a little can be added to the dry left the day before, and a little fresh meal stirred in. Three or four threads of white darning-cotton, which is of two twists, make very good match; knitting or crochet cotton, which is of three twists, produces, alone, excellent match; two or three pieces of the first, or two of the latter, put into a leader pipe, side by side, blow through with a violent report. Match may also be made of the very narrowest white tape, 3⁄16 of an inch broad; this, from its flatness, is peculiarly suited for enveloped stars. For general purposes, however, lamp cotton is decidedly the best, as it is most loosely twisted, and therefore the most absorbent.[Pg 30] If match is liable to be exposed to damp, it should be cased in thick leaders, and be prepared with starch; in other respects, nothing can surpass gum-water. Of course iron pound-weights, with a ring in them, will answer the purpose, or an iron pestle tied to the cotton, or anything heavy; but the kind I have advised are most convenient. They will weigh about a pound and a quarter each. The weight may hang over a chair-back.

Match, to be perfect, ought, when cut across, to look black throughout; it should, also, be stiff, straight, and round; but, to test it, cut off about 10 inches; put one end of this into a leader pipe, so that 5 inches will be in the pipe, and 5 out. Hold the end of the leader with a pair of tongs, or lay it on the ground; light the naked end. If the match is good it will burn gradually, though swiftly, till it gets to the pipe; it will then blow through with a bang. The nearer the leader pipe fits the match the better, only it ought to be large enough to allow it to go easily in, without force: if laid in a roman candle case it would hardly puff: the smaller and smaller the tube becomes the louder and louder the report: the increase[Pg 31] of power being in the inverse ratio of the diminution of space. A train of gunpowder laid in the open air, or confined in a tube, comports itself in the same way, as is well known. Match, when dry, should be kept straight; for, if it gets broken, it acts like a cracker, snapping at every break.

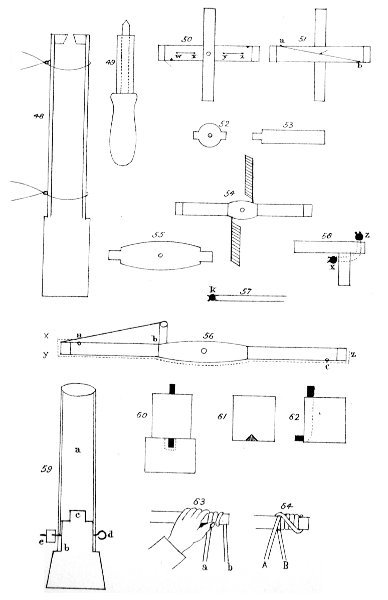

A piece of zinc rainwater pipe, of suitable length, furnished with a bottom and lid, or a couple of bungs, is convenient for keeping it in; but a far better contrivance is a deal box, 5 feet long, 3 inches deep, and 3 broad, made of 1⁄2-inch pine. The lid of this box can be readily furnished with three or five hinges, like a piano, only made with string instead of brass. Take two pieces of string, fig. 57, and tie them in a knot near the end, as at k. At x, fig. 58, make a bradawl hole through the back of the box, near the top, and push the strings through it; make another hole through the lid, put the string through it, and tie in a knot on the top, as at z: and so with the other four. This will render the explanation easier to understand; but, practically, a single piece of thicker string is best, if you can manage to tie the second knot in the exact spot you[Pg 32] wish. The knots must not be too close to each other, as the lid requires a little play. For safety, the box ought to be furnished with a lock.

Rockets are charged in choked cases, on a spindle, to leave a hollow up the middle, through which the fire may be communicated to nearly the whole of the composition at once: this causes the sudden generation of an enormous quantity of elastic vapour, which, being unable to escape instantly through the contracted aperture left for its exit, exerts its pressure in the contrary direction, and hurries the rocket forward. A stick, attached to it, guides it, like the rudder of a vessel, or tail of a bird, or fish; while its weight and leverage keep the centre of gravity a little below the case, and prevent the rocket from pitching over. Its manufacture, therefore, from the commencement of cutting the paper for the case, to its finish of fitting on the stick, requires an accurate adjustment of all its parts. Disregarding the trade names of pound, ounce,[Pg 33] &c., which, now that moulds are dispensed with, are useful only for enabling the makers, from tradition, to understand each other; the internal diameter, instead of the external, as formerly, may be selected, from which to compute the relative measures. Taking the bore of the case as unity, the proportions will be as follow:—

| 1 | Internal diameter of case. |

| 11⁄2 | External diameter. |

| 8 | Length of case. |

| 6 | Length of spindle. |

| 3⁄5 | Bottom diameter of spindle. |

| 64 | Length of stick. |

| 1⁄2 by 1⁄2 | Thickness and breadth of stick. |

These proportions are most readily calculated by taking the diameter in eighths of an inch. Selecting, for instance, a 6⁄8 rocket, we have, 6⁄8, inner diameter; half as much again, 9⁄8, outer diameter.

