This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org

Title: A Textbook of Assaying: For the Use of Those Connected with Mines.

Author: Cornelius Beringer and John Jacob Beringer

Release Date: July 3, 2006 [eBook #18751]

Language: English

Character set encoding: ISO-8859-1

***START OF THE PROJECT GUTENBERG EBOOK A TEXTBOOK OF ASSAYING: FOR THE USE OF THOSE CONNECTED WITH MINES.***

Transcriber's Note:

Parentheses have been added to clarify fractions. Letters in brackets with a = sign before it means that the letters have a macron over them, e.g. H[=A=c] signifies that the Ac has a macron over it.

Minor typographical errors have been corrected. Footnotes have been moved to the end of the chapter, and all advertisements have been moved to the end of the book.

ASSOC. OF THE ROYAL SCHOOL OF MINES; FELLOW OF THE CHEMICAL SOCIETY AND OF THE INST. OF CHEMISTRY; PRINCIPAL OF THE CAMBORNE MINING SCHOOL; AND LATE PUBLIC ANALYST FOR THE COUNTY OF CORNWALL.

LONDON:

CHARLES GRIFFIN AND COMPANY, Limited,

EXETER STREET, STRAND.

1904.

The continued popularity of the present work, the last edition of which was published only a little over a year ago, continues to be a source of gratification to the publishers, who have much pleasure in issuing the present edition.

January 1904.

The principal changes in this edition are additions to the articles on Gold, Cyanides, and Nickel, and a much enlarged Index. The additional matter covers more than forty pages.

J. J. BERINGER.

Camborne,

January 1900.

The Text-book now offered to the public has been prepared to meet the existing want of a practical "handy book" for the Assayer.

To mining men the word "assaying" conveys a sufficiently clear meaning, but it is difficult to define. Some writers limit it to the determination of silver and gold, and others imagine that it has only to do with "furnace-work." These limitations are not recognised in practice. In fact, assaying is becoming wider in its scope, and the distinction between "assayers" and "analysts" will in time be difficult to detect. We have endeavoured rather to give what will be of use to the assayer than to cover the ground within the limits of a faulty definition.

At first our intention was to supply a description of those substances only which have a commercial value, but on consideration we have added short accounts of the rarer elements, since they are frequently met with, and occasionally affect the accuracy of an assay.

Under the more important methods we have given the results of a series of experiments showing the effect of varying conditions[Pg vii] on the accuracy of the process. Such experiments are often made by assayers, but seldom recorded. Statements like those generally made—that "this or that substance interferes"—are insufficient. It is necessary to know under what conditions and to what extent.

Students learning any particular process cannot do better than repeat such a series of experiments. By this means they will, at the same time, acquire the skill necessary for performing an assay and a confidence in their results based upon work under different conditions.

The electrolytic method of copper assaying given under Copper is a modification of Luckow's; it was introduced by us into the offices of the Rio Tinto Copper Company, and has been in use for many years with success. This modification is now employed in copper-works in Spain, Germany, and England, and is used in place of the dry assay for the commercial valuation of copper ores.

We have adhered to the gram and the "c.c." as the units of weight and volume. Those who prefer working with grains and grain-measures can use the figures given, multiplied by ten. For example:—When 1 gram is mentioned, 10 grains should be used, and 10 grain-measures take the place of 1 "c.c." It is not advisable to mix the two systems, as by using gram weights and grain-measures.

We have intentionally to a large extent omitted to mention the names of those who have originated or modified the various processes. The practice of naming a process after its discoverer has developed of late years, and is becoming objectionable. It is a graceful thing to name a gas-burner after Bunsen, or a condenser after Liebig; but when the practice has developed[Pg viii] so far that one is directed to "Finkenerise" a residue, or to use the "Reichert-Meissl-Wollny" process, it is time to stop.

We are indebted to the standard works of Allen, Crookes, Fresenius, Lunge, Michell, Percy, and Sutton, and wish to express our sense of special indebtedness to Mr. Richard Smith, of the Royal School of Mines. One or two of the illustrations are taken from Mr. Sexton's excellent little book on Qualitative Analysis. Our obligation to some others is mentioned in the text.

Finally, we have to thank for assistance in the experimental work Messrs. Bailey, Beswick, Clarke, Grant, Higgins, and Smith.

THE AUTHORS.

Camborne, Nov. 1889.

