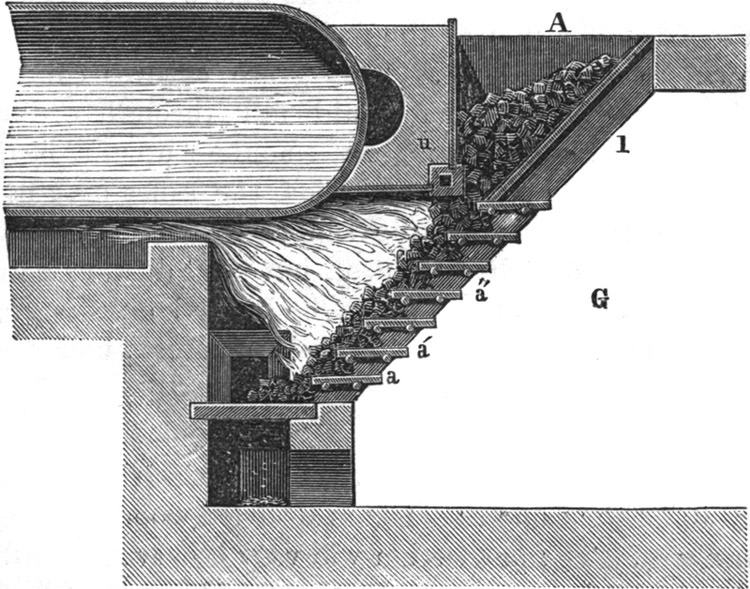

Fig. 1.—STAIR GRATE.

The Project Gutenberg EBook of Peat and its Uses as Fertilizer and Fuel, by Samuel William Johnson This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org Title: Peat and its Uses as Fertilizer and Fuel Author: Samuel William Johnson Release Date: July 28, 2008 [EBook #26142] Language: English Character set encoding: ISO-8859-1 *** START OF THIS PROJECT GUTENBERG EBOOK PEAT AND ITS USES *** Produced by Steven Giacomelli, Barbara Kosker, Jeannie Howse and the Online Distributed Proofreading Team at http://www.pgdp.net (This file was produced from images produced by Core Historical Literature in Agriculture (CHLA), Cornell University)

Lovejoy & Son,

Electrotypers and Stereotypers

15 Vandewater street N. Y.

| Introduction | vii | ||||

| PART I.—Origin, Varieties, and Chemical Characters of Peat. | |||||

| PAGE | |||||

| 1. | What is Peat? | 9 | |||

| 2. | Conditions of its Formation | 9 | |||

| 3. | Different Kinds of Peat | 14 | |||

| Swamp Muck | 17 | ||||

| Salt Mud | 18 | ||||

| 4. | Chemical Characters and Composition of Peat | 18 | |||

| a. | Organic or combustible part | 19 | |||

| Ulmic and Humic Acids | 19 | ||||

| Ulmin and Humin—Crenic and Apocrenic Acids | 20 | ||||

| Ulmates and Humates | 21 | ||||

| Crenates and Apocrenates | 22 | ||||

| Gein and Geic Acid—Elementary Composition of Peat | 23 | ||||

| Ultimate Composition of the Constituents of Peat | 25 | ||||

| b. | Mineral Part—Ashes | 25 | |||

| 5. | Chemical Changes that occur in the Formation of Peat | 26 | |||

| PART II.—On the Agricultural Uses of Peat and Swamp Muck. | |||||

| 1. | Characters that adapt Peat for Agricultural Use | 28 | |||

| A. | Physical or Amending Characters | 28 | |||

| I. | Absorbent Power for Water, as Liquid and Vapor | 31 | |||

| II. | Absorbent Power for Ammonia | 32 | |||

| III. | Influence in Disintegrating the Soil | 34 | |||

| IV. | Influence on the Temperature of Soils | 37 | |||

| B. | Fertilizing Characters | 38 | |||

| I. | Fertilizing Effects of the Organic Matters, excluding Nitrogen | 38 | |||

| 1. | Organic Matters as Direct Food to Plants | 38 | |||

| 2. | Organic Matters as Indirect Food to Plants | 40 | |||

| 3. | Nitrogen, including Ammonia and Nitric Acid | 42 | |||

| II. | Fertilizing Effects of the Ashes of Peat | 46 | |||

| III. | Peculiarities in the Decay of Peat | 50 | |||

| IV. | Comparison of Peat with Stable Manure | 51 | |||

| 2. | Characters of Peat that are detrimental, or that need correction | 54 | |||

| I. | Possible Bad Effects on Heavy Soils | 54 | |||

| II. | Noxious Ingredients | 55 | |||

| a. | Vitriol Peats | 55 | |||

| b. | Acidity—c. Resinous Matters | 57 | |||

| 3. | Preparation of Peat for Agricultural Use | 57 | |||

| a. | Excavation | 57 | |||

| b. | Exposure, or Seasoning | 59 | |||

| c. | Composting | 62 | |||

| Compost with Stable Manure | 63 | ||||

| Compost with Night Soil | 68 | ||||

| Compost with Guano | 69 | ||||

| Compost with Fish and other Animal Matters | 70 | ||||

| Compost with Potash-lye & Soda-ash; Wood-ashes, Shell-marl, Lime | 72 | ||||

| Compost with Salt and Lime Mixture | 73 | ||||

| Compost with Carbonate of Lime, Mortar, etc. | 75 | ||||

| 4. | The Author's Experiments with Peat Composts | 77 | |||

| 5. | Examination of Peat with reference to its Agricultural Value | 81 | |||

| 6. | Composition of Connecticut Peats | 84 | |||

| Method of Analysis | 86 | ||||

| Tables of Composition | 88-89-90 | ||||

| PART III.—On Peat as Fuel | |||||

| 1. | Kinds of Peat that Make the Best Fuel | 92 | |||

| 2. | Density of Peat | 95 | |||

| 3. | Heating Power of Peat as Compared with Wood and Anthracite | 96 | |||

| 4. | Modes of Burning Peat | 102 | |||

| 5. | Burning of Broken Peat | 103 | |||

| 6. | Hygroscopic Water of Peat-fuel | 104 | |||

| 7. | Shrinkage | 105 | |||

| 8. | Time of Excavation and Drying | 105 | |||

| 9. | Drainage | 106 | |||

| 10. | Cutting of Peat for Fuel—a. Preparations for Cutting | 107 | |||

| b. | Cutting by Hand; with Common Spade; German Peat Knife | 108 | |||

| Cutting with Irish Slane—System employed in East Friesland | 109 | ||||

| c. | Machines for Cutting Peat; Brosowsky's Machine; Lepreux's Machine | 113 | |||

| 11. | Dredging of Peat | 115 | |||

| 12. | Moulding of Peat | 116 | |||

| 13. | Preparation of Peat-fuel by Machinery, etc | 116 | |||

| A. | Condensation by Pressure | 116 | |||

| a. | Of Fresh Peat | 116 | |||

| Mannhardt's Method | 117 | ||||

| The Neustadt Method | 119 | ||||

| b. | Of Air-dried Peat—Lithuanian Process | 120 | |||

| c. | Of Hot-dried Peat—Gwynne's Method; Exter's Method | 121 | |||

| Elsberg's Process | 125 | ||||

| B. | Condensation without Pressure | 127 | |||

| a. | Of Earthy Peat | 128 | |||

| Challeton's Method, at Mennecy, France | 128 | ||||

| Challeton's Method, at Langenberg, Prussia | 130 | ||||

| Roberts' Method, at Pekin, N. Y. | 132 | ||||

| Siemens' Method, at Bœblingen, Wirtemberg | 134 | ||||

| b. | Condensation of Fibrous Peat—Weber's Method; 135 Hot-drying Gysser's Method and Machine | 140 | |||

| c. | Condensation of Peat of all Kinds—Schlickeysen's Machine | 144 | |||

| Leavitt's Peat Mill, Lexington, Mass | 146 | ||||

| Ashcroft & Betteley's Machine | 148 | ||||

| Versmann's Machine, Great Britain | 150 | ||||

| Buckland's Machine, Great Britain | 151 | ||||

| 14. | Artificial Drying of Peat | 152 | |||

| 15. | Peat Coal | 157 | |||

| 16. | Metallurgical Uses of Peat | 162 | |||

| 17. | Peat as a Source of Illuminating Gas | 165 | |||

| 18. | Examination of Peat with regard to its Value as Fuel | 167 | |||

In the years 1857 and 1858, the writer, in the capacity of Chemist to the State Agricultural Society of Connecticut, was commissioned to make investigations into the agricultural uses of the deposits of peat or swamp muck which are abundant in this State; and, in 1858, he submitted a Report to Henry A. Dyer, Esq., Corresponding Secretary of the Society, embodying his conclusions. In the present work the valuable portions of that Report have been recast, and, with addition of much new matter, form Parts I. and II. The remainder of the book, relating to the preparation and employment of peat for fuel, &c., is now for the first time published, and is intended to give a faithful account of the results of the experience that has been acquired in Europe, during the last twenty-five years, in regard to the important subject of which it treats.