Taking the numerator as inches: 6 inches, length of case; 3⁄4 of this, or, which is the same, 1⁄2 the outer diameter, as inches, 41⁄2 inches, length of spindle; putting 20 for the denominator, instead of 8 (8 being 2⁄5 of 20), 6⁄20 of an inch, bottom diameter of spindle; 6 × 8, (nume[Pg 34]rator multiplied by denominator) = 48 inches, length of stick; 3⁄8 by 3⁄8, size of stick.

The following table exhibits the usual sizes in inches.

| Name of Rocket. |

Inner Diameter. |

Outer Diameter. |

Length of Case. |

Length of Spindle. |

Bottom Diam. of Spindle. |

Length of Stick. | Size of Stick. |

| 10/8 | 10/8 | 15/8 | 10 | 71⁄2 | 10/20 | 10 times 8=80 | 5/8 by 5/8 |

| 9/8 | 9/8 | 131⁄2/8 | 9 | 63⁄4 | 9/20 | 9 times 8=72 | 41⁄2/8 by 41⁄2/8 |

| 8/8 | 8/8 | 12/8 | 8 | 6 | 8/20 | 8 times 8=64 | 4/8 by 4/8 |

| 7/8 | 7/8 | 101⁄2/8 | 7 | 51⁄4 | 7/20 | 7 times 8=56 | 31⁄2/8 by 31⁄2/8 |

| 6/8 | 6/8 | 9/8 | 6 | 41⁄2 | 6/20 | 6 times 8=48 | 3/8 by 3/8 |

| 5/8 | 5/8 | 71⁄2/8 | 5 | 33⁄4 | 5/20 | 5 times 8=40 | 21⁄2/8 by 21⁄2/8 |

| 41⁄2/8 | 41⁄2/8 | 63⁄4/8 | 41⁄2 | 33⁄8 | 41⁄2/20 | 41⁄2 times 8=36 | 21⁄4/8 by 21⁄4/8 |

| 4/8 | 4/8 | 6/8 | 4 | 3 | 4/20 | 4 times 8=32 | 2/8 by 2/8 |

| 3/8 | 3/8 | 41⁄2/8 | 3 | 21⁄4 | 3/20 | 3 times 8=24 | 11⁄2/8 by 11⁄2/8 |

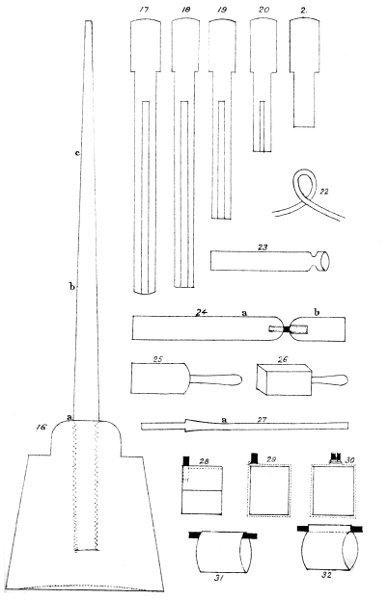

Have the former, fig. 7, a brass tube 6⁄8 of an inch external diameter; the gauge, fig. 8, with a 9⁄8 aperture; procure some imperial brown paper, 70 lb. or 84 lb., the thicker and heavier the better. The best kind is made[Pg 35] of old ropes, is air-dried, and rough. This is not easily obtained now. The smooth machine-made, cylinder-dried answers very well. The sort used for laying under carpets, and which is 5 feet broad, is almost equal to the original rough imperial, and should be procured, if possible, in preference to the smooth. Cut it into strips 6 inches wide. Paste the pieces well, and roll the cases as hard as possible, with the rolling board fig. 6, till they fit the gauge. Lay them by for a few hours to get partially dry. They must, then, be choked or strangled, about half a diameter from one end of the case, that end that lay nearest to the left hand in rolling, till they assume the shape of the neck of a vial. For this purpose have a cylindrical piece of deal, alder, or any kind of wood, fig. 24, about 9 or 10 inches long, made to fit easily into the case; cut it into 2 pieces, a and b; b may be an inch and a half long; round off the ends, just cut. In a, fasten a screw, the solid wire, or uncut part of which, is 1⁄4 of an inch thick; saw, or file off the head, and slightly taper the part projecting; in the piece b bore a hole to just fit the wire of a. Slip b upon[Pg 36] a, and push them into the case, so that the interval between the two reaches within about 1⁄2 an inch of one end of the case; slightly draw out b, to leave a neck, or hollow, round which to form the choke; fix a staple, or screw-eye in a post: tie to it one end of a piece of cord, about a yard long, and 1⁄10 of an inch thick; fasten the other end round the middle of a stick, for a handle; take hold of the stick with the right hand; hold the case in the left; pass the cord round the space left vacant and gradually tighten it, turning the case round and round, so as to pinch it in equally on all sides, till it assumes the shape of fig. 23. Hitch a piece of string, about 1⁄16 of an inch thick, a few times round the neck, until it is filled up flush with the other part of the case, remove the choker, and hang the case up to dry. A hitch is made by simply bending the string backwards into a loop, like fig. 22; passing it round the choke; pulling it tight; looping it again, again passing it round the choke, and so on. The first loop is called a half hitch, and will not hold of itself; the second loop completes the hitch, and makes it hold: the re[Pg 37]maining hitches are for filling up the choke, and restoring the cylindrical shape. Practise, by hitching the string upon your thumb, 4 or 5 times: it will hold after the second loop; but push it off at the end, and it will all fall loose again.

