Project Gutenberg's Paint Technology and Tests, by Henry A. Gardner This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org Title: Paint Technology and Tests Author: Henry A. Gardner Release Date: September 13, 2011 [EBook #37420] Language: English Character set encoding: ISO-8859-1 *** START OF THIS PROJECT GUTENBERG EBOOK PAINT TECHNOLOGY AND TESTS *** Produced by Chris Curnow, Harry Lamé and the Online Distributed Proofreading Team at https://www.pgdp.net (This file was produced from images generously made available by The Internet Archive)

Please see Transcriber's Notes at the end of this document

BY

HENRY A. GARDNER

Assistant Director, The Institute of Industrial Research,

Washington, D. C.

Director, Scientific Section, Paint Manufacturers’ Association

of the United States, etc.

McGRAW-HILL BOOK COMPANY

239 WEST 39TH STREET, NEW YORK

6 BOUVERIE STREET, LONDON, E.C.

1911

Copyright, 1911, by the McGraw-Hill Book Company

THE·PLIMPTON·PRESS·NORWOOD·MASS·U·S·A

TO

MY MOTHER

A few years ago the producer and consumer of paints possessed comparatively little knowledge of the relative durability of various pigments and oils. There existed in some cases a prejudice for a few standard products, that often held the user in bondage, discouraging investigation and exciting suspicion whenever discoveries were made, that brought forth new materials. Such conditions indicated to the more progressive, the need of positive information regarding the value of various painting materials, and the advisability of having the questions at issue determined in a practical manner.

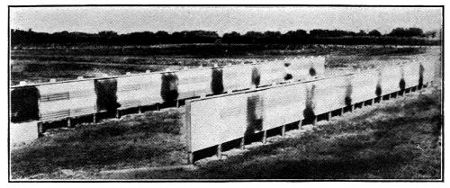

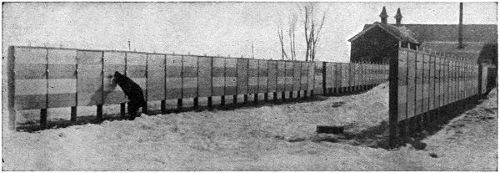

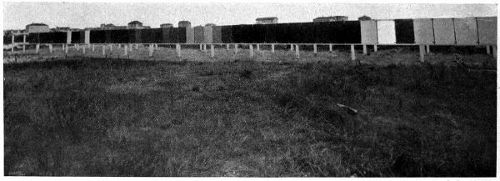

The desire that such work should be instituted, resulted in the creation of a Scientific Section, the scope of which was to make investigations to determine the relative merits of different types of paint, and to enlighten the industry on various technical problems. Paint exposure tests of an extensive nature were started in various sections of the country where climatic conditions vary. This field work was supplemented in the laboratory by a series of important researches into the properties of pigments, oils, and other raw products entering into the manufacture of protective coatings. The results of the work were published in bulletin form and given wide distribution. The demand for these bulletins early exhausted the original impress, and a general summary therefore forms a part of this volume.

The purpose of the book is primarily to serve as a reference work for grinders, painters, engineers, and students; matter of an important nature to each being presented. Without repetition of the matter found in other books, two chapters on raw products have been included, and they present in condensed form a summary of information that will prove of aid to one who desires to become conversant with painting materials with a view to continuing tests such as are outlined herein. In other chapters there has been compiled considerable matter from lectures and technical articles presented by the writer before various colleges, engineering societies, and painters’ associations.

[viii]The writer wishes to gratefully acknowledge the untiring efforts of the members of the Educational Bureau of the Paint Manufacturers’ Association, whose early endeavors made possible many of the tests described in this volume. Kind acknowledgment is also made to members of the International Association of Master House Painters and Decorators of the United States and Canada, who stood always ready to aid in investigations which promised to bring new light into their art and craft.

HENRY A. GARDNER.

Washington, October, 1911.

| CHAPTER | PAGE | |

| I | Paint Oils and Thinners | 1 |

| II | A Study of Driers and Their Effect | 21 |

| III | Paint Pigments and Their Properties | 42 |

| IV | Physical Laboratory Paint Tests | 70 |

| V | The Theory and Practice of Scientific Paint Making | 93 |

| VI | The Scope of Practical Paint Tests | 105 |

| VII | Conditions Noted at Inspection of Tests | 114 |

| VIII | Results of Atlantic City Tests | 124 |

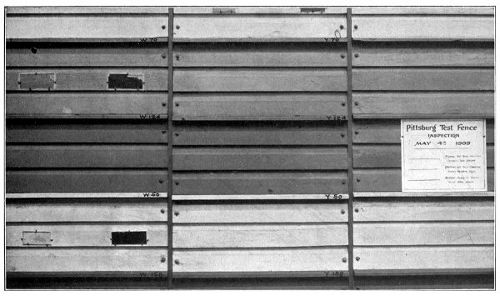

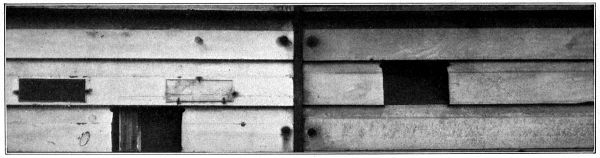

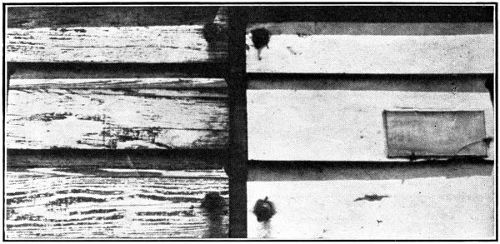

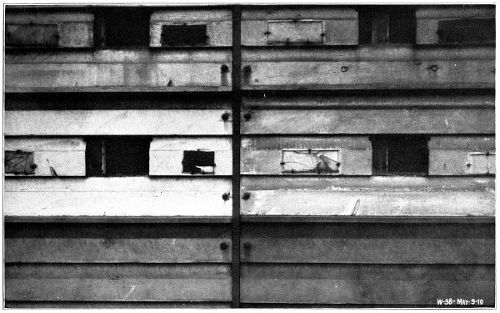

| IX | Results of Pittsburg Tests | 135 |

| X | A Laboratory Study of Test Panels | 149 |

| XI | Additional Tests at Atlantic City and Pittsburg | 174 |

| XII | North Dakota Paint Tests | 182 |

| XIII | Tennessee Paint Tests | 201 |

| XIV | Washington Paint Tests | 207 |

| XV | Cement and Concrete Paint Tests | 214 |

| XVI | Structural Steel Paint Tests | 220 |

| XVII | The Sanitary Value of Wall Paints | 252 |

Constants and Characteristics of Oils and Their Effect upon Drying. An attempt has been made to give in this chapter a brief summary of the most important characteristics of those oils finding application in the paint and varnish industry. For methods of oil analysis, the reader is referred to standard works on this subject; the analytical constants herein being given only for comparative purposes.

It is well known that one of the most desirable features of a paint oil is the ability to set up in a short period to a hard surface that will not take dust. This drying property is dependent upon the chemical nature of the oil. If it is an unsaturated compound, like linseed oil, rapid absorption of oxygen will cause the film to dry rapidly and become hard. If the oil be of a fully satisfied nature, like mineral oil, oxygen cannot be taken up to any great extent and drying will not take place. The various animal and vegetable oils differ in their power of oxygen absorption to a lesser or greater extent. This difference is referred to by the chemist in terms of the iodine value. The iodine value of linseed oil is approximately 190, meaning that one gram of the oil will take up 190 centigrams of iodine. Oils with high iodine values have good drying powers, while those with low iodine values are, as a rule, very slow drying in nature.

For a description of the working and drying properties of various oils used in paints, see Chapter XIV. The oxygen absorption of various oils and mixtures is shown in Chapter II.

Linseed Oil. The seed of the flax plant which is extensively grown in North Dakota, Argentine Republic and Russia, contains approximately 36% of oil which may be obtained by grinding, heating, and expression. Ripe native seed generally produces[2] a pale oil of little odor; the oil from Argentine seed often having a greenish tint and an odor resembling sorghum. While filtering, pressing and ageing will remove considerable of the (“foots”) mucilaginous matter, phosphates, silica, etc., from the oil, the better grades which are intended for varnish making are often refined with sulphuric acid. A light colored oil which may be heated without “breaking” results from this treatment, but such oils are apt to contain considerable free fatty acid, unless they are washed with alkali subsequent to the sulphuric acid treatment. On account of its rapid drying properties and general adaptability for all classes of paints and varnishes, linseed oil has never been supplanted by any other oil. Chemically it consists of the glycerides of linoleic, oleic, and isolinoleic acid, its constitution being responsible for its very high iodine value.

Boiled linseed oil, a heavier and darker product, is made by heating the raw oil in open kettles to high temperatures, generally with the addition of metallic driers such as litharge, and black manganese. The resinates of lead and manganese are often added to oil heated at a lower temperature, to obtain a boiled oil of lighter color.

New type of Flax Harvester which pulls plant up by the roots, thus preventing infection of soil

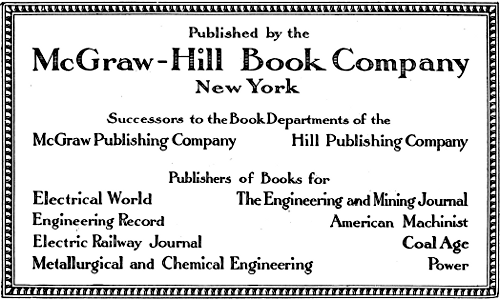

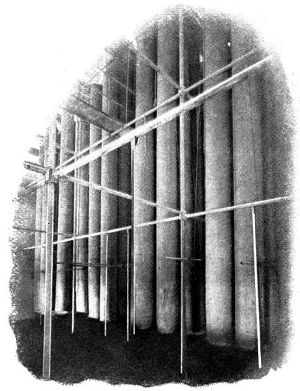

Modern Concrete Elevators for storing Flaxseed

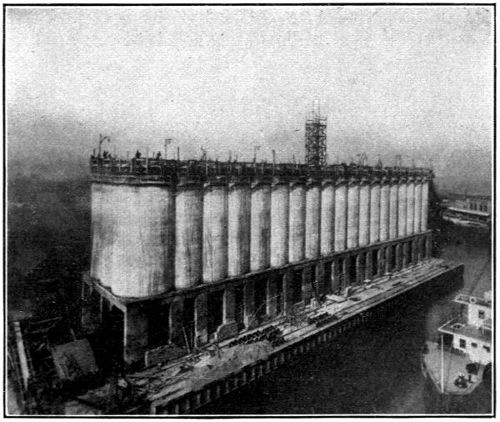

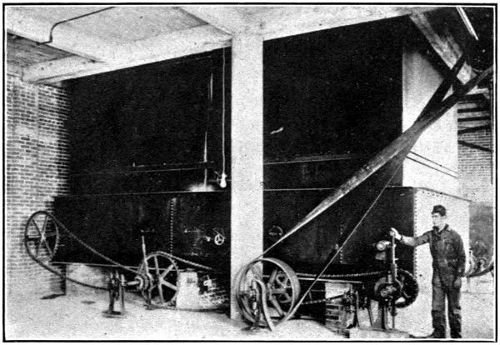

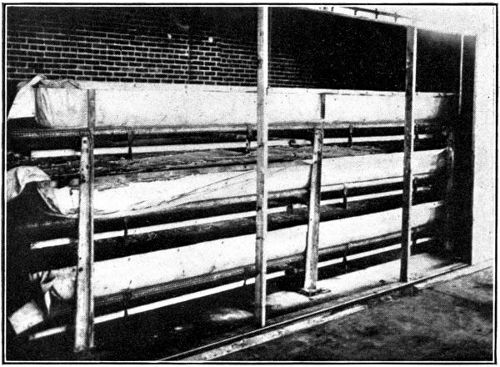

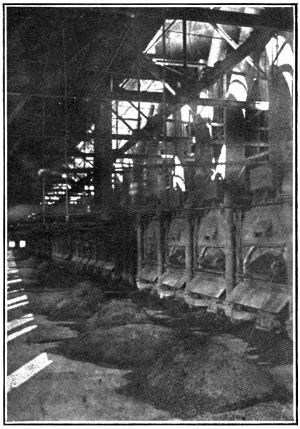

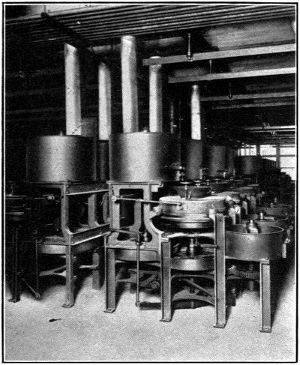

View of Linseed Oil Factory showing hydraulic press, tanks, etc.

Photographs courtesy of Spencer Kellogg Sons

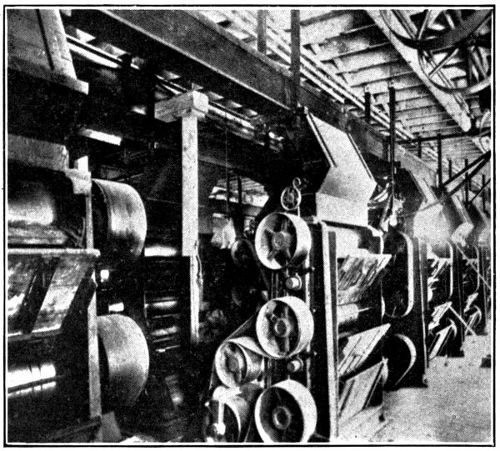

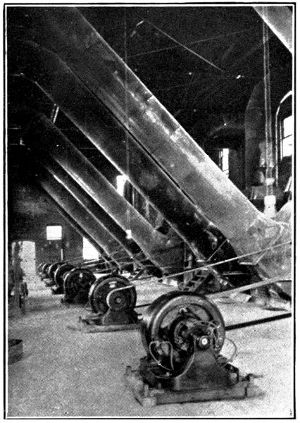

Flaxseed Crushers

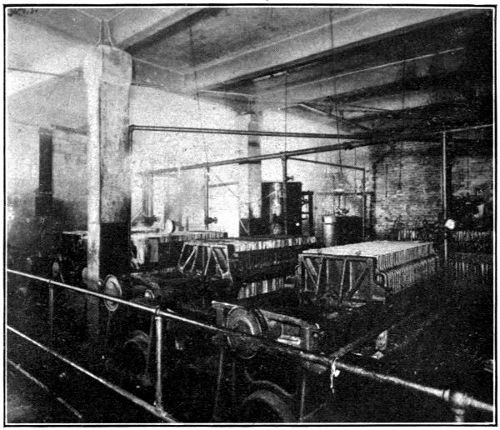

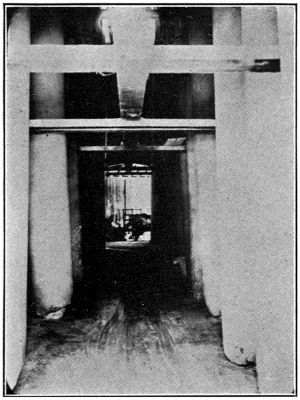

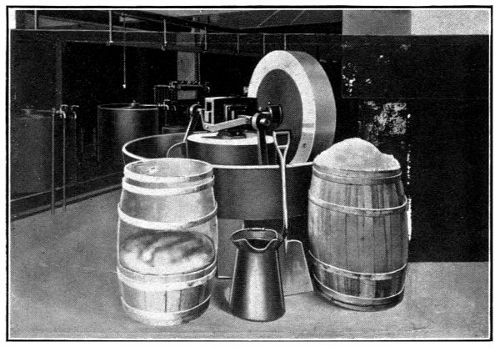

Filter Presses for removing extraneous matter from linseed oil

Linseed Cake from Oil Press

Glycine Hispida

Mammoth soya bean plants

Photographs courtesy of David Fairchild, Plant Explorer, U. S. Dept. of Agriculture

Glycine Hispida

Soya bean plants under cultivation at Arlington, Va.