| PART I. | |

| CHAPTER I. | |

| INTRODUCTORY. | |

| Page | |

| Object of assaying | 1 |

| Sampling | 1 |

| Drying: determination of moisture | 5 |

| Calculation and statement of results | 7 |

| Laboratory books and report forms | 9 |

| Quantity to be taken for an assay | 11 |

| Exercises | 14 |

| CHAPTER II. | |

| METHODS OF ASSAYING.—DRY GRAVIMETRIC METHODS. | |

| Methods of assaying | 15 |

| Gravimetric methods | 15 |

| Mechanical separations | 16 |

| Dry assays | 16 |

| (a) Fluxes | 16 |

| (b) Reducing agents | 21 |

| (c) Oxidising agents | 22 |

| (d) Apparatus | 24 |

| CHAPTER III. | |

| WET GRAVIMETRIC METHODS. | |

| Wet gravimetric methods | 27 |

| (a) Solution | 29 |

| (b) Precipitation | 30 |

| (c) Filtration | 31 |

| (d) Drying and igniting | 32 |

| CHAPTER IV. | |

| VOLUMETRIC ASSAYS. | |

| Titrometric assays | 35 |

| (a) Standard solutions | 36 |

| (b) Standardising | 37 |

| (c) Methods of working | 42 |

| (d) Indirect titration | 43 |

| Colorimetric assays | 44 |

| Gasometric assays | 44 |

| CHAPTER V. | |

| WEIGHING AND MEASURING. | |

| Weighing | 47 |

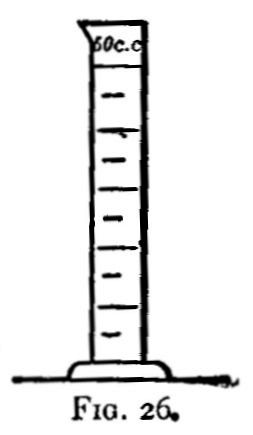

| Measuring liquids | 49 |

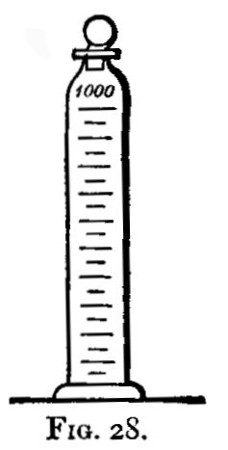

| (a) Graduated flasks | 49 |

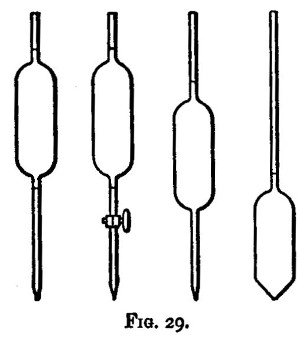

| (b) Pipettes | 50 |

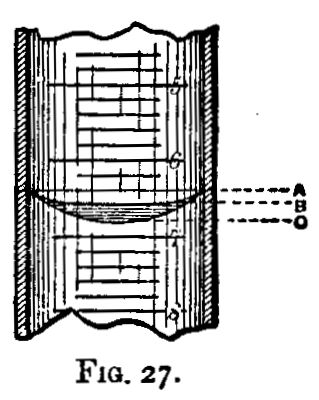

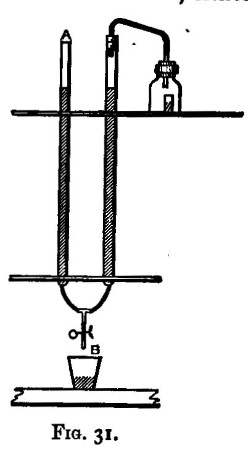

| (c) Burettes | 51 |

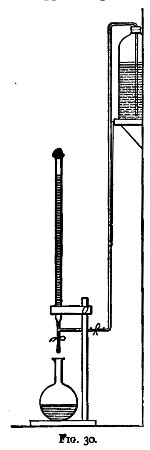

| Measuring gases | 52 |

| CHAPTER VI. | |

| REAGENTS. | |

| Acids, &c. | 54 |

| Bases, salts, &c. | 59 |

| CHAPTER VII. | |

| Formulæ, equations, &c. | 68 |

| CHAPTER VIII. | |

| SPECIFIC GRAVITY. | |

| Introductory | 75 |

| Determination of specific gravity— | |

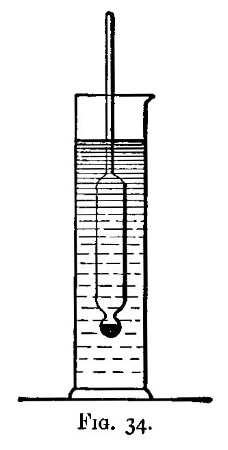

| (a) Hydrometers | 76 |

| (b) Specific gravity bottles | 78 |

| Calculations depending on specific gravity | 84 |

| PART II. | |

| CHAPTER IX. | |

| SILVER, GOLD, PLATINUM, CYANIDES, MERCURY. | |

| Silver—Detection | 87 |

| Dry assay | 87 |

| (1) Scorification | 88 |

| (2) Pot assays, average ores | 90 |

| " ores with metallic oxides | 91 |

| " ores with metallic sulphides | 91 |

| Explanatory notes on the fusion | 93 |

| The effect of charcoal, flour, &c. | 94 |

| The effect of nitre | 95 |

| The effect of mineral sulphides | 95 |

| (3) Cupellation | 98 |

| The loss of silver | 101 |

| Condition affecting the loss | 102 |

| Methods of correction | 103 |

| Lead required for cupellation | 105 |

| (4) Calculation of the results in ounces to the ton of 2240 lbs. Table | 107 |

| Ores with metallic particles | 108 |

| (5) Explanatory notes | 110 |

| (6) Examples of dry silver assays | 113 |

| Wet assays | 116 |

| Gravimetric method | 117 |

| Gay-Lussac's method | 119 |

| Volhard's method | 121 |

| A modified Gay-Lussac | 123 |

| Volhard's method applied to arsenic | 124 |

| Gold—Detection | 126 |

| Amalgamation assay | 126 |

| Dry assay | 127 |

| (1) Size of charges | 127 |

| (2) Sampling | 127 |

| (3) Assay tons | 131 |

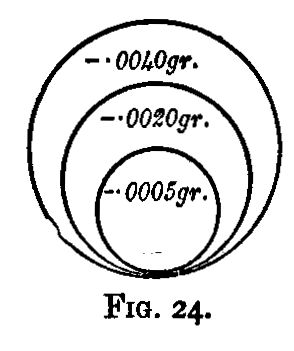

| (4) Small buttons, weighing | 131 |

| " " measuring | 133 |

| (5) Concentration in lead | 136 |

| Quartz ores | 136 |

| Ores with oxide of iron | 138 |

| Ores with metallic sulphides | 139 |

| (6) Cyanide charges, residues, &c. | 140 |

| (7) Cupellation | 142 |

| Cupels | 142 |

| Cupellation temperature | 143 |

| Cupellation loss | 145 |

| (8) Inquartation | 146 |

| (9) Flatting | 149 |

| (10) Parting, in flasks | 151 |

| " in test tubes | 152 |

| " in glazed crucibles | 153 |

| " Loss, &c. | 154 |

| (11) Check assays, surcharge | 154 |

| (12) Bullion assays in special apparatus | 156 |

| Silver, &c., in gold bullion | 157 |

| (13) Sampling of base bullion, &c. | 157 |

| Cyanides—Commercial cyanides | 160 |

| Double cyanides | 161 |

| Prussic acid | 162 |

| Gold-dissolving power of cyanide liquor | 162 |

| Assay for cyanide strength | 163, 165 |

| Assay of commercial cyanide | 167 |

| Alkalinity of cyanides | 167 |

| Acidity of ores | 168 |

| Metals in cyanide liquors | 169 |

| Cyanicides | 169 |

| Platinum | 170 |

| Iridium | 171 |

| Mercury | 171 |

| Dry assay | 172 |

| Wet method | 173 |

| CHAPTER X. | |

| COPPER, LEAD, THALLIUM, BISMUTH, ANTIMONY. | |

| Copper—Introductory | 175 |

| Dry assay | 176 |

| Valuation of copper ores | 181 |

| Wet methods | 183 |

| (1) Electrolytic assay | 184 |

| Volumetric methods | 194 |

| (1) Cyanide method | 194 |

| (2) Iodide method | 199 |

| (3) Colorimetric method | 203 |

| Examination of commercial copper | 205 |

| Lead | 211 |

| Dry assay | 211 |

| Wet assay | 213 |

| (1) Gravimetric method | 213 |

| (2) Volumetric method | 214 |

| (3) Colorimetric method | 218 |

| Thallium | 219 |

| Bismuth | 220 |

| Dry assay | 221 |

| Wet method | 221 |

| (1) Gravimetric determination | 222 |

| (2) Colorimetric assay | 223 |

| Antimony | 225 |

| Dry assay | 225 |

| Wet method | 227 |

| (1) Gravimetric assay | 228 |

| (2) Volumetric method | 229 |

| CHAPTER XI. | |

| IRON, NICKEL, COBALT, ZINC, CADMIUM. | |

| Iron | 231 |

| Gravimetric determination | 233 |

| Permanganate and bichromate methods | 234 |

| Stannous chloride method | 244 |

| Colorimetric determination | 247 |

| Nickel | 251 |

| Dry assay | 251 |

| Electrolytic assay | 254 |

| Titration by cyanide | 255 |

| Cobalt | 259 |

| Zinc | 261 |

| Gravimetric method | 262 |

| Volumetric method | 263 |

| Gasometric method | 266 |

| Cadmium | 269 |

| CHAPTER XII. | |

| TIN, TUNGSTEN, TITANIUM. | |

| Tin | 271 |

| Vanning | 273 |

| Dry assay | 276 |

| Detection, &c. | 279 |

| Gravimetric determination | 281 |

| Volumetric determination | 282 |

| Examples | 284 |

| Titanium | 292 |

| Tungsten | 295 |

| Niobic and Tantalic Oxides | 297 |

| CHAPTER XIII. | |

| MANGANESE, CHROMIUM, ETC. | |

| Manganese | 298 |

| Gravimetric determination | 300 |

| Volumetric determination | 300 |

| Ferrous sulphate assay | 301 |

| Iodine assay | 302 |

| Colorimetric determination | 306 |

| Chromium | 307 |

| Vanadium | 310 |

| Molybdenum | 311 |

| Uranium | 312 |

| CHAPTER XIV. | |

| EARTHS, ALKALINE EARTHS, ALKALIES. | |

| Alumina | 314 |

| Thoria | 317 |

| Zirconia | 317 |

| Cerium | 318 |

| Lanthanum and Didymium | 319 |

| Yttria | 319 |

| Beryllia | 319 |

| Lime | 320 |

| Strontia | 324 |

| Baryta | 326 |

| Magnesia | 328 |

| The Alkalies | 330 |

| Sodium | 334 |

| Potassium | 336 |

| Lithium | 338 |

| Cæsium | 339 |

| Rubidium | 340 |

| Ammonium | 340 |

| PART III. | |

| CHAPTER XV. | |

| OXYGEN AND OXIDES—THE HALOGENS. | |

| Oxygen | 344 |

| Oxides | 345 |

| Water | 350 |

| The Halogens | 358 |

| Chlorine | 359 |

| Bromine | 361 |

| Iodine | 362 |

| Fluorine | 363 |

| CHAPTER XVI. | |

| SULPHUR AND SULPHATES. | |

| Sulphur | 367 |

| Gravimetric determination | 369 |

| Volumetric determination | 370 |

| Sulphates | 377 |

| Selenium | 379 |

| Tellurium | 379 |

| CHAPTER XVII. | |

| ARSENIC, PHOSPHORUS, NITROGEN. | |

| Arsenic | 381 |

| Gravimetric determination | 383 |

| Volumetric method, "iodine" | 384 |

| " " "uranic acetate" | 389 |

| Phosphorus | 394 |

| Gravimetric determination | 396 |

| Volumetric determination | 397 |

| Nitrogen and Nitrates | 400 |

| CHAPTER XVIII. | |

| SILICON, CARBON, BORON. | |

| Silicon and Silicates | 405 |

| Carbon and Carbonates | 414 |

| Coals | 418 |

| Shales | 420 |

| Carbonates | 424 |

| Boron and Borates | 429 |

| APPENDIX A. | |

| Table of atomic weights and other constants | 433 |

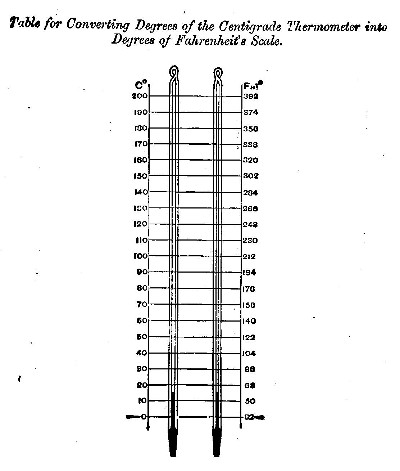

| Table for converting degrees of the centigrade thermometer | |

| into degrees of Fahrenheit's scale | 435 |

| Tables showing strengths of aqueous solutions of nitric and hydrochloric acids, | |

| of ammonia and of sulphuric acid | 436 |

| APPENDIX B. | |

| Estimation of small quantities of gold | 440 |

| Practical notes on the iodide process of copper assaying | 441 |

| Method of separating cobalt and nickel | 442 |

| APPENDIX C. | |

| A lecture on the theory of sampling | 444 |

| Index | 450 |

Assaying has for its object the determination of the quantities of those constituents of a material which add to or detract from its value in the arts and manufactures. The methods of assaying are mainly those of analytical chemistry, and are limited by various practical considerations to the determination of the constituents of a small parcel, which is frequently only a few grains, and rarely more than a few ounces, in weight. From these determinations calculations are made, which have reference to a mass of material of, perhaps, hundreds of tons. But in all cases, whether the mass under consideration be large or small, whether the material be obtained by mining, grown, or manufactured, the assayer is supposed to receive a small quantity, called "the sample," which is, or ought to be, the exact counterpart of the mass of material that is being dealt with. The taking and making of this sample is termed "sampling"; and the men whose special work it is to select such samples are "the samplers."

But although "sampling" is thus distinct from "assaying," the assayer should be familiar with the principles of sampling, and rigorous in the application of these principles in the selecting, from the sample sent him, that smaller portion upon which he performs his operations.

Sampling.—In the case of gases, there is absolutely no trouble in mixing. The only difficulty is in drawing off a fair sample where, as in flues, the body of the gas is in motion, and varies a little in composition from time to time. In this case, care must be taken to draw off uniformly a sufficient volume of the gas during a prolonged period; any portion of this larger volume may then be taken for the analytical operation.[Pg 2]

In the case of liquids, which mix more or less easily—and this class includes metals, &c., in the state of fusion—more or less severe agitation, followed by the immediate withdrawal of a portion, will yield a fairly representative sample.

In the case of solids, the whole mass must be crushed, and, if not already of fairly uniform quality, mixed, before sampling can take place. Most of the material which a sampler is called upon to deal with, is, however, in a more or less divided state and fairly uniform. In practice it is assumed that 5 per cent. of the whole (= 1/20th), if taken in portions of equal weight and at frequent and regular intervals, will represent the mass from which it was taken. Taking a heap of ore, A, and selecting one out of every twenty spade-, bag-, barrow-, or wagon-fuls, according to the quantity of stuff in the heap, there is obtained a second heap, B, containing one-twentieth of the stuff of the heap A. If we crush the stuff in B until this heap contains approximately the same number of stones as A did—which means, crushing every stone in B into about twenty pieces—B will become the counterpart of A. Selecting in the same manner 5 per cent. of B, there is got a third heap, C. This alternate reduction and pulverising must be carried on until a sample of suitable size is obtained. This may be expressed very clearly thus:—

A = 1000 tons of rocks and lumpy ore.

B = 50 " " rough stones, 1/20th of A.

C = 2.5 " " small stones, 1/20th of B.

D = 0.125 " " coarse powder, 1/20th of C.

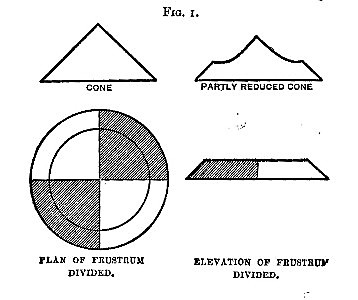

If the material to be sampled is already a dry powder, 5 per cent. of it should be heaped in a cone; each lot being added on[Pg 3] the apex of the cone already formed, so that it may distribute itself by falling evenly in all directions. When the cone is completed, convert it into a low frustrum of a cone by drawing stuff uniformly and in a direct line from the centre to the circumference. Draw two diameters at right angles to each other, and reserving any two alternate quarters, reject the others. Mix; and form another cone, and proceed until a sample is got of the bulk required.

This is the usual plan, and all samples should be treated in this way when the stuff is fine enough to fall evenly down the sides of a cone.

Samples as they reach the assay office are seldom in a fit state for the work of the assayer; they are generally too coarse, and ought always to be more than he wants for any particular determination. The portion he requires should never be taken at hap-hazard; the sample must be reduced systematically to the quantity required.

1. If the sample is a liquid: it is sufficient to shake the bottle, and take out a measured or weighed quantity for the assay.

2. If a liquid with a solid in suspension: measure the whole of it. Filter. Make up the filtrate with the wash-water or water to the original bulk. Assay it. Dry and weigh the residue, and make a separate assay of it.

3. If of a creamy consistency, free from heavy particles: mix well; spread out evenly on a glazed tile. Take up equal portions at equal distances. Mix and assay.

