The Project Gutenberg EBook of Scientific American Supplement, No. 611, September 17, 1887, by Various This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org Title: Scientific American Supplement, No. 611, September 17, 1887 Author: Various Release Date: October 26, 2005 [EBook #16948] Language: English Character set encoding: ISO-8859-1 *** START OF THIS PROJECT GUTENBERG EBOOK SCIENTIFIC AMERICAN *** Produced by Juliet Sutherland and the Online Distributed Proofreading Team at www.pgdp.net

The motor of MM. Schaltenbrand & Moller is adapted for use for household purposes, where small power is required, as in driving sewing machines.

Fig. 1 shows the motor with all its parts in side elevation, the flywheel and head rest being in section. Fig. 2 is a side view, with the air reservoir and distribution valve in section through the line 1-2. Figs. 3 and 4 represent the same apparatus, but without support, as where it is to be used on the table of a sewing machine, with the crank of the motor directly fastened to the flywheel of the sewing machine. Fig. 5 is a plan or horizontal section at the level of the line 3-4, and Fig. 6 is a section passing through the same line, but only including the cylinder and axis of the distributing valve. Fig. 7 is a horizontal section of the button of the cock through the line 5-6 of Fig. 3. Finally, Fig. 8 shows in detail, plan, and elevation the arrangement of the starting valve.

This little motor does not show any new principle. It uses the old oscillating cylinder, but it embraces in its construction ingenious details which render its application very simple and very easy, especially, as we have already said, to sewing machines.

In the first place, the oscillating bronze cylinder, A, is cast in one piece with the distribution cock, a, Fig. 3, and its seat, b, also of bronze, is adjusted and fastened by means of the screw, b, to the air reservoir, C', cast with its cistern, C, acting as foundation or bed plate for the motor. This cistern is held either on the base of the cast iron bearing frame, D, of the main shaft, d, d, Figs. 1 and 2, or directly on the sewing machine table, Figs. 3 and 4, by means of two pins, e and e', so that it can oscillate about an axis which is perpendicular to the shaft, d, to which is attached the disk, F, carrying the crank.

This arrangement of parts, in combination with the horizontal axis of the distribution valve and with the piston rod, g, considered as a vertical axis of rotation, forms a species of universal joint between the crank pin and the table, so that it can be put in place without adjustment by any workman, who only has to screw up the two screws, h, to fasten to the table the standard, E, and the piece, E', in which are screwed the pivots, e and e', which support the tank, and this all the rest of the motor.

As is seen more clearly in Fig. 2, the water under pressure enters by the pipe, c, to which is attached a small tube of India rubber, and leaves by the pipe, c', and is carried away by another India rubber tube.

The openings of the distribution cock are symmetrically pierced in the seat and plug, which latter is divided internally by a horizontal diaphragm so arranged that at each oscillation communication is established alternately above and below the piston. So that it can be started or stopped quickly, the opening and closing of the throttle valve, i (Fig. 2), is effected by a single pulling movement upon the handle, I, and this draws out the valve horizontally. For this end the lever is pivoted upon the extremity of the valve stem, and ends in a bar engaging with a fork which acts as its fulcrum. This fork is cast in one piece with the plug, J, which closes the opening through which the valve is put in place, as shown in detail in Fig. 8. To prevent the lever from spinning out of the fork when it is pulled or pushed, this lever is prevented from turning by the valve stem, provided for this purpose with a double rib, i' (Figs. 2 and 8), which engages in slots in one piece, j, secured in the interior of the plug, J.

Lest the friction of the conical distribution valve oscillating with the cylinder should occasion a loss of power, care is taken to leave the key free in its seat, b, by not forcing the pivot, k (Figs. 1, 3, and 5), whose position in its seat is regulated by the screw, k'. It follows that a very slight escape of water may be produced, but that does no harm, as it is caught in the reservoir, C, provided with a little pipe, K (Figs. 1 and 3), to carry it away.

To maintain proper relations between the pressure of the water, or the work it is called upon to do, and the motor, the quantity of water introduced into the cylinder at each stroke of the piston is regulated by adjusting the length of stroke by the crank pin. For this end the course of the latter is made variable by means of the piece, f, adjusted by set-screw in the interior of the disk, F (Figs. 3 and 7), and tapped for the reception of a screw terminated by a milled button, f. If this button is turned, it moves the piece, f, and therefore regulates the distance of the crank pin, g', to which the piston rod, g, is attached (Fig. 3) from the center of rotation.