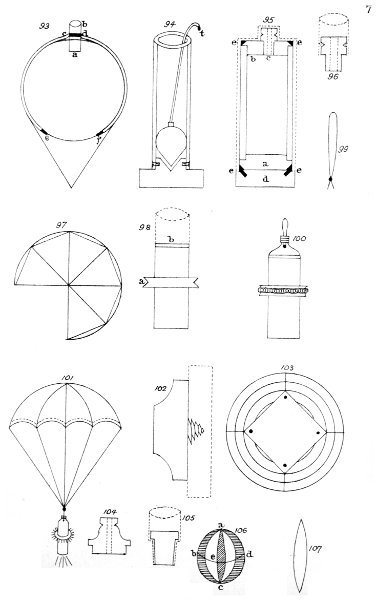

A case must not be choked when wet, or it will tear; nor must it be too dry, or it will be difficult to choke it at all. The drier, however, it can be choked, the better. Experience is the only guide. If properly dry, the wrinkles of the choke will be small, and perfectly regular. Should the string stick to the case, chalk it; but this is not likely to occur unless the paper is too wet. Have a foot, fig. 16, turned of ash, or beech, or box, with a hemispherical nipple, 6⁄8 of an inch diameter, as drawn. Bore it with a twist drill, or nosebit, to the depth of an inch and a half. Procure a brass, iron, or steel wire, but preferably brass, 6 inches long, and 3⁄10 of an inch diameter, and perfectly straight. Cut, on one end of it, a screw, 11⁄2 inch long, fix it in a vice, wet the screw with glue, and screw the foot on. File the 41⁄2 inches gradually tapering. The[Pg 38] object of tapering it is simply to make it deliver. A cylindrical hollow up the rocket would answer as well, but the spindle could not be got out. The more conically true it is tapered, of course, the better. Finish it off with a very fine file, and smooth it with glass paper. The block into which it is screwed may be larger than drawn; the bottom should be turned slightly concave, to make it stand firm, on the same principle as the bottoms of plates, cups, &c., are made with a rim. The block and spindle are better if cast in gun-metal, in one solid piece: the pattern to give to the caster should be in one solid piece of wood. After casting, the rough parts must be filed smooth; not many turners will be found willing to undertake to turn it.

The next articles required are a setting-down piece, fig. 17; three hollow rammers, or drifts, figs. 18, 19, and 20; and one solid rammer, fig. 21. They are simply cylindrical pieces of wood, turned with a head, to bear the blows of the mallet. Beech, or box free from knots, will answer. The lengths of figs. 18, 19, 20, and 21, are to be 8, 6, 4, and 2 diameters, respectively, exclusive of the head;[Pg 39] that is, 6, 41⁄2, 3, and 11⁄2 inches. The hollow drifts are to have a cylindrical, not conical, hole, bored up them, with a nosebit, or twist drill, to within one inch of the handle, so as to clear the spindle by 1⁄2 an inch, to allow of any dust being driven up it. The hollow in figs. 17 and 18 must be large enough to fit the spindle loosely at a; in fig. 19, a trifle smaller, to fit loosely at b; and in fig. 20, a trifle smaller still, to fit loosely at c.

The next requisite is a mallet, fig. 25, which may be of ash, or beech. It may be a cylinder, 5 inches long, and 3 inches diameter, with a handle about 5 inches long, and 1 inch diameter. Let it be turned at the end slightly concave, like the bottom of fig. 16, that it may be set to stand upright, like a wine bottle. Or the head may be made 3 inches square, like fig. 26; or, a small carpenter's mallet, about a pound and a quarter weight, will answer.