4. If a mud of coarse and fine particles, or of particles of unequal density: weigh and transfer to a porcelain dish, or weigh in the dish. Dry at 100° C., weigh. Treat the residue as a solid capable of being powdered.

5. If a solid capable of being powdered, or already powdered: heap up into a cone; flatten with a spatula; divide along two diameters at right angles, and carefully reject the whole of two alternate quarters, brushing away any fine powder. Mix the other quarters, and repeat (if necessary). For small quantities a fine state of division is essential.

6. If a solid with metallic particles: powder and pass through a sieve; the metallic particles will not pass through. Weigh both portions and assay separately. Sifting should be followed by a very thorough mixing.

7. If a metal or alloy in bar or ingot: clean the upper surface of the bar, and bore through the bar. Use the borings. If the ingot or bar is small, cut it through and file the section. Filings must be freed from fragments of the file by means of a magnet; and from oil, if any be present, by washing with a suitable[Pg 4] solvent.[1] Where practicable, metals and alloys are best sampled by melting and granulating. The student must carefully avoid any chance of mixing dirt or particles of other samples with the particular sample which he is preparing. One ore should be done at a time, and when finished, it should be labelled and wrapped up, or bottled, before starting on a fresh sample.

When an ore requires to be very finely ground in an agate mortar, it is often advisable to mix with a little pure alcohol and rub until free from grit; dry at 100° C. and mix well before weighing.

When an assay is required of a quantity of ore made up of parcels of different weight and quality, each parcel should be separately sampled and parts of each sample, bearing to each other the same proportion by weight as the original parcels, should be taken and mixed. For example, a lot of ore is made up of one parcel of A, 570 tons, one of B, 180 tons, and another of C, 50 tons; a sample representing the whole may be got by mixing 57 parts of a sample of A with 18 parts of a sample of B, and 5 parts of a sample of C.

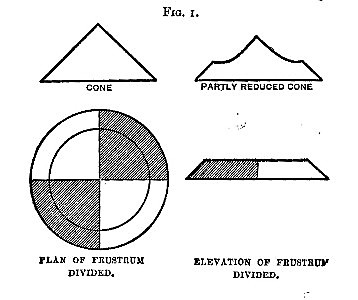

A bruising plate, like that in fig. 2, is convenient for general office work. The slab is of cast iron, about an inch thick. It is firmly supported on a solid block of wood, and pivoted for convenience in emptying. The bruising-hammer is steel-faced, about 4 inches square, and 1-1/2 inch thick. The block is firmly fixed to a small table or tressel, so that the slab is about 2 feet 6 inches[Pg 5] from the ground. The slab is cleaned, and the sample collected with the help of a stiff-haired brush.

Drying: Determination of Moisture.—In practice, the moisture is generally determined by the samplers, and the proportion is specified in grains per pound on the label attached to the sample when it reaches the assay office. The method adopted is usually to dry 1 lb. = 7000 grs. of the ore in a frying-pan heated over a gas flame, or in an ordinary oven, until a cold bright piece of metal or glass is no longer damped when held over it. The loss of weight in grains = moisture.

Properly, however, this work should be done by the assayer, if only for the following reason. It is assumed that the dry ore of the sampler and of the assayer are the same thing; according to the nature of the ore, this may or may not be the case. The assayer, however, uses the sample which he has dried for his moisture-determination, as the dry ore on which he makes his other assays, and no variation in moisture would influence the other and more important determinations. Some ores are sent to the smelter with from 5 to 15 per cent. of adherent water. In these cases it is best to spread out the sample, and taking equal portions fairly at regular intervals, weigh into a Berlin dish 20 grams. This should then be dried over a sand-bath, or if the ore is likely to be injured by excess of heat, over a water-bath until the weight is constant. The loss of weight multiplied by 5 gives the percentage of water present.

Example:—

| Weight of dish + wolfram | 32.67 | grms. |

| " " dish | 12.67 | " |

| ——— | ||

| " " wolfram | 20.00 | " |

| " " dish + wolfram | 32.67 | " |

| " " " dried | 30.15 | " |

| ——— | ||

| " " water | 2.52 | " |

| 2.52 × 5 = 12.6 | 12.6%. |

There are other ores which are not apparently wet, but in the state called "air-dried." It is easier to take fair samples of these, and, consequently, it is not necessary to use so large a quantity as 20 grams. But with a smaller quantity, extra precautions must be taken. All dry solids at ordinary temperatures absorb moisture from the air. The amount varies with the nature of the material and with the quantity of surface exposed. Light bulky powders absorb more than heavy ones, because of the greater condensing surface. It is on this account that it is well to weigh substances, which have been dried, between close-fitting watch-glasses. The[Pg 6] method of determining moisture is to weigh out into the glasses 5 grams of ore, and dry in the water-oven until there is no further loss of weight. On taking the glasses out of the oven, they should be at once closed, the clip put on, and after cooling in a desiccator weighed. If after a second trial the loss is the same, or only increased by a milligram, the determination is finished.

Example:—

| Weight of glasses + pyrites | 31.0470 | grms. |

| " " glasses | 26.0470 | " |

| ——— | ||

| " " pyrites | 5.0000 | " |

| " " glasses + pyrites, dried 1 hour | 30.8965 | " |

| " " " " dried 1-1/2 " | 30.8957 | " |

| " " " " | 31.0470 | " |

| " " " " dried | 30.8957 | " |

| ——— | ||

| " " moisture | 0.1513 | " |

| 0.1513 × 20 = 3.026 | 3.02%. |

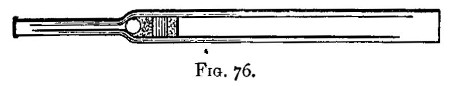

Sometimes it may be advisable to dry 10 grams, in which case multiplying the loss by 10 will give the percentage. The dried ore should be transferred to a weighing-tube (fig. 3), and reserved for the subsequent determinations. The weighing-tube with the ore must be marked, and kept in a desiccator.

Most ores and inorganic substances can be dried, and their moisture determined by the loss in this way. When, however, the substance contains another somewhat volatile ingredient, it is exposed over sulphuric acid in a desiccator for two days (if in vacuo, all the better), and the loss determined. Moisture in dynamite should be determined in this way.

When water is simply mechanically mixed with a substance it presents but little difficulty. The combined water is a different matter. Slaked lime, even when perfectly dry, contains much water; and if the water of soda crystals were separated and frozen, it would occupy a volume equal to that of the original crystals. Perfectly dry substances may contain much water, and this combined water is retained by different materials with very unequal vigour. Sodium sulphate and sodium phosphate crystals lose water even when exposed under ordinary conditions to dry air. Soda crystals when heated melt, and at a moderate temperature give off their water with ebullition. The temperature at which all the water is given up varies with each particular salt; the actual determination of the water in each case will require somewhat different treatment. Such determinations, however, are seldom[Pg 7] required; and from a practical point of view this combined water causes no trouble.

In assaying ores, we term "moisture" all water which is lost by exposure in a water-oven at 100° C., and the "dry ore" is the ore which has been dried at this temperature. No advantage, but rather endless confusion, would be caused by varying the temperature with the object of estimating the whole of the water which a hydrated salt may contain. The results of the assay of the other components should be calculated on the "dry ore." One advantage of this is obvious:—The dry ore has a constant composition, and the results of all assays of it will be the same, no matter when made; the moisture, however, may vary from day to day, and would be influenced by a passing shower of rain. It is well to limit this variability to the moisture by considering it apart, and thus avoid having the percentage, say, of copper rising and falling under the influence of the weather.

In the case of certain salts, however, such as soda crystals and hydrated sulphate of copper (when these constitute the bulk of the substance to be assayed), it is as well to perform the assay on the moist, or at any rate air-dried, substance.[2] It would be equally convenient to calculate on the substance dried at 100° C.; but in this case it would be well, in order to avoid a somewhat shallow criticism, to replace the term "moisture" by the longer but equivalent phrase "water lost at 100° C."

Calculation and Statement of Results.—By far the most generally convenient method of stating the results of an assay is that of the percentage or parts in a hundred, and to avoid a needlessly troublesome calculation it is well to take such a quantity of ore for each assay as by a simple multiplication will yield the percentage. In these calculations decimals are freely employed, and students should make themselves familiar with the methods of using them.

Other methods of statement are in use, and have advantages in certain special cases. With bullion the parts in a thousand are given, and in those cases in which the percentage is very small, as in water analysis, it is convenient to report on parts in 100,000, or even on parts per 1,000,000. These are easily got from the corresponding percentages by shifting the decimal point one, three, or four places to the right. Thus 92.5 per cent. is 925 per thousand; and 0.0036 per cent. is 3.6 per 100,000, or 36 per million.

With ores of tin, silver, and gold, the result is stated as so many cwts., lbs., or ozs., in the ton. With dressed tin ores as they are[Pg 8] sent to the smelter, the produce is given in cwts. and quarters to the ton. The corresponding percentage may be obtained by multiplying by five; or, inversely, if the percentage is given, the produce may be got by dividing by five. A produce of 13-1/2 equals a percentage of 13.5 × 5 = 67.5; and a percentage of 70.0 equals a produce of 70 / 5 = 14. With tin ores as raised (in which the percentage is small) the reduction must be carried to pounds per ton. One per cent. equals 22.4 lbs. to the ton; consequently, if we multiply the percentage by 22.4, the produce will be given. Thus, if an ore contains 6.7 per cent. of oxide of tin, the produce is 6.7 × 22.4 = 150 lbs. (or 1 cwt., 1 quarter, and 10 lbs.) to the ton. With gold and silver ores, the proportion of precious metal is small, and it is necessary to carry the reduction to ozs. and dwts. to the ton; and since gold and silver are sold by troy weight, whilst the ton is avoirdupois, it is of importance to remember that the ounces in the two systems are not the same. A ton contains 15,680,000 grains, which equal 653,333.3 dwts. or 32,666.6 ozs. (troy). The following rules are useful:—

To get ozs. (troy) per ton, multiply parts per 100,000 by 0.327;

To get dwts. per ton, multiply parts per 100,000 by 6.53;

To get grains per ton, multiply parts per 100,000 by 156.8.

Where liquids are being assayed, cubic centimetres are held to be equivalent to grams, and the usual method of statement is, "so many parts by weight in so many by measure." Where the statement is made as grams per litre or grains per gallon, there can be no doubt as to what is meant; and even if it be expressed in parts per 100,000, parts by weight in a measured volume must be understood unless the contrary is expressly stated.

In some cases, where the density of the solution differs greatly from that of water, the percentage by weight may be given; and in others, mixtures of two or more liquids, the percentages may be given by volume or by weight; as so many c.c. in 100 c.c., or as so many grams in 100 grams, or even as so many grams in 100 c.c. In such cases it must be distinctly shown which method of statement is adopted.

One grain per gallon means 1 grain in 70,000 grain-measures, or one part in 70,000. Dividing by 7 and multiplying by 10 will convert grains per gallon into parts per 100,000. Inversely, dividing by 10 and multiplying by 7, will convert parts per 100,000 into grains per gallon.