When the motor is arranged as shown in Figs. 1 and 2, or for the transmission of motion by means of a band wheel, p, cast in one with the flywheel, P, the disk which receives the crank pin of variable position is fixed directly upon the axle, d, of the same flywheel carried by the support, D; but when the motor can be applied directly, as is the case for example in the Singer sewing machine, upon the axle of the machine, no support is used, and the arrangement shown in Figs. 3 and 4 is adopted. In this case the disk, F', is cast with three arms which serve, by means of a screw, to fasten it to the flywheel carried by the axle of the sewing machine.

When the motor is used on the upper stories of buildings, the changes of speed incidental to drawing the water from the lower stories from the same pipe can be compensated by the use of an accumulator. This accessory apparatus is composed of a reservoir of a capacity of 10 liters or more, intercalated in the pipe which supplies the motor, so that the water coming from the principal pipe enters the bottom of this reservoir, passing through an India rubber valve opening inward, the supply for the motor coming through a tube always open and placed above this valve. The air trapped in the accumulator is compressed by the water, and when the pressure in the pipe decreases, the valve closes and the compressed air drives the water through the motor with decreasing pressure until normal pressure is re-established in the pipes.—Publication Industrielle.

Some important trials of the new machinery of the screw steamer Ohio, belonging to the International Navigation Company, have recently taken place on the Clyde. The Ohio is an American built steamer measuring 343 ft. by 43 ft. by 34 ft. 6 in., and of 3,325 tons gross. She has been entirely refitted with new engines and boilers by Messrs. James Howden & Co., Glasgow, who also rearranged the bunker, machinery, and hold spaces, so as to give the important advantage of increased cargo accommodation obtainable from the use of their improved machinery, which occupies considerably less space than the engines and boilers of the same power which have been replaced. The new engines are of the triple expansion type, and the boilers, which are designed for supplying steam of 150 lb. pressure, are worked on Howden's system of forced draught, which combines increased power with high economy in fuel. The object of the owners in refitting the Ohio was to test the capability and economy of this system of forced draught on a sufficient scale to guide them in dealing with steamships of the largest class and great power.

In the refit of the Ohio the boilers were designed to work with a very moderate air pressure, this being sufficient for the power required by the contract. The combined power and economy, however, guaranteed by Messrs. Howden & Co. for the use of their system of forced draught was higher than has hitherto been attempted in any steamship, and sufficient, if attained, to prove the large reduction that could safely be made in the number and size of boilers for the use of the system, and the quantity of coal required to produce a given power. The contract for the refit of the steamer required that 2,100 indicated horse power (which was the maximum power of the engines removed) should be maintained during the trial on a consumption of 1.25 lb. of coal per indicated horse power per hour. Originally the boilers of the Ohio, from which this power was produced, were three in number, double ended, 12 ft. 6 in. in diameter by 17 ft. 6 in. in length, having each six furnaces 3 ft. in diameter, or eighteen furnaces in all, with an aggregate fire grate area of 300 square feet. The new boilers, fitted with the forced draught, are likewise three in number, but single ended, 13 ft. in diameter by 11 ft. 2 in. in length, having each three furnaces 3 ft. 3 in. in diameter, or nine furnaces in all, with an aggregate fire grate area of 112 square feet. Air for combustion is supplied to the boilers by one of Messrs. W.H. Allen & Co.'s fans, 5 ft. 6 in. in diameter, driven direct by an engine having a cylinder 7 in. in diameter with stroke of 4 in. The boilers removed had two stoke holds across the ship, one fore and one aft of the boilers, while the new boilers have only one stoke hold on the after side. The engines removed have cylinders 57 in. and 90 in. in diameter by 48 in. stroke, while the new engines have three cylinders 31 in., 46 in., and 72 in. in diameter respectively, with piston stroke of 51 in.

During the trials the coals were weighed out under the supervision of the officers of the company, who also took the record of speed and other data. After running down Channel for a considerable time, the trial on the coals weighed out began, and lasted 4 hours 10 minutes, during which time 10,885 lb. of Welsh coal were burned, the trial ending with the same revolutions of engines and the same pressure in boilers with which it began. The mean indicated horse power, calculated from the mean of seven sets of indicator cards, taken during the trial, and the mean revolutions per minute, found by dividing the total revolutions recorded on the engine counter by the minutes in the period of the trial, amounted to 2,124, thus making the consumption 1.23 lb. per indicated horse power per hour, and the power per square foot of fire grate almost exactly 19 indicated horse power. While testing the indicated horse power and consumption of coal, the steamer ran to and fro between the Cloch and Cumbrae lights, and also made several runs on the measured mile at Skelmorlie, from which the mean speed of the vessel was found to be 14.12 knots per hour. The remarkably high results obtained were most satisfactory to the representatives of the owners, and a large party of experts on board congratulated Mr. Howden on the successful fulfillment of the onerous guarantees undertaken.—Engineering.