By blowing air through linseed oil that has been heated to approximately 200 degrees Fahrenheit, either with or without drier, heavy bodied oils are obtained, which find special application in varnishes and technical paints. As the viscosity of these oils increase, the iodine values decrease, and a slight rise in [7]saponification value and specific gravity is observed. The following analyses of various types of linseed oil were recently made by the writer:

| Pure Raw Linseed Oil |

Boiled L. O. (Linoleate) |

Boiled L. O. (Resinate) |

Blown L. O. |

Litho. L. O. |

Old Treated Oil |

|

| Color | Amber | Dark | Reddish | Pale | Dark | Amber |

| Clear | Brown | Brown | Brown | Clear | ||

| Sp. Gr. at 15° C. | .933 Average |

.941 | .930 | .968 | .970 | .943 |

| Iodine No. | 180 | 172 | 176 | 133 | 102 | 172 |

| Saponification No. | 191 | 187 | 186 | 189 | 199 | 197 |

| Free Fatty Acid | 3.2 | 2.7 | 2.2 | 2.8 | 2.7 | 6.9 |

| Unsaponifiable | 1.4 | — | — | — | — | 1.8 |

| Maumene | 111 | — | — | — | — | 96 |

| Moisture | .2% | — | — | — | — | none |

Soya Bean Oil. The soya plant which is extensively cultivated in Asia produces a seed bearing up to 22% and over of a golden colored oil having a peculiar leguminous odor. The oil, which probably consists of the glycerides of oleic, linoleic, and palmitic[8] acids, is secured by crushing, steaming and pressing the seed. There are several varieties of the plant, and they are said to be the best annual legume for forage, the straw and fruit being rich in nitrogen and very fattening as a cattle food. Soya may be grown in nearly any country and is a great carrier of nitrogen to land deficient in this element. Although the oil has been used abroad for many years for soap-making purposes, its use as a drying oil is comparatively recent; being introduced into the paint industry of the United States during the year 1909, when linseed oil started on its phenomenal rise in price.

The oil has given fair service in some paints when mixed with upwards of 75% of pure linseed oil. It is of a semi-drying nature, but may be made to dry rapidly when mixed with manganese and lead linoleate driers. By compounding it under heat with tung oil and rosin, a substitute for linseed oil is produced, which some claim to be quite valuable.

Table I gives the constants of several samples of soya oil examined by the writer. Table II shows the iodine value of mixtures of soya and linseed oils. Table III shows the results of drying experiments on soya oils containing different percentages of lead and manganese driers.

| Sample No. | Specific gravity | Acid No. | Saponification No. |

Iodine No. | Per cent. of foots |

| 1 | 0.9233 | 1.87 | 188.4 | 127.8 | 3.81 |

| 2 | 0.9240 | 1.92 | 188.3 | 127.2 | — |

| 3 | 0.9231 | 1.90 | 187.8 | 131.7 | — |

| 4 | 0.9233 | 1.91 | 188.4 | 129.8 | — |

| 5 | — | — | — | 130.0 | — |

| 6 | — | — | — | 132.6 | — |

| 7 | — | — | — | 136.0 | — |

| Average | 0.9234 | 1.90 | 188.2 | 130.7 | — |

| Sample No. | Straight linseed |

Soya 25 per cent. Linseed 75 per cent. |

Soya 50 per cent. Linseed 50 per cent. |

Soya 75 per cent. Linseed 25 per cent. |

| 1 | 190.3 | 175.2 | 160.7 | 140.4 |

| 2 | 189.5 | 175.9 | 161.7 | 140.8 |

| 3 | 188.0 | 175.4 | 160.3 | 139.0 |

| Average | 189.3 | 175.5 | 160.9 | 140.4 |

| Per cent. PbO |

0.05 | 0.10 | 0.30 | 0.50 | 0.70 | 1.00 | 1.30 | 1.60 | |||

| ⎧ | 1 | day | — | 0.07 | 0.63 | 1.34 | 1.05 | 1.53 | 0.93 | 1.35 | |

| ⎪ | 3 | days | — | 0.07 | 3.52 | 4.31 | 2.75 | 4.86 | 4.82 | 4.12 | |

| ⎪ | 5 | days | — | 0.09 | 5.04 | 6.06 | 6.09 | 6.75 | 6.66 | 5.52 | |

| Per ct. gain | ⎨ | 12 | days | — | — | 6.88 | 7.54 | 7.43 | 7.76 | 7.32 | 6.47 |

| ⎪ | 15 | days | — | — | 8.84 | 8.93 | 8.59 | 8.81 | 8.44 | 7.46 | |

| ⎩ | 20 | days | 0.05 | 0.20 | 9.02 | 9.08 | 8.90 | 9.03 | 8.65 | 7.83 | |

| Per cent. MnO2 | 0.01 | 0.05 | 0.15 | 0.26 | 0.30 | |||

| Per ct. gain | ⎧ | 1 | day | — | — | 0.02 | 0.02 | 0.01 |

| ⎨ | 10 | days | — | 5.06 | 6.48 | 6.10 | 5.97 | |

| ⎩ | 20 | days | 0.05 | 9.07 | 8.80 | 6.78 | 6.51 | |

| Per cent. PbO | 0.20 | 0.30 | 0.50 | |||

| MnO2 | 0.05 | 0.15 | 0.25 | |||

| Per ct. gain | ⎧ | 1 | day | 3.04 | 3.77 | 3.74 |

| ⎨ | 8 | days | 5.96 | 6.43 | 6.47 | |

| ⎩ | 12 | days | 6.33 | 6.78 | 6.67 | |

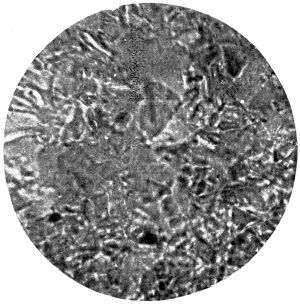

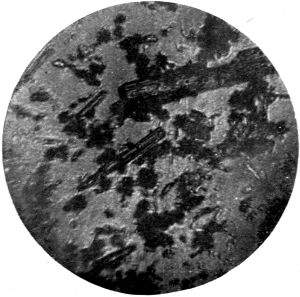

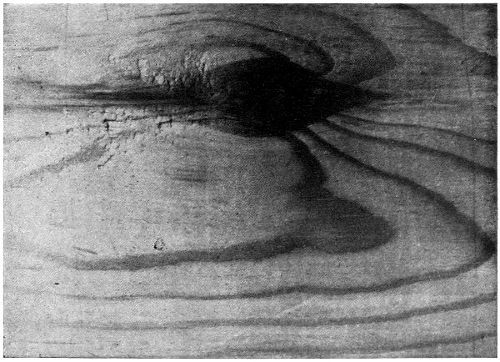

Tung Oil. There are grown in China and Japan many varieties of the “aleurites cordata,” popularly known as the tung tree. This tree bears great quantities of large sized nuts containing as high as 40% of an oil which yields itself in a viscous yellow form upon heating and crushing of the fruit. The raw oil, which chemically consists of the glycerides of oleic, oleo-margaric, and probably isomeric acids, is distinguished by its rapid drying properties. When spread in a thin layer it produces a hard film with an opaque frosted surface, often showing a tendency to wrinkle. Treated tung oil will dry to a clear, water-shedding, elastic film. This oil is made by heating the raw tung oil at a comparatively low temperature with other oils and a metallic drier such as litharge.

Photographs courtesy of David Fairchild

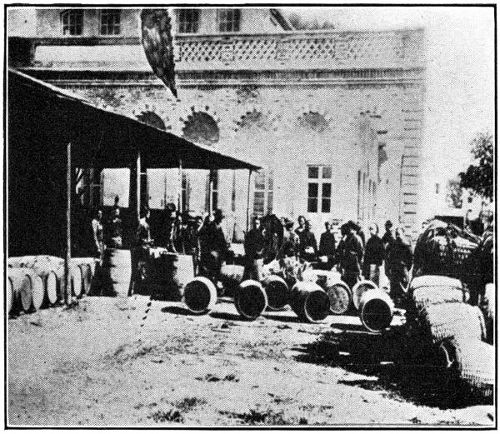

Aleurites Cordata (Chinese Wood Oil) Barrel Factory at Cooperage Shop

Photographs courtesy of David Fairchild

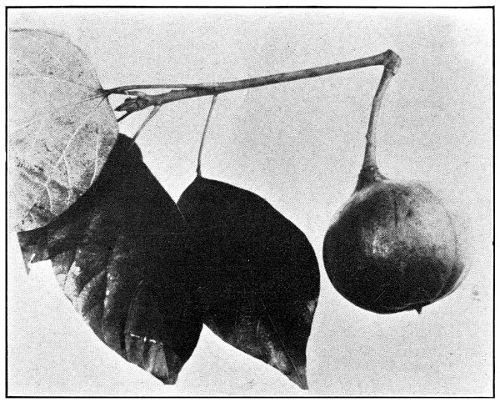

Aleurites Fordii (Chinese Wood Oil)

Fruit from trees at the end of fourth year

The affinity of tung oil for rosin has resulted in the production of a series of moderate-priced varnishes most suitable for use in floor and deck paints or wherever great hardness is required. These varnishes are also finding application in the manufacture of concrete, steel, and flat wall paints; being especially suitable for the above purposes when compounded with kauri gum japan.

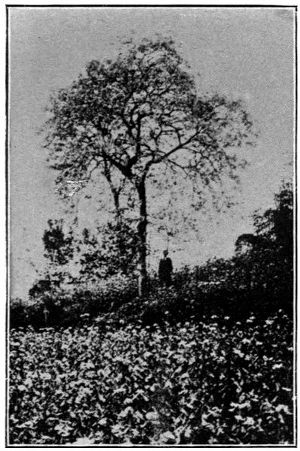

Aleurites Fordii

Wood Oil tree, thirty feet high and three feet in diameter, on

banks of Yangtse River, Western Szechuan, China. Opium Poppy in the foreground

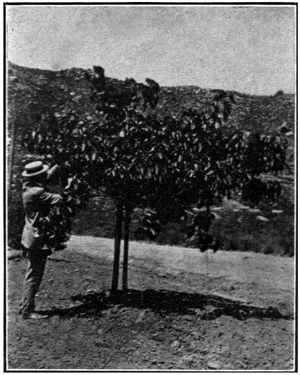

Aleurites Cordata

Flowering specimen of the Chinese Wood Oil tree at Riverside, California,

planted in 1907. Photograph taken in 1910, when tree had borne fifty fruits

During the boiling of raw tung oil the temperature must not exceed much over 400 degrees Fahrenheit. Otherwise a peculiar “hamming” will take place, the whole mass becoming solid and of no further value as a varnish or paint vehicle. Some peculiar internal disturbance or rearrangement of the molecules is evidently effected by heat, and although the reaction is not clearly understood, it has been ascribed to auto-polymerization. Scott has stated that the phenomenon of gelatinization is due to the exposure of the surface of the oil to the air, and that boiling in vacuo obviates such results. The lusterless surface produced when tung oil varnishes are dried in vitiated air would tend to confirm the conclusion that the oil is very subject to atmospheric influences.

[12]Lumbang Oil, which is obtained from a tropical species of Tung, is very similar in appearance and properties to Linseed Oil.

| Sp. Gr. | Iodine No. | Saponifi- cation No. |

Acid No. | |

| No. 1 | .944 | 166 | 188 | 3.6 |

| No. 2 | .940 | 164 | 184 | 1.8 |

Photographs courtesy Alpin I. Dunn

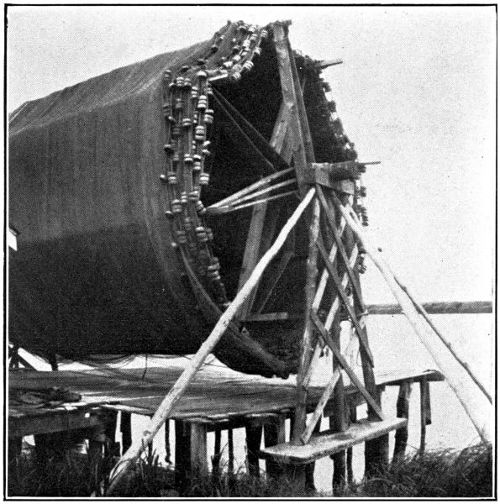

Menhaden Net drying in the Sun

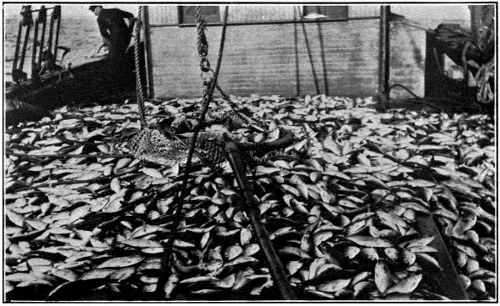

A big catch of Menhaden made off Narragansett Bay

Menhaden Oil. Of all the marine-animal oils, such as seal, herring, sardine, whale, and menhaden, the latter is the most valuable. It is produced by steam digestion and pressure of the menhaden or “piogey” fish, which are caught in great quantities off the Atlantic Coast. Prompt cooking and treatment of the fish results in a light-colored oil having very little odor, the residue left in the presses being of great value as a fertilizer. Although several grades of oil termed crude, brown, light, etc., are produced, the most satisfactory for use in paint is that grade termed “light winter pressed.” This oil is of a pale straw color and has a high iodine number which is responsible for its rapid drying value. It contains less of the stearates that precipitate from crude oil, but sufficient to render its film water-shedding and elastic. The presence of too great a quantity of stearates is apt to result in a[14] very soft film, and the use of hard driers, such as the metallic tungates, is therefore advisable with menhaden oil. When mixed with linseed oil paints the odor of menhaden oil is sometimes noticeable, but it disappears entirely after such paints are applied. Its use with linseed oil in technical paints exposed to the salty air of the Coast has given good results, often preventing “checking” and “chalking.”