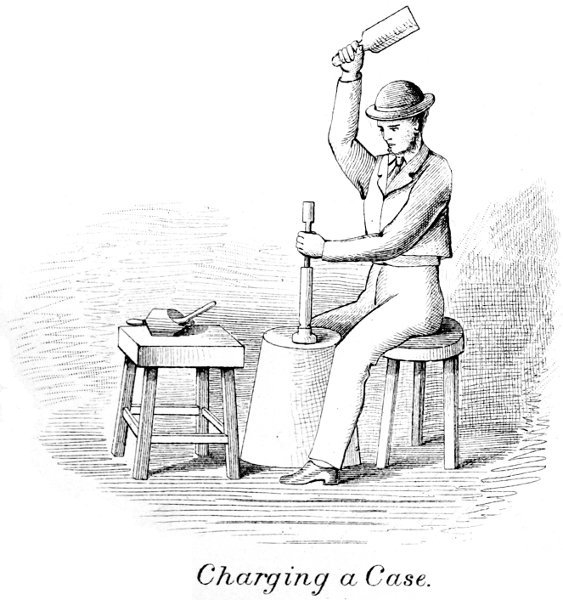

The first requisite is a solid block of wood, 6 or 8 inches square, and 18 or 20 high. This is indispensable. A piece of an old[Pg 40] oak gate post, answers well. It must be set upon the ground, or on a flag stone, not on a floor. It is impossible to ram a rocket properly on the floor, because of the vibration. It is, also, necessary to sit, not stand, at the work.

Put the setting down piece, fig. 17, into the case; press the case over the spindle, and give the head a few blows with the mallet; this will smooth out the wrinkles of the choke, which is all that fig. 17 is used for. Now put in a very little powdered clay, and mallet it with fig. 18; as much clay as will reach up 1⁄12 of an inch will be sufficient; its object is to preserve the choke from burning, and getting enlarged. One cannot be too precautious with rockets. Now put in a scoop of rocket fuse, insert drift, fig. 18, and mallet the fuse in firm, with about a dozen and a half blows, or till it offers a resistance to the hand. The blows must be light and numerous, not slow and heavy, like driving a post into the ground. 18 blows with a momentum of 3, will consolidate the fuse: 3 violent blows, with a momentum of 18, would perhaps bend the case, or drive the dust up into your eyes. The mallet need[Pg 41] not be lifted above 4 or 5 inches at a time. If the rocket is not rammed firm throughout, it will, upon lighting, explode.

As soon as the case is charged about 11⁄2 inch, make a pencil or ink mark, round the drift, where it stands level with the top of the case, for future guidance; then charge another 11⁄2 inch with the second rammer, fig. 19, and mark it in like manner; proceed in the same way with fig. 20. It is obvious that if fig. 19 were used too soon it would get split by the spindle being driven up it, and the spindle would be bent or broken, hence the advisability of marking the drifts to know when to lay aside one, and take the other. Just before you get to the top of the spindle, put in the solid rammer to feel how high the spindle reaches near the top of the case; hold it by the thumb and finger to keep the distance, and mark it down the outside of the case, by indenting the case with the edge of the drift. Exactly 11⁄3 diameter, that is, in this case, exactly 1 inch, above this indentation make another mark: then as soon as you have covered the spindle, till you can no longer see it, with the use of fig. 20,[Pg 42] begin charging with the solid drift, fig. 21, till the composition inside is level with the top mark. This being done drive in a little dry clay, till the case is full. Remove the rocket from the spindle, by giving it a turn or two round to the right, not backwards; then bore a hole through the clay, till you can see the composition, with a 3⁄16 inch shell-bit. The shell-bit should be fixed in a handle, and kept for the purpose. It is not advisable to use a stock and bit, unless the bit is shielded, as it is apt to bore too deeply. The bit may be fixed in a handle, by boring a large hole in the handle, and pouring in melted lead, or pressing in plaster of paris.

Instead of driving in dry clay on the top of the composition, a little plaster of paris may be pressed in; this, when dry, will allow of a perfectly clean hole being bored through it; whereas the clay is apt to crumble, and chip out. The object of the clay, or plaster, is to prevent the composition, which, containing much charcoal, does not bind well, from getting disturbed, and the solid part diminished, which would cause the stars to be ignited while the rocket was ascending, or[Pg 43] the fuse, perhaps, to blow through at the beginning. A piece or two of naked quickmatch is to be inserted in the hole through the clay or plaster, and a long piece is to be pushed up the core, or hollow, of the rocket, as far as it will go; it is, then, to be cut off flush with the mouth, and fastened to the side with a little dab of wetted meal powder, pressed on it with the blade of a knife. If the rocket is intended to be lit with a port-fire, take a circular piece of touch-paper, about 2 inches diameter, slightly paste it all over, lay it in the left hand, press the mouth of the rocket down upon it, and smooth the edges of the touch-paper up round the case. Otherwise, smear the end of the case with the sash-tool dipped into meal paste, and when dry, paste a bit of touch-paper round it, and twist to a point, like a squib. The appearance of the rocket is shown at fig. 36; the dotted line round the mouth shows the touch-paper.

In driving with the hollow rammers, it generally happens that a little of the fuse gets driven up the hole; this, if allowed to accumulate, is very troublesome to remove; it should, therefore, be knocked out every[Pg 44] time, by holding the drift in the left hand, and giving the head a rap or two with the mallet.