Grams per litre are parts per 1000; multiplying by 100 will give parts per 100,000, and multiplying by 70 will give grains per gallon.

Among foreign systems of weights, the French is by far the best. Kilograms (2.205 lbs.) per quintal (220.5 lbs.) are parts per cent.; and grams (15.43 grs.) per quintal are parts per[Pg 9] 100,000. From the rule already given, grams per quintal may be converted into ounces to the ton by multiplying by 0.327.

The German loths per centner (1/2 oz. (avoirdupois) to 100 lbs.) equal parts per 3200; they are converted into parts per cent. by dividing by 32, or into ounces (troy) per ton by multiplying by 10.208.

In the United States, as a sort of compromise between the avoirdupois and metric systems, a ton is taken as 2000 lbs. There, too, the custom is adopted of reporting the gold and silver contents of an ore as so many dollars and cents to the ton. In the case of gold, an ounce is considered to be worth 20.6718 dollars. With silver, the nominal value is 1.2929 dollars per ounce, but frequently in assay reports it is taken as one dollar. The practice is objectionable. The prices of metals vary with the fluctuations of the market, and if the assayer fixed the price, the date of his report would be all important; if, on the other hand, he takes a fixed price which does not at all times agree with the market one, it leaves a path open for the deception of those unacquainted with the custom. American "dollars on the ton of 2000 lbs." may be converted into "ounces in the ton of 2240 lbs." by dividing by 1.1544 in the case of silver, and by 18.457 in the case of gold.

Laboratory Books and Report Forms.—The record which the assayer makes of his work must be clear and neat, so that reference, even after an interval of years, should be certain and easy. One method should be adopted and adhered to. Where there are a large number of samples, three books are required.

Sample Book.—This contains particulars of the samples (marks, &c.), which are entered by the office-clerk as they arrive. He at the same time puts on each sample the distinguishing number.

Example of Page of Sample Book.

| Date. | Number. | Sample. | Remarks. |

| Feb. 1 | 482 | Tough Copper | For Arsenic. |

| " 2 | X | Piece of Metal | For Ni and Cu. |

| " | 483 | Tough Copper. | |

| " | 73 | Silver Precipitate, 4 casks, 24 cwt. 1 qr. | With Letter. |

| " | 494 | Purple Ore, 200 tons. | |

| " | 1 J.T. | Lead Ore, 1 J.T. | From Corsica. |

| " | 2 J.T. | " 2 J.T. |

Laboratory Book. This is the Assayer's note-book, in which he enters clearly the particulars of his work—the results obtained, as[Pg 10] well as how these results were arrived at. The calculations should be done on scrap-paper, and should not be entered, although, of course, detail enough must be shown to enable the results to be recalculated.

Example of Page of Laboratory Book.

____________________________________________________________

Purple Ore 5 grams

19/10/89 0.0042 grm.

0.0021 "

———

Colorimetric 0.0063 × 20 = 0.13% Copper

______________________________________________________________

482

Tough Copper 10 grams

Feb. 1/89 10.5 c.c. Uranium.

= 0.52% Arsenic

______________________________________________________________

2082

Tough Copper 10 grams

12.7 c.c. Uranium.

= 0.63% Arsenic

______________________________________________________________

491 10 grams

Tough Copper 13.7 c.c. Uranium

Feb. 1/89

= 0.68% Arsenic

______________________________________________________________

Standard of Uranium acetate.

0.150 gram As2O3 = 23.3 c.c. Uranium.

∴ 100 cc. Uranium = 0.5 gram As.

______________________________________________________________

10071 5 grams

Tin Ore Cruc. and SnO2 9.6065 grms.

Feb. 3/89 Cruc. and Ash 9.4235 "

———

SnO2 = 0.1830 = 2.88% Tin

______________________________________________________________

The Assay Book.—This is the Official book, and is a combination of the Sample and Laboratory books. It corresponds with the report-forms. Without being loaded with detail, it should contain sufficient to characterise each sample.[Pg 11]

Example of Page of Assay Book.

Description of Sample.

| Date. | Material. | Weight. | No. | Water Lost at 100° C. | Assay on the Dry Material. | Date Reported. | ||||

| 1889 | ton | cwt | qrs | lbs | ||||||

| Feb. 1 | Tough cake copper | ... | ... | ... | ... | 482 | ... | Arsenic, 0.52% | 7 | |

| " | Tough cake copper | ... | ... | ... | ... | 2082 | ... | Arsenic, 0.63% | 7 | |

| " | Tough cake copper | ... | ... | ... | ... | 491 | ... | Arsenic, 0.68% | 7 | |

| Feb. 2 | Nickel disc for C.R. | ... | ... | ... | ... | X | ... | Copper, 73.75 | 7 | |

| Nickel, 24.34 | ||||||||||

| Iron, 2.18 | ||||||||||

| ——— | ||||||||||

| 100.27 | ||||||||||

| ——— | ||||||||||

| " | Silver precipitate, 4 casks | ... | 24 | 1 | 0 | 73 | Not det. | Silver, 4.851 | 10 | |

| Gold, 0.0215 | ... | |||||||||

| Lead, 19.37 | ... | |||||||||

| Zinc, 2.00 | ... | |||||||||

| Silver, 1584.7 ozs. per ton | ... | |||||||||

| Gold, 7.0 ozs. per ton | ... | |||||||||

| " | Purple ore | ... | 200 | ... | ... | ... | 494 | Not det. | Copper, 0.13% | 11 |

| Sulphur 0.15% | ... |

When the number of samples is small, the Sample Book may be omitted, and the entries made in the Assay Book as the samples arrive.

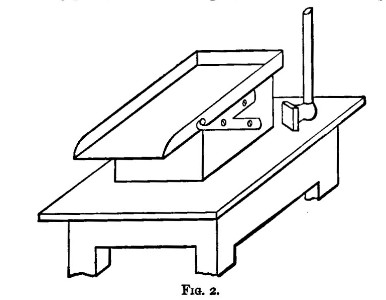

Report-forms. These should entail as little writing as possible in making out the report. For general purposes the form given on p. 12 is useful.

The quantity of substance to be taken for any particular assay depends largely upon the method of assay adopted. There are, however, some general considerations which should be remembered, and some devices for simplifying the calculations which should be discussed.

The smaller the percentage of the substance to be determined, the larger should be the amount of the ore taken. The following table will give a general idea as to this:—

| Percentage of the substance to be determined. | Amount of ore, &c. to be weighed. |

| 100-10 | 1 gram. |

| 10-5 | 2 grams. |

| 5-1 | 5 " |

| 1-0.1 | 10 " |

| 0.1-0.01 | 20 " |

ASSAY NOTE

ASSAY NOTE

The rougher the method of assay adopted, the larger should be the[Pg 13] quantity of ore taken. If the degree of accuracy attainable with the methods and instruments at the assayer's service is known, it is easy to calculate what quantity should be taken for any particular case. If the results are good within 0.001 gram, then, taking 1 gram of ore we can report within 0.1 per cent., or if they are good within 0.0002 gram, taking 20 grams of ore, we can report within 1 part per 100,000, or very closely within 6-1/2 dwt. to the ton. If it is wished to be yet more particular in reporting, larger quantities must be taken. The difficulty of manipulating very small or very large precipitates, &c., must be borne in mind. So, too, must the fact that the greater the weight of the final product of an assay, the less, as a rule, is the percentage error. The distinction between absolute and percentage error, often overlooked, is important. If 0.5 gram of silver be cupelled with 20 grams of lead, there may be obtained a button of 0.495 gram; the absolute loss is 0.005 gram, and this equals 1 per cent. of the silver present. Similarly, cupelling 0.1 gram, the resulting button may be 0.098; the absolute loss is only 0.002 gram, but this equals 2 per cent. of the silver present. In the same way the student should see that the two results, 91.5 per cent. and 92.0 per cent., are really more concordant than the results 9.1 per cent. and 9.2 per cent.

A device often adopted in practice where a large number of assays of one kind are made, and the report is given as so many ounces or pounds to the ton, is that known as the assay ton. The assay ton may be any arbitrary and convenient weight, but its subdivisions must bear to it the same relations as pounds and ounces bear to the actual ton. On the other hand, in a laboratory where many kinds of work are performed, different sets of weights of this kind would only tend to confusion, even if they were not unnecessary. With a set of gram weights and its subdivisions anything may be done. If it is desired to report as pounds to the ton, then, since there are 2240 lbs. to the ton, a weight of 2.240 grams may be taken as the assay ton, and each 0.001 gram yielded will equal 1 lb., or 22.4 grams may represent the ton, and each 0.01 gram a pound. Similarly, since there are 32,666.6 ozs. troy to the ton; if we take 32.6667 grams as the assay ton, each 0.001 gram will equal 1 oz. to the ton. In some cases it may be convenient to have, in addition to the usual gram weights, one or other of the "assay tons" mentioned above, but generally it is better to work on a purely decimal system, and convert when required into ounces per ton, &c., either by actual calculation or by reference to a set of tables.[Pg 14]

Practical Exercises.

The student should practise such calculations as the following:—

1. Calculate the percentages in the following cases:—

(a) Ore taken, 2 grams; copper found, 0.2155.

(b) " 1.5 gram; iron found, 0.8340.

(c) " 30 grams; lead found, 23.2.

2. Calculate the parts per thousand in the following:—

(a) Bullion taken, 1.1 gram; silver found, 1.017.

(b) " 1.14 gram; silver found, 1.026.

(c) " 0.6 gram; gold found, 0.5500.

3. Calculate parts per 100,000 in the following:—

(a) Ore taken, 20 grams; silver found, 0.0075.

(b) " 50 grams; gold found, 0.0026.

(c) Water taken, 500 c.c.; solids found, 0.1205.

4. Calculate cwts. to the ton in the following:—

(a) Ore taken, 5 grams; tin found, 2.816.

(b) " 5 grams; tin found, 3.128.

(c) An ore with 68.2 per cent. of tin.

5. Calculate lbs. to the ton in the following:—

(a) An ore with 3.28 per cent. oxide of tin.

(b) Ore taken, 20 grams; oxide of tin found, 1.67.

6. Calculate ozs. (troy) to the ton in the following:—

(a) Ore taken, 50 grams; gold found, 0.0035.

(b) " 20 grams; silver found, 0.0287.

(c) " 25 grains; silver found, 0.0164.

7. Calculate in grains per gallon:—

(a) 0.51 gram per litre.

(b) 24.6 parts per 100,000.

(c) Solution taken, 100 c.c.; copper found, 0.0045 gram.

(d) " 50 c.c.; iron found, 0.165 gram.

8. Convert into ozs. (troy) per ton:—

(a) 7 loths per centner.

(b) 30 grams per quintal.

(c) 15 parts per 100,000.

[1] Ether or carbon bisulphide.

[2] Such substances are best dried by pressing between folds of dry filter-paper.

