The Project Gutenberg EBook of Photographic Reproduction Processes by P.C. Duchochois

This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at http://www.gutenberg.org/license

Title: Photographic Reproduction Processes Author: P.C. Duchochois Release Date: December 24, 2007 [Ebook #24016] Language: English Character set encoding: UTF-8 ***START OF THE PROJECT GUTENBERG EBOOK PHOTOGRAPHIC REPRODUCTION PROCESSES***

A Practical Treatise of the Photo-Impressions Without Silver Salts New York

The Scovill & Adams Company

423 Broome Street.

1891

Contents

- INTRODUCTION.

- THE DESIGNS.

- THE CYANOTYPE OR BLUE PROCESS.

- THE CYANOFER. (Pellet's Process.)

- THE BLACK OR INK PROCESS. (Ferro-tannate Process.)

- THE CUPROTYPE. (Burnett's Process.)

- THE ANILINE PROCESS.

- THE PRIMULINE OR DIAZOTYPE PROCESS.

- TRACING PROCESS ON METAL.

- GRAPHOTYPY.

- THE URANOTYPE.

- THE PLATINOTYPE.

- ARTIGUES' PROCESS

- THE CARBON PROCESS.

- APPENDIX.

Illustrations

Preparer's Note

Please remember that this book was published over a century ago, long before today's chemical safety standards. Please get expert advice before attempting to perform any of the procedures described in this book.

Authors Quoted

INTRODUCTION.

The photographic processes with the salts of iron are all derived from the researches of Sir John Herschel. The investigations of that great philosopher are so valuable, so full of instructions that we are led to reprint them, together with those of Mr. C. J. Burnett, on the salts of uranium, etc., as an Introduction. It will be seen that the process by which blue prints are to-day obtained is exactly that Sir John Herschel devised in 1840.

“It is no longer an insulated and anomalous affection of certain salts of silver or gold, but one which, doubtless, in a greater or less degree, pervades all nature, and connects itself intimately with the mechanism by which chemical combination and decomposition is operated. The general instability of organic combinations might lead us to expect the occurrence of numerous and remarkable cases of this affection among bodies of that class, but among metallic and other elements inorganically arranged, instances enough have already appeared, and more are daily presenting themselves, to justify its extension to all cases in which chemical elements may be supposed combined with a certain degree of laxity, and so to speak in a tottering equilibrium. There can be no doubt that the process, in a great majority, if not in all cases, which have been noticed among inorganic substances, is a deoxidizing one, so far as the more refrangible rays are concerned. It is obviously so in the cases of gold and silver. In the case of the bichromate of potash it is most probable that an atom of oxygen is parted with, and so of many others. A beautiful example of such deoxidizing action on a non-argentine compound has lately occurred to me in the examination of that interesting salt, the ferrosesquicyanuret [pg 8] of potassium described by Mr. Smee in the Philosophical Magazine, No. 109, September, 1840, and he has shown how to manufacture in abundance and purity, by voltaic action on the common or yellow ferrocyanuret. In this process nascent oxygen is absorbed, hydrogen given off, and the characters of the resulting compound in respect of the oxides of iron, forming as it does Prussian blue with proto salts, indicate an excess of electro-negative energy, a disposition to part with oxygen, or which is the same thing, to absorb hydrogen (in the presence of moisture), and thereby to return to its pristine state, under circumstances of moderate solicitation, such as the affinity of protoxide of iron (for instance) for an additional dose of oxygen, etc.”

“Paper simply washed with a solution of this salt is highly sensitive to the action of the light. Prussian blue is deposited (the base being necessarily supplied by the destruction of one portion of the acid, and the acid by the destruction of another). After half an hour or an hour's exposure to sunshine, a very beautiful negative photograph is the result, to fix which, all that is necessary is to soak it in water in which a little sulphate of soda is dissolved. While dry the impression is of a dove color or lavender blue, which has a curious and striking effect on the greenish yellow ground of the paper produced by the saline solution. After washing the ground color disappears and the photograph becomes bright blue on a white ground. If too long exposed, it gets ‘over-sunned,’ and the tint has a brownish or yellowish tendency, which, however, is removed in fixing; but no increase of intensity beyond a certain point is obtained by the continuance of exposure.”

“If paper be washed with a solution of ammonio-citrate of iron and dried and then a wash passed over it of the yellow ferro-cyanuret of potassium, there is no immediate formation of true Prussian blue, but the paper rapidly acquires a violet-purple color, which deepens after a few minutes, as it dries, to almost absolute blackness. In this state it is a positive photographic paper of high sensibility, and gives pictures of great depth and sharpness, but with this peculiarity, that they darken again spontaneously on exposure to the air in darkness, and are soon [pg 9] obliterated. The paper, however, remains susceptible to light, and capable of receiving other pictures, which in their turn fade, without any possibility (so far as I can see) of arresting them, which is to be regretted, as they are very beautiful, and the paper of such easy preparation. If washed with ammonia or its carbonate, they are for a few moments entirely obliterated, but presently reappear with reversed lights and shades. In this state they are fixed, and the ammonia, with all that it will dissolve, being removed by washing in water, their color becomes a pure Prussian blue, which deepens much by keeping. If the solution be mixed there results a very dark violet-colored ink, which may be kept uninjured in an opaque bottle, and will readily furnish by a single wash at a moment's notice the positive paper in question, which is most sensitive when wet.”

“It seems at first sight natural to refer these curious and complex changes to the instability of the cyanic compounds; and that this opinion is to a certain extent correct is proved by the photographic impressions obtained on papers to which no iron has been added beyond what exists in the ferrocyanic salts themselves. Nevertheless, the following experiments abundantly prove that in several of the changes above described, the immediate action of the solar rays is not exerted on these salts, but on the iron contained in the ferruginous solution added to them, which it deoxidizes or otherwise alters, thereby presenting it to the ferrocyanic salts in such a form as to precipitate the acids in combination with the peroxide, or protoxide of iron, as the case may be. To make this evident, all that is necessary is simply to leave out the ferrocyanate in the preparation of the paper, which thus becomes reduced to a simple washing over with the ammonio-citric solution. Paper so washed is of a bright yellow color, and is apparently little, but in reality highly sensitive to photographic action. Exposed to strong sunshine, for some time indeed, its bright yellow tint is dulled into an ochrey hue, or even to gray, but the change altogether amounts to a moderate percentage of the total light reflected, and in short exposures is such as would easily escape notice. Nevertheless, if a slip of this paper be held for only four or [pg 10] five seconds in the sun (the effect of which is quite imperceptible to the eye), and when withdrawn into the shade be washed over with the ferrosesquicyanate of potash, a considerable deposit of Prussian blue takes place on the sunned part, and none whatever on the rest; so that on washing the whole with water, a pretty strong blue impression is left, demonstrating the reduction of iron in that portion of the paper to the state of protoxide. The effect in question is not, it should be observed, peculiar to ammonio-nitrate of iron.”

“The ammonio and potasso-tartrate fully possess and the perchloride exactly neutralized partakes of the same property; but the experiment is far more neatly made and succeeds better with the other salts.”

“The varieties of cyanotype processes seem to be innumerable, but that which I shall now describe deserves particular notice not only for its pre-eminent beauty while in progress, but as illustrating the peculiar power of the ammoniacal and other parsalts of iron above-mentioned to receive a latent picture susceptible of development by a great variety of stimuli. This process consists in simply passing over the ammonio-citrated paper on which such a latent picture has been impressed, very sparingly and evenly, a wash of the solution of the common yellow ferrocyanate (prussiate) of potash. The latent picture, if not so faint as to be quite invisible (and for this purpose it should not be so), is negative. As soon as the liquid is applied, which cannot be in too thin a film, the negative picture vanishes, and by very slow degrees is replaced by a positive one of a violet blue color on a greenish yellow ground, which at a certain moment possesses a high degree of sharpness and singular beauty and delicacy of tint. If at this instant it be thrown into water, it passes immediately to a Prussian blue, losing, at the same time, however, much of its sharpness, and sometimes indeed becoming quite blotty and confused.”