The whole of the composition ought to be put in in about 12 scoops: try 2 or 3 scoops till you get one of the right size, then write upon the handle what-sized rocket it belongs to. These directions may appear minute, but they will save much trouble if attended to.

As it is convenient to know, beforehand, about what quantity of composition will be required for any particular rocket, the following formula will be useful:—

E3 / 9 = drams.

Where E denotes the size of the rocket, in eighths of an inch.

Required the quantity of fuse for a 6⁄8 rocket.

(6 × 6 × 6) / 9 = 4 × 6 = 24 drams = 11⁄2 ounce.

For a 3⁄8 rocket?

(3 × 3 × 3)/9 = 3 drams.

The same weights denote the quantity of stars which the rocket will safely carry: thus[Pg 45] an ounce and a half of stars may be put into the head of a 6⁄8 rocket; and 3 drams into a 3⁄8 rocket. Along with the stars is to be put in 1⁄9 the weight of the stars of bursting powder; this may be pure meal powder; or a mixture of 8 meal powder, 1 fine charcoal, well sifted together: or half meal, half grain; thus the quantity of bursting powder for a 6⁄8 rocket will be 24⁄9 = 22⁄3 drams; and for a 3⁄8 rocket, 3⁄9 = 1⁄3 of a dram. It is advisable to keep nearly to these directions, for the weight of the stars; but it is not necessary to be minutely exact; but to ascertain whether the head is too heavy or not, take a table knife, or any thing an inch broad, and lay the rocket flat and horizontally upon it in such a manner that the commencement of the head lies close to the back edge of the knife, the cutting edge lying towards the choke: if the head pitches over, it is too heavy, and some of the stars must be taken out; if it balances, it is correct.

Rockets should be fired from two staples, or two screweyes, fixed in a post, one near the top, the other half a yard below, as in fig. 70. They should never be propped against[Pg 46] a wall, a chairback, a gate, or railing, as they might fall, especially on a windy night, after the touch-paper was lit, and before the fuse had caught. Every possible care should be taken in guiding them, as it is too late to think about any mischief they may cause, after they have once started.

In making rockets, it is essential, above all things, to have good nitre and charcoal. The best way, with fresh materials, is to weigh out as much nitre, charcoal, and sulphur, as will make one small rocket. Have the nitre as fine as possible, and dry it over the fire in a 6-inch frying pan, which should be kept for the purpose. If the rocket ascends well you will know that the articles are pure, and you can proceed to use them; but if the rocket does not rise, you may conclude the articles are adulterated, the nitre with salt, or that the charcoal is perhaps merely deal sawdust, burnt in a retort. In this case you must buy the nitre in crystals, and the charcoal in sticks. To powder the nitre, put it into a pipkin, pour on it a little water, set it on the fire, make the water boil, and keep stirring the nitre with a piece of wood, until it is dry and[Pg 47] of a fine powder. Charcoal is best ground up in a coffee-mill. It must first be broken into small pieces, about the size of coffee-beans. After being ground it should be sifted through the sieve, the interstices of which are about 1⁄40 of an inch square. To get a correct idea of this size, lay down a line on paper, an inch long: mark it off into eight equal parts by taking the divisions from a foot-rule; then carefully divide one of the eighths into five equal parts. But the best way is to make a square deal sieve, about 8 inches square, and 3 inches deep; then nail on the bottom a piece of perforated zinc, with quarter-inch flemish tacks. The perforations are circular, and should be 20 to the inch, measured diagonally; that is, a diamond-shaped inch, or inch rhombus, consisting of 20 oblique rows, each row containing 20 holes; 20 times 20 = 400. These holes will be about the same size as the ones mentioned in the sieve, because the solid parts between the perforations are also about 1⁄40 of an inch. A strip of deal, 1⁄4 of an inch thick, should be nailed round the bottom, to keep the zinc tight. A square box for a receiver, and[Pg 48] another for a lid, should also be constructed, otherwise you will be smothered in sifting charcoal. Making use of the perforated zinc sieve just described, all the charcoal that goes through, fine and coarse, should be used for rockets. It need not be shaken much, but brushed through with a sash-tool. Construct a second sieve with 15 perforations to the lineal inch. Iron borings for gerbes should be sifted through this; use all that goes through. Construct, also, a third sieve with 9 perforations to the lineal inch. Nothing can equal iron and steel for making sparks; but neither will keep long from rusting, after coming in contact with nitre. Coke grains, about the size of pinheads, are a fair substitute. Beat coke into lumps about as large as peas, then grind it in a coffee-mill, and brush it through the 9-perforation sieve; sift the fine dust from what passes through: throw the dust away, and keep the grains. Porcelain may be powdered in an iron mortar, for gerbes; brush through the 9-perforation sieve; sift out the dust with a fine sieve; throw it away and keep the grains. The intense heat of the focus of the choke renders[Pg 49] them incandescent; and, from their weight, they are projected to a considerable distance. They are inferior, however, to coke grains, as the latter are to steel filings. We may say, alliteratively; positive, porcelain; comparative, coke; superlative, steel.