The employment of peat as an amendment and absorbent for agricultural purposes has proved to be of great advantage in New-England farming.

It is not to be doubted, that, as fuel, it will be even more valuable than as a fertilizer. Our peat-beds, while they do not occupy so much territory as to be an impediment and a reproach to our country, as they have been to Ireland, are yet so abundant and so widely distributed—occurring from the Atlantic to the Missouri, along and above the 40th parallel, and appearing on our Eastern Coast at least as far South as North Carolina[1]—as to present, at numberless points, material, which, sooner or later, will serve us most usefully when other fuel has become scarce and costly.

The high prices which coal and wood have commanded for several years back have directed attention to peat fuel; and, such is the adventurous character of American enterprise, it cannot be [Pg viii]doubted that we shall rapidly develop and improve the machinery for producing it. As has always been the case, we shall waste a vast deal of time and money in contriving machines that violate every principle of mechanism and of economy; but the results of European invention furnish a safe basis from which to set out, and we have among us the genius and the patience that shall work out the perfect method.

It may well be urged that a good degree of caution is advisable in entering upon the peat enterprise. In this country we have exhaustless mines of the best coal, which can be afforded at a very low rate, with which other fuel must compete. In Germany, where the best methods of working peat have originated, fuel is more costly than here; and a universal and intense economy there prevails, of which we, as a people, have no conception.

If, as the Germans themselves admit, the peat question there is still a nice one as regards the test of dollars and cents, it is obvious, that, for a time, we must "hasten slowly." It is circumstances that make peat, and gold as well, remunerative or otherwise; and these must be well considered in each individual case. Peat is the name for a material that varies extremely in its quality, and this quality should be investigated carefully before going to work upon general deductions.

In my account of the various processes for working peat by machinery, such data as I have been able to find have been given as to cost of production. These data are however very imperfect, and not altogether trustworthy, in direct application to American conditions. The cheapness of labor in Europe is an item to our disadvantage in interpreting foreign estimates. I incline to the belief that this is more than offset among us by the quality of our labor, by the energy of our administration, by the efficiency of our overseeing, and, especially, by our greater skill in the adaptation of mechanical appliances. While counselling caution, I also recommend enterprise in developing our resources in this important particular; knowing full well, however, that what I can say in its favor will scarcely add to the impulse already apparent among my countrymen.

"Samuel W. Johnson.

Sheffield Scientific School,

Yale College, June, 1866.

[1] The great Dismal Swamp is a grand peat bog, and doubtless other of the swamps of the coast, as far south as Florida and the Gulf, are of the same character.

1. What is Peat?

By the general term Peat, we understand the organic matter or vegetable soil of bogs, swamps, beaver-meadows and salt-marshes.

It consists of substances that have resulted from the decay of many generations of aquatic or marsh plants, as mosses, sedges, coarse grasses, and a great variety of shrubs, mixed with more or less mineral substances, derived from these plants, or in many cases blown or washed in from the surrounding lands.

2. The conditions under which Peat is formed.

In this country the production of Peat from fallen and decaying plants, depends upon the presence of so much water as to cover or saturate the vegetable matters, and thereby hinder the full access of air. Saturation with water also has the effect to maintain the decaying matters [Pg 10]at a low temperature, and by these two causes in combination, the process of decay is made to proceed with great slowness, and the solid products of such slow decay, are compounds that themselves resist decay, and hence they accumulate.

In the United States there appears to be nothing like the extensive moors or heaths, that abound in Ireland, Scotland, the north of England, North Germany, Holland, and the elevated plains of Bavaria, which are mostly level or gently sloping tracts of country, covered with peat or turf to a depth often of 20, and sometimes of 40, or more, feet. In this country it is only in low places, where streams become obstructed and form swamps, or in bays and inlets on salt water, where the flow of the tide furnishes the requisite moisture, that our peat-beds occur. If we go north-east as far as Anticosti, Labrador, or Newfoundland, we find true moors. In these regions have been found a few localities of the Heather (Calluna vulgaris), which is so conspicuous a plant on the moors of Europe, but which is wanting in the peat-beds of the United States.

In the countries above named, the weather is more uniform than here, the air is more moist, and the excessive heat of our summers is scarcely known. Such is the greater humidity of the atmosphere that the bog-mosses,—the so-called Sphagnums,—which have a wonderful avidity for moisture, (hence used for packing plants which require to be kept moist on journeys), are able to keep fresh and in growth during the entire summer. These mosses decay below, and throw out new vegetation above, and thus produce a bog, especially wherever the earth is springy. It is in this way that in those countries, moors and peat-bogs actually grow, increasing in depth and area, from year to year, and raise themselves above the level of the surrounding country.

[Pg 11]Prof. Marsh informs the writer that he has seen in Ireland, near the north-west coast, a granite hill, capped with a peat-bed, several feet in thickness. In the Bavarian highlands similar cases have been observed, in localities where the atmosphere and the ground are kept moist enough for the growth of moss by the extraordinary prevalence of fogs. Many of the European moors rise more or less above the level of their borders towards the centre, often to a height of 10 or 20 and sometimes of 30 feet. They are hence known in Germany as high moors (Hochmoore) to distinguish from the level or dishing meadow-moors, (Wiesenmoore). The peat-producing vegetation of the former is chiefly moss and heather, of the latter coarse grasses and sedges.

In Great Britain the reclamation of a moor is usually an expensive operation, for which not only much draining, but actual cutting out and burning of the compact peat is necessary.

The warmth of our summers and the dryness of our atmosphere prevent the accumulation of peat above the highest level of the standing water of our marshes, and so soon as the marshes are well drained, the peat ceases to form, and in most cases the swamp may be easily converted into good meadow land.

Springy hill-sides, which in cooler, moister climates would become moors, here dry up in summer to such an extent that no peat can be formed upon them.

As already observed, our peat is found in low places. In many instances its accumulation began by the obstruction of a stream. To that remarkable creature, the beaver, we owe many of our peat-bogs. These animals, from time immemorial, have built their dams across rivers so as to flood the adjacent forest. In the rich leaf-mold at the water's verge, and in the cool shade of the standing trees, has begun the growth of the sphagnums, sedges, and va[Pg 12]rious purely aquatic plants. These in their annual decay have shortly filled the shallow borders of the stagnating water, and by slow encroachments, going on through many years, they have occupied the deeper portions, aided by the trees, which, perishing, give their fallen branches and trunks, towards completing the work. The trees decay and fall, and become entirely converted into peat; or, as not unfrequently happens, especially in case of resinous woods, preserve their form, and to some extent their soundness.

In a similar manner, ponds and lakes are encroached upon; or, if shallow, entirely filled up by peat deposits. In the Great Forest of Northern New York, the voyager has abundant opportunity to observe the formation of peat-swamps, both as a result of beaver dams, and of the filling of shallow ponds, or the narrowing of level river courses. The formation of peat in water of some depth greatly depends upon the growth of aquatic plants, other than those already mentioned. In our Eastern States the most conspicuous are the Arrow-head, (Sagittaria); the Pickerel Weed, (Pontederia;) Duck Meat, (Lemna;) Pond Weed, (Potamogeton;) various Polygonums, brothers of Buckwheat and Smart-weed; and especially the Pond Lilies, (Nymphœa and Nuphar). The latter grow in water four or five feet deep, their leaves and long stems are thick and fleshy, and their roots, which fill the oozy mud, are often several inches in diameter. Their decaying leaves and stems, and their huge roots, living or dead, accumulate below and gradually raise the bed of the pond. Their living foliage which often covers the water almost completely for acres, becomes a shelter or support for other more delicate aquatic plants and sphagnums, which, creeping out from the shore, may so develop as to form a floating carpet, whereon the leaves of the neighboring wood, and dust [Pg 13]scattered by the wind collect, bearing down the mass, which again increases above, or is reproduced until the water is filled to its bottom with vegetable matter.

It is not rare to find in our bogs, patches of moss of considerable area concealing deep water with a treacherous appearance of solidity, as the hunter and botanist have often found to their cost. In countries of more humid atmosphere, they are more common and attain greater dimensions. In Zealand the surfaces of ponds are so frequently covered with floating beds of moss, often stout enough to bear a man, that they have there received a special name "Hangesak." In the Russian Ural, there occur lakes whose floating covers of moss often extend five or six feet above the water, and are so firm that roads are made across them, and forests of large fir-trees find support. These immense accumulations are in fact floating moors, consisting entirely of peat, save the living vegetation at the surface.