“To prevent this confusion gum arabic may be added to the prussiated solution, by which it is hindered from spreading unmanageably within the pores of the paper, and the precipitated Prussian blue allowed time to agglomerate and fix itself on the fibers. By the use of this ingredient also, a much thinner [pg 9] and more equal film may be spread over the surface, and when perfectly dry, if not sufficiently developed, the application may be repeated. By operating thus I have occasionally (though rarely) succeeded in producing pictures of great beauty and richness of effect, which they retain (if not thrown in water) between the leaves of a portfolio, and have a certain degree of fixity—fading in strong light and recovering their tone in the dark. * * *”

“If paper be washed with a mixture of the solutions of ammonio-citrate of iron and ferrosesquicyanate (red prussiate) of potash, so as to contain the two salts in about equal proportions, and being then impressed with a picture, be thrown into water and dried, a negative blue picture will be produced. This picture I have found to be susceptible of a very curious transformation. To effect this it must be washed with a solution of protonitrate of mercury, which in a little time entirely discharges it. The nitrate being thoroughly washed out and the picture dried, a smooth iron is passed over it, somewhat hotter than is used for ironing linen, but not sufficiently so to scorch or injure the paper. The obliterated picture immediately reappears, not blue, but brown. If kept for some weeks in this state between the leaves of a portfolio, in complete darkness, it fades, and at length almost disappears. But what is very singular, a fresh application of heat revives and restores it to its full intensity.”

“This curious transformation is instructive in another way. It is not operated by light, at least not by light alone. A certain temperature must be attained, and that temperature suffices in complete darkness. Nevertheless, I find that on exposing to a very concentrated spectrum (collected by a lens of short focus) a slip of paper prepared as above (that is to say, by washing with the mixed solutions, exposure to sunshine, washing and discharging the uniform blue color so induced, as in the last article), its whiteness is changed to a brown over the whole region of the red and orange rays, but not beyond the luminous spectrum. Three conclusions seem unavoidable: first—that it is the heat of these rays, not their light, which operates the change; second—that this heat possesses a peculiar chemical quality which is not possessed by the purely calorific [pg 13] rays outside of the visible spectrum, though far more intense; and third—that the heat radiated from obscurely hot iron abounds especially in rays analogous to those of the region of the spectrum above indicated.”

Sir John Herschel then proceeds to show that whatever be the state of the iron in the double salts in question, its reduction by blue light to the state of protoxide is indicated by many other agents. “Thus, for example,” says Robert Hunt, “if a slip of paper prepared with the ammonio-citrate of iron be exposed partially to sunshine, and then washed with the bichromate of potash, the bichromate is deoxidized and precipitated upon the sunned portion, just as it would be if directly exposed to the sun's rays.”

“I have proved this fact with a great number of preparations of cobalt, nickel, bismuth, platinum and other salts which have been thought hitherto to be insensitive to the solar agency; but if they are partially sunned and then washed with nitrate of silver and put aside in the dark, the metallic silver is slowly reduced upon the sunned portion. In many instances days were required to produce the visible picture; and in one case paper being washed in the dark with neutral chloride of platinum was sunned and then washed in the dark with nitrate of silver; it was some weeks before the image made its appearance, but it was eventually perfectly developed, and, when quite so, remained permanently impressed upon the paper.”

The following process, discovered at the same time as the cyanotype, and termed chrysotype, is thus described by Sir John Herschel:

“In order to ascertain whether any portion of the iron in the double ammoniacal salt employed has really undergone deoxidation, I had recourse to a solution of gold, exactly neutralized by carbonate of soda. The proto-salts of iron, as is well known to chemists, precipitate gold in the metallic state. The effect proved exceedingly striking, and, as the experiment will probably be repeated by others, I shall here describe it ab initio. Paper is to be washed with a moderately concentrated solution [pg 13] of ammonio-citrate of iron and dried. The strength of solution should be such as to dry into a good yellow color, not at all brown. In this state it is ready to receive a photographic image, which may be impressed on it either from nature in the camera obscura, or from an engraving on a frame in sunshine. The image so impressed is, however, very faint, and sometimes hardly perceptible. The moment it is removed from the frame or camera, it must be washed over with a neutral solution of chloride of gold of such strength as to have about the color of a sherry wine. Instantly the picture appears, not, indeed, at once of its full intensity, but darkening with great rapidity up to a certain point, depending on the strength of the solutions used, etc. At this point nothing can surpass the sharpness and perfection of detail of the resulting photograph. To arrest this process and to fix the picture (so far at least as the further agency of light is concerned), it is to be thrown into water very slightly acidulated with sulphuric acid, and well soaked, dried, washed with hydrobromate of potash, rinsed and dried again. * * *”

“In point of direct sensibility, the chrysotype paper is certainly inferior to the calotype; but it is one of the most remarkable peculiarities of gold as a photographic ingredient, that extremely feeble impressions once made by light go on afterwards, darkening spontaneously and very slowly, apparently without limit so long as the least vestige of unreduced chloride of gold remains in the paper. To illustrate this curious and (so far as applications go) highly important property, I shall mention incidentally the results of some experiments made during the late fine weather on the habitudes of gold in presence of oxalic acid. It is well known to chemists that this acid, heated with solutions of gold, precipitates the metal in its metallic state; it is upon this property that Berzelius has founded his determination of the atomic weight of gold. Light, as well as heat, also operates this precipitation; but to render it effectual, several conditions are necessary:—First—the solution of gold should be neutral, or at most very slightly acid; secondly—the oxalic acid must be added in the form of a neutral oxalate; and thirdly—it must be present in a certain considerable quantity, which quantity [pg 14] must be greater the greater the amount of free acid present in the chloride. Under this condition, the gold is precipitated by light as a black powder if the liquid be in any bulk; and if merely washed over paper, a stain is produced, which, however feeble at first, under a certain dosage of the chloride, oxalate and free acid, goes on increasing from day to day and from week to week, when laid by in the dark and especially in a damp atmosphere, till it acquires almost the black of ink; the unsunned portion of the paper remaining unaffected, or so slightly as to render it almost certain that what little action of the kind exists is due to the effect of casual dispersed light incident in the preparation of the paper. I have before me a specimen of paper so treated in which the effect of thirty seconds' exposure to sunshine was quite invisible at first, and which is now of so intense a purple as may be well called black, while the unsunned portion has acquired comparatively but a slight brown. And (what is not a little remarkable, and indicates that in the time of exposure mentioned the maximum of effect was attained) other portions of the same paper exposed in graduated progression for longer times, viz., one minute, two minutes, and three minutes, are not in the least perceptible degree darker than the portion on which the light has acted during thirty seconds only.”

“If paper prepared as above recommended for the chrysotype, either with the ammonio-citrate or ammonio-tartrate of iron, and impressed, as in that process, with a latent picture, be washed with nitrate of silver instead of a solution of gold, a very sharp and beautiful picture is developed of great intensity. Its disclosure is not instantaneous; a few moments elapse without apparent effect; the dark shades are then first touched in, and by degrees the details appear, but much more slowly than in the case of gold. In two or three minutes, however, the maximum of distinctness will not fail to be obtained. The picture may be fixed by the hyposulphite of soda, which alone, I believe, can be fully depended on for fixing argentic photographs.”

“The best process for fixing the photographs prepared with gold is as follows: As soon as the picture is satisfactorily [pg 15] brought out by the auriferous liquid, it is to be rinsed in spring water, which must be three times renewed, letting it remain in the third water five or ten minutes. It is then to be blotted off and dried, after which it is to be washed on both sides with a somewhat weak solution of hydriodate of potash. If there be any free chloride of gold present in the pores of the paper it will be discolored, the lights passing to a ruddy brown; but they speedily whiten again spontaneously, or at all events on throwing it (after lying a minute or two) into fresh water, in which, being again rinsed and dried, it is now perfectly fixed.”

As the chrysotype will be no more referred to, we shall state, first, that the image can be developed with a plain solution of silver nitrate or one acidified with citric or any other organic acid, which generally gives a brown impression that can be toned with an acid or alkaline gold bath, the color varying with the solution employed; and secondly, that the process may be employed to obtain outlines of any picture on paper or canvas to be colored in oil-paints. The impression developed with gold terchloride is pale blue, quite permanent, and does not at all interfere with the work of the artist. The canvas should first be washed with a mixture of alcohol and aqueous ammonia, then dried and rubbed with pumice stone powder to give a tooth. The modus operandi suggests itself.