Zinc may be obtained with half-inch perforations; a size useful for garden sieves, bottoms of soap boxes, &c.

Before grinding a fresh substance in a coffee-mill, it must be taken to pieces, brushed clean, and screwed up again. Fine lawn or hair sieves should be used for sifting chemicals; excellent sieves may be made with book-muslin: the cylinders may be 4 inches diameter, 3 deep; the muslin should be cut into a circular form, and hemmed round a piece of string; it may then be slipped over the drum or cylinder, and secured; or it may be pasted up and round the sides, and if above 4 inches diameter, two pieces of string may be crossed over the middle to strengthen it.

Charcoal may be made by putting some dry pieces of willow, alder, poplar, sycamore, maple, or almost any kind of wood, except[Pg 50] the pine or turpentine tribe, into an old iron saucepan, covering them with perfectly dry sand, and setting the saucepan in the middle of a fire, to remain red hot till the wood is completely burnt through. Remove when judged sufficiently charred; and when cold, not before, pour away the sand.

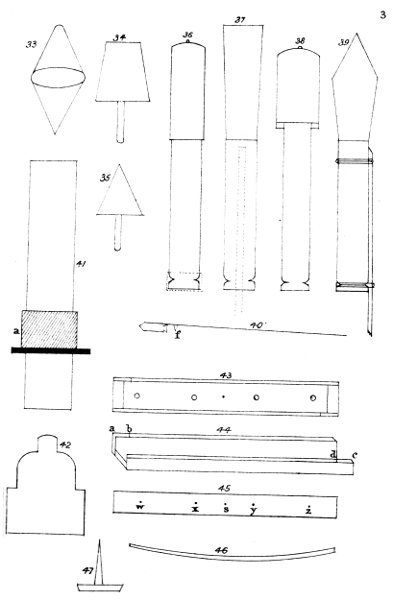

Sulphur is used in the state of sublimed sulphur, sulphur sublimatum, or flowers of sulphur, and, when mixed with nitre, requires no preparation; but as it is always more or less impregnated with sulphuric acid, as is readily shown by testing it with litmus paper, it might, on coming into contact with chlorate of potash, cause spontaneous combustion. To prevent this, it is necessary to wash the sulphur. For this purpose put it into a pan, and pour upon it boiling water, in which some salts of tartar (carbonate of potash) have been dissolved; stir it well and break down all lumps. Let it stand to subside; pour off the supernatant liquor; fill up with cold water and let it stand, to again subside. Make a conical bag, fig. 33, with a piece of linen or calico, sewed at the top, round a ring or hoop of wire, or cane, or whalebone; fasten a string to[Pg 51] it, by which to hang it up. Put the washed sulphur into it, and hang it under a water-tap; turn the water gently on, and let it drip all night; this will wash away every trace both of acid and alkali. Afterwards hang the bag up three or four days till the sulphur is dry; it may then be bottled, and kept exclusively for colours.

Oxalate of soda may be made thus—procure 3 lbs. of carbonate of soda, the common washing soda used by the laundress, not bicarbonate of soda; boil it up in a saucepan with just as little water as will suffice to dissolve it. Dissolve, in another vessel, 1 lb. of oxalic acid in boiling water, and pour it into a deep jar, capable of holding two or three quarts; a wash-hand jug will answer. Now put to this the dissolved carbonate of soda, with a table-spoon, a spoonful at a time. A violent effervescence takes place. The soda is to be slowly added till effervescence ceases. It should be tested with a strip of litmus paper, to see if the acid is perfectly neutralized.

To prepare litmus paper, dissolve 1⁄4 of an ounce of litmus in an ounce and a half of[Pg 52] water; when thoroughly dissolved, and the water is of a dark blue colour, take some white blotting paper, and with a sash-tool or camel's-hair pencil, go over it on both sides with the litmus solution. When dry, wet some of these prepared pieces, with the brush dipped into vinegar: this will turn them red. Dry, and preserve both. They may be cut into strips, half an inch broad; the blue strips will be tests for acids; the red, for alkalies. Wet a strip of the blue, and touch it with oxalic acid, it will turn red; wet a strip of the red, or the piece just reddened, with carbonate of soda, it will turn blue.

To make sulphuret of copper, procure some thin sheet copper, about as thick as a card; cut it into pieces, and put it into a crucible, with sulphur, a layer of sulphur, and a layer of copper alternately, till full. Set the crucible in a clear fire, and keep it red hot for an hour. Remove it; when cold, break it up, and grind it in a coffee-mill. Sift it in a lawn or book-muslin sieve as fine as possible. Half-a-pound of copper and a quarter of a pound of sulphur may be employed.