Sometimes these floating peat-beds, bearing trees, are separated by winds from their connection with the shore, and become swimming peat islands. In a small lake near Eisenach, in Central Germany, is a swimming island of this sort. Its diameter is 40 rods, and it consists of a felt-like mass of peat, three to five feet in depth, covered above by sphagnums and a great variety of aquatic plants. A few birches and dwarf firs grow in this peat, binding it together by their roots, and when the wind blows, they act as sails, so that the island is constantly moving about upon the lake.

On the Neusiedler lake, in Hungary, is said to float a peat island having an area of six square miles, and on lakes of the high Mexican Plateau are similar islands which, long ago, were converted in fruitful gardens.

[Pg 14]3. The different kinds of Peat.

Very great differences in the characters of the deposits in our peat-beds are observable. These differences are partly of color, some peats being gray, others red, others again black; the majority, when dry, possess a dark brown-red or snuff color. They also vary remarkably in weight and consistency. Some are compact, destitute of fibres or other traces of the vegetation from which they have been derived, and on drying, shrink greatly and yield tough dense masses which burn readily, and make an excellent fuel. Others again are light and porous, and remain so on drying; these contain intermixed vegetable matter that is but little advanced in the peaty decomposition. Some peats are almost entirely free from mineral matters, and on burning, leave but a few per cent. of ash, others contain considerable quantities of lime or iron, in chemical combination, or of sand and clay that have been washed in from the hills adjoining the swamps. As has been observed, the peat of some swamps is mostly derived from mosses, that of others originates largely from grasses; some contain much decayed wood and leaves, others again are free from these.

In the same swamp we usually observe more or less of all these differences. We find the surface peat is light and full of partly decayed vegetation, while below, the deposits are more compact. We commonly can trace distinct strata or layers of peat, which are often very unlike each other in appearance and quality, and in some cases the light and compact layers alternate so that the former are found below the latter.

The light and porous kinds of peat appear in general to be formed in shallow swamps or on the surface of bogs, where there is considerable access of air to the decaying matters, while the compacter, older, riper peats are found [Pg 15]at a depth, and seem to have been formed beneath the low water mark, in more complete exclusion of the atmosphere, and under a considerable degree of pressure.

The nature of the vegetation that flourishes in a bog, has much effect on the character of the peat. The peats chiefly derived from mosses that have grown in the full sunlight, have a yellowish-red color in their upper layers, which usually becomes darker as we go down, running through all shades of brown until at a considerable depth it is black. Peats produced principally from grasses are grayish in appearance at the surface, being full of silvery fibres—the skeletons of the blades of grasses and sedges, while below they are commonly black.

Moss peat is more often fibrous in structure, and when dried forms somewhat elastic masses. Grass peat, when taken a little below the surface, is commonly destitute of fibres; when wet, is earthy in its look, and dries to dense hard lumps.

Where mosses and grasses have grown together simultaneously in the same swamp, the peat is modified in its characters accordingly. Where, as may happen, grass succeeds moss, or moss succeeds grass, the different layers reveal their origin by their color and texture. At considerable depths, however, where the peat is very old, these differences nearly or entirely disappear.

The geological character of a country is not without influence on the kind of peat. It is only in regions where the rocks are granitic or silicious, where, at least, the surface waters are free or nearly free from lime, that mosses make the bulk of the peat.

In limestone districts, peat is chiefly formed from grasses and sedges.

This is due to the fact that mosses (sphagnums) need little lime for their growth, while the grasses require much; [Pg 16]aquatic grasses cannot, therefore, thrive in pure waters, and in waters containing the requisite proportion of lime, grasses and sedges choke out the moss.

The accidental admixtures of soil often greatly affect the appearance and value of a peat, but on the whole it would appear that its quality is most influenced by the degree of decomposition it has been subjected to.

In meadows and marshes, overflowed by the ocean tides, we have salt-peat, formed from Sea-weeds (Algæ,) Salt-wort (Salicornia,) and a great variety of marine or strand-plants. In its upper portions, salt-peat is coarsely fibrous from the grass roots, and dark-brown in color. At sufficient depth it is black and destitute of fibres.

The fact that peat is fibrous in texture shows that it is of comparatively recent formation, or that the decomposition has been arrested before reaching its later stages. Fibrous peat is found near the surface, and as we dig down into a very deep bed we find almost invariably that the fibrous structure becomes less and less evident until at a certain depth it entirely disappears.

It is not depth simply, but age or advancement in decomposition, which determines these differences of texture.

The "ripest," most perfectly formed peat, that in which the peaty decomposition has reached its last stage,—which, in Germany, is termed pitchy-peat or fat peat, (Pechtorf, Specktorf)—is dark-brown or black in color, and comparatively heavy and dense. When moist, it is firm, sticky and coherent almost like clay, may be cut and moulded to any shape. Dried, it becomes hard, and on a cut or burnished surface takes a luster like wax or pitch.

In Holland, West Friesland, Holstein, Denmark and Pomerania, a so-called mud-peat (Schlammtorf, also Baggertorf and Streichtorf,) is "fished up" from the bottoms [Pg 17]of ponds, as a black mud or paste, which, on drying, becomes hard and dense like the pitchy-peat.

The two varieties of peat last named are those which are most prized as fuel in Europe.

Vitriol peat is peat of any kind impregnated with sulphate of iron (copperas,) and sulphate of alumina, (the astringent ingredient of alum.)

Swamp Muck.—In New England, the vegetable remains occurring in swamps, etc., are commonly called Muck. In proper English usage, muck is a general term for manure of any sort, and has no special application to the contents of bogs. With us, however, this meaning appears to be quite obsolete, though in our agricultural literature—formerly, more than now, it must be admitted,—the word as applied to the subject of our treatise, has been qualified as Swamp Muck.

In Germany, peat of whatever character, is designated by the single word Torf; in France it is Tourbe, and of the same origin is the word Turf, applied to it in Great Britain. With us turf appears never to have had this signification.

Peat, no doubt, is a correct name for the substance which results from the decomposition of vegetable matters under or saturated with water, whatever its appearance or properties. There is, however, with us, an inclination to apply this word particularly to those purer and more compact sorts which are adapted for fuel, while to the lighter, less decomposed or more weathered kinds, and to those which are considerably intermixed with soil or silt, the term muck or swamp muck is given. These distinctions are not, indeed, always observed, and, in fact, so great is the range of variation in the quality of the substance, that it would be impossible to draw a line where muck leaves off and peat begins. Notwithstanding, a [Pg 18]rough distinction is better than none, and we shall therefore employ the two terms when any greater clearness of meaning can be thereby conveyed.

It happens, that in New England, the number of small shallow swales, that contain unripe or impure peat, is much greater than that of large and deep bogs. Their contents are therefore more of the "mucky" than of the "peaty" order, and this may partly account for New England usage in regard to these old English words.

By the term muck, some farmers understand leaf-mold (decayed leaves), especially that which collects in low and wet places. When the deposit is deep and saturated with water, it may have all the essential characters of peat. Ripe peat, from such a source is, however, so far as the writer is informed, unknown to any extent in this country. We might distinguish as leaf-muck the leaves which have decomposed under or saturated with water, retaining the well established term leaf-mold to designate the dry or drier covering of the soil in a dense forest of deciduous trees.

Salt-mud.—In the marshes, bays, and estuaries along the sea-shore, accumulate large quantities of fine silt, brought down by rivers or deposited from the sea-water, which are more or less mixed with finely divided peat or partly decomposed vegetable matters, derived largely from Sea-weed, and in many cases also with animal remains (mussels and other shell-fish, crabs, and myriads of minute organisms.) This black mud has great value as a fertilizer.

4. The Chemical Characters and Composition of Peat.

The process of burning, demonstrates that peat consists of two kinds of substance; one of which, the larger [Pg 19]portion, is combustible, and is organic or vegetable matter; the other, smaller portion, remaining indestructible by fire is inorganic matter or ash. We shall consider these separately.

a. The organic or combustible part of peat varies considerably in its proximate composition. It is in fact an indefinite mixture of several or perhaps of many compound bodies, whose precise nature is little known. These bodies have received the collective names Humus and Geine. We shall employ the term humus to designate this mixture, whether occurring in peat, swamp-muck, salt-mud, in composts, or in the arable soil. Its chemical characters are much the same, whatever its appearance or mode of occurrence; and this is to be expected since it is always formed from the same materials and under essentially similar conditions.

Resinous and Bituminous matters.—If dry pulverized peat be agitated and warmed for a short time with alcohol, there is usually extracted a small amount of resinous and sometimes of bituminous matters, which are of no account in the agricultural applications of peat, but have a bearing on its value as fuel.