The researches of Mr. C. J. Burnett on the application of uranium salts and other compounds to photography are recorded in the Photographic Notes of Ths. Sutton for 1857. We give in the following lines the most interesting parts of the two papers of Mr. Burnett:

* * * “The next class of processes are dependent on the sensitiveness to light of the salts of uranic oxide or sesquioxide of uranium, U2O3.”

“In the first process, the paper being charged with the uranic salt and exposed to the solar influence under the negative to be copied, is washed with a solution of the ferridcyanide or [pg 16] red prussiate of potash. The ‘Harvest Scene’ in the exhibition, being from an albumen negative lent me by Mr. Ross, the well-known Edinburgh photographer, is an example, the salt of the sesquioxide of uranium being in this case the hydrofluate, and the time of exposure from the strength of the albumen negative fully an hour of good sunshine. I have used for the solution of the uranic oxide for this process a variety of acids with very similar results; the sensitiveness of the prepared paper to light varying much, however. For instance, a collodion negative with the hydrofluate paper producing a very good print in half an hour of unsteady sun, while with a paper prepared with the tartaric acid solution of the oxide, it gave an equally good impression in less than five minutes of the same intermitting sunshine, indicating thus a difference of sensitiveness of six to one in favor of the tartrate.”

“The rationale of this process is the reduction of the sesqui-oxide of uranium, U2O3, on those parts of the paper exposed to the solar influence, to a lower state of oxidation, the photo-oxide UO, the salts of which have the property of forming with soluble alkaline ferridcyanides a rich chocolate-brown precipitate, while the salts of the sesquioxide are destitute of this reaction. Hence the brown deposit on the parts of the picture on which the sun has been allowed to act when the developing solution is applied, and the absence of any such appearance on those parts which have been protected from its influence.”

“As to the manipulatory details of this process, the paper is floated on the solution in a dark room and hung up to dry, and then preserved from light in a portfolio. If carefully secluded from light it appears to keep well. After exposure for the proper time under this negative, there is in some cases scarcely any visible impression; while in other cases, particularly when using the tartaric solution, I have found the impression very distinguishable, of a brownish or blackish shade, although still quite faint. The development is best conducted by floating it, anything like rubbing the picture being very objectionable.”

“When the picture has fully come out, which is generally from three to ten minutes at the very most, it is removed from the [pg 17] developing bath, placed in cold water and washed very gently for a few minutes, the water being frequently changed till it ceases to acquire a yellow tinge from the dissolved red prussiate. The picture is then drained from the water, pressed between folds of blotting paper, dried (I dry in the dark), and the process is complete. * * * I may state, as one recommendation of this process to ladies and other lovers of clean hands, that any brown stains left by it on the fingers or elsewhere are at once removable by a little weak ammonia or soap and water. * * * I would particularly suggest, as deserving of notice, the development of the salts of sesquioxide of uranium, and still more iron, by the metals and metallic-cyanic alkaline salts, as also by the mellonides and nitro-prussides, and the latter also by itself and as developed by many metallic salts.”

“I have since had the opportunity of trying the nitro-prusside of sodium, which, by itself, gives a blue and white picture, in color like that obtained from the red prussiate of potash.”

“When mixed with a solution of ammonio-nitrate of copper, previous to its application to the paper, the color obtained is pale purplish pink or peach-blossom color. By mixing it in the same way with ammonio-oxalate of sesquioxide of iron, we get a dull green picture, changeable through intermediate stages into brown by alkaline carbonates, and that into a dirty black by gallic acid. It may be well to know that the blue of the picture given by the red prussiate in the process of Sir John Herschel may be considerably modified or entirely changed to another color, in many ways, without interfering with the purity of the white ground, by steeping the picture, after the undecomposed red prussiate has been washed out, in solution of salts of various metals, copper, uranium or cobalt, for instance, and that the colors so produced may be modified as desired, according to the stage at which the action is stopped.”

“There remains but one class of uranic photographs to be described, namely, that obtained when we develop with a salt of silver or gold (or platinum?). This class may be made to print much more rapidly than our ordinary silver printing process, approaching sometimes more nearly to the calotype development in this respect. We get the minutest details [pg 18] with great fidelity, and the picture is effectually fixed by a simple fresh hyposulphite solution, with a good color in many cases, or by ammonia, which will be considered an advantage by those who hold the hyposulphite an enemy to durability. Different shades of color are produced according to different solvent acids and different details. I have got a good black perfectly like that of an engraving, by the nitrate of uranic oxide, developed by ammonio-nitrate of silver (or plain nitrate) and fixed by plain hyposulphite without any coloring bath. * * * I have tried the hyposulphite of gold on some of the silver-developed prints prepared with the hydrofluate of the uranic oxide and fixed with ammonia, which had an exceedingly unpleasant raw-red color, a very agreeable gray was at once obtained. I have succeeded in getting very beautiful impressions by development of the uranic paper by chloride of gold alone.”

In another communication to the Photographic Notes, more interesting perhaps than the foregoing, Mr. Burnett says:

“The clearest and brightest of my results have been obtained by the action of gallic acid, tannin, or especially a mixture of tannin and carbonate of ammonia, potash or soda, on the blue pictures obtained by the solarization of paper prepared with ferridcyanide of potassium, ferrocyanide or ferridcyanide of ammonium. * * * I have also experimented with the bichromate and iron, with gallic, tannin and other developer; but I must confess to not having been, in this particular way, so successful as Mr. Sella appears to have been in the preservation of the whites, owing possibly to my not having taken the trouble to wash out sufficiently the iron before toning.”1

“I have experimented most extensively in many ways with the chromates and bichromates, and have succeeded in various ways in getting very good results. A very capital process for many purposes is to float or steep your paper in a mixed solution of bichromate of potash and sulphate of copper. As for E. Hunt's chromotype process,” 2 I have mixed gelatine, or occasionally grape sugar, or both, with the solution, but instead of developing it by a silver solution, as in the chromotype, wash out the salts unacted on by light, and develop by floating on a solution of ferrocyanide of potassium. The color of the red copper salt which now forms the picture may be modified or changed in many ways, viz., by soaking the picture, after the ferrocyanide of potassium has been washed out of the lights, in a solution of sulphate of iron (or the iron salt may, but not so advantageously, have been applied to the picture before the application of the ferrocyanide). Solutions of chloride of tin, gallic and tannic acids, alone or with alkalies or alkaline carbonates, may also be employed to modify or change the color. Instead of developing by ferrocyanide you may develop by the cobalt or chromo-cyanogen salts, or by an alkaline mellonide arsenite, etc. Sulphureted hydrogen, or a sulphide, will give a brown, or black tone, which may be protected against oxygen and dampness by a resinous varnish.

[pg 20]“Of all the simple pictures obtainable with bichromated papers, without complications or other tonings, those obtainable by the combination of a salt (say the sulphate) of manganese, with the bichromate in the paper preparation, are about the best; these pictures being, however, capable of being toned and modified in many different ways if desired. This may be accomplished by the use of toning baths of ferridcyanide or ferrocyanide, or other metal cyanogen salts, etc., or by either mixing the salts of other metals, as copper or iron, with the cyanic toning baths, or using them in the original solution, or by soaking the paper in them, as in Sella's process, previously to the application of the metal cyanic, mellonic or other toning baths. Alkalies and alkaline carbonates may also be used to remove the chromic acid, and leave a subsalt, or the very stable oxide or carbonate of manganese, which may be peroxidized by the use of chloride of lime, peroxide of hydrogen, or ozone.”