The methods of assaying are best classed under two heads, Gravimetric and Volumetric, in the former of which the final results are weighed, whilst in the latter they are measured. A commoner and older division is expressed in the terms much used in practice—wet assays and dry assays. Wet assays include all those in which solvents, &c. (liquid at the ordinary temperature), are mainly used; and dry assays, those in which solid re-agents are almost exclusively employed. Dry assays form a branch of gravimetric work, and we shall include under this head all those assays requiring the help of a wind furnace. Wet assays, as generally understood, would include not only those which we class as wet gravimetric assays, but also all the volumetric processes.

Gravimetric Methods aim at the separation of the substance from the other matters present in the ore, so that it may be weighed; and, therefore, they must yield the whole of the substance in a pure state. It is not necessary that a metal should be weighed as metal; it may be weighed in the form of a compound of definite and well known composition. For example, one part by weight of silver chloride contains (and, if pure, always contains) 0.7527 part of silver; and a quantity of this metal can be as exactly determined by weighing it as chloride as by weighing it in the metallic state. But in either case the metal or its chloride must be pure.

Exact purity and complete separation are not easily obtained; and methods are used which are defective in one or both of these respects. It is well to note that an impure product increases the result, whilst a loss of the substance decreases it; so that if both defects exist in a process they tend to neutralise each other. Of dry methods generally, it may be said that they neither give the whole of the substance nor give it pure; so that they are only calculated to show the amount of metal that can be extracted on a manufacturing scale, and not the actual quantity of it present.[Pg 16] Their determinations are generally rough and always low. The gold and silver determinations, however, will compare very favourably with any of the other processes for the estimation of these metals in their ores.

The calculation of the results of a gravimetric assay has already been referred to. If the result is to be stated as percentage, it may always be done by the following rule:—Multiply the weight of the substance got by the percentage of metal it contains, and divide by the weight of ore taken.

Gravimetric methods are divided into three groups: (1) mechanical separations; (2) dry methods; and (3) wet methods.

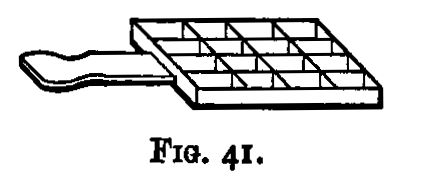

Mechanical Separations.—Under this head are classed the method of assaying tin ores, known as vanning, and the amalgamation assay for gold. A set of sieves to determine the relative proportion of powders of different degrees of fineness is sometimes useful. A set with 10, 20, 40 and 80 meshes to the inch is convenient.

Dry Assays.—An important distinction between wet and dry methods of assaying is, that in the former the substance is got into the liquid state by solution, whilst in the latter fusion is taken advantage of.

The difference between solution and fusion is easily illustrated: a lump of sugar heated over a candle-flame melts or fuses; suspended in water it dissolves. Many substances which are insoluble or infusible of themselves, become soluble or fusible when mixed with certain others; thus, in this way, solution is got with the aid of reagents, and fusion with the help of fluxes. For example, lead is insoluble in water, but if nitric acid be added, the metal rapidly disappears. It is convenient, but somewhat inaccurate, to say that the acid dissolves the lead. If the lead be acted on by nitric acid alone, without water, it is converted into a white powder, which does not dissolve until water is added; in this case it is obvious that the water is the solvent. The function of the acid is to convert the lead into a soluble compound.

Fluxes may act as true solvents. Fused carbonate of soda dissolves baric carbonate, and perhaps in many slags true solution occurs; but in the great majority of cases a flux is a solid reagent added for the purpose of forming a fusible compound with the earthy or stony minerals of the ore. Few of the minerals which occur in the gangue of an ore are fusible; and still fewer are sufficiently fusible for the purposes of the assayer, consequently the subject is one of importance, and it ought to be treated on chemical principles. An idea of the composition of some of the more frequently occurring rocks may be gathered from the following table, which represents rough averages:[Pg 17]—

| Silica. | Alumina. | Oxide of iron | Lime and Magnesia. | Alkalies. | |

| % | % | % | % | % | |

| Sandstone, grit, quartzite, &c. | 80-100 | — | — | — | — |

| Granite, gneiss, quartz-porphyry, fire-clay, &c. | 70-75 | 13-20 | 2 | 2 | 5-8 Less in fire-clay. |

| Mica-schist | 65 | 18 | 5 | 3 | 3 |

| Trachyte, syenite | 60 | 17 | 7 | 4-7 | 6-9 |

| Clay-slate | 60 | 18 | 10 | 8 | 3 |

| Diorite | 54 | 17 | 12 | 9 | 3-4 |

| Horneblende-rock | 50 | 18 | 15 | 12 | 3-4 |

| Brick-clay | 50 | 34 | 8 | 6 | — |

| China-clay | 47 | 39 | — | — | — |

| Basalt, dolerite, &c. | 50 | 15 | 15 | 16 | 3 |

| Serpentine | 44 | — | — | 44 | — |

| Chalk, limestone, dolomite, &c. | — | — | — | 45-55 | — |

Silica itself, and the silicates of alumina, of lime, and of magnesia, are practically infusible; the silicates of soda, of potash, and of iron are easily fusible if the base (soda, potash, or oxide of iron) be present in sufficient quantity, and if, in the case of the iron, it is present mainly as lower oxide (ferrous silicate). The addition of lime, oxide of iron, or alkali to silicate of alumina results in the formation of a double silicate of alumina and lime, or of alumina and iron, &c., all of which are easily fusible. Similarly, if to a silicate of lime we add oxide of iron, or soda, or even alumina, a fusible double silicate will be formed. Thus lime, soda, oxide of iron, and clay, are fluxes when properly used; but since lime, clay (and oxide of iron if there be any tendency to form peroxide), are of themselves infusible, any excess of these fluxes would tend to stiffen and render pasty the resulting slag. So, too, soda, which is a very strong base, may act prejudicially if it be in sufficient excess to set free notable quantities of lime and magnesia, which but for that excess would exist in combination as complex fusible silicates. There are many minerals which with but little soda form a glass, but with more yield a lumpy scoriacious mass. There are many minerals, too, which are already basic (for example, calcite), and which, when present, demand either a less basic or an acid flux according to the proportions in which they exist. For purposes of this kind borax, or glass, or clay with more or less soda may be used, and of these borax is by far the most generally useful. An objection to too basic a slag (and a very important one) is the speed with which it corrodes[Pg 18] ordinary crucibles. These crucibles, consisting of quartz and clay, are rapidly attacked by lime, soda and bases generally.

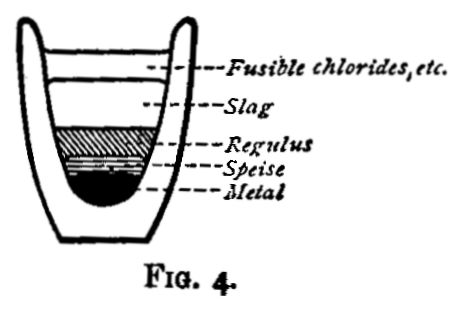

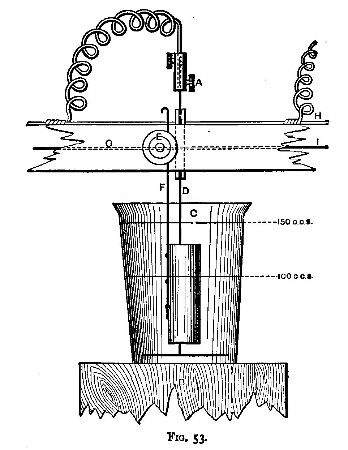

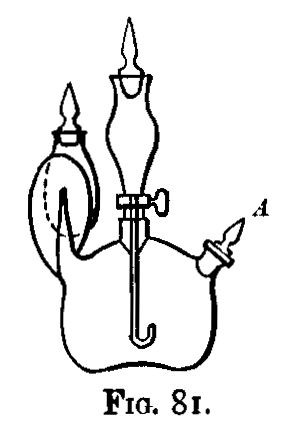

In considering what is and what is not a good slag, certain chemical properties are of importance. If a mixture of many substances be fused and allowed to solidify in a crucible, there will be found some or all of the following. At the bottom of the crucible (fig. 4) a button of metal, resting on this a speise; then a regulus, next a slag made up of silicates and borates and metallic oxides, and lastly, on the top another layer of slag, mainly made up of fusible chlorides and sulphates. In assaying operations the object is generally to concentrate the metal sought for in a button of metal, speise or regulus, and to leave the earthy and other impurities as far as possible in the slag; whether there be one or two layers of slag is a matter of indifference;[3] but the chemical action of the lower layer upon the speise, or regulus, or metal, is of great importance.

A regulus is a compound of one or more of the metals with sulphur; it is usually brittle, often crystalline, and of a dull somewhat greasy lustre. It is essential that the slag, when solid, shall be so much more brittle than the regulus, that it shall be easy to crumble, and remove it without breaking the latter; and it must not be basic. The effect of fusing a regulus with a basic slag is well seen when sulphide of lead is fused with carbonate of soda; the result is a button of metal (more or less pure), and a slag containing sulphides of lead and sodium; and again, if sulphide of lead be fused with an excess of oxide of lead, a button of lead will be got, and a slag which is simply oxide of lead (with whatever it may have taken up from the crucible), or if a sufficient excess has not been used, oxide of lead mixed with some sulphide. When (as is most frequently the case) the desire is to prevent the formation of regulus, these reactions may be taken advantage of, but otherwise the use of a flux having any such tendency must be avoided. A good slag (from which a regulus may be easily separated) may be obtained by fusing, say, 20 grams of ore with borax 15 grams, powdered glass 15 grams, fluor spar, 20 grams, and lime 20 grams; by quenching the slag in water as soon as it has solidified, it is rendered very brittle.

Sulphide of iron formed during an assay will remain diffused[Pg 19] through the slag, instead of fusing into a button of regulus, if the slag contain sulphide of sodium. The same is true of other sulphides if not present in too great a quantity, and if the temperature is not too high.

Speises are compounds of a metal or metals with arsenic. They are chiefly of interest in the metallurgy of nickel, cobalt, and tin. They are formed by heating the metal or ore in covered crucibles with arsenic and, if necessary, a reducing agent. The product is fused with more arsenic under a slag, consisting mainly of borax. They are very fusible, brittle compounds. On exposure to the air at a red heat the arsenic and the metal simultaneously oxidize. When iron, cobalt, nickel, and copper are present in the same speise, they are eliminated in the order mentioned.

Slags from which metals are to be separated should not be too acid; at least, in those cases in which the metal is to be reduced from a compound, as well as separated from earthy impurities. Where the object is simply to get a button of metal from a substance in which it is already in the metallic state, but mixed with dross (made up of metallic oxides, such as those of zinc or iron), from which it is desired to separate it, an acid flux like borax is best; or, if the metal is easily fusible, and there would be danger of loss of metal by oxidation or volatilising, it may be melted under a layer of resin or fat. Common salt is sometimes used with a similar object, and is often useful. Under certain conditions, however, it has a tendency to cause the formation of volatile chlorides with a consequent loss of metal.