Ulmic and Humic acids.—On boiling what remains from the treatment with alcohol, with a weak solution of carbonate of soda (sal-soda), we obtain a yellowish-brown or black liquid. This liquid contains certain acid ingredients of the peat which become soluble by entering into chemical combination with soda.

On adding to the solution strong vinegar, or any other strong acid, there separates a bulky brown or black substance, which, after a time, subsides to the bottom of the vessel as a precipitate, to use a chemical term, leaving the liquid of a more or less yellow tinge. This deposit, if obtained from light brown peat, is ulmic acid; if from [Pg 20]black peat, it is humic acid. These acids, when in the precipitated state, are insoluble in vinegar; but when this is washed away, they are considerably soluble in water. They are, in fact, modified by the action of the soda, so as to acquire much greater solubility in water than they otherwise possess. On drying the bulky bodies thus obtained, brown or black lustrous masses result, which have much the appearance of coal.

Ulmin and Humin.—After extracting the peat with solution of carbonate of soda, it still contains ulmin or humin. These bodies cannot be obtained in the pure state from peat, since they are mixed with more or less partially decomposed vegetable matters from which they cannot be separated without suffering chemical change. They have been procured, however, by the action of muriatic acid on sugar. They are indifferent in their chemical characters, are insoluble in water and in solution of carbonate of soda; but upon heating with solution of hydrate of soda they give dark-colored liquids, being in fact converted by this treatment into ulmic and humic acids, respectively, with which they are identical in composition.

The terms ulmic and humic acids do not refer each to a single compound, but rather to a group of bodies of closely similar appearance and properties, which, however, do differ slightly in their characteristics, and differ also in composition by containing more or less of oxygen and hydrogen in equal equivalents.

After complete extraction with hydrate of soda, there remains more or less undecomposed vegetable matter, together with sand and soil, were these contained in the peat.

Crenic and apocrenic acids.—From the usually yellowish liquid out of which the ulmic and humic acids have been separated, may further be procured by appropriate [Pg 21]chemical means, not needful to be detailed here, two other bodies which bear the names respectively of Crenic Acid and Apocrenic Acid. These acids were discovered by Berzelius, the great Swedish chemist, in the water and sediment of the Porla spring, in Sweden.

By the action upon peat of carbonate of ammonia, which is generated to some extent in the decay of vegetable matters and is also absorbed from the air, ulmic and humic acids are made soluble, and combine with the ammonia as well as with lime, oxide of iron, etc. In some cases the ulmates and humates thus produced may be extracted from the peat by water, and consequently occur dissolved in the water of the swamp from which the peat is taken, giving it a yellow or brown color.

Ulmates and Humates.—Of considerable interest to us here, are the properties of the compounds of these acids, that may be formed in peat when it is used as an ingredient of composts. The ulmates and humates of the alkalies, viz.: potash, soda, and ammonia, dissolve readily in water. They are formed when the alkalies or their carbonates act on ulmin and humin, or upon ulmates or humates of lime, iron, etc. Their dilute solutions are yellow, or brown.

The ulmates and humates of lime, magnesia, oxide of iron, oxide of manganese and alumina, are insoluble, or nearly so in water.

In ordinary soils, the earths and oxides just named, predominate over the alkalies, and although they may contain considerable ulmic and humic acids, water is able to extract but very minute quantities of the latter, on account of the insolubility of the compounds they have formed.

On the other hand, peat, highly manured garden soil, leaf-mold, rotted manure and composts, yield yellow or brown extracts with water, from the fact that alkalies are here present to form soluble compounds.

[Pg 22]An important fact established by Mulder is, that when solutions of alkali-carbonates are put in contact with the insoluble ulmates and humates, the latter are decomposed; soluble alkali-ulmates and humates being formed, and in these, a portion of the otherwise insoluble ulmates and humates dissolve, so that thus, in a compost, lime, magnesia, oxide of iron, and even alumina may exist in soluble combinations, by the agency of these acids.

Crenates and Apocrenates.—The ulmic and humic acids when separated from their compounds, are nearly insoluble, and, so far as we know, comparatively inert bodies; by further change, (uniting with oxygen) they pass into or yield the crenic and apocrenic acids which, according to Mulder, have an acid taste, being freely soluble in water, and in all respects, decided acids. The compounds of both these acids with the alkalies are soluble. The crenates of lime, magnesia, and protoxide of iron are soluble, crenates of peroxide of iron and of oxide of manganese are but very slightly soluble; crenate of alumina is insoluble. The apocrenates of iron and manganese are slightly soluble; those of lime, magnesia, and alumina are insoluble. All the insoluble crenates and apocrenates, are soluble in solutions of the corresponding salts of the alkalies.

Application of these facts will be given in subsequent paragraphs. It may be here remarked, that the crenate of protoxide of iron is not unfrequently formed in considerable quantity in peat-bogs, and dissolving in the water of springs gives them a chalybeate character. Copious springs of this kind occur at the edge of a peat-bed at Woodstock, Conn., which are in no small repute for their medicinal qualities, having a tonic effect from the iron they contain. Such waters, on exposure to the air, shortly absorb oxygen, and the substance is thereby [Pg 23]converted into crenate and afterwards into apocrenate of peroxide of iron, which, being but slightly soluble, or insoluble, separates as a yellow or brown ochreous deposit along the course of the water. By further exposure to air the organic acid is oxidized to carbonic acid, and hydrated oxide of iron remains. Bog-iron ore appears often to have originated in this way.

Gein and Geic acid.—Mulder formerly believed another substance to exist in peat which he called Gein, and from this by the action of alkalies he supposed geic acid to be formed. In his later writings, however, he expresses doubt as to the existence of such a substance, and we may omit further notice of it, especially since, if it really do occur, its properties are not distinct from those of humic acid.

We should not neglect to remark, however, that the word gein has been employed by some writers in the sense in which we use humus, viz.: to denote the brown or black products of the decomposition of vegetable matters.

It is scarcely to be doubted that other organic compounds exist in peat. As yet, however, we have no knowledge of any other ingredients, while it appears certain that those we have described are its chief constituents, and give it its peculiar properties. With regard to them it must nevertheless be admitted, that our chemical knowledge is not entirely satisfactory, and new investigations are urgently demanded to supply the deficiencies of the researches so ably made by Mulder, more than twenty years ago.

Elementary Composition of Peat.

After this brief notice of those organic compounds that have been recognized in or produced from peat, we may give attention to the elementary composition of peat itself.

[Pg 24]Like that of the vegetation from which it originates, the organic part of peat consists of Carbon, Hydrogen, Oxygen and Nitrogen. In the subjoined table are given the proportions of these elements as found in the combustible part of sphagnum, of several kinds of wood, and in that of a number of peats in various stages of ripeness. They are arranged in the order of their content of carbon.

| Analyst. | Carbon. | Hydrogen. | Oxygen. | Nitrogen. | |

| 1—Sphagnum, undecomposed | Websky | 49.88 | 6.54 | 42.42 | 1.16 |

| 2—Peach wood, undecomposed | Chevandier | 49.90 | 6.10 | 43.10 | 0.90 |

| 3—Poplar wood, undecomposed | Chevandier | 50.30 | 6.30 | 42.40 | 1.00 |

| 4—Oak wood, undecomposed | Chevandier | 50.60 | 6.00 | 42.10 | 1.30 |

| 5—Peat, porous, light-brown, sphagnous | Websky | 50.86 | 5.80 | 42.57 | 0.77 |

| 6—Peat, porous, red-brown | Jæckel | 53.51 | 5.90 | 40.59 | |

| 7—Peat, heavy, brown | Jæckel | 56.43 | 5.32 | 38.25 | |

| 8—Peat, dark red-brown, well decomposed | Websky | 59.47 | 6.52 | 31.51 | 2.51 |

| 9—Peat, black, very dense and hard | Websky | 59.70 | 5.70 | 33.04 | 1.56 |

| 10—Peat, black, heavy, best quality for fuel | Websky | 59.71 | 5.27 | 32.07 | 2.59 |

| 11—Peat, brown, heavy, best quality for fuel | Websky | 62.54 | 6.81 | 29.24 | 1.41 |

From this table it is seen that sphagnum, and the wood of our forest trees are very similar in composition, though not identical. Further, it is seen from analyses 1 and 5, that in the first stages of the conversion of sphagnum into peat—which are marked by a change of color, but in which the form of the sphagnum is to a considerable extent preserved—but little alteration occurs in ultimate composition; about one per cent. of carbon being gained, and one of hydrogen lost. We notice in running down the columns that as the peat becomes heavier and darker in color, it also becomes richer in carbon and poorer in oxygen. Hydrogen varies but slightly.