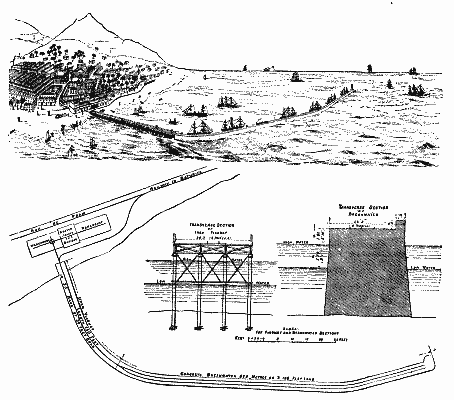

The works illustrated by the engravings are now being constructed under a concession from the imperial government of Brazil. The province of Ceara has an area of about 50,000 square miles, and is one of the richest in Brazil. Its produce comprises sugar, coffee, cocoa, cotton, tobacco, spices, fruit, cabinet and dye woods, India rubber, etc. Its population at the last census, taken in 1877, amounted to 952,624 inhabitants, that of the capital, the city and port of Ceara, being about 40,000. Although Ceara is the principal seaport at which lines of English, French, American, Brazilian, and other steamers regularly call, prior to the commencement of the harbor improvements it was almost an open roadstead, passengers and goods having to be conveyed by lighters and boats between vessels and the shore. The official statistics of the trade and shipping of the port show that an income of £35,750 per annum will be collected by the Ceara harbor corporation from the dues which they are authorized by their concession to charge on all imports and exports and on the vessels using the port and from the rent of the bonded warehouses.

The drawings given here show the nature of the works, which are of a simple character. The depth of water along the principal quay, which is being constructed of solid concrete, and is connected with the shore by an iron and steel viaduct over 750 ft. in length—which is already completed—will be 19 ft. at low water and 25 ft. at high. This quay and breakwater is shown in perspective, in plan, and in section, and is of a very heavy section, as will be gathered by the scale given immediately below it. Meanwhile the landing of cargo is temporarily carried on at the end of the viaduct, which at high tide has a depth of about 20 ft. of water. The custom house and bonded warehouses are being built of the fine granite obtained at the Monguba quarries, which adjoin the Baturite railway, about sixteen miles from the port. A new incline has also been constructed from the rail way down to the port. The line has been laid along the viaduct, and will be extended over the quays as soon as they are completed. The concrete, of which a large quantity is being used, is mixed by Carey & Latham's patent mixers, and the contractors have supplied the very large and complete plant for carrying out the operations.

The engineer to the corporation is Mr. R.E. Wilson, M. Inst. C.E., Westminster, and his resident at Ceara is Mr. R.T.H. Saunders, M. Inst. C.E. The contractors for the work are Messrs. Punchard, McTaggart & Co., their representative at Ceara being Mr. George Wilson, M. Inst. C.E.—The Engineer.

Why should we prefer electricity as the propelling agent of our street cars over all other known methods? I answer, without hesitation, because it is the best, and being the best is the cheapest. Briefly I will present the grounds upon which I take my stand.

To-day the only methods for tramway service are three in number: Horses, with a history of fifty years and over; cables, with a history of fifteen years; and electricity, with a history of two years. I give the latter two years on the basis of the oldest electric street railroad in existence to-day, and that is the Baltimore railroad, equipped with the Daft system.

The main points for consideration common to each are six in number:

Each of these requires a paper by itself, but in as concise a way as possible, presenting only the salient reasons and figures, I shall endeavor to embody it in one.

1st. Obtaining of franchise.

I assume the municipal officers and the promoters honest men.

It is the universal settled conviction that a street car propelled with certainty and promptness by mechanical means is infinitely to be preferred to horses. Hence, if this guarantee can be given, there need be no fear from the other side of the house. Years of experience prove that this guarantee can be given.

The mechanical methods are electricity and the cable. To suit local conditions the former has three general applications—overhead, underground, and accumulator systems; while the latter has but one, the underground. Hence, the former, electricity, has three chances to the latter's one to meet the whims, opinions, or decisions of municipal authorities. Other advantages accruing from mechanical methods are cleaner streets, absence of noise, quick time, no blockades, no stables accumulating filth and breeding pestilence, and lastly the great moral sympathetic feeling for man's most faithful and valuable servant, the horse. These all are directly in favor of obtaining the right franchise.

The three general ways of obtaining the same are a definite payment of cash to the authorities, a guarantee of an annual payment of a certain per cent. of the earnings, and lastly a combination of the two. For the city or town the latter way is the safest, and the best, all things considered. As electricity is mechanical, and as it can be shown that it is the cheapest to construct and most economical, and has three chances to operate, it stands by far the most likely to obtain the franchise.