“In all the processes with metallic salts, alone with bichromates, the use of sized or unsized paper along with gelatine, etc., has some advantages. I have got good results by such processes on albumen paper, the albumen tending to prevent mealiness in the print; also on paper soaked in gelatine before the application of the bichromic solution. * * * There is great interest connected with the action of all such papers, along with the tannin and vegetable coloring matters. I have long been of opinion that by the steeping of papers or textile fabrics, containing the salts not only of iron, as recommended by Mr. Sella, but of tin, copper, bismuth, lead, etc., in solutions of cochineal, red cabbage, beetroot, grass or the most ordinary foliage, etc., that the most useful results might be obtained; though for certain permanence I am not sure but that some of the other processes which I have briefly run over with the cyanogen acid salts or metallic acid salts, as precipitators, may be more to be depended upon. The processes with precipitated oxides, such as the one with manganese and similar ones, with other metals which I have described, I also consider as deserving of more attention than almost any processes which have been stated, on the score of probable permanence; but perhaps the best process for black, or generally useful [pg 21] neutral tint, without silver, that has yet been offered to the public, I believe to be the process alluded to with the bichromate of potash and sulphate of copper, toned by an iron salt. * * * This process, the cuprotype (as also the uranotype and manganotype) is applicable perfectly to films of albumen or gelatine on glass or porcelain, textile fabrics, parchment, paper, tiles and many other substances besides paper.”

THE DESIGNS.

HOW TO MAKE A NEGATIVE DRAWING

The drawing paper for designs to be reproduced by the cyantotype and the other processes described in this book should be of a fine texture, free from opacities and very white; and, as the design must serve as a cliché it is a sine qua non that it be drawn with a very black ink and with well-fed lines, especially those which are very fine. To obtain a complete opacity, and, at the same time, to keep the ink quite fluid, which gives great facility to the designer, one adds some gamboge (or burnt sienna) to the India ink. The ink of Bourgeois, which is compounded with yellow and can be diluted as easily as India ink, is excellent, so is also the American ink of Higgins.3

As much as possible it is desirable to replace the colored lines indicating the constructions, the axis, projections, etc., by differently punctuated lines made with India ink. However, if the use of colors be obligatory on the original design, one should trace the red lines with very thick vermilion or sienna, the yellow lines with gamboge, and the blue and green lines with a thick mixture of Prussian blue and chrome yellow in different proportions.

One must abstain from applying washes of any tints on the original. If necessary they should be brushed over when the reproductions are made; moreover they can be often replaced by cross-lines more or less open, and the shadowing represented by thicker but not closer lines.

Tracing paper is recommended instead of linen, which latter, on account of its thickness and granulation, gives less satisfactory results in regard to the transparency of the ground and the continuity of the lines.

To reproduce a design on ordinary paper—not too thick—or [pg 26] an engraving, etc., the paper is rendered transparent by rubbing over on the back of the original a solution of 3 parts in volume of castor oil in 10 parts of alcohol, by means of a small sponge. When the paper is quite transparent, the oil in excess is removed by pressure between sheets of blotting paper, and the paper dried before the fire or spontaneously. The design so treated is not in the least injured, for it assumes its primitive condition by dissolving the oil from the paper by immersion into strong alcohol, which it is necessary to renew once or twice, then rinsing in alcoholized water if the drawing be in India ink, or simply in water in the case of an engraving, and finally drying between sheets of blotting paper.

Instead of an alcoholic solution of castor oil, vaseline can be employed. The paper is more transparent.

The method by which are made negative drawings, that is, those which can be used as negative clichés to reproduce the design in black lines on a white ground, is thus described by Mr. Cheysson, wlio originated it, in a manual published by the Department of Public Works of France, from which we have borrowed most of the above instructions for the drawing of designs suitable for the photo-reproduction processes:4

“One can avoid the necessity of making a negative from the original drawing by transforming the drawing itself into a negative.”

“To that effect it suffices to draw with lithographic ink, then to cover the paper with aniline brown, and, after drying, to wash it with turpentine oil which dissolves the lithographic ink without altering the aniline. The lines appear then white on a brown ground impervious to light (that is, non-actinic). The design is thus transformed into a negative, and can yield positive impressions with paper sensitized with silver salts, the ferriprussiate or the bichromate of potash. The lithographic ink should be very black and the lines well fed.”

“When the drawing is finished it is placed on a board lined with sheets of blotting paper, then one spreads all over it the aniline brown with a brush, and, lastly, after drying, the paper is carefully rubbed with a bung of cotton or a rag imbued with turpentine until the lines of the design are dissolved.”

[pg 27]In our practice we have often taken a negative cliché from drawings made in the ordinary manner, without the aid of the camera obscura (which would have been too expensive for drawings of a certain size), by simply printing a proof by contact on plain or albumenized silvered paper, and fixing, without toning, in a new solution of sodium thiosulphate, then washing as usual. The proofs thus obtained from designs drawn with an opaque ink, which allows a long insulation and, therefore, yields an intense reduction, are of a deep brick-red color, quite non-actinic, and give very good positives by the Artigues process.

N.B.—Paper in drying never assumes its original shape; it is, therefore, necessary to make the figures on the reproductions from plans when they are not on the originals.

CHOICE OF PAPER. SIZING.

In all the photographic processes by precipitation of metallic oxides the quality of the paper has a great influence on the results. When the paper is not well sized and not well calendered, the sensitizing solution is absorbed, instead of simply impregnating the surface of the paper, and not only the image is sunk in and its sharpness impaired, but good whites can never be obtained, especially if the image should be toned, owing to the impossibility of eliminating the metallic salts not acted on, that is, not reduced by the action of light which the fibers of the paper mechanically retain.

The “endless” rolls of paper, 54: inches wide—or “blue print paper,” as it is sometimes termed—of Blanchet fréres et Kléber, of Rives, better known as “Rives' paper”, that of Johannot, of Annonay (France), and the Steinbach (Saxe) paper are recommended.

For small prints from negatives in half tone the positive paper, 18×22 inches, of Rives or Saxe, should be preferred to the heavy kind. It is advisable to size it, so that the impressions be entirely formed on the surface of the paper. Moreover, an additional sizing is always advantageous, whatever be the photographic process employed, to prevent the imbibition of the sensitizing compound and to obtain more brilliant and [pg 28] vigorous images, for the iron, chromium, uranium and other metallic soluble salts require the presence of an organic matter (alcohol, ether, gum arabic, glucose, caseine, etc.) to be reduced by the agency of light; and as a consequence, the greater, within certain limits, of course, the amount of organic matters, and the more thoroughly they are mixed with the salts, the more sensitive the preparation and the better the results.

Arrowroot is the best sizing for our purposes. Gelatine may be employed, albumen also, but the coating should be insolubized when applied on the paper and dry.

Sizing with Arrowroot.—In a porcelain dish diffuse 4 parts of powdered arrowroot and one part of liquid glucose in 200 parts of distilled or rain water and dissolve by heat over an alcohol lamp, stirring all the while. Let the solution boil for an instant, and when the paste is homogeneous let it cool down and then remove the skin formed on its surface and strain it through a fine canvas. Now provide with three small sponges free from gritty matters and cleaned in water, and nail by the four corners, one over the other, felt size uppermost, as many sheets of paper as you wish to size on a board somewhat smaller than the paper. This done, with one of the sponges take a small quantity of the arrowroot and, brushing it length-way and cross-way, spread the paste into an even layer, then, by rubbing very lightly with the second sponge, efface the striae and smooth the coating as well as possible. The third sponge serves to remove the excess of paste when too much is at first spread on. From six to seven sheets of paper, 18×22, can be sized with the quantity of arrowroot paste above given.

Another, but not quite so effective a manner of sizing although sufficient for the cyanotype, is the following, employed by Mr. Pizzighelli for the paper used in the platinotypic process:

Ten parts of arrowroot are powdered in a mortar with a little water and then mixed by small quantities to 800 parts of boiling water. After a few minutes 200 parts of alcohol are added and the mixture filtered. The paper is immersed for two or three minutes in the warm solution and hung up to dry.

[pg 29]Sizing, with Gelatine.—Dissolve at a temperature of about 140 deg. Fahr. (60 deg. C.) 10 parts of good gelatine in 800 parts of water, then add 200 parts of alcohol and 3 parts of alum dissolved in a little water. Filter and prepare the paper by immersion as above directed. The gelatinized paper when dry should be prepared a second time and dried by hanging it up in the opposite direction in order to obtain an even coating.

THE CYANOTYPE OR BLUE PROCESS.

This process gives white impressions on a blue ground with diapositives or drawings on transparent or semi-transparent materials, and blue impressions on a white ground from negatives. It is commonly known under the names of “blue print process,” “negative ferrotype process” and “ferro-prussiate process.”