There is a black sulphide or sulphuret of[Pg 53] copper produced by passing sulphuretted hydrogen through a solution of protoxide of copper: this is useless.

For want of a coffee-mill, charcoal may be beaten in a leather bag, with a hammer.

A variety of rocket fuses will be found in the Tables; the first is as good as any, and will answer for all sizes from 3⁄8 to 12⁄8. As a rule, the fiercer fuses, containing meal powder, may be used for small rockets; but are, by no means, necessary.

A rocket, when starting, makes a roar; but this is not on account of the fierceness of the fuse, but of the extent of the surface ignited. Rocket composition, laid in a train, burns very slowly.

Rocket stars are made in three or four ways. First cut, or chopped, or naked stars. This mode is used for nitre stars only: chlorate of potash stars require different methods. It is a singular circumstance that, though chlorate of potash stars are much fiercer than nitrate of potash stars, yet the latter light without any trouble, while the former, if made in the same way, would be almost sure to miss.

Wet the composition with thin starch, or dextrine solution, or gum water, sufficiently to bind; press it into a flat mass, on a slate, or Dutch tile, with a knife, or small trowel, till about 3⁄8 of an inch thick. Indent the surface with the edge of the knife, in parallel lines, about 3⁄8 of an inch apart, and cross these with equidistant indentations, at right angles. Set the mass by, to dry gradually. When nearly dry, break it up into little 3⁄8 cubes, and lay them out, to dry thoroughly. The broken edges will be rough, and will catch easily.

Take a sheet of note paper, and cut it into four equal parts; each part will be about 41⁄2 inches by 31⁄2. Paste and roll them on a 31⁄2/8 brass tube, so as to have the cases 41⁄2 inches long. To make these into pill-boxes, perfectly true, like those used by the druggist, they must be cut in the lathe. For this purpose, turn a cylindrical piece of wood, fig. 27, which is to fit easily into the case, except at a, where it is to be turned sloping a little larger,[Pg 55] so that when the case is slipped over it, it will bite at the part a; otherwise, on putting the chisel to it, it would slip round, without getting cut. Mark the case, with a black-lead pencil, at every half-inch; suspend it in the lathe; and cut it at the marks. Next procure a 7⁄16 inch punch, with which to cut out the bottoms. These are to be made of card, or bristol-board. Lay the card on a piece of sheet-lead, or the grain end of a piece of beech, and give it a smart blow or two with a hammer; keep on punching till the punch contains a dozen or more discs, then push them out. When a number are ready, press them into the pill-boxes, with a rammer that fits loosely.

The composition is to be put into these dry, and driven in with a solid rammer, and the little mallet, before described.

This was the original way of making them, but is perfectly unnecessary. Roll the tubes as directed, of two thicknesses of paper, with a little bit to lap over. Cut them across, with one sharp clip, with a strong pair of scissors. This will slightly flatten them; but they may readily be restored to the cylindrical form, by slipping them on a piece of wood, and round[Pg 56]ing them to shape with the fingers. No bottoms need be provided, no punch used.

Rest the box on a flat surface, put in some composition, and drive it in with a brass or boxwood drift and the little mallet, till half full, as in fig. 28. Then fill up the box with more colour, set a little bit of match upright in the side, and mallet it in, till the box is almost full. The drift for this must be cut flat on one side, to allow for the match. On the top put a very little dry meal powder, or shell-fuse, and press it in with the finger. Cut a piece of double-crown, about an inch broad, and long enough to go rather more than once round the pill-box: paste it all over; lay the pill-box on it, and roll it up; tuck in one end, to make a bottom, and press the other end round the match, and on the meal powder, or shell-fuse, till it assumes the form of fig. 29.

Set the pill-box on a flat surface, put in a very little meal powder or shell-fuse, then[Pg 57] some composition, and mallet it in till full. Roll this up in a piece of double-crown as before; tuck in the bottom, and set by to dry; when dry, put into the other end—the end containing the film of meal or shell-fuse—a piece or two of thin match, and tie it in, as in fig. 30. Dry pill-boxes are best for making chameleon stars; these are half one colour and half another. Make a dozen stars, half yellow and half green, and a dozen more half blue and half crimson; put these into a rocket; they will burst green and crimson, and change to blue and yellow.

The cases are the same as before. To fill them, damp the composition as for Roman candle stars; put a bit of quickmatch into the case, as at fig. 31, and press in the composition. This is usually done with the fingers, but is not very pleasant work, especially with lac solution. A cleaner way, though more tedious, is to fit the case on to a little foot, with a side notch in it, fig. 60; then slightly mallet in the composition. Or a notch may be cut in the side of the box,[Pg 58] fig. 61, and the match put in, as fig. 62, and slightly malleted.

Instead of making the cases entirely of writing paper, they may be made half of writing paper and half of coloured double-crown, to indicate the colour of the star.