2d. Construction of buildings.

The governing factors under this head are the local land valuation and tax. The system necessitating a spread eagle policy on the land question will cost. What could be a more perfect illustration than the horse railroad system? The motive power of the New York Central Railroad between New York and Albany could be comfortably stowed in the barns of some of the New York City street railways. What a contrast! The real estate, buildings, and fixtures of the Third Ave. line are valued at $1,524,000, and what buildings! Cattle sheds in the metropolis of America. Surely they did not cost a tithe of this great sum. What did? The land, a whole block and more. Henry George advocates might find food for thought here. All this is true of the other lines in every city in the Union. Enormous expenditures for land. A good one half of their capital sunk in purchasing the necessary room. Go where you will, a good fifty per cent. of the capital is used for land for their stables. This obviously does not include equipment.

How is it with mechanical systems? The land is one of the minor considerations, the last thing considered. Let us look at some figures. From careful examination of many engine plants, considering the ratio between a certain number of horses with their necessary adjuncts and a steam plant of numerically equal power, I find it stands as 1 to 30. That is, a steam plant complete of 30 horse power capacity would need only one thirtieth the floor space of thirty horses. With larger powers this ratio is still greater, and from one estimate I found that it stood as 1 to 108, i.e., for horses I should have to have 108 times more floor space than for an equal number of mechanical horse power. It must be remembered also that the mechanical horse power is 50 per cent. greater than the best animal horsepower.

From one maker, taking the engine alone, I found that a rated 100 horse power engine, guaranteed in every particular, would have ample room in the stall for one horse in the average stable. Another instance showed that I could get a steam plant complete, engine, boiler, etc., of 50 horse power, in a space 5 by 6 feet, which is smaller than the average stall. Here is shown the enormous saving in land purchase.

For car room a building several stories high would answer perfectly, since quick-hoisting elevators could be put in and the tracks on each floor have wire connections with the dynamos, so that the cars could be run across the floor to where you please, facilitating storage and dispensing with handling. This would not be possible with the cable.

Comparing electricity and cable on this point, all things favor the former clearly and beyond all question. Furthermore, if locality so favored, the subject of land purchase for electricity could be tabooed entirely, since distance can be so readily overcome. Way out in the suburbs or back in the country by the side of some waterfall, your station might be, while the current is sent to the great city over heavy conductors. Here land rent or tax would be at the minimum. With horses or cable plainly proximity must be had. It is estimated that the land occupied by the Madison Avenue line of New York City is worth the cost of 40 miles of ordinary double track.

3d. Equipment at station and rolling stock.

The rolling stock would be in each case approximately the same. Consisting of cars of equal seating capacity, the difference of cost would be the necessary attachments for the mechanical systems.

I believe, however, that the mechanical system is bound to work material changes in car construction, in fact it is almost imperative. In all probability a car with 15 to 20 per cent. greater seating capacity than the horse car can be constructed on a different plan for the price given for the electric car. This price, it must be noted, is the one for attachment of motor to the present horse car. The horse cars produced to-day are most carefully planned, thoroughly built, and admirably adapted to their service, but the inexorable law of progress decrees their extinction, for something better.

Motive power. To represent clearly the costs, etc., of the three systems under this head, let us assume a road. Take, if you please, a double line 6 miles long, and operating 24 cars with speed of 6 miles an hour, and running 20 hours out of 24. This would call for 48 horses on the track and 192 horses in the stables, or a total of 240 horses; at $160, counting harness, etc., this would cost $38,400.

With electricity we will proceed as follows: The weight of car with 30 passengers and motor attachments would be about 9,000 lb. It is easily calculated that to propel the same at the specified rate on a level would take about 1.75 horse power, a total of 42 horse power. To make allowances for grades we can calculate that, if the entire road was one gradient of three per cent., each car would take about 6.4 horse power, or since only 12 are going up, a total of 76.8 horse power. It will be fair now to take the average of these two, or 59.4 horse power for an average road. Allowing 35 per cent. loss from engine to work done in actually propelling car, we would have to have 91.3 horse power. Allowing a good safety factor, it would be well to put in a 150 horse power plant. This would cost complete $7,000; necessary dynamos, $3,500. Among these figures should be counted cost of conductor of sufficient size to allow of but three per cent. in energy to overcome its resistance. This I have calculated using a potential of 600 volts; and find that the total cost of six miles copper conductor is $16,000 with above conditions. The total cost is now seen to be $26,500.