The process is indeed exceedingly simple. A sheet of paper, impregnated or sensitized, as it is termed, with a solution of ferric citrate and ferricyanate is impressed under a cliché,5 then immersed in pure water, whereby the image is developed and at the same time fixed. It is on account of the great advantages offered by its simplicity that this process is generally preferred by civil engineers and architects for the reproduction of their plans.

The sensitizing solution is prepared in mixing by equal volumes the two solutions following:

| A. | Iron, ammonio citrate | 20 parts |

| Water | 100 parts | |

| B. | Potassium ferricyanate (red prussiate) | 15 parts |

| Water | 100 parts |

Although the mixture keeps pretty well for a certain period in the dark, it is best to prepare only the quantity wanted for actual use.6

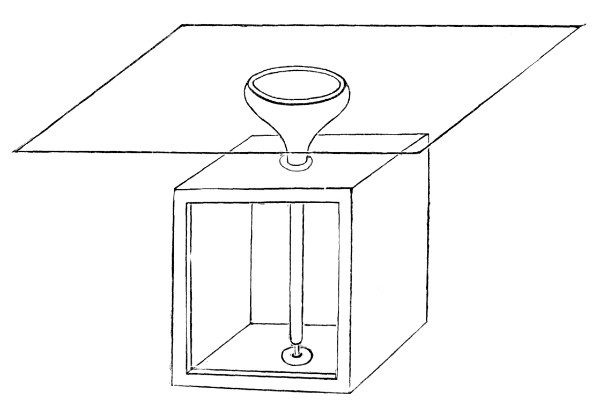

The paper is preferably sensitized in operating as follows:

Take hold of the paper by the two opposite corners and fold it into a loop, lay it on the iron solution, the center of the sheet first placed in contact with the liquid, and then gradually spread it by lowering the corners with a little pressure. No solution should run over on the back of the paper; it would be [pg 31] a cause of stain. This done, and without allowing the liquid to penetrate in the paper, immediately take hold of the two corners near the body and withdraw the paper by dragging it over on a glass rod for this purpose fixed on the edge of the tray. Now pin up the paper to dry, which should be done rapidly, and sensitize a second time in proceeding in the same manner. If this second sensitizing be found objectionable, let float the paper for no more than ten seconds; of course this method of sensitizing is not applicable to prepare larger sheets of paper. In this case the paper is pinned by the four corners on a drawing board or any other support, lined with blotting paper and quickly brushed over with a sponge sparingly imbued with the sensitizing mixture, so as to wet the paper with a very small excess of liquid.

The rationale of this manner of sensitizing is to impregnate only the very surface of the paper with the ferric salts, and thereby to obtain an intense blue with very good whites, which latter it would be impossible of obtaining should the sensitizing solution be allowed to reach in the fibers of the paper, for, in this condition, it is impossible, owing to the exigencies of the process, to wash out thoroughly the iron salts to prevent the chemical changes which cause the whites to be tinted blue. It is for this reason that better results are also obtained with well sized papers.

The sensitizing should be done by a very diffused daylight, and the drying, of course, in a dark room. When sensitized the paper is yellowish green. It should be well dried for keeping, and rolled or wrapped in orange or brown paper and preserved from the action of dampness and of the air. It does not keep well, however, no more than two or three months, perhaps, in good condition; but the sooner it is employed the finer the proofs, the better the whites and more rapidly is the paper impressed.

There is in the market a paper which keeps for a long time. It is prepared by adding a small quantity of gum arabic or of dextrine to the sensitizing solution. Good for the reproduction of line work, it does not give very satisfactory results for pictures in half tones.

[pg 32]The following compound gives a paper much more sensitive, but not keeping so long, than that prepared according to the formula previously given:

| Tartaric acid | 25 parts |

| Ferric chloride, solution at 45 deg. Baumé | 80 parts (in volume) |

| Water | 100 parts |

When the acid is dissolved, add gradually concentrated aqueous ammonia, just enough to neutralize the solution—170 volumes, about. The chemical change consists in the formation of ferric tartrate. Let cool the solution, then, after adding the following, keep it in the dark:

| Potassium ferricyanate | 21½ parts |

| Water | 100 parts |

Another and very sensitive preparation is the following:

| A. | Iron perchloride, cryst | 40 parts |

| Oxalic acid | 10 parts | |

| Water | 100 parts | |

| B. | Potassium ferricyanate | 20 parts |

| Water | 100 parts | |

| Mix |

Printing.—The process we describe yields negative impressions, that is a positive image from a negative cliché, and a negative image from a positive cliché, exactly as the silver printing-out process ordinarily employed in photography. Consequently, for the production of non-reversed proofs from plans, etc., the original drawing should be placed face downwards on the glass plate of the printing frame, and, upon the back, the sensitive paper is laid and pressed into perfect contact by means of a pad, felt or thick cloth.

The printing frame is that used by photographers. The lid is divided, according to the side, in two, three and even four sections, held by hinges and fastened for printing by as many cross-bars, in order that by opening one section, from time to time, the operator can follow the progressive changes resulting from the action of light on the iron salts. To print, the frame should be placed in the light in such a manner as the luminous rays fall perpendicularly upon the drawing or cliché. The reason of this is obvious, since the sensitive paper is not in direct [pg 33] contact with the design, but separated by the material upon which it is drawn.

During the insolation—whose time depends necessarily from the more or less transparency of the cliché, and, also, from the intensity of the light7—the paper assumes first a violet tint, which gradually intensifies to a dark shade; then this tint fades, becomes brownish, then pale lilac, while the parts under the lines—that is, the design—upon which the light has, therefore, no action, are visible by keeping the original yellow-green tint of the prepared paper. It is when the lilac color is produced that the exposure is sufficient.

To ascertain when the exposure is correct, a few black lines can be traced on one of the edges of the margin of the design, and strips of the sensitive paper placed upon them to serve as tests in operating, as it will be explained in the description of the Cyanofer process. When one of them is taken out and show, by being washed in water, a clear white line on a deep blue ground, the exposure is at an end. One understands that the blue color of the ground is more or less intense according to time of insolation, for the chemical actions between the reduced and the non-reduced iron salts is so much more complete as the salts acted on are more or less deoxidized, that is, reduced to ferrous salts; and that to obtain the maximum of effect, which, therefore, depends on the allowable time of exposure, the drawing ink should be opaque and non-actinic as far as possible, because when, on testing, the lines are tinted the exposure should be discontinued. However, a slight coloration of the lines is not very objectionable, for it disappears by a longer washing after the development.

The image is developed and fixed by washing in water two or three times renewed. The water must be free from calcareous salts; these salts converting the iron into carbonates which impart an ochrey tinge to the proof. Rain water—any water in which no precipitate is thrown down by the addition of a few drops of a weak solution of silver nitrate—may be used with safety.

[pg 34]During the development the ground takes a blue color which rapidly intensifies, while the iron compound, not acted on and imparting a yellow green tint to the design, is washed out from the white paper. If the print has not been sufficiently exposed the ground remains pale blue, more or less; the reason has been explained. In this case the development should be done quickly, as the blue is always discharged by washing. On the other hand, whenever the whites are tinted by excess of exposure, they can be cleared partly or entirely by a prolonged immersion in water, but the ground is also to some extent lightened.

When the proof is well developed and fixed, that is, when the soluble iron salts are eliminated, the blue color can be brightened by adding to the last but one washing water a small quantity of citric acid, or of potassium bisulphate, or a little of a solution of hypochlorite of lime (bleaching powder).