In the great majority of cases, the fusion of the metal is accompanied by reduction from the state of oxide; in these the slag should be basic. It is not easy to reduce the whole of a reducible oxide (say oxide of copper or of iron) from a slag in which it exists as a borate or silicate; there should be at least enough soda present to liberate it. When the object is to separate one metal, say copper, without reducing an unnecessary amount of another (iron) at the same time, a slag with a good deal of borax is a distinct advantage. The slag then will probably not be free from copper, so that it will be necessary to powder and mix the slag with some soda and a reducing agent, and to again fuse the slag in order to separate this residual metal. In all those cases in which the slag retains an oxide of a heavy metal, this cleaning of the slag is advisable, and in the case of rich ores necessary. Slags containing sulphides are especially apt to retain the more easily reducible metals.

The following are the ordinary and most useful fluxes:—

Soda.—The powdered bicarbonate, sold by druggists as "carbonate[Pg 20] of soda," is generally used. It gives off its water and excess of carbonic acid readily and without fusion. Where the melting down is performed rapidly, the escaping gas is apt to cause trouble by frothing, and so causing waste of the material. Ordinary carbonate of soda, when hydrated (soda crystals), melts easily, and gives off its water with ebullition. It is unfit for use in assaying, but when dried it can be used instead of the bicarbonate. One part of the dried carbonate is equivalent to rather more than one and a half parts of the bicarbonate. From two to four parts of the flux are amply sufficient to yield a fluid slag with one part of earthy matter. This statement is also true of the fluxes which follow.

Borax is a hydrated biborate of soda, containing nearly half its weight of water. When heated it swells up, loses its water, and fuses into a glass. The swelling up may become a source of loss in the assay by pushing some of the contents out of the crucible. To avoid this, fused or dried borax may be used, in which case a little more than half the amount of borax indicated will suffice. Borax will flux almost anything, but it is especially valuable in fluxing lime, &c., and metallic oxides; as also in those cases in which it is desired to keep certain of the latter in the slag and out of the button of metal.

Oxide of Lead, in the form of red lead or litharge, is a valuable flux; it easily dissolves those metallic oxides which are either infusible or difficultly fusible of themselves, such as oxides of iron or copper. The resulting slag is strongly basic and very corrosive; no crucible will long withstand the attack of a fused mixture of oxides of lead and copper. With silicates, also, it forms very fusible double silicates; but in the absence of silicates and borates it has no action upon lime or magnesia. Whether the lead be added as litharge or as red lead, it will exist in the slag as monoxide (litharge); the excess of oxygen of the red lead is thus available for oxidising purposes. If this oxidising power is prejudicial, it may be neutralised by mixing the red lead with 1 per cent. of charcoal.

Glass: broken beakers and flasks, cleaned, dried, and powdered will do. It should be free from lead.

Fluor: fluor-spar as free as possible from other minerals, powdered. It helps to flux phosphate of lime, &c., and infusible silicates.

Lime: should be fresh and powdered. It must not be slaked. Powdered white marble (carbonate of lime) will do; but nearly double the quantity must be taken. One part of lime produces the same effect as 1.8 parts of the carbonate of lime.

Tartar and "black flux," are reducing agents as well as fluxes.[Pg 21] The "black flux," which may be obtained by heating tartar, is a mixture of carbonate of potash and charcoal.

Reducing Agents.—The distinction between reducing agents and fluxes (too often ignored) is an important one. Fluxes yield slags; reducing agents give buttons of regulus or of metal. The action of a reducing agent is the separation of the oxygen or sulphur from the metal with which it is combined. For example, the mineral anglesite (lead sulphate) is a compound of lead, sulphur, and oxygen; by carefully heating it with charcoal the oxygen is taken away by the charcoal, and a regulus of lead sulphide remains. If the regulus be then fused with metallic iron the sulphur is removed by the iron, and metallic lead is left. The charcoal and the iron are reducing agents. But in defining a reducing agent as one which removes oxygen, or sulphur, from a metallic compound so as to set the metal free, it must be remembered that sulphur itself will reduce metallic lead from fused litharge, and that oxygen will similarly set free the metal in fused lead sulphide. There is no impropriety in describing sulphur as a reducing agent; but it is absurd to call oxygen one. Some confusion will be avoided if these substances and those which are opposite to them in property be classed as oxidising and de-oxidising, sulphurising, and de-sulphurising agents. Most oxidising agents also act as de-sulphurisers.

The de-oxidising agents most in use are the following:—

Charcoal.—Powdered wood charcoal; it contains more or less hygroscopic moisture and about 3 or 4 per cent. of ash. The rest may be considered carbon. Carbon heated with metallic oxides takes the oxygen; at low temperatures it forms carbon dioxide, and at higher ones, carbon monoxide. Other conditions besides that of temperature have an influence in producing these results; and as the quantity of charcoal required to complete a definite reaction varies with these, it should be calculated from the results of immediate experience rather than from theoretical considerations.

Flour.—Ordinary wheat flour is convenient in use. On being heated it gives off inflammable gases which have a certain reducing effect, and a residue of finely divided carbon is left. It is likely to vary in the quantity of moisture it contains. Two parts of flour should be used where one part of charcoal would be otherwise required.

Tartar.—This is crude hydric potassic tartrate; the purified salt, cream of tartar, may be used. On being heated it gives off inflammable gases, and leaves a residue formed of potassic carbonate mixed with finely divided carbon. Five parts of tartar should be used in the place of one of charcoal.[Pg 22]

Anthracite or Culm is a kind of coal containing 90 per cent. or more of carbon. It gives off no inflammable gas. It is denser, and takes longer in burning, than charcoal. Its reducing effect is little inferior to that of charcoal. Almost any organic substance can be used as a reducing agent, but it is well not to select one which melts, swells up, or gives off much water and gas when heated in the furnace.

Potassic Cyanide is an easily fusible and somewhat volatile salt, which, when fused, readily removes oxygen and sulphur from metallic compounds, and forms potassic cyanate or sulphocyanate as the case may be. Commercial samples vary much in purity; some contain less than 50 per cent. of the salt. For assaying, only the better qualities should be used.

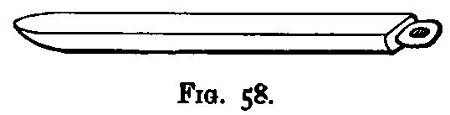

Iron is a de-sulphurising rather than a de-oxidising agent. Iron is used in the form of rods, 1/2-inch in diameter, or of nails, or of hoop iron. In the last case it should be thin enough to be bent without difficulty. Wrought iron crucibles are very useful in the processes required for making galena assays.

The chief oxidising agents (which are also de-sulphurisers) are the following:—

Nitre, or Potassic Nitrate.—This salt fuses very easily to a watery liquid. It oxidises most combustible substances with deflagration, and thereby converts sulphides into sulphates, arsenides into arsenates, and most metals into oxides. In the presence of strong bases, such as soda, the whole of the sulphur is fully oxidised; but in many cases some arsenic is apt to escape, and to give rise to a peculiar garlic-like odour. The sulphates of soda and potash are thus formed, and float as a watery liquid on the surface of the slag.

Red lead is an oxide of lead. About one-quarter of its oxygen is very loosely held, and, hence, is available for oxidising purposes, without any separation of metallic lead. The rest of the oxygen is also available; but for each part of oxygen given off, about 13 parts of metallic lead are deposited. In silver assays this power of readily giving up oxygen is made use of. The residual oxide (litharge) acts as a flux.

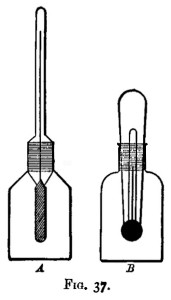

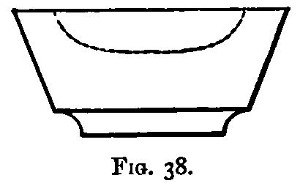

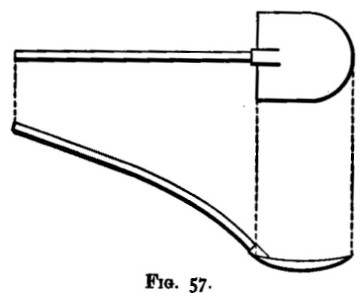

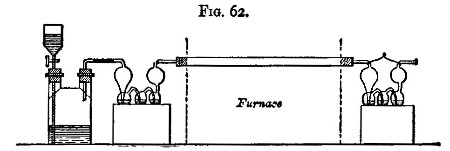

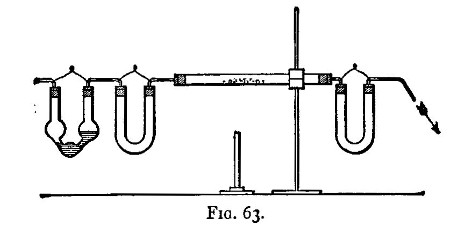

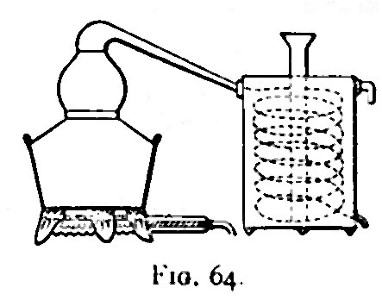

Hot air is the oxidising agent in roasting operations. The sulphur and arsenic of such minerals as mispickel and pyrites are oxidised by the hot air and pass off as sulphur dioxide and "white arsenic." The metals generally remain in the form of oxide, mixed with more or less sulphate and arsenate. The residue may remain as a powdery substance (a calx), in which case the process of roasting is termed calcination; or it may be a pasty mass or liquid. In the calcination of somewhat fusible minerals, the roasting should be done at a low temperature to avoid clotting;[Pg 23] arsenic and sulphur being with difficulty burnt off from the clotted mineral. A low temperature, however, favours the formation of sulphates; and these (if not removed) would reappear in a subsequent reduction as sulphides. These sulphates may be decomposed by a higher temperature towards the end of the operation; their removal is rendered more certain by rubbing up the calx with some culm and re-roasting, or by strongly heating the calx after the addition of solid ammonic carbonate. In roasting operations, as large a surface of the substance as possible should be exposed to the air. If done in a crucible, the crucible should be of the Cornish type, short and open, not long and narrow. For calcinations, roasting dishes are useful: these are broad and shallow, not unlike saucers, but unglazed. In those cases in which the products of the roasting are liquid at the temperature used, a scorifier (fig. 38) is suitable if it is desired to keep the liquid; but if the liquid is best drained off as quickly as it is formed, a cupel (fig. 5) should be used.