As to cables, since the recovery of energy available for tractive purposes is but 35 percent., then the engine of 169 horse power represents what must be had. Allowing a generous factor of safety, let us say that a 250 is all sufficient. This would cost complete and erected about $12,000. The cable would cost $15.000, and gears, etc., $8,000, making a total of $35,000.

The ratio of the three systems stands: Electricity, 1; cable, 1.09; horse, 1.45.

4th. Construction of tramway.

Figures upon this point must necessarily be either averages or approximations. The nature of the locality socially, naturally, and we grieve to say it, politically, has a strong influence upon its construction. Estimating on single track only, a horse road would cost as an average $9,000 per mile. With electricity we have several methods we can avail ourselves of: Surface, costing about $10,000; overhead double conductor, $15.696; underground, $23,500.

With cable but one method, the underground, is possible. This cost is variously estimated at from $30,000 to $110,000 per mile; however, the latter figure is excessive. A fair average would be $35,000.

The ratio of constructions could be fairly placed as follows, putting electricity as 1, by taking the average of the three methods at $16,732: Horse road, 0.53; cable, 2.09.

Unquestionably a great majority of roads of the past have not been constructions of engineering, and of all places requiring care, skill, and engineering, the street roads are the places.

5th. Cost of operation.

A fair figure for cost of one horse for one year is $220.

For electricity, allowing 35 per cent. loss in transmission, etc., 1.54 horsepower would be the work done by engine to get 1 horse power on the track. There are to-day plenty of steam plants producing 1 horse power for work at from $30 to $50 per annum. Take the average, $40. With electricity then $65 would well represent the price of producing 1.54 horsepower.

With cable these figures would hold true, but more work is required. A greater loss is entailed. Since but 32 per cent. is recovered, the figure for 1 horse power on the track would be 2.86 horse power. At the above rates this would be $110 per horse power per year.

Our ratio here is: Electricity, 1; cables, 1.71; horses, 3.38.

This is by no means the whole of the story, for just here must we compute the depreciation and hence repairs due to time. Let us take the road figured on heretofore, and make three tables.

In the following I have under each system taken the estimated costs, allowed a fair per cent. for depreciation, summed up and obtained the ratios.

Any figure then like interest, etc., which would not affect ratios, I have omitted.

| ELECTRICITY. | |

| Conductors, 1 per cent. | $160.00 |

| Engine and dynamos, 5 per cent. | 525.00 |

| Cars, 10 per cent. | 5,280.00 |

| Roadway, 10 per cent. | 2,007.00 |

| Total. | $7,972.00 |

| HORSES. | |

| Horses and appurtenances, 20 per cent. | $7,780.00 |

| Cars, 10 per cent. | 2,880.00 |

| Roadway, etc., 10 per cent. | 3,500.00 |

| Total. | $11,740.00 |

| CABLES. | |

| Cable, 50 per cent. | $7,500.00 |

| Engine and boiler, etc., 5 per cent. | 1,000.00 |

| Cars, 10 per cent. | 4,320.00 |

| Roadway, 10 per cent. | 3,500.00 |

| Total. | $16,320.00 |

These totals put in ratio are as follows: Electricity, 1; cable, 2.04; and horses, 1.47.

Placing all the ratios obtained in a table, we have the following:

| Electricity. | Horses. | Cables. | |

| Depreciation. | 1 | 1.47 | 2.04 |

| Operating expenses. | 1 | 3.38 | 1.71 |

| Construction of tramway. | 1 | 0.53 | 2.09 |

| Motors, cars, etc. | 1 | 1.63 | 1.21 |

| Cars. | 1 | 0.54 | 0.81 |

| Totals. | 5 | 7.55 | 7.86 |

| Average. | 1 | 1.51 | 1.57 |

Now this table must stand by itself for what it represents, and no more. It will be noted that I have not introduced the subject of men. This would unquestionably show favorably for both electricity and cable. Again, note, please, that this table does not represent your profits exactly as per ratios. I have to get them operated the same number of cars and under the same headway. Now with either electricity or cable a higher rate of speed can be maintained with but a very small proportionate increase of cost. This means quicker time, more trips, and greater receipts.

Evidently, as a financial investment, even if cost of maintenance and operating is greater, the cable is to be preferred to horses.

How is it with electricity? The ratios of expenses, etc., stand for themselves, the law of speed is far simpler than with cable, bringing even greater receipts, and again in practice the saving of coal in proportion to work done on track day or night is immensely more economical than with the cable. This point will be touched upon later.

6th. Individual characteristics and advantages.

Under this head a few of the salient features of each system will be mentioned. As the possibilities and limitations of the horse railroad system are, however, so well known, it is needless to go over them. I therefore will confine myself to the electric and cable systems.