The action of light in this, as well as in the other photographic processes with metallic salts described in this work, is one of deoxidation, as shown by Herschel. The chemical changes which produce the blue precipitate is quite complicated. It is evident that both the ferric citrate and the ferric cyanate are partly reduced to ferrous salts under the luminous influence, and react in presence of water with the unreduced part of each of these compounds, the ferric citrate with the ferrous cyanate forming Prussian blue (ferric-ferrocyanate), and the ferric cyanate with the ferrous citrate giving rise to Turnbull's blue (ferrous ferricyanate). The blue of the print is consequently a mixture in a certain proportion of the two compounds; and as the color of Prussian blue is quite different from that of Turnbull's, it follows that by varying in a certain measure the percentage of the two ferric salts forming the sensitizing solution, the color of the blue may be varied thereby. Hence the difference in the formulas given by different authors.8

The blue color of the image can be changed into black or dark green. But to that purpose the paper should be, although [pg 35] not exactly necessary, well sized as before directed, and sensitized with extra care to prevent the imbibition of the iron solution into the paper. After exposure the proof should necessarily be thoroughly washed to eliminate the soluble iron salts, then immersed for a moment in water acidified with nitric acid, 1:100, and this done and without washing treated by a solution of aqueous ammonia at 2 per 100 of water. In this the blue color disappears, being changed into a red brownish tint, which indicates that the Turnbull's and Prussian blues are transformed, the former into ferroso-ferric hydrate, with formation of ferrocyanate, and the latter into ferric hydrate. It is by the action of tannin (gallotannic acid) on the ferric oxides thus formed that the black is produced, and by that of catechu-tannic acid contained in the extract of catechu that one obtains a dark green, almost black color.

To obtain the black tone it suffices to immerse the proof on its removal from the ammoniacal in a solution of tannin at 5 per 100 of water, and when toned, to wash it in a few changes of water.

The process to turn the blue color into a green was devised by Mr. Paul Roy. It is as follows: Dissolve 7 parts of borax in 100 parts of water, and acidify the solution with sulphuric acid added drop by drop until the litmus paper becomes red; then, in the same manner, neutralize with aqueous ammonia not in excess, but just enough to show an alkaline reaction; this done dissolve 1 part of powdered catechu and filter. In this the proof is immersed after development until the desired effect is attained. Wash, etc.

To clear the lines, or to make additions, or to write on the blue margin of the proof a solution of potassium oxalate is employed. It dissolves the blue without leaving scarcely any trace of it. The solution can be prepared by mixing the two solutions whose formula is given below:9

| A. | Oxalic acid | 10 parts |

| Water | 100 parts | |

| B. | Caustic potassa | 12½ parts |

| Water | 100 parts |

The blue prints are permanent. When drying they darken a little from oxidation; exposed to sunshine for some hours, they bleach considerably; but in the shade the faded pictures progressively absorb oxygen from the air and assume their original intensity and color in a period so much the longer as the insulation has been more prolonged; it may take weeks if the picture were much bleached.

THE CYANOFER. (Pellet's Process.)

This process gives blue impressions on a white ground from positive clichés, and white impressions on a blue ground from negative clichés. It is termed “positive ferrotype process.”

The cyanofer is an application of one of the numerous and useful inventions for which photography is indebted to A. Poitevin. In 1863 he discovered that certain organic substances were rendered insoluble by ferric chloride, and that they again became soluble; when under the influence of light the ferric chloride has been reduced to a ferrous salt. This curious phenomenon is the base of the process now to be described. As usual the process has been modified by compounding the sensitive solution in various ways and by minor details in the manner operating. But although these modifications have rendered the process easier to work with, there is not a great difference in the results obtained. We give two formulas. Aside from the addition of gum arabic, which was suggested by Mr. Pellet, and which constitutes the capital improvement of the process, the formula is substantially that devised by Mr. Poitevin.

Prepare three solutions as follows:

| A. | Gum arabic, best quality | 50 parts |

| Water | 170 parts | |

| B. | Tartaric acid | 12 parts |

| Water | 80 parts | |

| C. | Ferric chloride solution at 45 deg. Baumé | 35 parts in volume |

Mix gradually B to C, then C, by small quantities, in agitating briskly. It is important to prepare the solution as directed, for by adding the ferric chloride before tartaric acid, the gum arabic would be at once coagulated. When the ferric chloride is mixed, the solution at first thickens, but [pg 38] becomes sufficiently fluid for use in a certain period. It does not keep, and should be employed the day it is made if possible.

The paper, which should be well sized and calendered, and which, when not giving good results by too much absorbing the sensitive solution, must be starched as before directed, is coated either by brushing or by floating. By the first method a roll of paper five yards long can be prepared without great trouble, and give, perhaps, better results than if prepared by floating; but the latter method is by far the the most convenient: one does not generally prepare by brushing sheets of paper larger than about 30×40 inches.

For brushing, the paper is pinned on a board, then, with a large badger brush dipped in the sensitive solution, the latter is applied as evenly as possible; after which, by lightly passing the brush over, the striae are removed, the coating well equalized, and the paper hung up to dry. The coating should not be very thin, and, above all, not too thick, for then it would require an unusually long exposure to allow the light acting through the whole thickness of the film, which is a sine qua non to obtain a clear ground, i.e., not stained blue.

To prepare by floating, pour the solution in a shallow tray, which needs not to be more than 20×34 inches, 30 inches being the width of the drawing paper usually employed; then roll the paper and place it on the solution. Now, taking hold of it by two corners, draw it out slowly: the paper will unroll by itself. This operation can be done by diffused daylight, but, of course, the paper should be dried in a dark room. It dries rapidly. Endless rolls are prepared by machinery. To expose, the drawing is placed in the printing frame, face downwards, and the sensitive paper laid over it. The whole is then pressed into contact by interposing a cushion between the lid of the frame and the paper, and exposed so that the rays of light fall perpendicularly upon it.

The cyanofer preparation is quite sensitive. From half a minute to two minutes exposure, according to the intensity of the light and the thickness of the coating, is sufficient in sunshine to reproduce a drawing made on the ordinary tracing paper. In the shade, by a clear sky, the exposure is about [pg 39] five times longer, and varies from half an hour to an hour and more in cloudy weather, but then the design is seldom perfectly sharp.

The progresses of the impression is followed by opening one side of the printing frame and examining the proof. The exposure is sufficient when the paper is tinged brown on the parts corresponding to the ground of the design. The image appears then negative, that is, yellowish on a tinged ground.

Another and more safe method of ascertaining the correct time of exposure, which can be employed concurrently with the other, is to place a few strips of the same sheet of sensitive paper between the margin of the design, upon which a few lines have been traced, and the paper, and, without opening the frame, to draw one of them, from time to time, and dip it in the developing solution. If the whole strip be tinted blue, the proof is not sufficiently exposed; but if the lines soon appear with an intense coloration on the yellowish ground of the paper, and the latter do not turn blue in a minute, at the most, the exposure is right. By excess, the lines are with difficulty developed or broken.

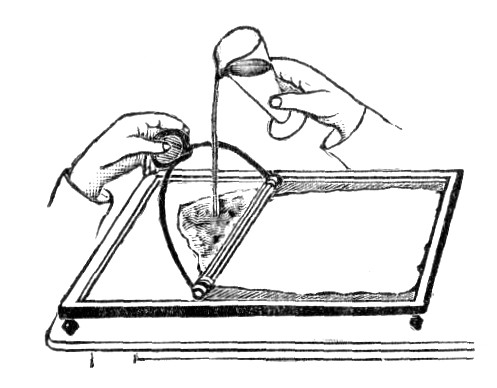

For developing, we provide with three wooden trays lined with lead or gutta-percha, or, more economically, coated with yellow wax. The wax is melted, then applied very hot, and, when it is solidified and quite cold, the coating is equalized with a hot iron, whereby the cracks produced by the contraction of the wax when cooling are filled up.

One of these trays should contain a layer, about three-quarters of an inch thick, of an almost saturated solution of potassium ferrocyanate (the developer); the next be filled with water, and the third with water acidified by sulphuric acid in the proportion of three per cent. in volumes.

All this being ready, the margin of the proof is turned upwards—so as to form a disk of which the outside is the impressed surface—in order that the ferrocyanate solution does not find its way on the back of the proof, which would produce stains. Now the proof is laid, the lower edge first, on the developer, and gradually lowered upon it, when, taking immediately hold of it by the two corners nearest to the body, [pg 40] it is lifted out and held upright to allow one following the development of the image; and, presently, if any air-bubbles are seen on the proof, they should at once be touched up with a brush wetted with the ferrocyanate solution; the reason explains itself.