The following constants were determined on samples of menhaden oil received in the writer’s laboratory:

| Sp. Gr. | Iodine Value |

Saponification Number |

Acid Number |

|

| Light | .927 | 175.8 | 187.9 | 7.55 |

| Medium | .925 | 178.7 | 187.6 | 6.19 |

| Dark | .927 | 178.0 | 187.3 | 7.19 |

Whale Oil. While ordinary whale oil is too dark and odorous to ever come into extensive use as a paint oil, it is probable that the refined oil will be utilized in the manufacture of certain technical paints. Whale oil is boiled from chopped whale blubber, the first trying being the lightest in color, while the later tryings, as well as the product made from bones, are of darker color and of very bad odor. Oil of mirbane is often used to mask this odor. The oil contains large quantities of stearin and palmitin, as well as wax-like constituents which are apt to be thrown out of solution in very cold weather, or when the oil is mixed with other oils. The refined oil, when ground with lead and zinc pigments and mixed with equal parts of linseed oil and treated tung oil, dries to an elastic and soft film. Experiments are being made to utilize whale oil in the linoleum industry.

The analyses of samples of whale oil tested by the writer are as follows:

| Sp. Gr. | Iodine Value |

Saponification Number |

Free Fatty Acid |

||

| Light Refined | .924 | 148 | 190 | .2 | 1.2 |

| Dark Yellow | .920 | 142 | 187 | 7.0 | |

| Dark Brown | .910 | 140 | 184 | 18.0 | |

Sunflower Oil. Sunflower oil is produced largely in Russia and Hungary, finding favor in those countries as an edible oil.[15] The ripe seeds of the sunflower plant contain over 30% of oil which is very pale in color and of a pleasant smell. It has been found that sunflowers may be grown to advantage in dry parts of the United States, and if suitable yields are obtained from a few experimental acres now being cultivated, the industry may receive encouragement in this country. The oil should be well suited for varnish making, and although the iodine number is not very high, it dries quite rapidly.

| Sp. Gr. | Iodine No. | Saponifica- tion No. |

Acid No. |

| .929 | 128 | 188 | 4 |

Cottonseed Oil. This oil is expressed from the seed of the cotton plant, varying in color according to the time of its pressing and degree of refinement. Being edible as well as highly suited for soap making, very little of it comes into the market as a paint oil. It contains large quantities of stearin and has a low iodine value, making it a slow drying oil. Some samples are extremely light in color and contain less mucilaginous matter and foots than is present in ordinary varieties.

| Sp. Gr. | Iodine No. | Saponifica- tion No. |

Acid No. |

| .922 | 106 | 190 | 2.4 |

[16]Corn Oil. As a by-product in the manufacture of starch and alcoholic liquids, this material comes into the market having a golden yellow color, and an odor resembling fermented grain. It has a lower drying value than cottonseed oil, and its use in the paint industry will probably be limited to color grinding, where an oil with a semi-drying value is often desired. Like cottonseed oil, it belongs more properly to the soap oil class. It contains glycerides of linoleic and especially palmitic acid.

| Sp. Gr. | Iodine No. | Saponification No. | Acid No. |

| .925 | 118 | 191 | 9.5 |

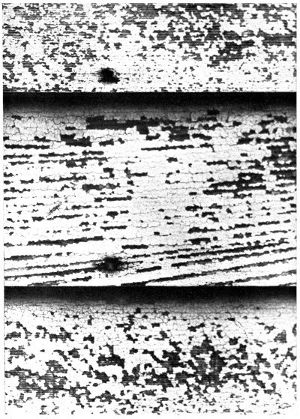

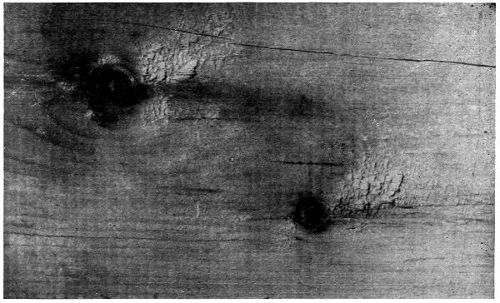

Rosin Oil. By the dry distillation of rosin, there is yielded a series of heavy dark oils consisting principally of hydrocarbons, resinous bodies, and free acid. These oils vary in their saponification number from 10 to 60, while their unsaponifiable value averages about 80. Of the grades termed first, second, third, and fourth run, the latter two are superior for use in paints, as a rule containing less free acid than the preliminary runs. Treatment with steam and alkali serve to neutralize the acid nature of the oils and to remove impurities. Refined oils are lighter in color and are often blown and bodied to fairly rapid drying products, especially when treated with manganese driers. Rosin oils are seldom used with lead pigments, on account of the presence of sulphur in the oils, which would result in darkening. Rosin oil paints work very smoothly, even when they are curdled, producing glossy surfaces. The rapid checking of rosin oil paints on wooden surfaces bars the use of this oil for such purposes.

| Sp. Gr. | Iodine Value |

Saponifica- tion No. |

Acid No. | ||

| A | .96 | 6 | 41 | 27 | 16.7 |

| B | .99 | 48 | 38 | 10.0 | |

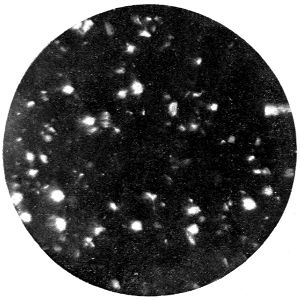

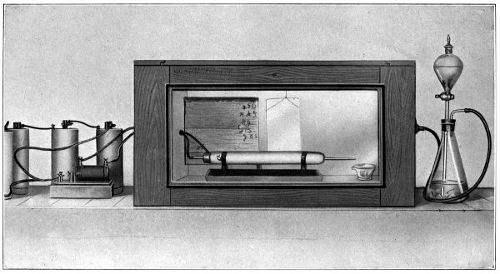

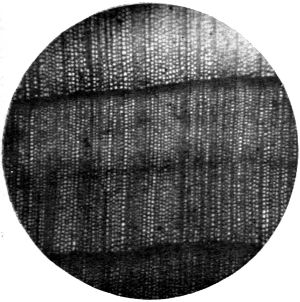

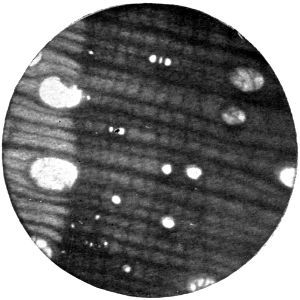

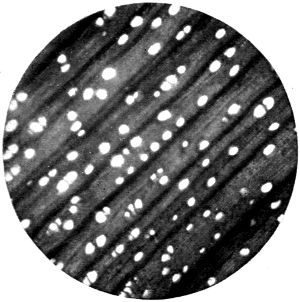

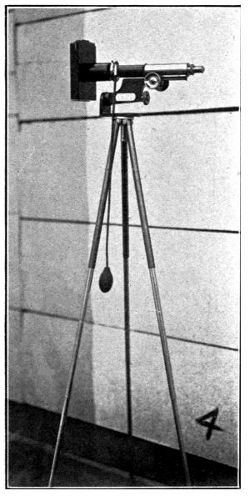

Hydrocarbon Oils. Several grades of neutral or mineral oils, varying somewhat in gravity, color, and quality, are produced[17] as the last distillate in the refining of petroleum. These oils when mixed with drying oils and strong driers find application in the manufacture of some freight-car, barn, and other paints which sell at a low price. A small percentage of mineral oil is said to be valuable in structural steel paints, acting as a preventative of hard drying and thus keeping the film soft and elastic. Streaking and sweating is apt to ensue if any great quantity is used. Mineral oils have a characteristic bloom, showing a greenish fluorescence when examined by transmitted light. This bloom is due to the presence of some strongly fluorescent material which is shown up with intensity when mineral oils are exposed to ultraviolet rays such as emanate from an enclosed arc light. Outerbridge[1] first proposed this test for mineral oils, and he has worked out a “fluorescent scale,” by which very small percentages of hydrocarbon oils may be detected in other oils. Several types of so-called debloomed oil have been placed upon the market, and although such oils appear under ordinary light conditions to be free from bloom, they fluoresce quite strongly when given the Outerbridge test.

[1] Alexander E. Outerbridge, Jr.: “A Novel Method of Detecting Mineral Oil and Resin Oil in Other Oils.” Proc. 14th Annual Meet., Amer. Soc. for Testing Mater., Atlantic City, N.J., June 28, 1911.

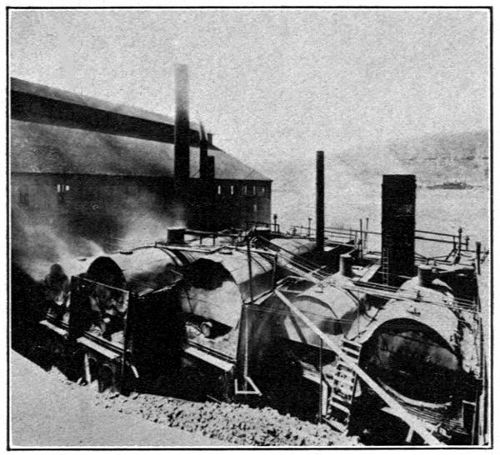

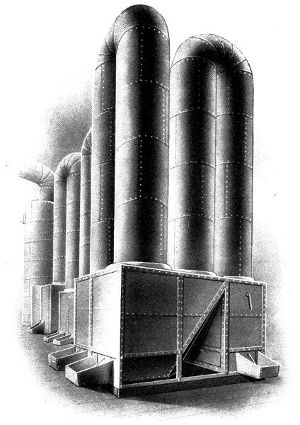

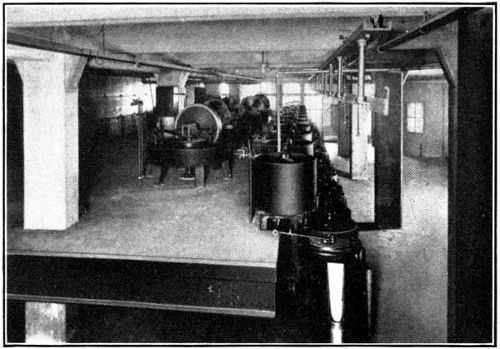

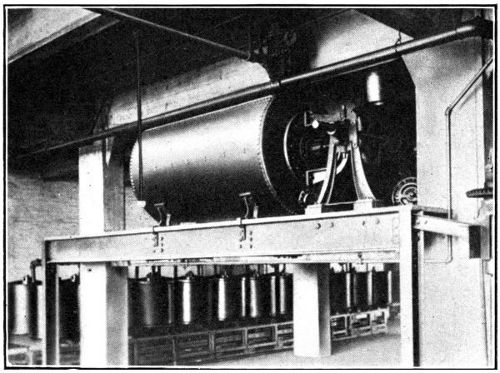

View of Stills Where Petroleum Paint Thinners are Manufactured (Waverly)

| Sp. Gr. | Iodine No. | Saponification No. | Acid No. |

| .92 | 12 | 4 | 0 |

[2] Oil of mirbane present, probably as a deblooming agent, or to mask the odor.

Pine Oil. This oil is produced by the redistillation of the heavy, high boiling point fractions resulting from the steam distillation of wood turpentine. It is a heavy straw-colored oil, and should be of some use in the paint and varnish industry, where a high boiling point solvent with an oxidizing principle is desired. It will probably find application in the manufacture of Baking Japans, Asphalt Paints and Enamels. Its oxidizing and solvent values are very high. It has a distinctive sweet pine smell, which makes it popular in the manufacture of turpentine substitutes from petroleum spirits.

The writer has examined samples of this material, and the following appear to be of the best grade:

| No. 1 | No. 2 | |

| Color | Straw Color | Light Yellow |

| Specific Gravity at 15° C. | .934 | .936 |

| Boiling Point | 192° C. | 202° C. |

| Distillation | 95% distils between 192-270° C. |

95% distils between 202-280° C. |

| Residue on Evaporation | 14.34% | 14.60% |

| Polymerization Test | 32⁄3% unpolymerized at end of 1⁄2 hour |

21⁄2% unpolymerized at end of 1⁄2 hour |

| Flash-Point | 72° C. | 76° C. |

| Spot Test | Leaves no grease spot but only evaporates completely in 24 hours |

Same as Pine Oil No. 1 |

Turpentine. By direct fire or steam distillation of the sap drippings collected in pockets cut into pine trees, there is obtained the turpentine of commerce. It consists largely of pinene and isomeric terpenes, and has the property of attracting oxygen, with the formation of peroxides which stimulate the drying of oils. It is a high-grade solvent for various gums, and is therefore[19] used in the manufacture of many lacquers as well as for thinning down oil-gum varnishes.

| Color | Water White |

| Specific Gravity at 15° C. | .862-.875 |

| Boiling Point | About 156° C. |

| Distillation | 95% should distil between 153 and 165° C. |

| Residue on Evaporation | Not over 2% |

| Polymerization | Not over 5% should remain unpolymerized at end of half hour |

| Flash-Point | Over 40.5° C. |

| Spot Test | No grease spot should remain when dropped on paper and allowed to evaporate |

| Water | None |

Wood Turpentine. High-grade wood turpentine is now produced by the steam distillation of finely cut fat pine wood. The lower-grade qualities are often produced from the destructive distillation of sawdust, stumpage, etc., and these products, on account of their content of formaldehyde, are objectionable in odor. In the steam distillation process, however, a high quality product is obtained by cutting out the heavy fractions and redistilling the lower and purer fractions. It has a high oxidizing value, causing the rapid drying of paints and varnishes to which it has been added. Its solvent value is often greater than that of gum turpentine. When properly refined it has a sweet smell and is to be highly recommended.