As a general statement we may say that the ripest and heaviest peat contains 10 or 12 per cent. more carbon and 10 or 12 per cent. less oxygen than the vegetable matter from which it is produced; while between the unaltered vegetation and the last stage of humification, the peat runs through an indefinite number of intermediate stages.

[Pg 25]Nitrogen is variable, but, in general, the older peats contain the most. To this topic we shall shortly recur, and now pass on to notice—

The ultimate composition of the compounds of which peat consists.

Below are tabulated analyses of the organic acids of peat:—

| Carbon. | Hydrogen. | Oxygen. | |

| Ulmic acid, artificial from sugar | 67.10 | 4.20 | 28.70 |

| Humic acid, from Frisian peat | 61.10 | 4.30 | 34.60 |

| Crenic acid | 56.47 | 2.74 | 40.78 |

| Apocrenic acid | 45.70 | 4.80 | 49.50 |

It is seen that the amount of carbon diminishes from ulmic acid to apocrenic, that of oxygen increases in the same direction and to the same extent, viz.: about 21 per cent., while the hydrogen remains nearly the same in all.

b. The mineral part of peat, which remains as ashes when the organic matters are burned away, is variable in quantity and composition. Usually a portion of sand or soil is found in it, and this not unfrequently constitutes its larger portion. Some peats leave on burning much carbonate of lime; others chiefly sulphate of lime; the ash of others again is mostly oxyd of iron; silicic, and phosphoric acids, magnesia, potash, soda, alumina and chlorine, also occur in small quantities in the ash of all peats.

With one exception (alumina) all these bodies are important ingredients of agricultural plants.

In some rare instances, peats are found, which are so impregnated with soluble sulphates of iron and alumina, as to yield these salts to water in large quantity; and sulphate of iron (green vitriol,) has actually been manufactured from such peats, which in consequence have been characterized as vitriol peats.

[Pg 26]Those bases (lime, oxide of iron, etc.,) which are found as carbonates or simple oxides in the ashes, exist in the peat itself in combination with the humic and other organic acids. When these compounds are destroyed by burning, the bases remain united to carbonic acid.

5.—Chemical Changes that occur in the formation of Peat. When a plant perishes, its conversion into humus usually begins at once. When exposed to the atmosphere, the oxygen of the air attacks it, uniting with its carbon producing carbonic acid gas, and with its hydrogen generating water. This action goes on, though slowly, even at some depth under water, because the latter dissolves oxygen from the air in small quantity,[2] and constantly resupplies itself as rapidly as the gas is consumed.

Whether exposed to the air or not, the organic matter suffers internal decomposition, and portions of its elements assume the gaseous or liquid form. We have seen that ripe peat is 10 to 12 per cent. richer in carbon and equally poorer in oxygen, than the vegetable matters from which it originates. Organic matters, in passing into peat, lose carbon and nitrogen; but they lose oxygen more rapidly than the other two elements, and hence the latter become relatively more abundant. The loss of hydrogen is such that its proportion to the other elements is but little altered.

The bodies that separate from the decomposing vegetable matter are carbonic acid gas, carburetted hydrogen (marsh gas), nitrogen gas, and water.

Carbonic acid is the most abundant gaseous product of the peaty decomposition. Since it contains nearly 73 per cent. of oxygen and but 27 per cent. of carbon, it is [Pg 27]obvious that by its escape the proportion of carbon in the residual mass is increased. In the formation of water from the decaying matters, 1 part of hydrogen carries off 8 parts of oxygen, and this change increases the proportion of carbon and of hydrogen. Marsh gas consists of one part of hydrogen to three of carbon, but it is evolved in comparatively small quantity, and hence has no effect in diminishing the per cent. of carbon.

The gas that bubbles up through the water of a peat-bog, especially if the decomposing matters at the bottom be stirred, consists largely of marsh gas and nitrogen, often with but a small proportion of carbonic acid. Thus Websky found in gas from a peat-bed

| Carbonic acid | 2.97 |

| Marsh gas | 43.36 |

| Nitrogen | 53.67 |

| 100.00 |

Carbonic acid, however, dissolves to a considerable extent in water, and is furthermore absorbed by the living vegetation, which is not true of marsh gas and nitrogen; hence the latter escape while the former does not. Nitrogen escapes in the uncombined state, as it always (or usually) does in the decay of vegetable and animal matters that contain it. Its loss is, in general, slower than that of the other elements, and it sometimes accumulates in the peat in considerable quantity. A small portion of nitrogen unites with hydrogen, forming ammonia, which remains combined with the humic and other acids.

After the foregoing account of the composition of peat, we may proceed to notice:

1.—The characters that adapt it for agricultural uses.

These characters are conveniently discussed under two heads, viz.:

Those which render it useful in improving the texture and physical characters of the soil, and indirectly contribute to the nourishment of crops,—characters which constitute it an amendment to the soil (A); and

Those which make it a direct fertilizer (B).

A.—Considered as an amendment, the value of peat depends upon

Its remarkable power of absorbing and retaining water, both as a liquid and as a vapor (I):

Its power of absorbing ammonia (II):

[Pg 29]Its effect in promoting the disintegration and solution of mineral ingredients, that is the stony matters of the soil (III): and

Its influence on the temperature of the soil (IV).

The agricultural importance of these properties of peat is best illustrated by considering the faults of a certain class of soils.

Throughout the State of Connecticut, for instance, are found abundant examples of light, leachy, hungry soils, which consist of coarse sand or fine gravel; are surface-dry in a few hours after the heaviest rains, and in the summer drouths, are as dry as an ash-heap to a depth of several or many feet.

These soils are easy to work, are ready for the plow early in the spring, and if well manured give fair crops in wet seasons. In a dry summer, however, they yield poorly, or fail of crops entirely; and, at the best, they require constant and very heavy manuring to keep them in heart.

Crops fail on these soils from two causes, viz.; want of moisture and want of food. Cultivated plants demand as an indispensable condition of their growth and perfection, to be supplied with water in certain quantities, which differ with different crops. Buckwheat will flourish best on dry soils, while cranberries and rice grow in swamps.

Our ordinary cereal, root, forage and garden crops require a medium degree of moisture, and with us it is in all cases desirable that the soil be equally protected from excess of water and from drouth. Soils must be thus situated either naturally, or as the result of improvement, before any steadily good results can be obtained in their cultivation. The remedy for excess of water in too heavy soils, is thorough drainage. It is expensive, but effectual. It makes the earth more porous, opens and maintains [Pg 30]channels, through which the surplus water speedily runs off, and permits the roots of crops to go down to a considerable depth.

What, let us consider, is the means of obviating the defects of soils that are naturally too porous, from which the water runs off too readily, and whose crops "burn up" in dry seasons?

In wet summers, these light soils, as we have remarked, are quite productive if well manured. It is then plain that if we could add anything to them which would retain the moisture of dews and rains in spite of the summer-heats, our crops would be uniformly fair, provided the supply of manure were kept up.

But why is it that light soils, need more manure than loamy or heavy lands? We answer—because, in the first place the rains which quickly descend through the open soil, wash down out of the reach of vegetation the soluble fertilizing matters, especially the nitrates, for which the soil has no retentive power; and in the second place, from the porosity of the soil, the air has too great access, so that the vegetable and animal matters of manures decay too rapidly, their volatile portions, ammonia and carbonic acid, escape into the atmosphere, and are in measure lost to the crops. From these combined causes we find that a heavy dressing of well-rotted stable manure, almost if not entirely, disappears from such soils in one season, so that another year the field requires a renewed application; while on loamy soils the same amount of manure would have lasted several years, and produced each year a better effect.

We want then to amend light soils by incorporating with them something that prevents the rains from leaching through them too rapidly, and also that renders them less open to the air, or absorbs and retains for the use of crops the volatile products of the decay of manures.

[Pg 31]For these purposes, vegetable matter of some sort is the best and almost the only amendment that can be economically employed. In many cases a good peat or muck is the best form of this material, that lies at the farmer's command.

I.—Its absorbent power for liquid water is well known to every farmer who has thrown it up in a pile to season for use. It holds the water like a sponge, and, according to its greater or less porosity, will retain from 50 to 100 or more per cent. of its weight of liquid, without dripping. Nor can this water escape from it rapidly. It dries almost as slowly as clay, and a heap of it that has been exposed to sun and wind for a whole summer, though it has of course lost much water, is still distinctly wet to the eye and the feel a little below the surface.