The image appears at once. As soon as the fine lines are well defined, the blue intense, and, especially, when the ground has a tendency to be tinged blue, the proof is placed in the tray filled with water and in this turned over two or three times, when it is immersed in the diluted sulphuric acid. In this bath the print acquires a deep blue coloration, consisting of Prussian blue, and the ground becomes tinted with a blue precipitate without adherence, which is easily washed off by throwing the liquid on the proof with a wooden spatula, or, better, by rubbing with a rag tied to a stick. When the ground is cleared, and after three or four minutes immersion to dissolve the iron salts acted on, the proof is rinsed in water several times renewed to free it from acid, and hung to dry.

There are two causes of failures in this process, viz., over and under-exposure. In the former case the fine lines are broken or washed out in clearing the proof (which may also arise from the drawing made with an ink not opaque enough); in the latter the ground is more or less stained.

The blue stains, the lines for corrections, etc., are erased with the the potassic oxalate (blue salving, as it is termed) whose formula has been given.

The additions, corrections and writing are made with a Prussian blue ink prepared by mixing the two following solutions:

| A. | Ferric chloride, dry | 4 parts |

| Water | 350 parts | |

| B. | Potassium ferrocyanate | 15 parts |

| Water | 250 parts |

The precipitate being collected on a filter and washed until the water commences to be tinged blue, is dissolved to the proper consistency in about 400 parts of water. This ink does not corrode steel pens.

It has been stated that the cyanofer process keeps for years [pg 41] if preserved from the combined action of dampness and the air. The writer found in his practice that the ferric salts in presence of the organic matters (the sizes) acts as does potassium bichromate and renders, in a certain period, the cyanofer film insoluble even after a prolonged insulation. Paper freshly prepared is always more sensitive and gives better whites and generally finer results.10

The prints can be toned black in operating as in the cyonotype, but the results are seldom good.

Captain Pizzighelli's formula is as follows: Prepare

| A. | Gum arabic | 15 parts |

| Water | 100 parts | |

| B. | Ammonia ferric citrate | 45 parts |

| Water | 100 parts | |

| C. | Ferric chloride | 45 parts |

| Water | 100 parts |

For sensitizing mix in order:

| Solution A | 100 parts |

| Solution B | 40 parts |

| Solution C | 20 parts |

The mixture very much thickens at first, but becomes sufficiently fluid for use in a few hours. It keeps well for two or three days. Leaving out B and replacing it by rain water, this makes also a good solution for the cyanotype.

THE BLACK OR INK PROCESS. (Ferro-tannate Process.)

This process gives black positive impressions on white ground from positive clichés, and negative impressions from negative clichés. It has been attributed to Mr. Colas, but in reality it was invented by Mr. Poitevin, who describes it as follows in his communication of May, 1860, to the Société Francaise de Photographie:

“I make a solution containing—”

| Iron perchloride, cryst | 10 parts |

| Tartaric acid | 3 parts |

| Water | 100 parts |

“I apply the paper on this mixture and let it dry spontaneously in the dark, and at the moment of using it I completely desiccate it at a gentle heat. Thus prepared the paper is of a deep yellow color. Light decolors it rapidly, and ten or twelve minutes' exposure through a positive cliché suffices to well impress it, that is, to reduce in the whites the iron perchloride to the state of protochloride.”

“To print, one is guided by the decoloration of the paper, and even for more facility I add to the solution of iron perchloride and tartaric acid a small quantity of a solution of potassium sulphocyanide for the purpose of obtaining a red tint, which is more visible and disappears also under the influence of light in proportion to the decomposition of the perchloride. One obtains then after exposure a red design on the white ground of the paper. This red color is not permanent. It even disappears by keeping the proof in the dark.”

“To develop and then to fix the design thus obtained I wash rapidly the paper in ordinary water, or better, in water holding chalk in suspension. The red coloration disappears, a part of the iron perchloride is washed out, and in the parts which have not been acted on by light the perchloride is transformed into sesquioxide. I replace then the water by solution of gallic acid or of tannin and the image progressively appears in ink-black. When I judge the image to be sufficiently intense I wash the proof in rain water, in preference to ordinary water, [pg 43] which might cause the gallic acid and tannin to turn brown. I sponge between sheets of blotting paper and let the proof dry spontaneously.”

“If in place of gallic acid I use a diluted solution of potassium ferricyanide (red prussiate of potash), Prussian blue is formed in the parts acted on by light. The preparation is even sensitive enough to permit one to obtain an impression in the camera obscura in developing by the ferricyanide.”

“As to the proofs in gallate (or tannate) of iron, they can be transformed into Prussian blue in a solution of potassium ferrocyanide (yellow prussiate of potash) slightly acidified by sulphuric acid.”

The paper most suitable for this process is that which has been previously well sized with starch, as explained in a special paragraph of this pamphlet. Paper prepared with a film of coagulated albumen gives also good results. It may be prepared by brushing as well as by floating, but in either case the paper should be wetted on the surface only and dried rapidly at a temperature of about 115 deg. Fahr. (46 deg. C.) and kept in a dry place. It does not keep for more than from ten to fifteen days, owing to the hygroscopicity of the iron compound. Mr. Colas, who prepares the paper for the Parisian market, I think, states that he avoids its deterioration by keeping it wrapped in blotting paper, between two sheets of India rubber, to exclude air and dampness. Silvered albumen and plain paper, well desiccated, could be kept in that way for a certain period, especially if the blotting paper is impregnated with sodium bicarbonate and well dried.

Mr. A. Fisch advises to discard the preliminary washing and to develop just on the removal of the proofs from the printing frame. In operating in this manner the development is best made by floating, taking care that the solution does not run off the back of the proof.

The developer may consist of a dilute solution of nutgalls or of

| Tannin or gallic acid | 4 parts |

| Oxalic acid | 0.15 parts |

| Water | 1,000 parts |

After developing the proof should be washed rapidly—under a jet of water, if possible—for were the iron salt and the [pg 44] reagent not soon removed, or any remain in the paper, the ground would be tinted violet. And whatever be the care taken, it very seldom occurs that the whites are pure when the proof is dry. This for half-tone pictures has not a great importance, but for the reproductions of plans it is sometimes objectionable. In fact it must be acknowledged that none of the processes now at our disposal—if we except the so-called Artigues process described further on—gives an entirely satisfactory result. A simple and expeditious process, yielding intense black impressions on a white ground, is yet to be found for the reproduction of plans, maps, etc., without resorting to a negative cliché or drawing.

THE CUPROTYPE. (Burnett's Process.)

This process gives positive impressions from negative clichés.

| Uranic nitrate | 10 parts |

| Cupric nitrate | 2 parts |

| Water | 100 parts |

Float for a minute strong, well-sized paper on this solution and let it dry spontaneously in the dark. Expose until the image is visible, then develop by floating on a solution of potassium ferricyanide at 5 per 100 of water—the image appears at once with a rich brown color. When developed, wash it in several changes of water until the unaltered salts are eliminated. The proof is then fixed, and, if too intense, can be reduced in water slightly acidified with hydrochloric acid. A fine black image is obtained by toning in a solution of platinic chloride at 1 per 100 of water.

The chemical actions giving rise to the formation of the metallic ferrocyanide, of which the image consists, are quite complicated. Under the luminous agency the uranic nitrate is first reduced, then the uranous oxide acts on the cupric nitrate, forming cupric oxide, which is finally reduced to the metallic state. This metal now converts the ferricyanate in the ferro compound, which, by another action, forms both cupric and uranic ferrocyanate.

The following uranium process gives black impressions:

In a saturated solution of tartaric acid dissolve freshly precipitated ferric oxide, and keep the solution—ferric tartrate—in the dark. To prepare the sensitizing solution, dissolve 20 parts of uranic nitrate and from 1 to 3 parts of tartaric acid in 100 parts of water, and add a small quantity of ferric tartrate, the proportion varying with the tint desired: an excess gives a blue black. With this solution brush the [pg 46] paper over, and, when dry, expose under the negative cliché, then develop with a solution of potassium ferricyanate at 4 per 100 of water. To fix, it suffices to wash in water, renewed three or four times.

As pointed out by Mr. B. J. Burnett (see Introduction), many photographic processes can be devised by basing them upon the various chemical changes, of which uranous oxide, reduced by light from the uranic nitrate or sulphate, is susceptible by means of metallic or organic reagents.

In the Appendix some of the most important processes, with or without silver salts as reagents, will be described.