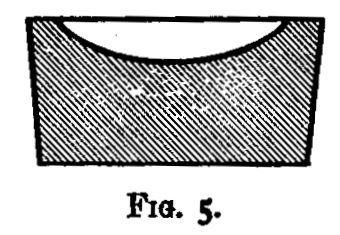

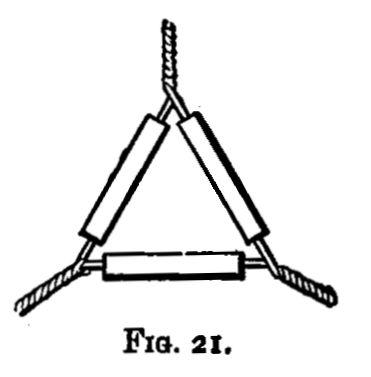

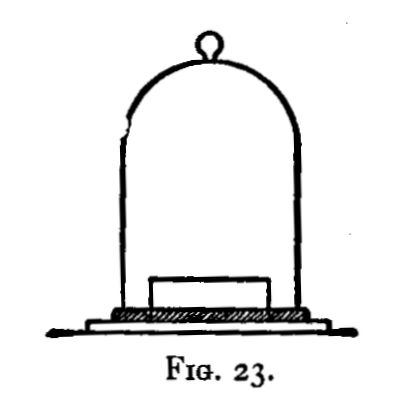

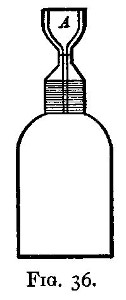

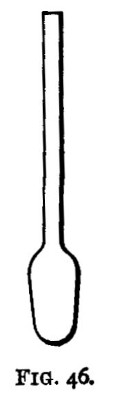

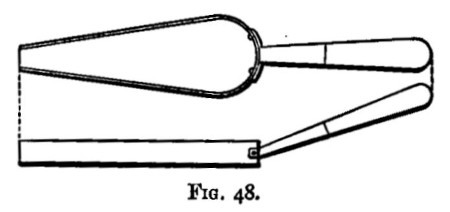

A scorifier is essentially a roasting dish sufficiently thick to resist, for a time, the corrosive action of the fused metallic oxides it is to contain. The essential property of a cupel is, that it is sufficiently porous to allow the fused oxide to drain into it as fast as it is formed. It should be large enough to absorb the whole of the liquid; and of course must be made of a material upon which the liquid has no corrosive action. Cupels do not bear transport well; hence the assayer generally has to make them, or to supervise their making. A quantity of bone ash is carefully mixed with water so that no lumps are formed, and the mixture is then worked up by rubbing between the hands. The bone ash is sufficiently wet when its cohesion is such that it can be pressed into a lump, and yet be easily crumbled into powder. Cupel moulds should be purchased. They are generally made of turned iron or brass. They consist of three parts (1) a hollow cylinder; (2) a disc of metal; and (3) a piston for compressing the bone ash and shaping the top of the cupel. The disc forms a false bottom for the cylinder. This is put in its place, and the cylinder filled (or nearly so) with the moistened bone ash. The bone ash is then pressed into shape with the piston, and the cupel finished with the help of three or four smart blows from a mallet. Before removing the piston, turn it half-way round upon its axis so as to loosen and smooth the face of the cupel. The cupel is got out by pressing up[Pg 24] the disc of metal forming the false bottom; the removal is more easily effected if the mould is somewhat conical, instead of cylindrical, in form. The cupels are put in a warm place to dry for two or three days. A conveniently sized cupel is 1-1/4 inches in diameter and about 3/4 inch high. The cavity of the cupel is about 1/4 inch deep, and something of the shape shown in fig. 5.

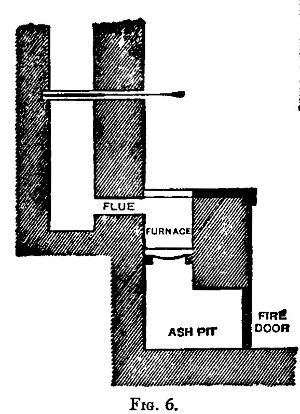

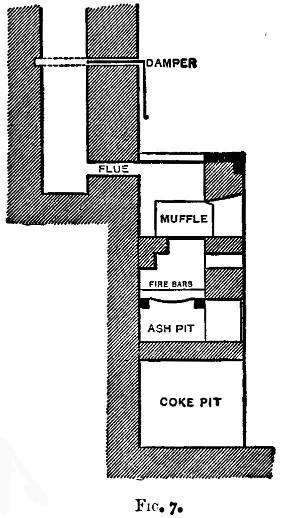

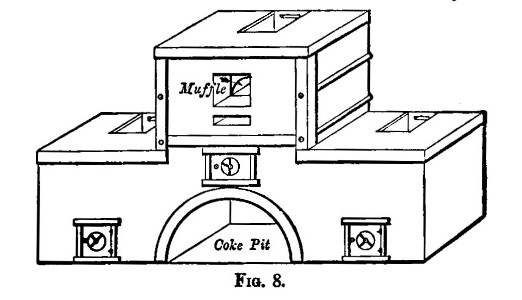

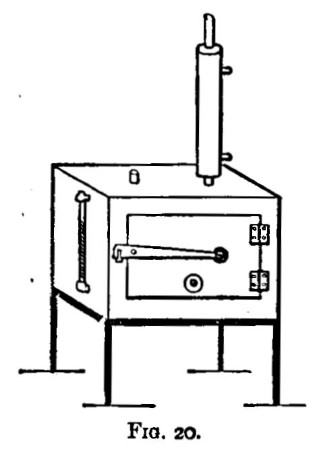

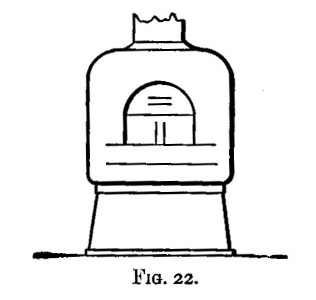

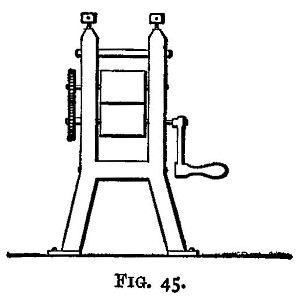

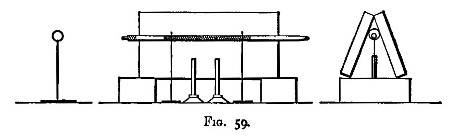

There are two kinds of furnaces required, the "wind" and "muffle" furnaces. These are built of brick, fire-brick, of course, being used for the lining. They are connected with a chimney that will provide a good draught. Figure 6 shows a section of the wind furnace, fig. 7 a section of the muffle furnace, and fig. 8 a general view of a group comprising a muffle and two wind furnaces suitable for general work. When in operation, the furnaces are covered with iron-bound tiles. The opening under the door of the muffle is closed with a loosely fitting brick. The floor of the muffle is protected with a layer of bone-ash, which absorbs any oxide of lead that may be accidentally spilt. The fire bars should be easily removable.

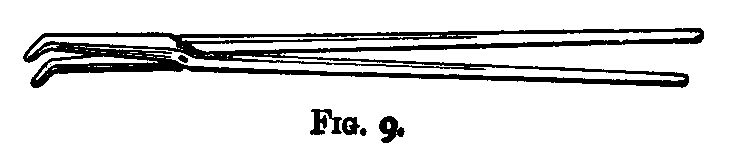

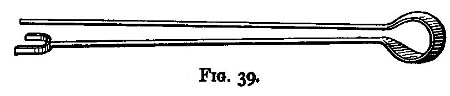

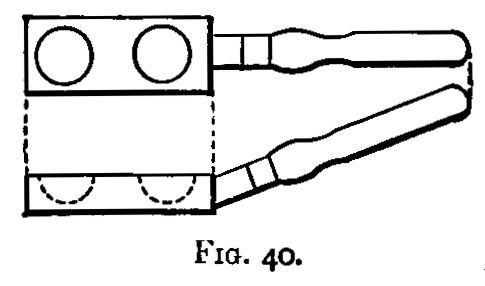

Few tools are wanted; the most important are some cast-iron moulds, tongs (fig. 9), stirrers for calcining (fig. 10), and light tongs of a special form for handling scorifiers and cupels (see Silver).

The coke used should be of good quality; the formation of a fused ash (clinker), in any quantity, causes ceaseless trouble, and requires frequent removal. The coke should be broken into lumps of a uniform size (about 2 in. across) before being brought into the office. The furnace should be well packed by stirring, raising the coke and not ramming it, and it should be uniformly heated, not hot below and cold above. In lighting a furnace, a start is made with wood and charcoal, this readily ignites and sets fire to the coke, which of itself does not kindle easily.

In commencing work, add (if necessary) fresh coke, and mix well; make hollows, and into these put old crucibles; pack around with coke, so that the surface shall be concave, sloping upwards from the mouths of the crucibles to the sides of the furnace; close the furnace, and, when uniformly heated, substitute for the empty crucibles those which contain the assays. It is rarely advisable to have a very hot fire at first, because with a gradual heat the gases and steam quietly escape through the unfused mass, while with too strong a heat these might make some of the matter in the crucible overflow. Moreover, if the heat should be too strong at first, the flux might melt and run to the bottom of the crucible, leaving the quartz, &c., as a pasty mass above; with a gentler heat combination is completed, and the[Pg 26] subsequent fiercer heat simply melts the fusible compound into homogeneous slag.

The fused material may be left in the crucible and separated from it by breaking when cold. It is generally more convenient to pour it into cast-iron moulds. These moulds should be dry and smooth. They act best when warmed and oiled or black-leaded.

Air entering through the fire-bars of a furnace and coming in contact with hot coke combines with it, forming a very hot mixture of carbonic acid and nitrogen; this ascending, comes in contact with more coke, and the carbonic acid is reduced to carbonic oxide; at the top of the furnace, or in the flue, the carbonic oxide meeting fresh air, combines with the oxygen therein and re-forms carbonic acid. In the first and third of these reactions, much heat is evolved; in the second, the furnace is cooled a little. It must always be remembered, that the carbonic oxide of the furnace gases is a reducing agent. When these gases are likely to exert a prejudicial effect, and a strongly oxidising atmosphere is required, the work is best done in a muffle.

[3] There is an exception to this, as when the slag is liable to be acted on when exposed to the air and to the gases of the furnace. In this case a layer of fused common salt floating on the slag, so as to protect it from the air and furnace gases, is a distinct advantage.

In dry assays the metal is almost always separated and weighed as metal; in wet gravimetric assays the metal is more usually weighed in the form of a definite compound of known composition. The general methods of working resemble those of ordinary chemical analysis, and their successful working is greatly helped by a knowledge of, at any rate, those compounds of the metal which enable it to be separated, and of those which are the most convenient forms in which it can be weighed. But the work of the assayer differs from that of the analyst, inasmuch as the bulk of his estimations are made upon material of practically the same kind, varying only in richness; consequently in assaying, it is possible (and necessary) to work on such a definite plan as will involve the least amount of labour in weighing and calculating.

The assayer connected with mining has generally two classes of material to deal with: those comparatively rich and those comparatively poor. For example, silver in bullion and in ores; copper precipitates or regulus, and copper ores and slags; and "black tin" and tin ores. He is only occasionally called on to assay the intermediate products. It is indispensable that he should have an approximate knowledge of the substance to be determined. With new ores this information is best got by a qualitative testing. Knowing that only certain bodies are present, it is evident that the number of separations can be reduced, and that simple methods can be devised for arriving at the results sought for. The best method is that which involves the least number of separations. The reactions must be sharp and complete, and yet not be liable to error under varying conditions.