With electricity single track lines, crooked streets, all descriptions of turnouts, crossings, branches, etc., are as easy to construct and operate as with horses. With the cable system they are either impossible or enormously expensive.

With electricity the line is not a unit, so that the complete stoppage of the whole line is absolutely impossible. With cable it is a unit and it is possible.

With electricity the life of the conductor is infinite; with cable, two years.

With electricity, and the improvements now being made in traction wheels, etc., the heaviest grades are as easily surmounted as with the cable; although it is true that for grades exceptional in character, such as 20 per cent. grades or over, I should be willing to give the contract to cable.

With electricity any speed can be attained by the individual cars. They are absolutely independent. Lost time can be made up, etc. With cable the cars are dependent upon speed of cable. Lost time cannot be made up except on down grades.

With electricity work done by engine is synchronous with work done on the track at any time of the day or night, with the loss of 35 per cent. due to the conversions in each case. In other words, for every horse power of useful work done on track the engine does 1.54 horse power. This ratio is constant. It makes no difference whether 1 or 100 horse power of work is necessary on the track, the engine has but to do 35 per cent. in excess.

With cable, if 1 horse power of work is all that is required on the track, the engine may be doing 25 horse power to get that amount there through the gears and cable. With heavier loads this is somewhat diminished, but about the very best figure that can be put forth is but 35 per cent. recovery, with 65 per cent. loss—the exact converse of electricity under heavy loads.—Street Railway Journal.

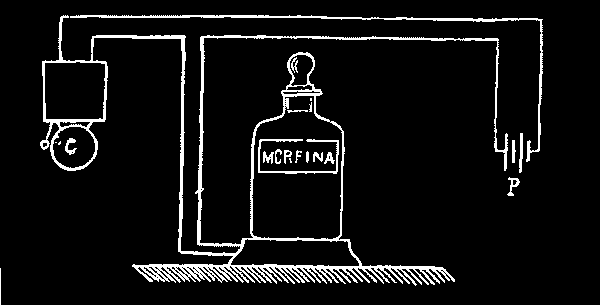

To avoid the errors which sometimes occur in a pharmacy or in a laboratory, where one bottle is taken for another, especially in the case of those containing highly poisonous or dangerous substances, a simple arrangement, shown in the cuts, has been proposed. The apparatus, in principle, is a species of electrical alarm, in circuit with an ordinary house telegraph line. It consists essentially, as shown in Fig. 1, of a battery, bell, and pedestal, provided with an electric contact on which the flask rests. Fig. 2 shows this contact or break piece. On a series of pedestals thus arranged and intercalated in the same circuit the flasks containing poisonous or dangerous substances, whose inadvertent handling might cause trouble, are placed. In removing one of these flasks the circuit is closed, and the electric bell notifies the pharmacist of the danger attendant on the use of the substances contained in the flask referred to, thus guarding against the errors due to carelessness, and quite too frequent, especially in pharmacies.—Chronica Cientifica.