Its absorbent power for vapor of water is so great that more than once it has happened in Germany, that barns or close sheds filled with partially dried peat, such as is used for fuel, have been burst by the swelling of the peat in damp weather, occasioned by the absorption of moisture from the air. This power is further shown by the fact that when peat has been kept all summer long in a warm room, thinly spread out to the air, and has become like dry snuff to the feel, it still contains from 8 to 30 per cent. (average 15 per cent.) of water. To dry a peat thoroughly, it requires to be exposed for some time to the temperature of boiling water. It is thus plain, as experience has repeatedly demonstrated, that no ordinary summer heats can dry up a soil which has had a good dressing of this material, for on the one hand, it soaks up and holds the rains that fall upon it, and on the other, it absorbs the vapor of water out of the atmosphere whenever it is moist, as at night and in cloudy weather.

When peat has once become air-dry, it no longer manifests this avidity for water. In drying it shrinks, loses [Pg 32]its porosity and requires long soaking to saturate it again. In the soil, however, it rarely becomes air-dry, unless indeed, this may happen during long drouth with a peaty soil, such as results from the draining of a bog.

II.—Absorbent power for ammonia.

All soils that deserve to be called fertile, have the property of absorbing and retaining ammonia and the volatile matters which escape from fermenting manures, but light and coarse soils may be deficient in this power. Here again in respect to its absorptive power for ammonia, peat comes to our aid.

It is easy to show by direct experiment that peat absorbs and combines with ammonia.

In 1858 I took a weighed quantity of air-dry peat from the New Haven Beaver Pond, (a specimen furnished me by Chauncey Goodyear, Esq.,) and poured upon it a known quantity of dilute solution of ammonia, and agitated the two together occasionally during 48 hours. I then distilled off at a boiling heat the unabsorbed ammonia and determined its quantity. This amount subtracted from that of the ammonia originally employed, gave the quantity of ammonia absorbed and retained by the peat at the temperature of boiling water.

The peat retained ammonia to the amount of 0.95 of one per cent.

I made another trial at the same time with carbonate of ammonia, adding excess of solution of this salt to a quantity of peat, and exposing it to the heat of boiling water, until no smell of ammonia was perceptible. The entire nitrogen in the peat was then determined, and it was found that the dry peat which originally contained nitrogen equivalent to 2.4 per cent. of ammonia, now yielded an amount corresponding to 3.7 per cent. The [Pg 33]quantity of ammonia absorbed and retained at a temperature of 212°, was thus 1.3 per cent.

This last experiment most nearly represents the true power of absorption; because, in fermenting manures, ammonia mostly occurs in the form of carbonate, and this is more largely retained than free ammonia, on account of its power of decomposing the humate of lime, forming with it carbonate of lime and humate of ammonia.

The absorbent power of peat is well shown by the analyses of three specimens, sent me in 1858, by Edwin Hoyt, Esq., of New Canaan, Conn. The first of these was the swamp muck he employed. It contained in the air-dry state nitrogen equivalent to 0.58 per cent. of ammonia. The second sample was the same muck that had lain under the flooring of the horse stables, and had been, in this way, partially saturated with urine. It contained nitrogen equivalent to 1.15 per cent. of ammonia. The third sample was, finally, the same muck composted with white-fish. It contained nitrogen corresponding to 1.31 per cent. of ammonia.[3]

The quantities of ammonia thus absorbed, both in the laboratory and field experiments are small—from 0.7 to 1.3 per cent. The absorption is without doubt chiefly due to the organic matter of the peats, and in all the specimens on which these trials were made, the proportion of inorganic matter is large. The results therefore become a better expression of the power of peat, in general, to absorb ammonia, if we reckon them on the organic matter alone. Calculated in this way, the organic matter of the Beaver Pond peat (which constitutes but 68 per cent. of the dry peat) absorbs 1.4 per cent. of free ammonia, and 1.9 per cent. of ammonia out of the carbonate of ammonia.

[Pg 34]Similar experiments, by Anderson, on a Scotch peat, showed it to possess, when wet, an absorptive power of 2 per cent., and, after drying in the air, it still retained 1.5 per cent.—[Trans. Highland and Ag'l Soc'y.]

When we consider how small an ingredient of most manures nitrogen is, viz.: from one-half to three-quarters of one per cent. in case of stable manure, and how little of it, in the shape of guano for instance, is usually applied to crops—not more than 40 to 60 lbs. to the acre, (the usual dressings with guano are from 250 to 400 lbs. per acre, and nitrogen averages but 15 per cent. of the guano), we at once perceive that an absorptive power of one or even one-half per cent. is greatly more than adequate for every agricultural purpose.

III.—Peat promotes the disintegration of the soil.

The soil is a storehouse of food for crops; the stores it contains are, however, only partly available for immediate use. In fact, by far the larger share is locked up, as it were, in insoluble combinations, and only by a slow and gradual change can it become accessible to the plant. This change is largely brought about by the united action of water and carbonic acid gas. Nearly all the rocks and minerals out of which fertile soils are formed,—which therefore contain those inorganic matters that are essential to vegetable growth,—though very slowly acted on by pure water, are decomposed and dissolved to a much greater extent by water, charged with carbonic acid gas.

It is by these solvents that the formation of soil from broken rocks is to a great extent due. Clay is invariably a result of their direct action upon rocks. The efficiency of the soil depends greatly upon their chemical influence.

[Pg 35]The only abundant source of carbonic acid in the soil, is decaying vegetable matter.

Hungry, leachy soils, from their deficiency of vegetable matter and of moisture, do not adequately yield their own native resources to the support of crops, because the conditions for converting their fixed into floating capital are wanting. Such soils dressed with peat or green manured, at once acquire the power of retaining water, and keep that water ever charged with carbonic acid: thus not only the extraneous manures which the farmer applies are fully economized; but the soil becomes more productive from its own stores of fertility which now begin to be unlocked and available.

Dr. Peters, of Saxony, has made some instructive experiments that are here in point. He filled several large glass jars, (2-½ feet high and 5-½ inches wide) with a rather poor loamy sand, containing considerable humus, and planted in each one, June 14, 1857, an equal number of seeds of oats and peas. Jar No. 2 had daily passed into it through a tube, adapted to the bottom, about 3-¼ pints of common air. No. 3 received daily the same bulk of a mixture of air and carbonic acid gas, of which the latter amounted to one-fourth. No. 1 remained without any treatment of this kind, i. e.: in just the condition of the soil in an open field, having no air in its pores, save that penetrating it from the atmosphere. On October 3, the plants were removed from the soil, and after drying at the boiling point of water, were weighed. The crops from the pots into which air and carbonic acid were daily forced, were about twice as heavy as No. 1, which remained in the ordinary condition.

Examination of the soil further demonstrated, that in the last two soils, a considerably greater quantity of mineral and organic matters had become soluble in water, [Pg 36]than in the soil that was not artificially aërated. The actual results are given in the table below in grammes, and refer to 6000 grammes of soil in each case:—

ACTION OF CARBONIC ACID ON THE SOIL.

| Substances soluble in water, etc. | No. 1, | ||

| Without | No. 2, | No. 3, | |

| Artificial | Common | Air and | |

| Supply of | Air | Carbonic | |

| Air. | Added. | acid added. | |

| Mineral matters | 2.04 | 3.71 | 4.99 |

| Potash | 0.07 | 0.17 | 0.14 |

| Soda | 0.17 | 0.23 | 0.28 |

| Organic matters | 2.76 | 4.32 | 2.43 |

| Weight of Crops | 5.89 | 10.49 | 12.35 |

It will be seen from the above that air alone exercised nearly as much solvent effect as the mixture of air with one-fourth its weight of carbonic acid; this is doubtless, in part due to the fact that the air, upon entering the soil rich in humus, caused the abundant formation of carbonic acid, as will be presently shown must have been the case. It is, however, probable that organic acids (crenic and apocrenic,) and nitric acid were also produced (by oxidation,) and shared with carbonic the work of solution.

It is almost certain, that the acids of peat exert a powerful decomposing, and ultimately solvent effect on the minerals of the soil; but on this point we have no precise information, and must therefore be content merely to present the probability. This is sustained by the fact that the crenic, apocrenic and humic acids, though often partly uncombined, are never wholly so, but usually occur united in part to various bases, viz.: lime, magnesia, ammonia, potash, alumina and oxide of iron.

The crenic and apocrenic acids (that are formed by the oxidation of ulmic and humic acids,) have such decided acid characters,—crenic acid especially, which has a strongly sour taste—that we cannot well doubt their dissolving action.