Analyses of samples of pure wood turpentine which have come to the writer for examination follow:

| No. 1 | No. 2 | |

| Sp. Gr. at 15° C. | .862 | .862 |

| Boiling Point | 158° C. | 162° C. |

| Distillation: 95% distils between | 158 and 185° C. | 162 and 177° C. |

| Residue on Evaporation | 1.03% | 3.06% |

| Polymerization Test | 4.1% remains unpoly- merized at end of 1⁄2 hour |

0.1 cc. out of 6 cc. unpolymerized = 1.66% |

| Spot Test | No grease spot on evap- oration |

No grease spot on evap- oration |

| Odor | Excellent | Not objectionable |

| Color | Water White | Water White |

| Flash Point | 47.6° C. |

Petroleum Spirits. There are produced from Texas crude oil which has an asphaltum base, and Pennsylvania crude oil which has a paraffin base, high boiling-point petroleum spirits which have come into wide use as paint and varnish thinners. When such materials have the proper evaporating value, high flash-point and freedom from sulphur, they are to be highly recommended as paint thinners. The following shows the analyses of a few of these materials examined in the writer’s laboratory:

| Texas Base | California Base | Penna. Base | |

| Color | Water White | White | Water White |

| Specific Gravity | .811 | .79 | .81 |

| Boiling Point | 156° C. | 138° C. | 146° C. |

| Flash-Point | 44° C. | 40.5° C. | 43° C. |

| Residue on Evaporation | .2 | .15 | .12 |

Benzol. “Solvent naphtha” or 160-degree benzol is a product obtained from the distillation of coal tar, differing from benzine, a product obtained from the distillation of petroleum. It is a valuable thinner to use in the reduction of paints for the priming of resinous lumber and refractory woods such as cypress and yellow pitch pine. The penetrating and solvent values of benzol are high, and it often furnishes a unison between paint and wood, that is a prime foundation to subsequent coatings, preventing the usual scaling and sap exudations which often appear on a painted surface. Because of the great solvent action of benzol, it should never be used in second and third coatings. The writer has successfully painted inferior grades of cypress with a paint containing benzol in the priming coat.

Benzine. Benzine is seldom used in paints on account of its rapid evaporation, which is apt to cause pinholing of films and other surface defects. In paints of the dipping type where rapid evaporation is essential, benzine finds its widest application.

The proper drying of oils and their behavior with various siccatives in varying quantity is an interesting problem, and obviously of considerable importance from a practical standpoint. Unfortunately there is a decided scarcity of reliable literature dealing with the subject for the guidance of those concerned in the manufacture or application of siccative products. Furthermore, when the problem is investigated, it is not difficult to see why this is so.

Uniform Conditions. At a glance it is evident that a decided obstacle in experimentation on the drying properties of oils is the difficulty in obtaining identical conditions for comparative purposes. Inasmuch as a multitude of factors, such as uniformity and homogeneity of the driers and the oils themselves, intensity and source of light, temperature, uniformity of application, and many others, play a decisive part in the siccative tendencies of oils, the resources and ingenuity of the chemist engaged in the research are severely taxed.

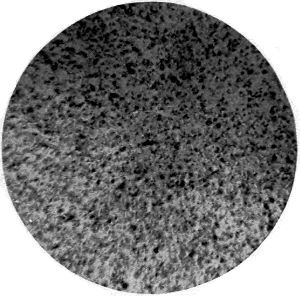

Oxygen Absorption. It is a well-known fact that linseed oil, when applied to a clean surface, such as a glass plate, will undergo oxidation and take up oxygen to the extent of about 16%, forming a hard, elastic, non-sticky product which has been called linoxyn. This material, unlike the oil from which it has been formed, is insoluble in most solvents. Other oils, such as cottonseed, hemp, rape, olive, etc., are more fully satisfied in nature and have not the power to absorb the amount of oxygen taken up by linseed oil.

In carrying out the following tests, on the drying of oils, a quantity of pure linseed oil of the following analysis was secured:

| Specific gravity at 15° C. | 0.934 | |

| Acid number | 5 | |

| Saponification number | 191 | 1⁄2 |

| Iodine number | 188 |

This oil was distributed into a number of 8-oz. oil sample bottles, and to a series of these bottles was added varying quantities of a very concentrated drier made by boiling oil to 400 degrees Fahrenheit in an open kettle, with the subsequent addition of lead oxide. The amount of drier added to each bottle varied according to the percentage desired; being calculated on the lead content of the drier, which was very accurately determined by analysis.

There was secured in this manner a series of oils containing varying amounts of lead oxide, and from this lot was selected a certain number of samples which would be representative and typical of paint vehicles now found in the market.

Another series of tests were made by combining with a large number of samples of pure linseed oil as used above, various percentages of a manganese drier made by boiling oil at 400° F. and incorporating therewith manganese dioxide.

Still another series of tests were made upon a number of oils into which were incorporated various small quantities of lead oxide and manganese oxide together, using the standard driers made in the above manner, all of which were carefully analyzed to determine their contents.

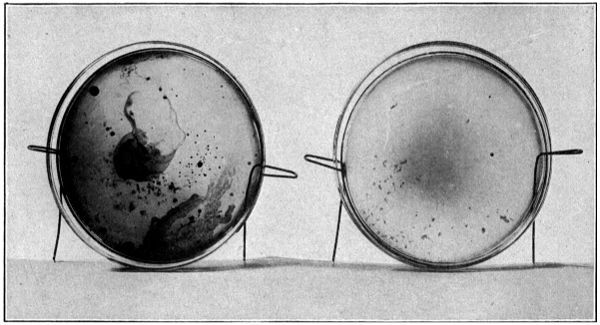

In view of the errors in manipulation that could occur where so many tests were made, it was not deemed advisable, in carrying out the tests, to use glass plates on which only a minute quantity of oil could be maintained. A much better solution of the difficulty presented itself in using a series of small, round, crimped-edge tin plates, about three inches in diameter, such as are used for lids of friction-top cans.

With paints it is impossible to secure films as thin as those presented by layers of oil on glass, nor would it be desirable to secure films of this same relative thickness. For this reason an endeavor was made to conduct the following tests with films of the same relative thickness as that possessed by the average coating of paint. The drying of the films did not take place in the same short period, nor in the same ratio, as with the thin layer that is secured by flowing oil upon glass. The results, however, are more practical, and of greater value to the manufacturer.

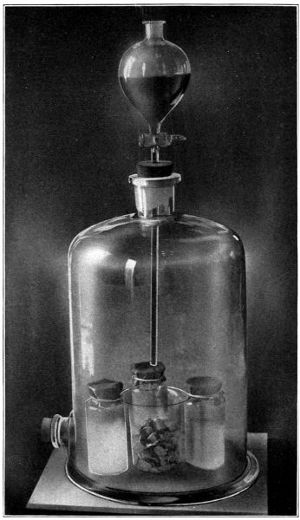

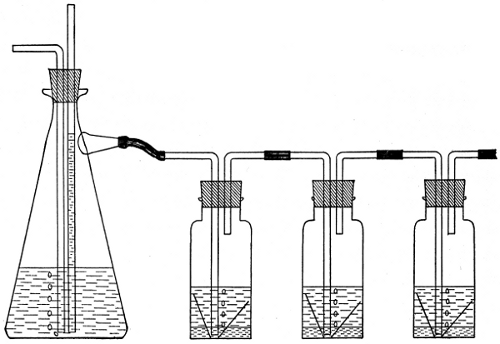

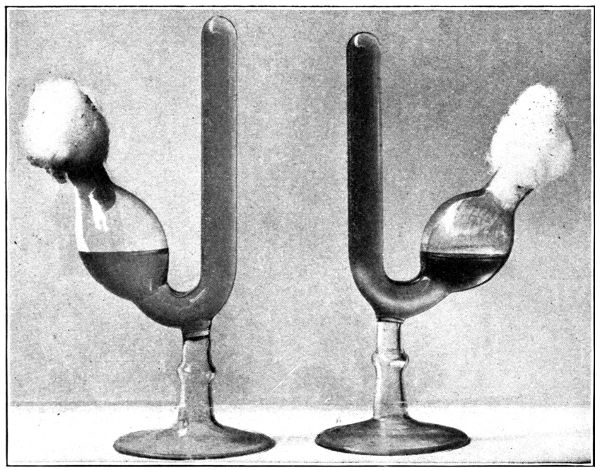

The cans were carefully numbered in consecutive order, corresponding to the numbers on the various samples of oil.[23] A very small quantity of oil was placed in each of the can covers, which were previously weighed, and allowed to distribute itself over the bottom surface thereof. Reweighing of the covers gave the amount of oil which was taken for each test. The test samples in the covers were all placed in a large box with glass sides, having a series of perforated shelves. In the side of this box is an opening through which a tube was passed, carrying a continual current of air washed and dried in sulphuric acid. Oxidation of the oil films commenced at once, and the amount of oxygen absorbed was determined at suitable periods by weighing, the increase in weight giving this factor. This test was kept up for a period of twenty days.

A test was also made in the same manner with a current of damp air passing into the box, to observe the relative oxidation under such conditions. A chart of the results obtained has been made (Table VI), to show the effect of the various driers.

Results of Tests. The following outline will present to the mind of the reader the most salient points which have been gleaned from these experiments, and which should give the manufacturer definite knowledge as to the best percentage of oxides to use either in boiled oil, paints or varnishes.

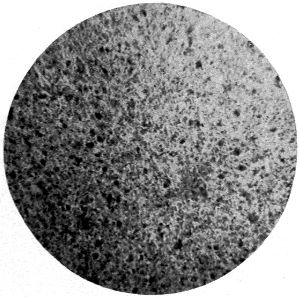

In the case of lead oxide, an increase in the percentage of lead oxide in the oil causes a relative increase in the oxygen absorption, but when a very large percentage of lead has been added, the film of oil dries to a leathery skin.

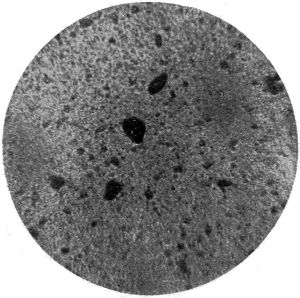

In the case of manganese oxide, the increase in oxygen absorption on the first day is much more pronounced than is the case with lead oxides. Furthermore, the oxidation of manganese oils seems to be relative to the increase in manganese up to a certain period, when the reverse of this law seems to take place, and beyond a certain definite percentage of manganese, added percentages seem to be of no value. It was furthermore observed that the films dry to a more brittle and harder skin than is the case when lead oxide is used. The oxygen absorption with oils high in manganese has been noticed to be excessive, and the film of oil becomes surface-coated, drying beneath in a very slow manner; a condition that often leads to checking. The critical percentage where the amount of manganese appears to give the greatest efficiency seems to be 0.02%. This critical percentage, as it may be termed, should not be exceeded, and any added amount of manganese has the effect of making the film much more brittle and causes the so-called “burning up” of the paint. The loading of paint with drier and the bad result therefrom may be explained to some extent from the above results.

| Per cent. MnO2 | 0.02 | 0.05 | 0.15 | 0.25 | 0.35 | 0.45 | 0.55 | 0.70 | 1.00 | |||

| Per cent. gain | ⎧ | 1 | day | 0.08 | 0.11 | 0.16 | — | 3.21 | 3.46 | 3.27 | 3.01 | 2.76 |

| ⎪ | 2 | days | 0.16 | 5.88 | 4.48 | — | 3.63 | 4.01 | 3.70 | 3.51 | 3.18 | |

| ⎪ | 3 | days | 0.21 | 6.79 | 4.61 | — | 3.83 | 4.31 | — | 3.91 | — | |

| ⎪ | 4 | days | — | — | 4.64 | — | — | — | — | — | — | |

| ⎪ | 5 | days | 3.01 | 6.84 | — | — | 4.13 | 4.68 | 4.19 | 3.91 | 3.99 | |

| ⎪ | 6 | days | 8.00 | — | 4.88 | — | 4.37 | — | 4.51 | 4.32 | 4.13 | |

| ⎪ | 7 | days | 8.58 | 6.92 | 4.90 | — | 4.48 | — | 4.61 | 4.52 | 4.23 | |

| ⎨ | 8 | days | 9.06 | — | 5.03 | — | 4.55 | 5.23 | 4.77 | 4.62 | 4.44 | |

| ⎪ | 9 | days | — | — | 5.12 | — | 4.63 | 5.40 | 4.94 | 4.79 | 4.51 | |

| ⎪ | 10 | days | 9.07 | 6.89 | 5.18 | — | 4.81 | 5.47 | — | 4.98 | 4.73 | |

| ⎪ | 11 | days | 9.15 | 7.03 | — | — | — | — | — | — | — | |

| ⎪ | 12 | days | — | — | — | — | 4.98 | — | 5.45 | 5.33 | 5.22 | |

| ⎪ | 13 | days | 9.22 | 7.17 | — | — | 5.25 | 6.00 | 5.60 | 5.42 | 5.33 | |

| ⎪ | 14 | days | 9.25 | 7.18 | 5.55 | — | — | — | — | — | — | |

| ⎩ | 20 | days | — | 7.21 | 5.81 | — | 5.84 | 6.70 | 5.94 | 5.84 | 5.77 | |

| Per cent. MnO2 | 0.02 | 0.05 | 0.15 | 0.25 | 0.35 | 0.45 | 0.55 | 0.70 | 1.00 | |||

| ⎧ | 1 | day | — | 3.12 | 4.42 | 3.86 | — | 3.19 | 2.98 | 3.27 | 2.56 | |

| ⎪ | 2 | days | — | 6.15 | 4.73 | — | — | 3.51 | 3.28 | 3.70 | 2.96 | |

| ⎪ | 3 | days | 0.28 | 6.29 | — | 4.12 | 3.72 | — | 3.39 | 3.71 | 3.15 | |

| ⎪ | 4 | days | 3.83 | 6.32 | 4.75 | 4.21 | 3.87 | 3.61 | 3.58 | 4.05 | 3.43 | |

| ⎪ | 5 | days | 6.64 | — | 4.84 | 4.23 | 3.94 | 3.73 | 3.65 | 4.21 | 3.56 | |

| Per cent. gain | ⎨ | 6 | days | 8.61 | — | 4.87 | — | 4.08 | 3.81 | 3.78 | 4.35 | 3.73 |

| ⎪ | 7 | days | 9.07 | 6.35 | 5.00 | 4.41 | 4.18 | 3.91 | 3.85 | 4.54 | 3.87 | |

| ⎪ | 9 | days | 9.25 | 6.39 | 5.16 | — | 4.44 | 4.11 | 4.21 | 4.63 | 4.26 | |

| ⎪ | 11 | days | — | — | — | 4.63 | 4.59 | 4.36 | 4.31 | 5.07 | 4.46 | |

| ⎩ | 16 | days | — | 6.43 | 5.30 | 4.91 | 4.83 | 4.72 | 4.71 | 5.40 | 4.87 | |

| Per cent. PbO | 0.00 | 0.05 | 0.10 | 0.30 | 0.50 | 0.70 | 1.00 | 1.30 | 1.60 | 1.30 | 1.60 | ||||||||||||