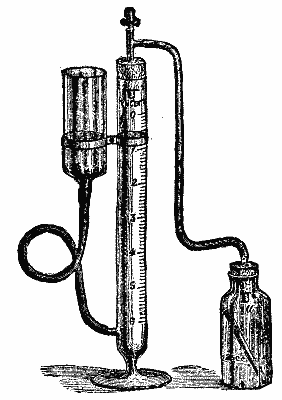

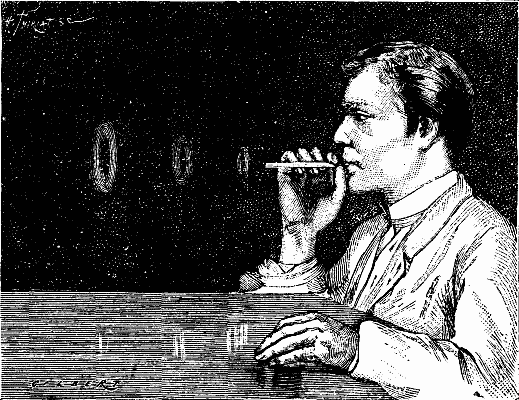

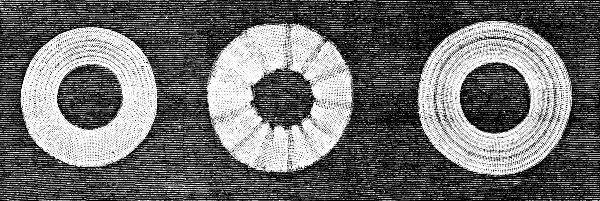

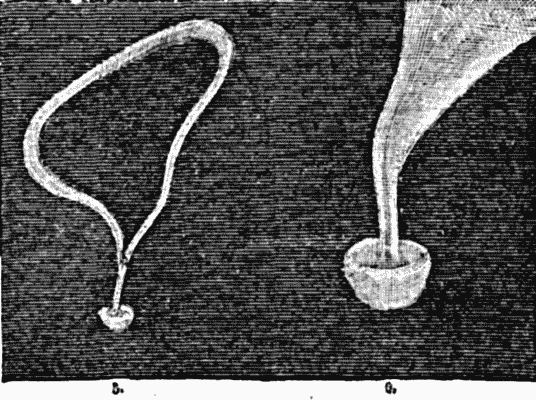

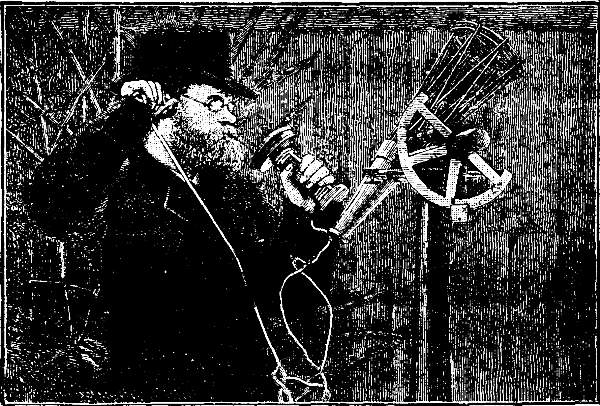

The following apparatus, constructed after the designs of Dr. Loeb, assistant in the Physiological Institute at Wurzburg, is for the purpose of measuring the reaction period of hearing, that is, the period which elapses between the time when a sound wave affects the auditory nerve and is thence transferred to the brain, then affecting the consciousness, and the moment when the motor nerves can be thrown into action by the will. It is, therefore, necessary to fix both instants—when the sound is produced and when the observer has, from its warning, received the impulse so as to press down a key. The great advantage of this instrument over others adapted for the same end consists in this, that the determination in its essentials is effected entirely by mechanism, and, therefore, the graphic results attained by it are free from all sources of error, which errors other methods always introduce to a greater or less extent. Thus its results are quite unexceptionable.

The apparatus shown in the cut rests on three feet, two of them consisting of strong screws, so that by aid of the circular level, l, on the base plate, it can be adjusted perfectly level. On a little shelf attached to a square rod, seen on the left of the instrument, rising from the base plate, and near its top, is a horizontal tube, through which, by a bulb not shown in the cut, a blast of air can be blown. In front of the other opening of the tube is a horizontal fork of ebonite, whose arms carry on the side opposite the tube a metallic ball. Through the arms of the fork pass the wires of the circuit of an electric battery. These terminate in two rounded ends, which, when the arms approach each other, are touched by the metallic ball, so that the latter also closes the metallic circuit. By the blast of air a wooden wedge contained in the tube is driven between the arms of the fork, the ball falls from them, and the electric stream is cut off. The ball drops upon the inclined metallic plate, p, bounces off it, and is received in a little sack, S. When the observer hears the ball strike the plate, he presses on the key, t, and the interval between the two instants, namely, the falling of the ball upon the plate and the pressing of the key, t, is what is to be mechanically fixed and measured.

The electric current, which is closed by the ball as long as it lies on the jaws of the fork, flows around the arms of the electro-magnet, m, which continually attracts an armature fastened to a lever arm, and coming over the poles of the magnet. If the circuit is broken by the fall of the ball, the armature at once rises upward. By this a spring contained in the tube, g, and hitherto kept compressed, is released, which gives a shock to the right angled ½frame, a a, containing a blackened or smoked plate of glass, so that, following the wire, b, acting as a guide, the plate flies from left to right of the apparatus. To prevent the plate from recoiling, a catch, d, is fastened to the side bar, c. Furthermore, lest the friction of the wire, b, in the guiding apertures of the frame should impair its velocity as it moves from left to right, it is connected with a weight pan by a cord passing over the pulley, g, which is so loaded that by the added velocity with which it strives to fall, the retardation already alluded to is overcome, so that the frame moves from left to right with even speed.

In front of the frame, a a, is the tuning fork, f, which as estimated makes 184 vibrations in a second. By the stylus, y, on the upper limb of the fork these oscillations are marked upon the sliding plate of glass as a wave line. Lest, after the first impulses of the fork have been registered, they should soon die away, in front of it is an electro-magnet, H, whose pole-faces near the arms of the tuning fork pass over them. The latter, to be more strongly affected by the magnet, are provided with faces of soft iron. To the lower face of the lower arm of the fork a small sharp stylus is fastened, which, with each beat of the fork, comes into contact with the mercury in the little cup, n, or a spring used instead of it. This closes an electric circuit, which passes around the magnet, thence going through the tuning fork by the binding screw, k, and thence by connections not shown in the cut back to the battery. In consequence of the magnetism thus excited, the arms of the tuning fork are attracted by the poles of the magnet, and forced to beat with increased amplitude. In a short time a constant amplitude of oscillation is reached, when the magnetic impulses are of equal influence with the atmospheric resistance and the internal force of the tuning fork restraining its movements.