[Pg 37]IV.—The influence of peat on the temperature of light soils dressed with it may often be of considerable practical importance. A light dry soil is subject to great variations of temperature, and rapidly follows the changes of the atmosphere from cold to hot, and from hot to cold. In the summer noon a sandy soil becomes so warm as to be hardly endurable to the feel, and again it is on such soils that the earliest frosts take effect. If a soil thus subject to extremes of temperature have a dressing of peat, it will on the one hand not become so warm in the hot day, and on the other hand it will not cool so rapidly, nor so much in the night; its temperature will be rendered more uniform, and on the whole, more conducive to the welfare of vegetation. This regulative effect on temperature is partly due to the stores of water held by peat. In a hot day this water is constantly evaporating, and this, as all know, is a cooling process. At night the peat absorbs vapor of water from the air, and condenses it within its pores, this condensation is again accompanied with the evolution of heat.

It appears to be a general, though not invariable fact, that dark colored soils, other things being equal, are constantly the warmest, or at any rate maintain the temperature most favorable to vegetation. It has been repeatedly observed that on light-colored soils plants mature more rapidly, if the earth be thinly covered with a coating of some black substance. Thus Lampadius, Professor in the School of Mines at Freiberg, a town situated in a mountainous part of Saxony, found that he could ripen melons, even in the coolest summers, by strewing a coating of coal-dust an inch deep over the surface of the soil. In some of the vineyards of the Rhine, the powder of a black slate is employed to hasten the ripening of the grape.

Girardin, an eminent French agriculturist, in a series of experiments on the cultivation of potatoes, found that the [Pg 38]time of their ripening varied eight to fourteen days, according to the character of the soil. He found, on the 25th of August, in a very dark soil, made so by the presence of much humus or decaying vegetable matter, twenty-six varieties ripe; in sandy soil but twenty, in clay nineteen, and in a white lime soil only sixteen.

It cannot be doubted then, that the effect of dressing a light sandy or gravelly soil with peat, or otherwise enriching it in vegetable matter, is to render it warmer, in the sense in which that word is usually applied to soils. The upward range of the thermometer is not, indeed, increased, but the uniform warmth so salutary to our most valued crops is thereby secured.

In the light soils stable-manure wastes too rapidly because, for one reason, at the extremes of high temperature, oxidation and decay proceed with great rapidity, and the volatile portions of the fertilizer are used up faster than the plant can appropriate them, so that not only are they wasted during the early periods of growth, but they are wanting at a later period when their absence may prove the failure of a crop.

B. The ingredients and qualities which make peat a direct fertilizer next come under discussion. We shall notice:

The organic matters including nitrogen (ammonia and nitric acid) (I):

The inorganic or mineral ingredients (II):

Peculiarities in the decay of Peat (III), and

Institute a comparison between peat and stable manure (IV).

I.—Under this division we have to consider:

1. The organic matters as direct food to plants.

Thirty years ago, when Chemistry and Vegetable [Pg 39]Physiology began to be applied to Agriculture, the opinion was firmly held among scientific men, that the organic parts of humus—by which we understand decayed vegetable matter, such as is found to a greater or less extent in all good soils, and abounds in many fertile ones, such as constitutes the leaf-mold of forests, such as is produced in the fermenting of stable manure, and that forms the principal part of swamp-muck and peat,—are the true nourishment of vegetation, at any rate of the higher orders of plants, those which supply food to man and to domestic animals.

In 1840, Liebig, in his celebrated treatise on the "Applications of Chemistry to Agriculture and Physiology," gave as his opinion that these organic bodies do not nourish vegetation except by the products of their decay. He asserted that they cannot enter the plant directly, but that the water, carbonic acid and ammonia resulting from their decay, are the substances actually imbibed by plants, and from these alone is built up the organic or combustible part of vegetation.

To this day there is a division of opinion among scientific men on this subject, some adopting the views of Liebig, others maintaining that certain soluble organic matters, viz., crenic and apocrenic acids are proper food of plants.

On the one hand it has been abundantly demonstrated that these organic matters are not at all essential to the growth of agricultural plants, and can constitute but a small part of the actual food of vegetation taken in the aggregate.

On the other hand, we are acquainted with no satisfactory evidence that the soluble organic matters of the soil [Pg 40]and of peat, especially the crenates and apocrenates, are not actually appropriated by, and, so far as they go, are not directly serviceable as food to plants.

Be this as it may, practice has abundantly demonstrated the value of humus as an ingredient of the soil, and if not directly, yet indirectly, it furnishes the material out of which plants build up their parts.

2. The organic matters of peat as indirect food to plants. Very nearly one-half, by weight, of our common crops, when perfectly dry, consists of carbon. The substance which supplies this element to plants is the gas, carbonic acid. Plants derive this gas mostly from the atmosphere, absorbing it by means of their leaves. But the free atmosphere, at only a little space above the soil, contains on the average but 1/2500 of its bulk of this gas, whereas plants flourish in air containing a larger quantity, and, in fact, their other wants being supplied, they grow better as the quantity is increased to 1/12 the bulk of the air. These considerations make sufficiently obvious how important it is that the soil have in itself a constant and abundant source of carbonic acid gas. As before said, organic matter, in a state of decay, is the single material which the farmer can incorporate with his soil in order to make the latter a supply of this most indispensable form of plant-food.

When organic matters decay in the soil, their carbon ultimately assumes the form of Carbonic acid. This gas, constantly exhaling from the soil, is taken up by the foliage of the crops, and to some extent is absorbed likewise by their roots.

Boussingault & Lewy have examined the air inclosed in the interstices of various soils, and invariably found it [Pg 41]much richer (10 to 400 times) than that of the atmosphere above. Here follow some of their results:

CARBONIC ACID IN SOILS.

| Key: | |||

| A - Volumes of Carbonic acid in 100 of air in pores of Soil. | |||

| B - Cubic feet of air in acre to depth of 14 inches. | |||

| C - Cubic feet of Carbonic acid in acre to depth of 14 inches. | |||

| D - Volumes of Carbonic acid to 100 of air above the soil. | |||

| E - Cubic feet of air over one acre to height of 14 inches. | |||

| F - Cubic feet of Carbonic acid over one acre to a height of 14 inches. | |||

| Designation and Condition of Soil. | A | B | C |

| Sandy subsoil of forest | 0.24 | 4,326 | 14 |

| Loamy subsoil of forest | 0.82 | 3,458 | 28 |

| Surface soil of forest | 0.86 | 5,768 | 56 |

| Clayey soil of artichoke field | 0.66 | 10,094 | 71 |

| Soil of asparagus bed, unmanured for one year | 0.79 | 10,948 | 86 |

| Soil of asparagus bed, newly manured | 1.54 | 10,948 | 172 |

| Sandy soil, six days after manuring, and three days of rain | 2.21 | 11,536 | 257 |

| Sandy soil, ten days after manuring, and three days of rain | 9.74 | 11,536 | 1144 |

| Compost of vegetable mold | 3.64 | 20,608 | 772 |

| Carbonic Acid in Atmosphere | D | E | F |

| 0.025 | 50,820 | 14 | |

From the above it is seen that in soils containing little decomposing organic matters—as the forest sub-soils—the quantity of carbonic acid is no greater than that contained in an equal bulk of the atmosphere. It is greater in loamy and clayey soils; but is still small. In the artichoke field (probably light soil not lately manured), and even in an asparagus bed unmanured for one year, the amount of carbonic acid is not greatly larger. In newly manured fields, and especially in a vegetable compost, the quantity is vastly greater.

The organic matters which come from manures, or from the roots and other residues of crops, are the source of the carbonic acid of the soil. These matters continually waste in yielding this gas, and must be supplied anew. Boussingault found that the rich soil of his kitchen garden (near Strasburg) which had been heavily manured [Pg 42]from the barn-yard for many years, lost one-third of its carbon by exposure to the air for three months (July, August and September,) being daily watered. It originally contained 2.43 per cent. At the conclusion of the experiment it contained but 1.60 per cent., having lost 0.83 per cent.

Peat and swamp-muck, when properly prepared, furnish carbonic acid in large quantities during their slow oxidation in the soil.

3. The Nitrogen of Peat, including Ammonia and Nitric Acid.

The sources of the nitrogen of plants, and the real cause of the value of nitrogenous fertilizers, are topics that have excited more discussion than any other points in Agricultural Chemistry. This is the result of two circumstances. One is the obscurity in which some parts of the subject have rested; the other is the immense practical and commercial importance of this element, as a characteristic and essential ingredient of the most precious fertilizers. It is a rule that the most valuable manures, commercially considered, are those containing the most nitrogen. Peruvian guano, sulphate of ammonia, soda-saltpeter, fish and flesh manures, bones and urine, cost the farmer more money per ton than any other manures he buys or makes, superphosphate of lime excepted, and this does not find sale, for general purposes, unless it contains several per cent. of nitrogen. These are, in the highest sense, nitrogenous fertilizers, and, if deprived of their nitrogen, they would lose the greater share of their fertilizing power.