| ⎧ | 1 | day | 0.042 | 0.04 | 9 | 0.09 | 2 | 0.05 | 8 | 0.06 | 6 | 0.06 | 2 | 0.06 | 2 | 0.07 | 9 | 0.03 | 9 | 0.14 | 0.72 | ||

| ⎪ | 2 | days | 0.098 | 0.10 | 4 | 0.15 | 3 | 0.11 | 6 | 0.15 | 8 | — | 0.19 | 4 | 4.83 | 4.79 | 5.27 | 6.11 | |||||

| ⎪ | 3 | days | 0.128 | 0.15 | 9 | 0.17 | 0 | 0.13 | 7 | 0.27 | 9 | 0.18 | 5 | 7.11 | 8.60 | 5.35 | 7.89 | 8.28 | |||||

| ⎪ | 4 | days | 0.164 | 0.21 | 4 | 0.20 | 6 | 0.17 | 8 | — | 4.07 | 7.39 | 9.55 | 8.53 | 7.93 | 8.68 | |||||||

| ⎪ | 5 | days | 0.176 | — | 0.30 | 6 | — | 0.34 | 0 | 7.60 | 7.47 | 9.87 | 8.78 | 8.18 | — | ||||||||

| ⎪ | 6 | days | 0.188 | 0.23 | 1 | — | 0.24 | 3 | 0.47 | 2 | 9.36 | 7.64 | 10.01 | 9.00 | 8.24 | 9.09 | |||||||

| Per cent. gain | ⎨ | 7 | days | 0.206 | 0.25 | 1 | — | 0.25 | 3 | 1.08 | 0 | 10.06 | — | 10.14 | — | — | — | ||||||

| ⎪ | 8 | days | 0.212 | 0.25 | 3 | — | 0.28 | 0 | 4.80 | 10.38 | 7.70 | 10.22 | 9.05 | — | — | ||||||||

| ⎪ | 9 | days | 0.226 | 0.29 | 1 | 0.30 | 6 | 0.33 | 1 | 7.36 | 10.41 | 7.73 | 10.23 | 9.07 | — | — | |||||||

| ⎪ | 13 | days | 0.327 | 0.42 | 8 | 0.51 | 0 | 0.67 | 4 | 11.01 | 10.67 | 7.91 | 10.48 | 9.29 | 8.62 | — | |||||||

| ⎪ | 15 | days | 0.466 | 0.45 | 5 | 0.65 | 0 | 2.41 | 11.05 | — | 7.92 | 10.50 | 9.30 | — | — | ||||||||

| ⎩ | 20 | days | 0.521 | 1.08 | 1.78 | 8.76 | 11.25 | 10.67 | 7.98 | 10.52 | 9.36 | — | — | ||||||||||

| Per cent. PbO | 0.1 | 0.3 | 0.5 | 0.7 | 0.9 | 1.1 | 1.4 | |||||||

| Per cent. MnO2 | .005 | .015 | 0.025 | 0.35 | 0.45 | 0.55 | 0.7 | |||||||

| Per cent. gain | ⎧ | 1 | day | 0.02 | 6 | 0.06 | 1 | 0.05 | 5 | 0.02 | 2 | 0.16 | 0.11 | 3.06 |

| ⎪ | 2 | days | 0.09 | 4 | 0.08 | 7 | 0.14 | 3 | 0.16 | 5.21 | 6.28 | 3.37 | ||

| ⎪ | 3 | days | 0.11 | 8 | — | 0.17 | 4.23 | 7.63 | 8.31 | 3.74 | ||||

| ⎪ | 4 | days | — | 0.11 | 0.23 | 7.36 | 8.87 | 9.20 | 4.02 | |||||

| ⎪ | 5 | days | 0.12 | 0 | 0.12 | 0.29 | 9.04 | 9.13 | 9.37 | 4.17 | ||||

| ⎨ | 6 | days | 0.17 | 0.13 | 1.44 | 9.88 | 9.26 | 9.51 | 4.34 | |||||

| ⎪ | 7 | days | 0.21 | 0.18 | 4.65 | 10.11 | 9.28 | — | 4.45 | |||||

| ⎪ | 11 | days | 0.30 | 0.26 | 10.03 | 10.35 | 9.61 | 9.85 | 5.11 | |||||

| ⎪ | 12 | days | — | — | — | 10.45 | 9.66 | — | — | |||||

| ⎪ | 13 | days | 0.35 | 0.54 | 10.37 | 10.51 | 9.67 | 10.03 | 5.33 | |||||

| ⎩ | 18 | days | 0.49 | 3.43 | 10.38 | 10.62 | 9.68 | — | 5.73 | |||||

[26]In the same way with lead driers, excessive amounts of lead oxide seem to have no beneficial effects on the drying of an oil, and when the percentage which seems to be the most beneficial, namely 0.5% lead oxide, is exceeded, the film is apt to become brittle.

Oils containing lead oxide driers are less influenced in their drying tendencies by conditions of moisture in the atmosphere than oils containing manganese, but frequently, however, the former dry much better in a dry atmosphere. As a general rule, varnishes rich in manganese dry more quickly in a dry atmosphere, while those containing small quantities dry more quickly in a damp atmosphere.

Volatile Products Formed. It was furthermore noticed in these tests that sulphuric acid, placed in dishes on the bottom of the large box in which the samples of oil were drying, was discolored and turned brown after several days, showing that the acid had taken up some material of a volatile nature that was a product of the oxidation.

Another curious feature of these tests was the development of a peculiar aromatic odor which was given off by the oils upon drying in dry air. When the oils were dried in moist air, a rank odor resembling propionic acid was observed, and this led the observer to believe that a reaction was effected by the absorbed oxygen, that caused the glycerin combined with the linoleic acid as linolein to split up into evil-smelling compounds. It has been suggested that the oxygen first attacks the glycerin, transforming it into carbonic acid, water, and other volatile compounds, which are eliminated before the oil is dried to linoxyn. Toch,[3] however, has shown that the drying of linseed oil gives off only very small percentages of carbon dioxide. Mulder has observed that in the process of linseed oil being oxidized, glycerin is set free, which becomes oxidized to formic,[27] acetic, and other acids, while the acid radicals are converted by oxygen into the anhydrides, from which they pass by further oxidation into linoxyn.

[3] Toch: The Chem. and Tech. of Mixed Paints, p. 89. D. Van Vostand Co., N. Y.

Auto-Oxidation of Oil. The theory of auto-oxidation of linseed oil has been very ably treated by Blackler, whose experiments indicated that during the drying process the slow absorption of oxygen was, at a critical period, followed by a rapid absorption, which he attributes to the presence of peroxides. The materials produced by this peroxide formation may act as catalyzers and accelerate the formation of more peroxide. Lead and manganese oxides may also be oxidized to peroxides by the action of oxygen, and in this event might act as very active catalyzing agents or carriers of oxygen. Blackler’s statement, that the presence of driers do not increase, but have a tendency to decrease the initial velocity of oxygen absorption, has been confirmed by these experiments, but it has been noticed throughout the tests that the driers have an accelerative action at a later period.

Effect of Metals on Drying of Oils. Some most interesting results were secured by dipping extremely fine copper gauze into linseed oil, and then suspending the gauze in the air. The adhesion of the oil to the copper caused the formation of films between the network, and remarkable drying action was observed. The copper or any superficial coating of copper oxide which may have been present on the metal, undoubtedly affected the result to some extent. It has been found that metallic lead is even more efficient than copper in this respect, but this may be due to the action of free acid in the linseed oil, forming lead linoleates, products that greatly accelerate drying. Another interesting experiment was made by immersing pieces of gauze cloth in linseed oil. After the excess oil had been removed, by pressing, the cloth was again weighed to determine the amount of oil used for the experiment. The increase in oxygen absorption in this case was very rapid, and the result obtained confirmed the results in the other experiments.

In order to secure a more evenly distributed state of the oil, tests were conducted by saturating pieces of stiff blotting papers, and, after exposure, weighing as usual.

Influence of Light. The influence of light on the drying of oils is unquestionably a potent one. The practical painter knows[28] that a certain varnish will dry quicker when exposed to the light than when in the dark.

Chevreul was one of the first pioneers in this field of research to observe the effects of colored lights on drying, and he claimed that oil exposed under white glass dried more rapidly than when exposed under red glass, which eliminates all light of short wave lengths.

Genthe obtained interesting results in the drying of oil submitted to the effect of the mercury lamp. Oxidation without driers was effected probably through the formation of peroxides. In commenting on this subject, Blackler[4] gives a description of the use of the Uveol Lamp, which is similar to the mercury lamp, but has, instead of a glass casing which cuts off the valuable rays, a fused-quartz casing which allows their passage.

[4] M. B. Blackler: “The Use and Abuse of Driers,” P. and V. Society, London, Sept. 9, 1909.

Driers in Boiled Oil. In the boiling of linseed oil, by certain processes the oil is heated to 250° F. and manganese resinate is incorporated therein. It goes into solution quite rapidly. In other processes the oil is heated to 400° F. or over, and manganese as an oxide is boiled into the oil. Although it is unsafe to say that a small percentage of rosin, such as would be introduced by the use of resinate driers, is not harmful, yet it appears that this process should give a good oil, inasmuch as it has been found that no matter whether the manganese is added to the oil, as a resinate, borate or oxide, practically the same drying effect is noticed in every case where the percentage of manganese is the same. It is the opinion of some, however, that the resinate driers are not as well suited for durability as oxide driers. However, if a boiled oil is found to contain on analysis a small percentage of rosin less than 0.5% or a percentage only sufficient to combine with the metal present, it should not be suspected of adulteration. Practical tests should be made with such oil along with an oil made with an oxide drier, before pronouncing on their relative values. Inasmuch as the addition of certain driers to linseed oil lessens the durability of the film, it is more practical to use the smallest amount of drier that will serve the purpose desired, that is, set the oil up to a hard condition which will not take dust and which will stand abrasion.

[29]The results of this investigation would indicate that when lead or manganese linoleates are used, the most efficient drying is shown with 0.5% lead or with 0.02% manganese, or with a combination of 0.5% lead and 0.02% manganese.

Until more definite results have been obtained with the tungates, which will probably prove of exceptional interest as driers, the above driers will probably be used to the greatest extent.

Co-operative Drying Tests. A series of important drying tests made by members of a special committee[5] appointed by the American Society for Testing Materials, of which the writer was chairman, is herewith shown:

[5] Sub-Committee C of Committee D-1, on Testing Paint Vehicles. Proc. Amer. Soc. for Test. Mater., 1911.

“At the January meeting of Committee D-1, a sub-committee consisting of the following members was appointed to investigate paint vehicles:

| G. B. Heckel, |

| Glenn H. Pickard, |

| Allen Rogers, |

| A. H. Sabin, |

| H. A. Gardner, Chairman. |

“At a subsequent meeting of the sub-committee it was determined to start the investigations with a series of tests on certain drying, semi-drying, and non-drying oils, determining their drying values, rate of oxygen absorption, etc., when spread out in thin films. A quantity of the following oils was selected for the tests and subsequently secured from sources known to be reliable:

| Lead and manganese linoleate drier.[6] | Cottonseed oil. |

| Lithographic linseed oil. | Sunflower oil. |

| Boiled linseed oil (resinate type). | Menhaden oil. |

| Boiled linseed oil (linoleate type). | Chinese wood oil, raw. |

| Blown linseed oil (containing drier while being blown). | Chinese wood oil, treated. |

| Heavy mineral oil. | Perilla oil.[7] |

| Rosin oil. | Lumbang oil.[7] |

| Soya bean oil. | Dry rosin 20%, boiled in 80% linseed oil. |

| Corn oil. |

[6] The drier used, upon analysis, showed the presence of 4.36% PbO and 2.51% MnO2.

[7] The lumbang and perilla oils were imported and arrived subsequent to the starting of the tests. They were therefore not included in the tests.

[30]“Four-ounce sample bottles of each oil were sent to the Committee members, with the request to proceed with the tests along the lines agreed upon at the Committee meeting. The instructions for making these tests are outlined as follows:

(a) A series of small glass plates, approximately 5 by 7 ins., are to be prepared by each member of the Committee. These plates are to be thoroughly cleaned and carefully numbered and weighed upon a chemical balance. The oils to be used for the tests are to be numbered corresponding to the plates. A test of each oil is to be made by painting it upon the surface of a glass plate with a camel’s-hair brush, subsequently weighing the plate and the oil. These tests are to be exposed under constant conditions of temperature, if possible, for three weeks’ time, making weighings of each plate every day for six days and then every other day for twelve days.

(b) Another series of tests shall be made, in which 80% of raw linseed oil is to be combined with each of the above oils named. Previous to making any of the tests, there should be added to each oil, or to each combination, 5% of a drier containing lead and manganese. The drier to be used is of the standard grade submitted, together with the oil samples. The results of the tests are to be charted and submitted at the end of the tests, so that they may be compared with the results obtained by each member of the Committee.

(c) If possible, the oils and mixture of oils used in the above tests are to be ground with pure silica and painted out upon sized paper, three-coat work, the films to be stripped and tested for strength upon a paint filmometer, at two periods two months apart.”

The drying of oils to a firm surface when spread in a thin layer is accompanied by an increase in weight, due to the absorption of oxygen. The percentage of oxygen absorbed often affords a criterion of the drying of the oil under examination, and this factor, together with data regarding the appearance of the oil film, should be taken into consideration when judging the value of an oil or oil mixture. Conditions of light, air, temperature, etc., often cause great variations in the drying of oils and the percentage of oxygen absorbed, as shown by the results obtained in the following tests. Although it was impossible in these tests to have the conditions under which each experimenter worked[31] parallel in nature, the tests afford nevertheless considerable information for guiding future work of a similar nature.

An examination of the results obtained showed generally that the greatest increase in weight occurred during the period in which the oil dried up to a firm film. This occurred in most cases within 48 hours. After this period a slight increase in weight was often noticed, and then a more or less steady decline, varying with the oil examined. Had the oil tests been continued for a greater length of time, a much greater loss might have been observed.