Another way is to sift a thin layer of French chalk over a sheet of paper, and to roll the stars in it, one by one, as they are punched. When dry, brush off the superfluous chalk, and prime with a bit of match, tied across the mouth.

Pump and drive the stars exactly as for roman candle stars, They may be 31⁄2/8 diameter, and 5⁄8 long; or they may be formed with figs. 1, 2, and 3, and the side pin of fig. 2 may be removed to c, in which case the stars will be 5⁄8 diameter, and 31⁄2/8 deep; the former will be an oblong cylinder, the latter an oblate. Cut a strip of red, blue, green, or yellow double-crown, of a suitable breadth, and long enough to go twice round the star. Paste the strip all over, or gum it at the edge only, and lay the star upon it, as at a, fig. 41,[Pg 59] with a bit of match behind it; then roll it up and put by to dry. When pasted, it shrinks and holds the match tight; when gummed at the edge this is not always the case; it may then have a piece of thin binding-wire twisted round it. It will have the appearance of fig. 32. In fig. 31, the match is embedded, and dries in the damped composition; in the enveloped stars the stars are dried first, and the match lies outside and blows through. Enveloped stars show well in the air.

The word envelope, as used in these pages, must not be confounded with the same word as applied to the coverings for letters. It is rather synonymous with the term wrapper; you lay an ounce of tobacco on a piece of paper, roll it up and tuck in the ends. So with cases: you roll them up in a piece of paper, and leave an inch vacant at each end to receive quickmatch, &c. This is termed the envelope, that is, the wrapper.

Heads for small rockets may be made of two or three rounds of paper rolled dry, and secured on the inner and outer edges with[Pg 60] paste. After sticking it on the case, which it may be made to fit, as in fig. 36, pinch the top in like a choke, only tight, and tie it round with twine or flax. For coloured rocket heads, 6⁄8 and upwards, the head may be enlarged by fixing a collar round the top of the case. To make the collar for a 6⁄8, roll a case on a 9⁄8 former, and when dry cut it into short lengths in the lathe, as recommended for pill-boxes; if unprovided with a lathe, saw it with a fine-toothed saw. The advantage of the enlarged head is, that it brings the stars nearer to the rocket, and prevents it from being top-heavy. Another way is to make the heads tapering, and the tops conical, as in fig. 39. One part is rolled on fig. 34, the other on fig. 35; or, a cone may be made of a circular piece of paper, without a former. Cut the circle, along the radius, to the centre; bend it into a cone; secure the edge with sealing-wax, and paste paper over it to overlap the rim: snip the edge with the scissors; paste it inside, and secure it to the other part. But the quickest way of all is to make a long paper bag, which may be made to fit to the greatest nicety. For this purpose take a[Pg 61] tape-measure; or lay down, on the edge of a strip of writing paper, 7 or 8 inches long, and 1 inch broad, 6 inches, divided into eighths, transferred from a foot-rule. Suppose the 6⁄8 rocket has a collar, which, on being measured by the paper just alluded to, is found to be 42⁄8 inches round; add to this 3⁄8 for lapping over, making 45⁄8 inches. Cut a piece of imperial brown 45⁄8 broad, and as long as the case, 6 inches. Make this into a paper bag, 21⁄8 inches broad. Be careful that the corners are perfect; a strip of double-crown may be pasted over them. When dry, pinch the mouth open till cylindrical, and merely allow the stars to drop in without forcing them; this will keep the top edge of a wedge shape, fig. 37, and answer the purpose of a cone. If the paper is thin, the bag must be made of two thicknesses; the paper will, then, require to be 9 inches by 6; 43⁄8 of this will have to be kept dry, and the other 45⁄8 pasted.

A head, made in this way, if required to hold gold rains, or serpents, can instantly be reduced to a cylindrical shape, by pushing the rocket-case right up it, to the top; this will cause the corners to stick out, like two[Pg 62] horns; press them down, and secure them with sealing-wax. Attach a cone, if desired.

Heads made like figs. 38 and 39 may be of three thicknesses of paper, pasted all over.

Fig. 39 shows the manner of tying on the sticks. No variation must be made in their lengths, and it is not advisable to alter their size. To adapt it to the wood, however, a slight alteration might be permitted. For instance, instead of 3⁄8 square, it might be 21⁄2/8 by 31⁄2/8, a slight increase one way, compensated by a slight diminution the other. It must, however, on no account, be so increased and diminished, as to approach the shape of a lath, as such stick would vibrate, and cause the rocket to quiver. When the heads are a paper bag of the shape of fig. 37, the stick must be tied on, as indicated by the dotted lines.

If the stick is suited to the rocket, it will, when suspended on the finger almost against the mouth, as at f, fig. 40, lie, not quite horizontal, but slightly sloping downward. The wood should be dry pine, free from knots. The sticks are generally cut with a carpenter's cutting-gauge. If the learner has a lathe he[Pg 63] will find a 6-inch circular saw convenient for cutting them.