To bring the richer and poorer materials under the same conditions for the assay, a small weight, say 1 gram of the richer, and a larger weight (5 or 10 grams) of the poorer, substance is weighed up. A method is then adopted which will concentrate the whole of the metal (either during or after solution) in a product which need not necessarily be pure. The work on this product is comparatively easy. In separating small quantities of a substance from a large bulk of impurities, the group separations must not[Pg 28] as a rule be too much relied on. Very large precipitates carry down small quantities of bodies not belonging to the group, more especially when there is a tendency to form weak double compounds. The re-dissolving and re-precipitating of bulky precipitates should be avoided.

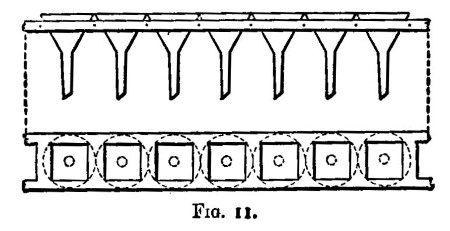

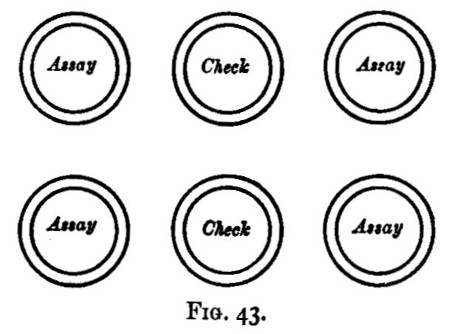

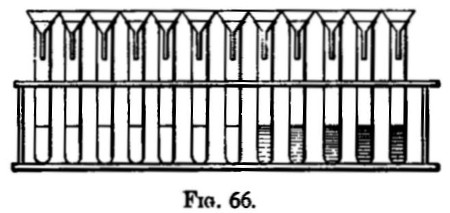

When a large number of assays of the same kind have to be carried out, a plan something like the following is adopted:—The samples, after having been dried, are placed in order on a table at the left hand of the assayer. He takes the first, marks it with a number, samples and weighs up the quantity required, and transfers it to a flask, which is similarly marked. As the weighings are finished, the samples are placed in the same order on his right hand. The assistant takes the flasks in batches of four or five at a time to the fume cupboard, where he adds a measured quantity of acid. When solution has been effected, dilution with a measured volume is generally necessary. The assayer sees to this and (whilst the funnels and filters are being prepared) makes any separation that is necessary. The filters are arranged in order on a rack (fig. 11), and need not be marked unless the precipitates or residues have subsequently to be dried. The filters are washed with hot water, and if the filtrates are wanted flasks are placed beneath, if not, the solution is drained off down the sink. Precipitation or reduction (or whatever it may be) is now made; the assistant filters the prepared samples, one at a time, whilst the assayer is engaged with the others. The same style of work is continued until the assays are completed. If one should be spoiled, it is better to allow it to stand over for assaying along with the next batch. If one filters slowly or is in any way less forward than the rest, it may lessen the accuracy of the other assays, owing to oxidation, &c., it should, therefore, be put on one side. The assays are dealt with in batches of ten or twenty, so that a large quantity of work can be quickly finished.

When the assays are finished, it is the duty of the assistant to clean the apparatus (with reagents, if necessary), and to put the[Pg 29] vessels in the place set apart for them. Flasks are best kept inverted on a rack, so that they may be dry and clean by the next morning. Berlin crucibles must be cleaned and ignited.

The amount of apparatus employed should be as little as is feasible. The assay should be carried out as much as possible in the same flask. The bench must be clean, and altogether free from apparatus not in actual use. Crucibles and dishes in which weighings are made should be marked with numbers or letters; and their weights recorded, together with the date of weighing, in a small ledger, which is kept in the drawer of the balance. By this means a record of the "wear" of each piece of apparatus is obtained, and, what is more important, much weighing is saved, and increased confidence is gained. The weight of each piece of apparatus need not be taken daily. It will be seen from the record in the book and a knowledge of the use it has been put to how often a checking of the weight is necessary. The entries are made in black lead as follows:—

| Dish, A. | Feb. 3 | 9.4210 grams. |

| 5 | 9.4225 | |

| 6 | 9.4230 | |

| 7 | 9.4200 |

Platinum vessels and apparatus lose, and porcelain ones slightly gain, weight with continued use.

The special details of the work is given under each assay; certain general instructions will be given here.

Solution.—It is not always necessary to get the whole of the mineral in solution, provided the body sought for is either completely dissolved or altogether left in the residue. It is often only by a qualitative examination of the solution (or residue, as the case may be) that the assayer can satisfy himself that it is free from the substance sought. But previous experience with the same kind of ore will show to what extent this testing is necessary.

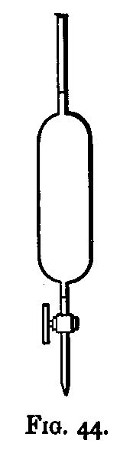

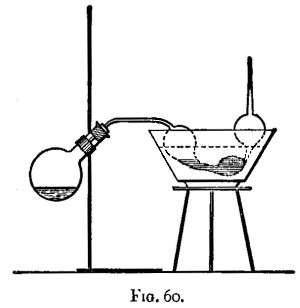

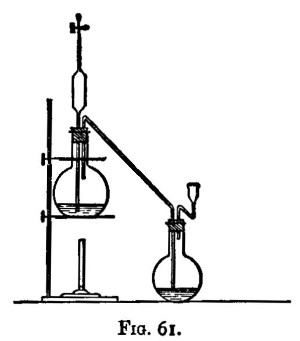

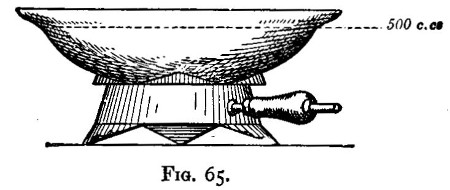

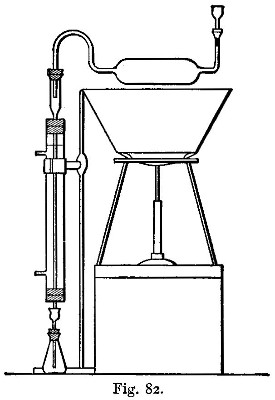

Solution is generally best effected in flasks; but where the resulting liquid has afterwards to be evaporated to dryness and ignited, evaporating dishes (fig. 12) are used. With them clock glasses are used as covers during solution to avoid loss through effervescence. Evaporating dishes are also best when an insoluble residue has to be collected, since it is difficult to wash out most residues from a flask. Bumping occurs less frequently in dishes than in flasks.

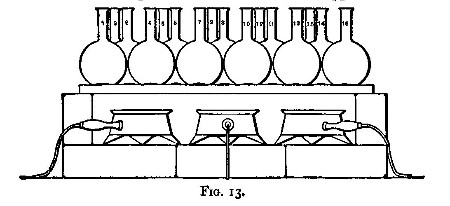

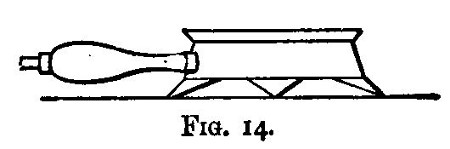

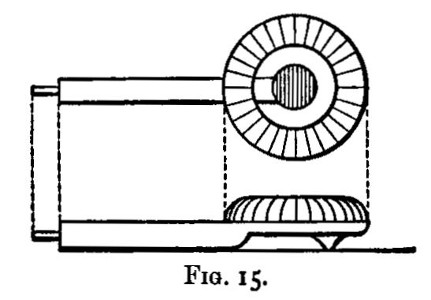

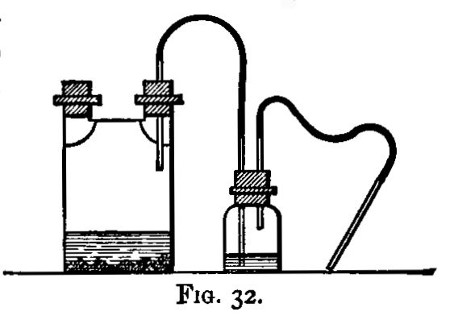

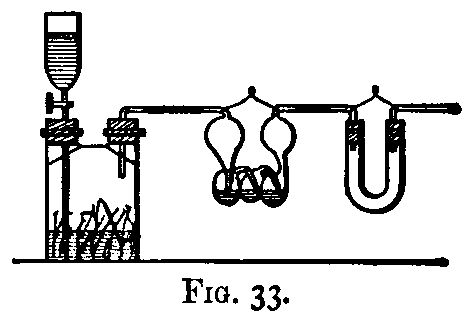

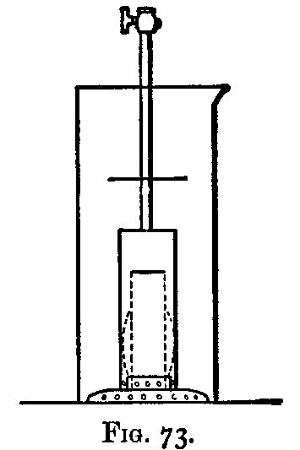

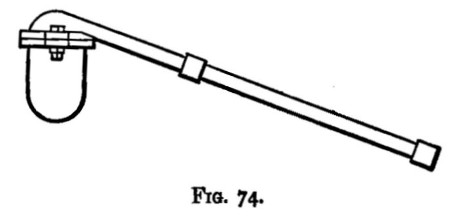

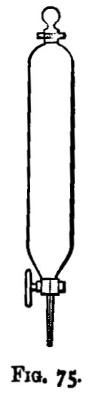

After the addition of the acid, and mixing by agitation, the vessel containing the substance is heated. This is best done on[Pg 30] the "hot plate" (fig. 13). This consists of a slab of cast iron about half or three-quarters of an inch thick, supported on loose fire bricks, and heated by two or three ring burners (figs. 14 and 15). The burners are connected to the gas supply by means of lead tubing, to which they are soldered. Flasks and dishes after being put on the plate are not further handled until solution is complete or the evaporation is carried to dryness. The hot plate is contained in a cupboard so as to be out of the reach of cold draughts.

The action of the acids and other solvents is described in the chapter on Reagents.

Precipitation.—In precipitating add sufficient of the reagent to complete the reaction. The student must be on his guard against adding a very large excess, which is the commoner error. In some reactions the finishing point is obvious enough; either no more precipitate is formed, or a precipitate is completely dissolved, or some well-marked colour or odour is developed or removed.

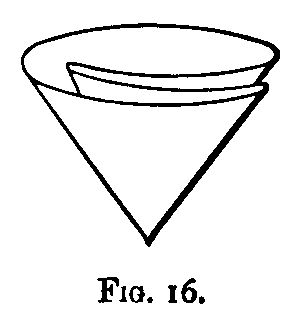

In those cases in which there is no such indication, theoretical considerations should keep the use of reagents within reasonable limits. The solutions of the reagents (see Reagents) are generally of five or ten per cent. strength. A small excess over that demanded by theory should be sufficient.[Pg 31]