It was impossible to include in the tests the oil-silica film work, on account of lack of time. It is believed, however, that these tests should be conducted, as they would throw much light on the elasticity and strength given to paint films by various oils.

| Table I.—(a) Boiled Linseed Oil (Resinate Type) 100 Per Cent. | ||||||||||||||||||||||||||||||||||||||||||||||||

| Observer. | Wt. of Oil for Test, grams. |

Percentage Increase in Weight, in Days. | Remarks. | |||||||||||||||||||||||||||||||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | ||||||||||||||||||||||||||||||

| Gardner | 0.1997 | 11.9 | 12.5 | 12.7 | 13.1 | 12.8 | 12.7 | — | 12.7 | — | 12.6 | — | 12.8 | — | 12.8 | — | 12.7 | — | 12.9 | — | { | Dried to firm, smooth film in 2 days. |

||||||||||||||||||||||||||

| Sabin | 0.6242 | 14.4 | 2 | 13.3 | 7 | 12.5 | 3 | 11.7 | 11.0 | 3 | — | 10.1 | 7 | 10.3 | 4 | 10.1 | 2 | 10.0 | 0 | — | 9.6 | 9 | — | — | 9.0 | 4 | — | 8.6 | 8 | — | 8.1 | 3 | ||||||||||||||||

| Pickard | 0.5027 | 10.2 | 1 | 10.0 | 0 | 9.5 | 7 | 9.6 | 5 | 8.9 | 9 | — | 8.5 | 7 | — | 8.9 | 3 | — | 8.8 | 1 | — | 9.3 | 1 | — | 9.4 | 3 | — | — | 9.1 | 1 | — | |||||||||||||||||

| Rogers North |

} | 0.6024 | 13.6 | 9 | 13.0 | 1 | 12.5 | 0 | 12.2 | 9 | 12.0 | 0 | 12.2 | 5 | — | 11.6 | 4 | — | 10.7 | 3 | — | 10.6 | 8 | — | 11.1 | 8 | — | 10.6 | 8 | — | — | — | { | Tacky at end of 1st day. Nearly dry, end of 2d day. Perfectly dry, end of 10th day. |

||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

| Gardner | 0.1933 | 13.6 | 14.7 | 14.9 | 14.9 | 14.8 | 14.8 | — | 14.8 | — | 14.8 | — | 14.7 | — | 14.5 | — | 14.7 | — | 14.7 | — | { | Dried to firm, smooth film in 2 days. |

||||||||||||||||||||||||||

| Sabin | 0.3660 | 0.5 | 7 | 1.6 | 6 | 10.5 | 0 | 13.3 | 0 | — | — | 12.5 | 1 | — | 11.4 | 0 | — | — | 10.2 | 0 | — | — | 9.8 | 4 | — | — | — | — | ||||||||||||||||||||

| Pickard | 0.4640 | 12.4 | 8 | 11.9 | 2 | 11.4 | 9 | 11.1 | 0 | 10.8 | 4 | — | 9.4 | 8 | — | 7.4 | 1 | — | 7.5 | 6 | — | 8.3 | 6 | — | 8.5 | 4 | — | — | 8.5 | 1 | — | |||||||||||||||||

| Rogers North |

} | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | |||||||||||||||||||||||||||

| Table II.—(a) Boiled Linseed Oil (Linoleate Type) 100 Per Cent. | ||||||||||||||||||||||||||||||||||||||||||||||||

| Observer. | Wt. of Oil for Test, grams. |

Percentage Increase in Weight, in Days. | Remarks. | |||||||||||||||||||||||||||||||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | ||||||||||||||||||||||||||||||

| Gardner | 0.1226 | 10.9 | 12.2 | 12.7 | 12.5 | 12.8 | 12.2 | — | 12.2 | — | 12.4 | — | 12.1 | — | 12. | — | 12.1 | — | 12.1 | — | { | Dried firmly with smooth, even film in 2 days. |

||||||||||||||||||||||||||

| Sabin | 0.5384 | 14.3 | 4 | 13.2 | 6 | 12.1 | 8 | 11.2 | 9 | 10.7 | 5 | — | 9.8 | 8 | 10.2 | 5 | 10.0 | 1 | 9.9 | 1 | — | 9.6 | 0 | — | — | 9.1 | 2 | — | 8.3 | 7 | — | 8.3 | 0 | |||||||||||||||

| Pickard | 0.5696 | 10.2 | 5 | 10.4 | 1 | 10.2 | 2 | 10.1 | 6 | 9.9 | 0 | — | 9.6 | 0 | — | 9.7 | 2 | — | 9.4 | 8 | — | 9.9 | 7 | — | 10.3 | 6 | — | — | 9.5 | 9 | — | |||||||||||||||||

| Rogers North |

} | 0.3306 | 12.0 | 9 | 11.3 | 3 | 10.9 | 4 | 11.1 | 0 | 10.8 | 6 | 11.2 | 5 | — | 10.8 | 7 | — | 9.7 | 2 | — | 10.0 | 2 | — | 10.6 | 2 | — | 10.4 | 6 | — | — | — | { | Tacky at end of 1st day. Slightly tacky, end 2d day. Dry, but curled, end of 10th day. |

||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

| Gardner | 0.1843 | 11.8 | 13.9 | 15.1 | 15.2 | 15.0 | 14.6 | — | 14.6 | — | 14.5 | — | 14.4 | — | 14.4 | — | 14.6 | — | 14.7 | — | { | Dried with smooth film in 2 days. |

||||||||||||||||||||||||||

| Sabin | 0.5790 | 10.1 | 4 | 15.7 | 1 | 13.2 | 9 | 12.1 | 2 | 11.4 | 3 | — | 10.0 | 5 | 10.2 | 6 | 9.5 | 5 | 9.3 | 2 | — | 8.8 | 4 | — | — | 8.4 | 6 | — | 7.6 | 8 | — | 7.5 | 5 | |||||||||||||||

| Pickard | 0.4653 | 12.4 | 0 | 11.9 | 0 | 11.5 | 0 | 11.1 | 1 | 10.9 | 0 | — | 9.3 | 7 | — | 8.5 | 3 | — | 7.4 | 8 | — | 8.4 | 3 | — | 8.0 | 2 | — | — | 7.2 | 7 | — | |||||||||||||||||

| Rogers North |

} | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | |||||||||||||||||||||||||||

| Table III.—(a) Lithographic Linseed Oil 100 Per Cent.[33] | ||||||||||||||||||||||||||||||||||||||||||||||||

| Observer. | Wt. of Oil for Test, grams. |

Percentage Increase in Weight, in Days. | Remarks. | |||||||||||||||||||||||||||||||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | ||||||||||||||||||||||||||||||

| Gardner | 0.4011 | 6.9 | 8.5 | 8.9 | 8.9 | 8.7 | 8.6 | — | 8.6 | — | 8.6 | — | 8.6 | — | 8.4 | — | 8.4 | — | 8.3 | — | { | Dried to glossy, firm film, slightly crinkled in 2 days. Oil made very thick film on account of heavy body. |

||||||||||||||||||||||||||

| Sabin | 0.8733 | 0.8 | 7 | 3.8 | 5 | 5.1 | 4 | 6.0 | 7 | 6.4 | 0 | — | 6.8 | 4 | 7.2 | 2 | 7.3 | 6 | 7.5 | 7 | — | 7.7 | 5 | — | — | 7.9 | 8 | — | 7.8 | 3 | — | 7.8 | 0 | |||||||||||||||

| Pickard | 0.8812 | 3.6 | 0 | 5.1 | 9 | 5.9 | 9 | 6.7 | 8 | 6.9 | 7 | — | 7.3 | 8 | — | 7.4 | 2 | — | 7.4 | 4 | — | 8.0 | 1 | — | 8.0 | 3 | — | — | 7.9 | 9 | — | |||||||||||||||||

| Rogers North |

} | 2.7318 | .0 | 51 | .0 | 51 | .0 | 51 | .0 | 41 | .0 | 81 | .1 | 69 | — | .1 | 9 | — | .7 | 52 | — | 1.1 | 84 | — | 1.6 | 41 | — | 2.0 | 0 | — | — | — | { | Remained sticky to 10 days, and even at end of 38 days was slightly tacky. |

||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

| Gardner | 0.1300 | 10.2 | 11.3 | 11.9 | 12.0 | 11.8 | 11.8 | — | 11.8 | — | 11.8 | — | 11.6 | — | 11.8 | — | 11.9 | — | 11.9 | — | { | Dried to firm, glossy film in 2 days. |

||||||||||||||||||||||||||

| Sabin | 0.7750 | 11.3 | 5 | 11.4 | 8 | 10.9 | 3 | 10.7 | 7 | 10.2 | 5 | — | 9.5 | 1 | 9.9 | 3 | 9.8 | 0 | 9.6 | 8 | — | 9.6 | 5 | — | — | 9.5 | 1 | — | 9.0 | 7 | — | 8.6 | 7 | |||||||||||||||

| Pickard | 0.6538 | 9.9 | 4 | 10.4 | 1 | 10.3 | 9 | 10.3 | 5 | 9.9 | 3 | — | 9.5 | 4 | — | 9.3 | 6 | — | 8.9 | 9 | — | 9.6 | 1 | — | 9.7 | 0 | — | — | 9.1 | 3 | — | |||||||||||||||||

| Table IV.—(a) Blown Linseed Oil 100 Per Cent. | ||||||||||||||||||||||||||||||||||||||||||||||||

| Observer. | Wt. of Oil for Test, grams. |

Percentage Increase in Weight, in Days. | Remarks. | |||||||||||||||||||||||||||||||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | ||||||||||||||||||||||||||||||

| Gardner | 0.2105 | 8.5 | 10.2 | 10.2 | 10.2 | 10.0 | 9.9 | — | 9.8 | — | 9.8 | — | 9.7 | — | 9.8 | — | 9.8 | — | 9.9 | — | { | Ropiness of oil made very thick film, but dried in less than 2 days to smooth film. Films exhibited ridges. |

||||||||||||||||||||||||||

| Sabin | 0.8394 | 9.3 | 0 | 8.9 | 7 | 5.3 | 0 | 9.3 | 0 | 8.9 | 9 | — | 8.4 | 9 | 8.8 | 9 | 8.7 | 3 | 8.8 | 9 | — | 8.7 | 3 | — | — | 8.5 | 2 | — | 8.0 | 7 | — | 7.7 | 4 | |||||||||||||||

| Pickard | 0.8457 | 5.0 | 7 | 6.1 | 6 | 6.4 | 8 | 6.9 | 4 | 6.7 | 3 | — | 6.9 | 9 | — | 6.8 | 9 | — | 7.1 | 1 | — | 7.6 | 0 | — | 7.9 | 5 | — | — | 7.8 | 6 | — | |||||||||||||||||

| Rogers North |

} | 1.0398 | 4.4 | 1 | 4.9 | 1 | 5.2 | 2 | 5.6 | 2 | 5.7 | 3 | 6.0 | 6 | — | 6.4 | 3 | — | 6.1 | 8 | — | 6.5 | 1 | — | 6.9 | 5 | — | 7.0 | 0 | — | — | — | { | Formed skin, end 1st day. Slightly tacky, end 2d; dry, but curled, end of 10th day. |

||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

| Gardner | 0.0774 | 10.4 | 12.8 | 13.1 | 12.9 | 12.1 | 11.9 | — | 12.0 | — | 11.8 | — | 11.7 | — | 11.6 | — | 11.6 | — | 11.8 | — | { | Dried up to very glossy film in 2 days. |

||||||||||||||||||||||||||

| Sabin | 0.5329 | 11.8 | 2 | 12.7 | 6 | 10.9 | 8 | 10.3 | 9 | 9.8 | 1 | — | 8.6 | 9 | 9.1 | 5 | 8.9 | 1 | 8.9 | 7 | — | 8.6 | 7 | — | — | 8.2 | 2 | — | 7.6 | 3 | — | 7.3 | 2 | |||||||||||||||

| Pickard | 0.6218 | 10.7 | 1 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | { | Glass broke. | |||||||||||||||||||||||||

| Table V.—(a) Mineral Oil 100 Per Cent.[34] | ||||||||||||||||||||||||||||||||||||||||||||||||

| Observer. | Wt. of Oil for Test, grams. |

Percentage Increase in Weight, in Days. | Remarks. | |||||||||||||||||||||||||||||||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | ||||||||||||||||||||||||||||||

| Gardner | 0.1632 | [8]12.5 | [8]14.2 | [8]16.7 | [8]19.4 | [8]19.4 | [8]19.5 | — | [8]19.5 | — | [8]19.5 | — | [8]19.3 | — | [8]19.4 | — | [8]19.5 | — | [8]19.5 | — | { | Oil lost in weight throughout test on account of presence of volatiles. No drying action observed. Film wet at end of test. |

||||||||||||||||||||||||||

| Sabin | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | { | Broken before weighings were made. |

||||||||||||||||||||||||||

| Pickard | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | ||||||||||||||||||||||||||||

| Rogers North |

} | 0.1975 | [8]8.1 | 2 | [8]16.2 | 2 | [8]21.2 | 3 | [8]25.5 | 8 | [8]28.4 | 1 | [8]28.9 | 2 | — | [8]35.2 | 5 | — | [8]35.7 | 6 | — | [8]43.8 | 6 | — | [8]45.2 | 8 | — | [8]48.0 | 8 | — | — | — | { | Remained oily during entire test. |

||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

| Gardner | 0.1884 | 6.4 | 6.8 | 7.2 | 7.8 | 8.1 | 7.9 | — | 7.9 | — | 8.1 | — | 7.8 | — | 7.8 | — | 7.8 | — | 7.8 | — | { | Fair drying observed end of 2d day. Film tacky until end 8th day; after that, fairly firm film shown. |

||||||||||||||||||||||||||

| Sabin | 0.5663 | 11.5 | 1 | 8.2 | 1 | 6.5 | 1 | 5.1 | 9 | 4.3 | 6 | — | 2.7 | 2 | 3.1 | 2 | 2.8 | 2 | 2.5 | 9 | — | 2.3 | 5 | — | — | 1.3 | 6 | — | 0.5 | 3 | — | [8]0.1 | 4 | |||||||||||||||

| Pickard | 0.405 | [9]9.6 | 6 | [9]8.9 | 2 | [9]6.8 | 2 | [9]6.0 | 3 | [9]4.6 | 8 | — | [9]2.6 | 4 | — | [8]0.3 | 0 | — | [8]0.5 | 6 | — | [8]0.0 | 4 | — | [8]0.1 | 4 | — | — | [8]0.8 | 6 | — | |||||||||||||||||

| Rogers North |

} | 0.2598 | [9]6.6 | 9 | [9]5.0 | 6 | [9]2.8 | 8 | [9]1.5 | 2 | [9]1.2 | 9 | [9]1.6 | 8 | — | [9]2.0 | 7 | — | [8]0.0 | 8 | — | [8]0.9 | 3 | — | [8]0.5 | 4 | — | — | — | — | — | { | Sticky, end of 1st day; tacky, end of 2d day and end of 38 days. |