THE ANILINE PROCESS.

The aniline process was published in 1865, by Mr. Willis, the inventor of the platinotype.11 It is based on the oxidation of aniline by chromic acid, thus: A sheet of paper brushed with a solution of potassium bichromate and sulphuric acid, dried, and after insolation under a cliché exposed to the fumes of aniline which, in reacting with the chromic compound not reduced by light, forms a blue-black image. The process gives, consequently, a positive impression from a positive cliché.

There are various methods of operating; we will briefly describe them.

| SENSITISING SOLUTION. | ||

|---|---|---|

| 1. | Potassium bichromate | 6 parts |

| Sulphuric acid | 6 parts | |

| Magnesium chloride | 10 parts | |

| Water | 150 parts | |

Willis recommended 10 parts of solid phosphoric acid instead of sulphuric acid; the latter forms a preparation about twice more rapidly reduced.

| 2. | Potassium bichromate | 10 parts |

| Manganous sulphate | 4 parts | |

| Potassium bisulphate | 20 parts | |

| Water | 300 parts | |

| 3. | Ammonium bichromate | 5 parts |

| Ammonium chloride | 5 parts | |

| Cupric sulphate | 1 part | |

| Sulphuric acid | 8 parts | |

| Water | 150 parts |

Good well-sized paper should be employed. Rives is too tender and absorbs too much. Steinbach is better. For small sizes, whatever be the paper selected, it is well to size it with starch and, if possible, to calender it on a hot steel plate, or, in lieu, to iron it. This is not, however, a sine qua non. [pg 48] The paper is sensitized by brushing or by floating. To sensitize by floating, it should be left but for a few seconds on the solution and removed by dragging it on a glass rod in order to remove the superfluous liquid. Only the surface of the paper should be impregnated, otherwise the whites would be more or less tinted and the image imbedded not as sharp.

Sensitized, the paper must be dried as rapidly as possible. It does not keep, and should be employed the day it is prepared or the day after, keeping it well wrapped in paper.

As said above, it is exposed under a positive cliché, plans, designs, etc., drawn on tracing paper or linen. The more transparent the material, the more rapid the chemical changes. During the insolation—and it is very short—the chromic compound is reduced, the parts corresponding to the ground, that is, the transparent parts of the cliché, are discolored, while those under the design remain unaltered; the image being, therefore, faintly visible, and being formed of the chromic mixture, it is developed by the fumes of aniline in a blue black tone. Therefore, if the paper be not sufficiently exposed, the ground is colored like the image, although not as deeply, since the dye formed is proportionate to the more or less quantity of unreduced compound, and if exposed too long the image is imperfectly developed or not at all by excess.

The discoloration of the ground, which turns to a greenish hue, easily indicates when the exposure is sufficient. But, to ascertain it, the beginner should use tests as in the cyanofer process. Mr. Endemann regulates the time of exposure by partly covering a strip of the sensitive paper with a piece of the tracing material upon which the design is made, and exposing the whole until the covered part of the paper assumes the same shade as the part directly exposed to light.

To develop the print is placed in the bottom of a tray, which is then covered with a lid upon which is pinned blotting paper well imbued with an aniline and benzine mixture, or the reverse; that is, exposing the print fastened to the lid and placing the aniline on the bottom of the tray. The tray should be hermetically closed; that is a condition to obtain a fine and equal coloration. For this purpose the lid should be [pg 49] well lined with sheets of blotting paper and a weight placed over it during the operation. Large prints are necessarily developed in a fumigating box made ad hoc. The aniline solution consists of

| Aniline (commercial for red) | 8 parts |

| Benzine, rectified | 100 parts |

In place of benzine, ether U.S.P., sp. grav. 0.837, may be used.

When the proof is not over-exposed the development commences in a few minutes. The image first takes a dirty black olive color which turns blue in water, then the tone darkens to a dark-brownish tint. The time of exposure to the aniline fumes depends on the time of insolation; if short, the ground is soon tinted, and consequently the development should then be stopped; if over-exposed, the development proceeds slowly. The darkest tone is obtained by a rather full exposure which admits a long fumigation. Sometimes the image takes a green color; it suffices then to wash the proof in water rendered alkaline by a few drops of aqueous ammonia to obtain the normal color.

To somewhat improve the tone of the image and, if objectionable, to remove the chromic oxide which tinges the ground greenish, the proof should be immersed in a dilute solution of sulphuric acid 1:100, then washed twice, and finally passed in ammoniacal water 1:100.

Mr. Hermann Endemann has published, in 1866, the following process in the Journal of the American Chemical Society, pp. 189 et seq.:

The paper, which must be well sized with glue, 1:50, is sensitized with the following solution and exposed when dry, but still slightly damp:

| A. | Potassium bicarbonate | 1 ounce or 480 parts |

| Salt | 1 ounce or 480 parts | |

| Sodium vanadate | 2/3 grain or 0.66 part | |

| Water | 20 ounces or 9,600 parts | |

| B. | Sulphuric acid | 2 ounces or 960 parts |

| Water | 10 ounces or 4,800 parts |

When cold mix to A.

[pg 50]“From the composition of the solution,” says Mr. Endemann, “it is evident that it must be strongly acid; but when this solution is exposed to light, in the presence of the organic substances of the paper, the acidity of the solution disappears, we obtain potassium and sodium sulphates, basic chromium sulphate, salt and vanadic acid. While, therefore, the unchanged parts of the paper remain acid, the changed parts acquire a neutral reaction, and while the first will readily assimilate bases, the second will not. Exposed in an atmosphere laden with water and aniline, the aniline will be absorbed in those parts where the solution remains acid and in proportion to the remaining acidity.”

To develop the image the paper is spread over the opening of a frame tightly placed on a pan, in the bottom of which is heated a solution of aniline in water, 1:50, until the image appears brown, and for further development in a box laden with steam water, which, according to Mr. Endemann, requires two hours to obtain a deep black coloration. To remove the chromium compound the picture is immersed in a solution of aqueous ammonia, 1:6, then washed and dried.

A few years ago the aniline process was improved by developing the image with the aniline-benzine mixture vaporized by steam in a box made specially for that purpose, whereby a reproduction can be obtained in less than ten minutes.

In the photographic department of Messrs Poulson & Eger's Hecia Architectural and Ornamental Iron Works, which is directed by Charles Bilordeaux, this process is worked in the following manner:

The developing is made of sheet iron with a door sliding up and down, it being balanced by a counterpoise, and provided with a chimney. In the box is a gutter, extending the whole length of the bottom, covered with muslin and connected to a steam pipe; there is also a coil similarly connected. After the insolation, which requires about one minute in sunshine, the print is suspended in the box, the muslin brushed over with the solution of aniline, and live steam allowed to pass through the gutter for only two minutes, whereby the aniline being vaporized acts on the chromic salt and develops the image; then the steam is allowed in the coil, and, in from three to four [pg 51] minutes, the paper is dry and the picture finished. The image stands on a slightly greenish ground, which is not objectionable for the purpose the reproductions are made.

The sensitizing solution is similar to that published by Mr. Endemann, viz.:

| Potassium bichromate | 460 grams |

| Sodium chloride | 460 grams |

| Ammonium vanadate | 0.75 gram |

| Sulphuric acid | 1 liter |

| Water | 13 liters |

THE PRIMULINE OR DIAZOTYPE PROCESS.

Primuline, discovered in 1887 by Mr. A. G. Green, an English chemist, is a dye of a primrose color, possessing a great affinity for cotton fibers, to which it is readily fixed by simply immersing the material for a few moments in a hot solution of the dye. If the material so dyed be placed in an acidified solution of nitrous oxide, the primuline is diazotized, forming a derivative compound of a deeper color, which fades in the light, and which in presence of amines and phenols gives rise to a variety of dyes whose color depends on the reagent employed, while, when acted on by light, the resulting compound is entirely deprived of this property. In other words, the diazotized primuline acts as a mordant only when not altered by the luminous action.

The chemical change light effects in the diazotized primuline is not well known. It is pretty certain, however, that nitrogen is set free, for if gelatine imbued with primuline be immersed in water after insulation, nitrogen is set free and can be collected as usual in a tub filled with water and inverted on the substance.