The importance of the nitrogen of manures depends upon the fact that those forms (compounds) of nitrogen which are capable of supplying it to vegetation are comparatively scarce.

[Pg 43]It has long been known that peat contains a considerable quantity of nitrogen. The average amount in thirty specimens, analyzed under the author's direction, including peats and swamp mucks of all grades of quality, is equivalent to 1-½ per cent. of the air-dried substance, or more than thrice as much as exists in ordinary stable or yard manure. In several peats the amount is as high as 2.4 per cent., and in one case 2.9 per cent. were found.

Of these thirty samples, one-half were largely mixed with soil, and contained from 15 to 60 per cent. of mineral matters.

Reducing them to an average of 15 per cent. of water and 5 per cent. of ash, they contain 2.1 per cent. of nitrogen, while the organic part, considered free from water and mineral substances, contains on the average 2.6 per cent. See table, page 90.

The five peats, analyzed by Websky and Chevandier, as cited on page 24, considered free from water and ash, contain an average of 1.8 per cent. of nitrogen.

We should not neglect to notice that peat is often comparatively poor in nitrogen. Of the specimens, examined in the Yale Analytical Laboratory, several contained but half a per cent. or less. So in the analyses of Websky, one sample contained but 0.77 per cent. of the element in question.

As concerns the state of combination in which nitrogen exists in peat, there is a difference of opinion. Mulder regards it as chiefly occurring in the form of ammonia (a compound of nitrogen and hydrogen), united to the organic acids from which it is very difficult to separate it. Recent investigations indicate that in general, peat contains but a small proportion of ready-formed ammonia.

The great part of the nitrogen of peat exists in an insoluble and inert form: but, by the action of the [Pg 44]atmosphere upon it, especially when mixed with and divided by the soil, it gradually becomes available to vegetation to as great an extent as the nitrogen of ordinary fertilizers.

It appears from late examinations that weathered peat may contain nitric acid (compound of nitrogen with oxygen) in a proportion which, though small, is yet of great importance, agriculturally speaking. What analytical data we possess are subjoined.

PROPORTIONS OF NITROGEN, ETC., IN PEAT.

| Analyst. | Total Nitrogen. |

Ammonia, per cent. |

Nitric Acid. | ||

| 1—Brown Peat | Air dry (?) | Boussingault | 2.20 | 0.018 | 0.000 |

| 2—Black Peat | Air dry (?) | Boussingault | Undetermined | 0.025 | Undetermined |

| 3—Peat | Dried at 212° | Reichardt[4] | Undetermined | 0.152 | 0.483 |

| 4—Peat | Dried at 212° | Reichardt | Undetermined | 0.165 | 0.525 |

| 5—Peat | Dried at 212° | Reichardt | Undetermined | 0.305 | 0.241 |

| 6—Peat | Dried at 212° | Reichardt | Undetermined | 0.335 | 0.421 |

Specimens 3, 4 and 5, are swamp (or heath) mucks, and have been weathered for use in flower-culture. 3 and 4 are alike, save that 3 has been weathered a year longer than 4. They contain respectively 41, 56 and 67 per cent. of organic matter.

Sample 6, containing 86 per cent. of organic matter, is employed as a manure with great advantage, and probably was weathered before analysis. It contained 85 per cent. of organic substance.

More important to us than the circumstance that this peat contains but little or no ammonia or nitric acid, and the other contains such or such a fraction of one per cent. of these bodies, is the grand fact that all peats may yield a good share of their nitrogen to the support of crops, when properly treated and applied.

Under the influence of Liebig's teachings, which were logically based upon the best data at the disposal of this distinguished philosopher when he wrote 25 years ago, it [Pg 45]has been believed that the nitrogen of a fertilizer, in order to be available, must be converted into ammonia and presented in that shape to the plant. It has been recently made clear that nitric acid, rather than ammonia, is the form of nitrogenous food which is most serviceable to vegetation, and the one which is most abundantly supplied by the air and soil. The value of ammonia is however positive, and not to be overlooked.

When peat, properly prepared by weathering or composting, is suitably incorporated with a poor or light soil, it slowly suffers decomposition and wastes away. If it be wet, and air have access in limited quantity, especially if lime be mixed with it, a portion of its nitrogen is gradually converted into ammonia. With full access of air nitric acid is produced. In either case, it appears that a considerable share of the nitrogen escapes in the free state as gas, thereby becoming useless to vegetation until it shall have become converted again into ammonia or nitric acid. It happens in a cultivated soil that the oxygen of the air is in excess at the surface, and less abundant as we go down until we get below organic matters: it happens that one day it is saturated with water more or less, and another day it is dry, so that at one time we have the conditions for the formation of ammonia, and at another, those favorable to producing nitric acid. In this way, so far as our present knowledge warrants us to affirm, organic matters, decaying in the soil, continuously yield portions of their nitrogen in the forms of ammonia and nitric acid for the nourishment of plants.

The farmer who skillfully employs as a fertilizer a peat containing a good proportion of nitrogen, may thus expect to get from it results similar to what would come from the corresponding quantity of nitrogen in guano or stable manure.

But the capacity of peat for feeding crops with, [Pg 46]nitrogen appears not to stop here. Under certain conditions, the free nitrogen of the air which cannot be directly appropriated by vegetation, is oxidized in the pores of the soil to nitric acid, and thus, free of expense to the farmer, his crops are daily dressed with the most precious of all fertilizers.

This gathering of useless nitrogen from the air, and making it over into plant-food cannot go on in a soil destitute of organic matter, requires in fact that vegetable remains or humified substances of some sort be present there. The evidence of this statement, whose truth was maintained years ago as a matter of opinion by many of the older chemists, has recently become nearly a matter of demonstration by the investigations of Boussingault and Knop, while the explanation of it is furnished by the researches of Schœnbein and Zabelin. To attempt any elucidation of it here would require more space than is at our disposal.

It is plain from the contents of this paragraph that peat or swamp muck is, in general, an abundant source of nitrogen, and is often therefore an extremely cheap means of replacing the most rare and costly fertilizers.

II.—With regard to the inorganic matters of peat considered as food to plants, it is obvious, that, leaving out of the account for the present, some exceptional cases, they are useful as far as they go.

In the ashes of peats, we almost always find small quantities of sulphate of lime, magnesia and phosphoric acid. Potash and soda too, are often present, though rarely to any considerable amount. Carbonate and sulphate of lime are large ingredients of the ashes of about one-half, of the thirty-three peats and swamp mucks I have examined. The ashes of the other half are largely mixed with sand and soil, but in most cases also contain [Pg 47]considerable sulphate of lime, and often carbonates of lime and magnesia.

In one swamp-muck, from Milford, Conn., there was found but two per cent. of ash, at least one-half of which was sand, and the remainder sulphate of lime, (gypsum.) In other samples 20, 30, 50 and even 60 per cent. remained after burning off the organic matter. In these cases the ash is chiefly sand. The amount of ash found in those peats which were most free from sand, ranges from five to nine per cent. Probably the average proportion of true ash, viz.: that derived from the organic matters themselves, not including sand and accidental ingredients, is not far from five per cent.

In twenty-two specimens of European peat, examined by Websky, Jæckel, Walz, Wiegmann, Einhof and Berthier, eleven contained from 0.6 to 3.5 per cent. of ash. The other eleven yielded from 5.3 to 22 per cent. The average of the former was 2.4, that of the latter 12.7 per cent. Most of these contained a considerable proportion of sand or soil.

Variation in the composition as well as in the quantity of ash is very great.

Three analyses of peat-ashes have been executed at the author's instance with the subjoined results:

ANALYSIS OF PEAT-ASHES.

| A. | B. | C. | |

| Potash | 0.69 | 0.80 | 3.46 |

| Soda | 0.58 | - | trace. |

| Lime | 40.52 | 35.59 | 6.60 |

| Magnesia | 6.06 | 4.92 | 1.05 |

| Oxide of iron and alumina | 5.17 | 9.08 | 15.59 |

| Phosphoric acid | 0.50 | 0.77 | 1.55 |

| Sulphuric acid | 5.52 | 10.41 | 4.04 |

| Chlorine | 0.15 | 0.43 | 0.70 |

| Soluble silica | 8.23 | 1.40 } | |

| Carbonic acid | 19.60 | 22.28 } | 67.01 |

| Sand | 12.11 | 15.04 } | |

| 99.13 | 100.74 | 100.00 |

A was furnished by Mr. Daniel Buck, Jr., of Poquonock, Conn., and comes from a peat which he uses as fuel.

[Pg 48]B was sent by Mr. J. H. Stanwood, of Colebrook, Conn.

C was sent from Guilford, Conn., by Mr. Andrew Foote.[5]