|||||||||||||||

| Table VI.—(a) Soya Bean Oil 100 Per Cent.[35] | ||||||||||||||||||||||||||||||||||||||||||||||||

| Observer. | Wt. of Oil for Test, grams. |

Percentage Increase in Weight, in Days. | Remarks. | |||||||||||||||||||||||||||||||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | ||||||||||||||||||||||||||||||

| Gardner | 0.1377 | 7.5 | 8.4 | 9.5 | 12.8 | 12.9 | 12.7 | — | 12.6 | — | 12.5 | — | 12.4 | — | 12.3 | — | 12.3 | — | 12.3 | — | { | Film tacky until 3d day. Clear and fairly firm after 4th day. |

||||||||||||||||||||||||||

| Sabin | 0.3972 | 9.7 | 9 | 9.6 | 9 | 8.5 | 6 | 7.6 | 0 | 7.0 | 9 | — | 6.0 | 0 | 6.2 | 2 | 6.0 | 0 | 5.5 | 4 | — | 5.3 | 6 | — | — | 4.7 | 3 | — | 4.2 | 3 | — | 3.7 | 0 | |||||||||||||||

| Pickard | 0.4366 | 9.8 | 7 | 9.8 | 7 | 9.3 | 5 | 8.6 | 6 | 8.1 | 3 | — | 6.4 | 4 | — | 4.8 | 8 | — | 4.2 | 6 | — | 4.9 | 9 | — | 4.9 | 4 | — | — | 4.9 | 4 | — | |||||||||||||||||

| Rogers North |

} | 0.3564 | 8.2 | 5 | 7.5 | 8 | 7.0 | 2 | 6.7 | 4 | 6.4 | 6 | 6.7 | 4 | — | 6.4 | 6 | — | 5.4 | 0 | — | 5.5 | 9 | — | 5.8 | 0 | — | 5.6 | 7 | — | — | — | { | Sticky, end of 1st day; tacky, end of 2d day; slightly tacky, end of 10th and 38th days. |

||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

| Gardner | 0.2218 | 11.5 | 11.8 | 12.5 | 13.9 | 14.0 | 14.0 | — | 14.1 | — | 14.1 | — | 13.8 | — | 13.6 | — | 13.6 | — | 13.6 | — | { | Clear, firm film observed at end of 2d day. |

||||||||||||||||||||||||||

| Sabin | 0.2877 | 12.7 | 8 | 12.7 | 8 | 11.7 | 4 | 12.2 | 3 | 10.6 | 0 | — | 9.3 | 5 | 10.0 | 8 | 9.7 | 6 | 9.5 | 9 | — | 9.5 | 9 | — | — | 9.0 | 0 | — | 8.0 | 9 | — | 8.0 | 0 | |||||||||||||||

| Pickard | 0.4581 | 13.1 | 6 | 12.6 | 4 | 11.8 | 4 | 11.5 | 0 | 11.0 | 1 | — | 9.1 | 5 | — | 7.2 | 9 | — | 6.6 | 1 | — | 7.4 | 3 | — | 6.9 | 6 | — | — | 6.6 | 6 | — | |||||||||||||||||

| Rogers North |

} | 0.2249 | 11.7 | 4 | 12.2 | 7 | 10.3 | 8 | 9.4 | 3 | 9.6 | 6 | 9.7 | 5 | — | 10.2 | 9 | — | 9.0 | 8 | — | 8.1 | 8 | — | 8.9 | 5 | — | — | — | — | — | { | Tacky at end of 1st and 2d days. Dry, end 10th day. |

|||||||||||||||

| Table VII.—(a) Rosin Oil 100 Per Cent. | ||||||||||||||||||||||||||||||||||||||||||||||||

| Observer. | Wt. of Oil for Test, grams. |

Percentage Increase in Weight, in Days. | Remarks. | |||||||||||||||||||||||||||||||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | ||||||||||||||||||||||||||||||

| Gardner | 0.2590 | 1.5 | 1.5 | 1.8 | 3.0 | 5.2 | 4.9 | — | 4.8 | — | 4.8 | — | 4.8 | — | 4.8 | — | 4.8 | — | 4.8 | — | { | Tacky throughout test. | ||||||||||||||||||||||||||

| Sabin | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | ||||||||||||||||||||||||||||

| Pickard | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | { | Too much on. Showed constantly increasing loss owing to the fact that it did not dry and ran off glass. |

||||||||||||||||||||||||||

| Rogers North |

} | 0.4822 | 2.2 | 4 | 2.5 | 3 | 2.3 | 2 | 1.2 | 7 | 1.0 | 6 | 0.6 | 6 | — | 0.2 | 4 | — | 0.7 | 8 | — | 0.6 | 8 | — | 0.4 | 1 | — | 0.3 | 9 | — | — | — | { | Oily on 1st and 2d days. Tacky, end of 10 and 38 days. |

||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

| Gardner | 0.1636 | 7.4 | 7.8 | 8.5 | 8.5 | 8.4 | 8.1 | — | 8.0 | — | 8.0 | — | 8.0 | — | 7.9 | — | 7.9 | — | 8.2 | — | { | Film dried up nicely during 3d day, but remained slightly soft. |

||||||||||||||||||||||||||

| Sabin | 0.7105 | 6.6 | 4 | 6.4 | 0 | 6.0 | 5 | 5.6 | 3 | 5.2 | 3 | — | 4.4 | 2 | 4.9 | 2 | 4.8 | 3 | 4.5 | 7 | — | 4.6 | 8 | — | — | 4.1 | 3 | — | 3.8 | 1 | — | 3.4 | 3 | |||||||||||||||

| Pickard | 0.4016 | 12.2 | 1 | 11.4 | 5 | 11.1 | 3 | 10.5 | 3 | 10.1 | 3 | — | 8.8 | — | 8.1 | 2 | — | 7.4 | 5 | — | 8.2 | 7 | — | 8.5 | 2 | — | — | 8.6 | 2 | — | ||||||||||||||||||

| Rogers North |

} | 0.3263 | 11.4 | 8 | 12.0 | 2 | 10.6 | 0 | 10.2 | 6 | 10.4 | 2 | 10.4 | 2 | — | 10.9 | 5 | — | 9.9 | 6 | — | 9.5 | 3 | — | 9.9 | 6 | — | — | — | — | — | { | Oily at end of 1st and 2d days. Slightly tacky, end of 10th day. |

|||||||||||||||

| Table VIII.—(a) Corn Oil 100 Per Cent. | ||||||||||||||||||||||||||||||||||||||||||||||||

| Observer. | Wt. of Oil for Test, grams. |

Percentage Increase in Weight, in Days. | Remarks. | |||||||||||||||||||||||||||||||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | ||||||||||||||||||||||||||||||

| Gardner | 0.0574 | 1.9 | 4.2 | 4.6 | 4.8 | 7.5 | 7.1 | — | 7.1 | — | 7.1 | — | 7.2 | — | 7.1 | — | 7.0 | — | 6.9 | — | { | Film soft and sticky throughout test. Very soapy in appearance. |

||||||||||||||||||||||||||

| Sabin | 0.5858 | [8]0.2 | 2 | 7.0 | 3 | 8.7 | 9 | 7.4 | 3 | 7.1 | 7 | — | 5.8 | 5 | 6.0 | 2 | 5.8 | 4 | 5.5 | 8 | — | 5.3 | 8 | — | — | 4.7 | 8 | — | 4.1 | 5 | — | 3.6 | 3 | |||||||||||||||

| Pickard | 0.4981 | 1.2 | 2 | 5.8 | 6 | 7.2 | 7 | [10]11.3 | 5 | 11.3 | 5 | — | 11.3 | 7 | — | 6.2 | 6 | — | 4.9 | 7 | — | 5.6 | 2 | — | 5.3 | 4 | — | — | 5.3 | 4 | — | |||||||||||||||||

| Rogers North |

} | 0.3300 | 4.6 | 3 | 7.2 | 7 | 7.1 | 4 | 6.9 | 9 | 6.6 | 9 | 6.9 | 3 | — | 6.8 | 4 | — | 5.1 | 1 | — | 5.1 | 7 | — | 5.3 | 8 | — | 5.1 | 7 | — | — | — | ||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

| Gardner | 0.1664 | 7.5 | 8.4 | 8.6 | 10.2 | 10.4 | 10.6 | — | 10.5 | — | 10.3 | — | 10.3 | — | 10.3 | — | 10.2 | — | 10.0 | — | { | Film tacky at end of test. | ||||||||||||||||||||||||||

| Sabin | 0.5469 | 13.0 | 1 | 12.4 | 1 | — | 11.1 | 3 | 11.5 | 2 | — | 11.2 | 2 | 10.9 | 8 | 10.3 | 8 | 9.6 | 4 | — | 9.0 | 7 | — | — | 8.3 | 8 | — | 8.7 | 7 | — | — | |||||||||||||||||

| Pickard | 0.3716 | 13.8 | 1 | 12.9 | 2 | 12.1 | 6 | 11.7 | 1 | 11.1 | 1 | — | 9.2 | 3 | — | 8.2 | 9 | — | 7.2 | 4 | — | 8.4 | 2 | — | 8.2 | 6 | — | — | 7.9 | 4 | — | |||||||||||||||||

| Rogers North |

} | 0.1711 | 11.8 | 7 | 11.6 | 9 | 9.7 | 8 | 8.3 | 3 | 8.5 | 0 | 8.6 | 2 | — | 9.6 | 1 | — | 8.1 | 6 | — | 7.0 | 0 | — | 8.2 | 8 | — | — | — | — | — | { | Tacky, end of 1st and 2d days. Dry, end 10th day. |

|||||||||||||||

| [37]Table IX.—(a) Cotton Seed Oil 100 Per Cent. | ||||||||||||||||||||||||||||||||||||||||||||||||

| Observer. | Wt. of Oil for Test, grams. |

Percentage Increase in Weight, in Days. | Remarks. | |||||||||||||||||||||||||||||||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | ||||||||||||||||||||||||||||||

| Gardner | 0.2026 | 4.5 | 4.8 | 4.8 | 5.1 | 8.6 | 8.7 | — | 8.1 | — | 7.9 | — | 8.0 | — | 8.0 | — | 8.1 | — | 8.0 | — | { | Film showed very little hardening and remained soft and tacky. |

||||||||||||||||||||||||||

| Sabin | 0.7247 | 8.0 | 3 | 7.4 | 8 | 6.6 | 8 | 6.0 | 0 | 5.6 | 5 | — | 4.8 | 5 | 5.0 | 9 | 4.9 | 5 | 4.8 | 0 | — | — | — | — | — | — | — | — | — | |||||||||||||||||||

| Pickard | 0.4135 | 7.0 | 4 | 7.1 | 6 | 6.6 | 2 | 6.2 | 4 | 5.7 | 8 | — | 3.7 | 2 | — | 2.0 | 8 | — | 1.7 | 2 | — | 2.5 | 2 | — | 2.3 | 5 | — | — | 2.3 | 2 | — | |||||||||||||||||

| Rogers North |

} | 0.3583 | 6.6 | 7 | 5.6 | 1 | 4.8 | 5 | 4.6 | 5 | 4.3 | 7 | 4.7 | 1 | — | 4.5 | 7 | — | 2.9 | 7 | — | 3.1 | 1 | — | 3.3 | 9 | — | 3.3 | 9 | — | — | — | { | Tacky, end 2d day. Slightly tacky, end 10th and 38th days. |

||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

| Gardner | 0.1516 | 8.5 | 8.7 | 9.1 | 10.8 | 11.9 | 11.8 | — | 11.9 | — | 11.9 | — | 11.8 | — | 11.8 | — | 11.8 | — | 10.7 | — | { | Fair drying observed at end of 4th day. Film slightly tacky at end of test. |

||||||||||||||||||||||||||

| Sabin | 0.9498 | 11.0 | 0 | 11.1 | 5 | 10.5 | 8 | 10.1 | 7 | 9.8 | 2 | — | 9.0 | 2 | 9.4 | 2 | 9.3 | 5 | 9.2 | 7 | — | 9.3 | 2 | — | — | 8.8 | 1 | — | 8.2 | 4 | — | 7.9 | 2 | |||||||||||||||

| Pickard | 0.6160 | 10.9 | 4 | 10.8 | 1 | 10.5 | 1 | 10.3 | 7 | 9.8 | 7 | — | 8.9 | 3 | — | 8.9 | 0 | — | 8.7 | 0 | — | 9.2 | 9 | — | 9.6 | 3 | — | — | 8.4 | 7 | — | |||||||||||||||||

| Rogers North |

} | 0.2553 | 11.8 | 3 | 11.8 | 3 | 10.1 | 5 | 9.2 | 9 | 9.2 | 9 | 9.4 | 5 | — | 10.0 | 0 | — | 8.9 | 5 | — | 8.0 | 6 | — | 8.6 | 1 | — | — | — | — | — | { | Tacky on 1st and 2d days. Dry on 10th day. |

|||||||||||||||

| Table X.—(a) Sun Flower Oil 100 Per Cent. | ||||||||||||||||||||||||||||||||||||||||||||||||

| Observer. | Wt. of Oil for Test, grams. |

Percentage Increase in Weight, in Days. | Remarks. | |||||||||||||||||||||||||||||||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | ||||||||||||||||||||||||||||||

| Gardner | 0.1414 | 6.3 | 8.2 | 11.5 | 11.6 | 11.5 | 11.5 | — | 11.3 | — | 11.3 | — | 11.3 | — | 11.3 | — | 11.2 | — | 11.0 | — | { | Film fairly firm, end of 3d day. |

||||||||||||||||||||||||||

| Sabin | 0.6292 | 9.6 | 9 | 9.4 | 2 | 7.9 | 9 | 7.4 | 3 | 7.0 | 4 | — | 6.1 | 2 | 6.4 | 5 | 6.1 | 2 | 5.9 | 2 | — | 5.6 | 9 | — | — | 5.2 | 4 | — | 4.5 | 7 | — | 4.2 | 6 | |||||||||||||||

| Pickard | 0.5837 | 7.8 | 5 | 7.7 | 3 | 7.4 | 5 | 7.0 | 2 | 6.3 | 6 | — | 5.1 | 6 | — | 4.5 | 7 | — | 4.2 | 0 | — | 4.5 | 4 | — | 4.6 | 1 | — | — | 4.3 | 0 | — | |||||||||||||||||

| Rogers North |

} | 0.2540 | 8.3 | 9 | 6.9 | 4 | 6.2 | 1 | 6.1 | 3 | 5.8 | 1 | 6.0 | 1 | — | 6.0 | 9 | — | 4.8 | 1 | — | 4.7 | 3 | — | 4.8 | 1 | — | 5.0 | 1 | — | — | — | { | Sticky, end 1st day; tacky, end 2d day; slightly tacky, end 10th day. |

||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

| Gardner | 0.1600 | 9.5 | 11.0 | 11.1 | 11.3 | 11.4 | 10.9 | — | 10.8 | — | 10.8 | — | 10.8 | — | 10.6 | — | 10.6 | — | 10.9 | — | { | Good firm, glossy film shown at end of 2d day. |

||||||||||||||||||||||||||

| Sabin | 0.5030 | 14.2 | 1 | 14.2 | 1 | 12.6 | 6 | 14.0 | 1 | 11.5 | 9 | — | 10.2 | 4 | 10.6 | 3 | 10.3 | 4 | 10.3 | 4 | — | 10.2 | 7 | — | — | 11.3 | 3 | — | 10.7 | 3 | — | 10.3 | 0 | |||||||||||||||

| Pickard | 0.4470 | 12.6 | 2 | 12.0 | 2 | 11.4 | 8 | 11.6 | 5 | 10.2 | 5 | — | 8.1 | 4 | — | 6.2 | 6 | — | 5.5 | 4 | — | 6.2 | 2 | — | 5.8 | 2 | — | — | 5.3 | 5 | — | |||||||||||||||||

| Rogers North |

} | 0.2261 | 11.5 | 4 | 11.8 | 5 | 9.9 | 2 | 9.1 | 3 | 8.9 | 5 | 9.0 | 4 | — | 9.5 | 2 | — | 8.5 | 5 | — | 7.6 | 7 | — | 8.2 | 0 | — | — | — | — | — | { | Dry on 1st, 2d and 10th days. | |||||||||||||||

| Table XI.—(a) Menhaden Oil 100 Per Cent. | ||||||||||||||||||||||||||||||||||||||||||||||||

| Observer. | Wt. of Oil for Test, grams. |

Percentage Increase in Weight, in Days. | Remarks. | |||||||||||||||||||||||||||||||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | ||||||||||||||||||||||||||||||

| Gardner | 0.1944 | 7.7 | 8.1 | 8.9 | 10.1 | 9.8 | 9.8 | — | 9.8 | — | 9.8 | — | 9.8 | — | 9.6 | — | 9.6 | — | 9.6 | — | { | Good drying during 2d day. Fairly firm film. |

||||||||||||||||||||||||||

| Sabin | 0.5282 | 12.4 | 7 | 12.1 | 7 | 11.7 | 0 | 11.4 | 7 | 11.1 | 3 | — | 10.2 | 8 | 11.2 | 0 | 11.1 | 5 | 11.0 | 2 | — | 11.3 | 7 | — | — | 10.8 | 5 | — | 10.3 | 4 | — | 9.9 | 0 | |||||||||||||||

| Pickard | 0.7005 | 10.7 | 9 | 10.9 | 8 | 10.8 | 5 | 10.9 | 0 | 10.5 | 7 | — | 9.2 | 7 | — | 8.4 | 8 | — | 8.2 | 7 | — | 8.9 | 1 | — | 8.7 | 5 | — | — | 9.2 | 1 | — | |||||||||||||||||

| Rogers North |

} | 0.3150 | 11.2 | 7 | 10.1 | 6 | 9.7 | 2 | 9.9 | 7 | 9.9 | 4 | 10.2 | 7 | — | 10.3 | 6 | — | 8.8 | 0 | — | 9.2 | 2 | — | 9.4 | 0 | — | 9.3 | 1 | — | — | — | { | Sticky, end 1st day. Slightly sticky, end 2d and 10th days. |

||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

| Gardner | 0.2448 | 8.5 | 10.4 | 12.2 | 12.9 | 12.9 | 12.9 | — | 12.9 | — | 12.9 | — | 12.9 | — | 12.8 | — | 12.7 | — | 12.9 | — | { | Good firm, elastic film shown after 2d day. |

||||||||||||||||||||||||||

| Sabin | 0.4959 | 14.1 | 1 | 13.4 | 7 | 12.6 | 8 | 12.0 | 4 | 11.5 | 9 | — | 10.4 | 4 | 11.0 | 9 | 11.0 | 4 | 10.7 | 4 | — | 10.9 | 0 | — | — | 10.1 | 8 | — | 9.4 | 8 | — | 8.9 | 3 | |||||||||||||||

| Pickard | 0.4201 | 13.1 | 9 | 12.8 | 8 | 12.2 | 3 | 11.8 | 1 | 11.1 | 7 | — | 9.5 | 0 | — | 8.4 | 8 | — | 7.7 | 7 | — | 8.3 | 3 | — | 8.2 | 4 | — | — | 8.1 | 2 | — | |||||||||||||||||

| Rogers North |

} | 0.2456 | 10.9 | 9 | 11.2 | 8 | 9.5 | 6 | 8.9 | 0 | 8.7 | 2 | 8.7 | 2 | — | 9.3 | 4 | — | 8.4 | 0 | — | 7.3 | 7 | — | 8.1 | 1 | — | — | — | — | — | { | Nearly dry on 1st and 2d days. | |||||||||||||||

| Table XII.—(a) Raw Chinese Wood Oil 100 Per Cent.[39] | ||||||||||||||||||||||||||||||||||||||||||||||||

| Observer. | Wt. of Oil for Test, grams. |

Percentage Increase in Weight, in Days. | Remarks. | |||||||||||||||||||||||||||||||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | ||||||||||||||||||||||||||||||

| Gardner | 0.2266 | 4.1 | 11.2 | 14.9 | 14.4 | 14.4 | 14.2 | — | 14.2 | — | 14.2 | — | 14.2 | — | 14.2 | — | 14.2 | — | 14.5 | — | { | Film crystallized and remained soft until 3d day. Hard but opaque film shown after 4th day. |

||||||||||||||||||||||||||

| Sabin | 0.5545 | — | — | 11.0 | 2 | 11.5 | 3 | 11.0 | 3 | — | 10.5 | 3 | 10.7 | 4 | 10.4 | 7 | 10.2 | 7 | — | 10.2 | 2 | — | — | 9.8 | 0 | — | 9.2 | 5 | — | 8.8 | 6 | |||||||||||||||||

| Pickard | 0.4933 | 0.5 | 9 | 2.0 | 9 | 5.1 | 3 | 7.5 | 6 | 8.6 | 8 | — | 10.1 | 1 | — | 9.6 | 5 | — | 9.4 | 3 | — | 9.7 | 7 | — | 9.7 | 3 | — | — | 9.3 | 3 | — | |||||||||||||||||

| Rogers North |

} | 0.4036 | 0.5 | 4 | 2.8 | 0 | 5.1 | 0 | 6.0 | 0 | 6.2 | 7 | 7.0 | 9 | — | 8.3 | 9 | — | 8.0 | 1 | — | 8.5 | 5 | — | 9.1 | 3 | — | 9.2 | 7 | — | — | — | { | Sticky, end of 1st and 2d days; dry but drawn, end of 10th day. |

||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

| Gardner | 0.2087 | 9.0 | 12.1 | 12.9 | 12.8 | 12.8 | 12.8 | — | 12.7 | — | 12.6 | — | 12.6 | — | 12.5 | — | 12.5 | — | 12.7 | — | { | Clear and firm film shown after 3d day. |

||||||||||||||||||||||||||

| Sabin | 0.2967 | 14.4 | 6 | 13.1 | 1 | 11.7 | 2 | 10.6 | 8 | 9.7 | 7 | — | 8.6 | 6 | 8.8 | 6 | 8.8 | 0 | 8.4 | 9 | — | 8.1 | 5 | — | — | 8.0 | 5 | — | 7.4 | 1 | — | 7.0 | 4 | |||||||||||||||

| Pickard | 0.3683 | 14.3 | 7 | 13.6 | 6 | 13.1 | 1 | 12.4 | 1 | 11.7 | 8 | — | 10.5 | 1 | — | 8.7 | 2 | — | 7.0 | — | 8.8 | 2 | — | 8.3 | 9 | — | — | 7.9 | 8 | — | ||||||||||||||||||

| Rogers North |

} | 0.2285 | 11.9 | 9 | 11.9 | 0 | 10.1 | 4 | 9.3 | 0 | 9.0 | 8 | 9.3 | 0 | — | 9.7 | 0 | — | 8.9 | 0 | — | 7.3 | 4 | — | 7.7 | 8 | — | — | — | — | — | Dry at end of 1st day. | ||||||||||||||||

| Table XIII.—(a) Chinese Wood Oil (Treated) 100 Per Cent. | ||||||||||||||||||||||||||||||||||||||||||||||||

| Observer. | Wt. of Oil for Test, grams. |

Percentage Increase in Weight, in Days. | Remarks. | |||||||||||||||||||||||||||||||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | ||||||||||||||||||||||||||||||

| Gardner | 0.1678 | [8]38.0 | [8]30.0 | [8]28.0 | [8]28.0 | [8]28.0 | [8]28.0 | — | [8]28.0 | — | 27.5 | — | [8]26.0 | — | [8]26.0 | — | [8]26.0 | — | [8]26.2 | — | { | Loss observed due to presence of volatiles. Firm, clear film shown at end of 1st day. |

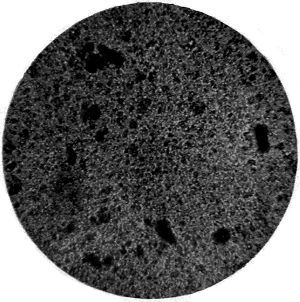

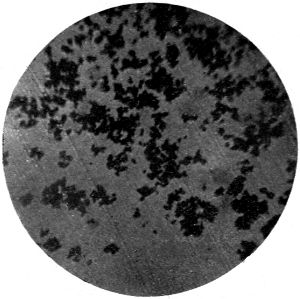

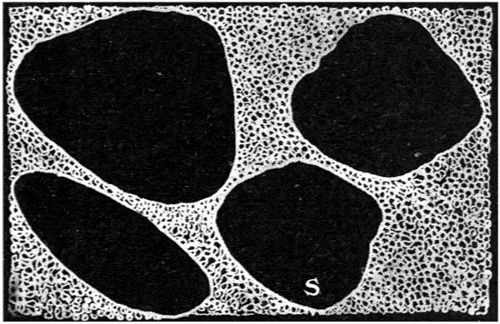

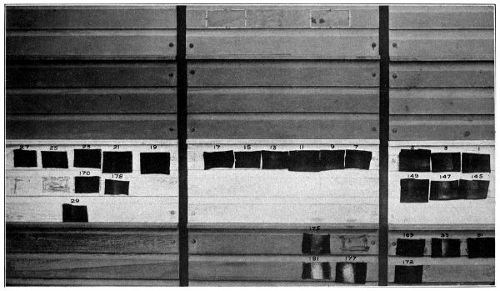

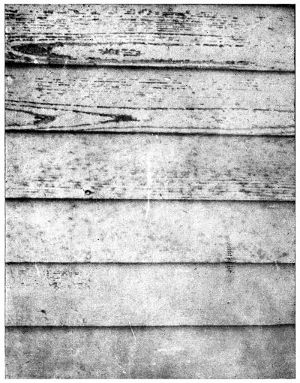

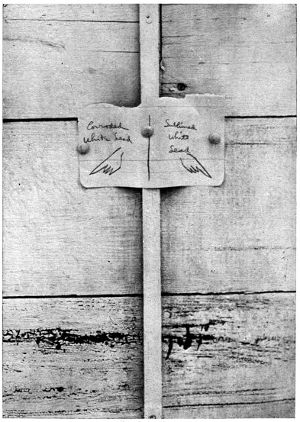

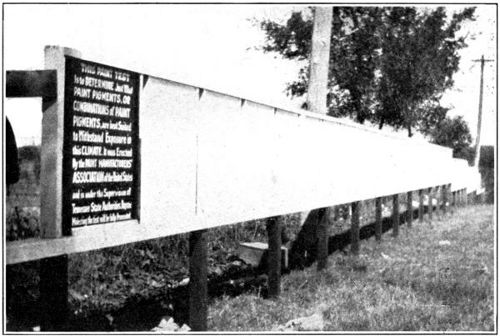

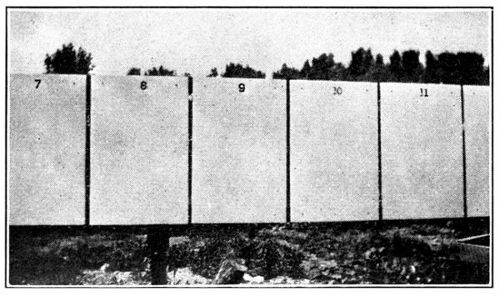

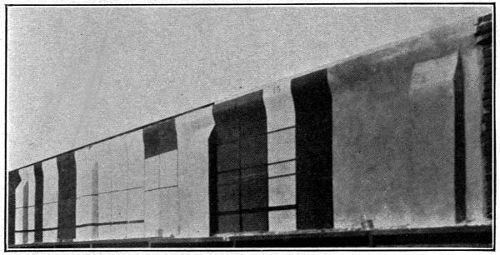

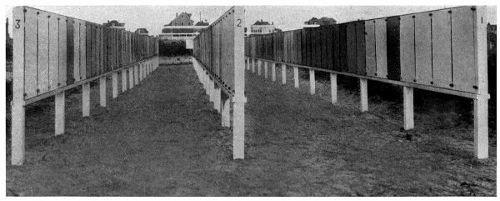

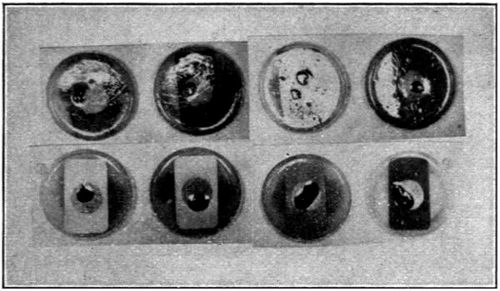

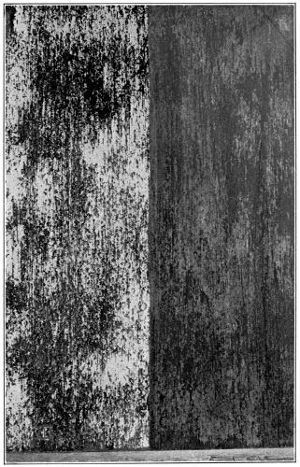

||||||||||||||||||||||||||