Finally, the stylus, s, which touches the glass plate directly above y, is for registering the moments when by the falling ball the sound is produced and when the observer presses the key. This is brought about by the rod, i, to which s is firmly screwed, being jerked upward a short distance at each of these instants, so that the horizontal lines which the stylus, s, marks upon the screen passing in front of it are broken at both places.

The mechanism which jerks the rod, i, upward is thus arranged: The inclined plate, p, on which the ball drops, is carried by the upper horizontal arm of an angular lever turning on the axis, x, and counterpoised by the balancing weight, x'. By the falling ball this arm is pressed downward, and the lower horizontal arm, w, of the lever is also moved. On a second horizontal axis the lever, v, partly concealed, moves, restricted as to its length of swing by the screws, n. As long as the concealed arm is not moved, v is lightly pressed by the small spring, e, against w. The projection, z, at the upper end of v holds the rod, i, which the strong spring, h, is continually pressing upward. When the ball falls upon the plate, p, the arm, w, presses against the lower end of v, the projection, z, sets free the rod, and it springs upward. This movement is soon arrested, as the projection, z', engages with a stud situated on the right side of the rod, i. This projection is situated on the vertical arm of an angular lever whose other arm is the key, t. When the observer presses the key, the rod, i, again is jerked upward by the spring, h. The screw, o, tapped into the rod, i, prevents the rod going higher than necessary, by striking a plate, which also serves as guide for i.

To determine the interval between the falling of the ball and pressing of the key, one has finally to count the waves inscribed by the tuning fork, which come under the portion of the line inscribed by s, which is bounded by the two breaks produced by the successive movements of the rod.

To make the glass plate carried by the frame available for more observations, which plate can be used as a photographic negative, the frame, T, is adjustable up and down upon the pillars, N. This frame carries the tuning fork, mercury cup, n, and the electro-magnet, M. The spring, s, can also be moved up and down along the rod, i.—H. Heele in Zeitschrift fur Instrumentenkunde.

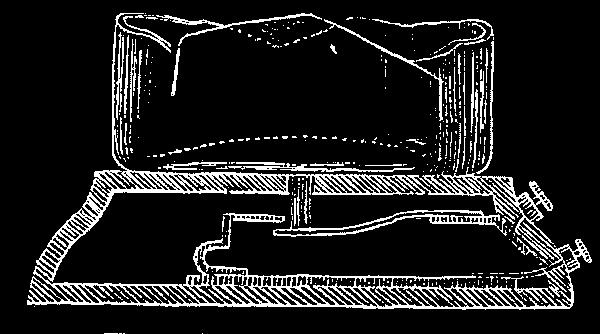

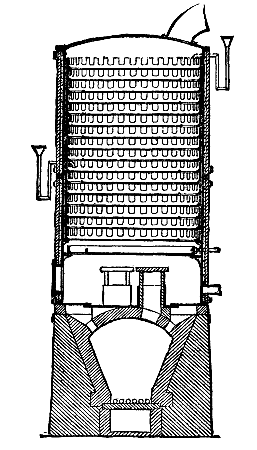

The accompanying engravings represent a new disinfecting apparatus invented by Mr. W.E. Thursfield, M. Inst. C.E., of Victorgasse, Vienna. The principle on which its action is based is that the complete destruction of all germs in wearing apparel and bedding, without any material injury whatever to the latter, is only to be obtained by subjecting the articles infected, for a period proportionate to their structural resistance, to a moist heat of at least 212 deg. Fah. Recent experiences in Berlin have shown that, for security's sake, a temperature of 220 deg. is better. To insure the thorough penetration of this temperature in every fiber, a heat of from 260 deg. to 270 deg. must be maintained in the disinfecting chamber itself. To obtain this by means of ordinary or superheated steam involves the employment of boilers working under a pressure of 2½ to 3 atmospheres, of disinfecting chambers capable of resisting an equal tension, and of skilled labor in attending to the same; in other words, a large initial outlay and correspondingly heavy working expenses in fuel and wages.

The disinfecting apparatus, illustrated in a portable and stationary form, of the dimensions adopted by the sanitary authorities of Vienna, Budapest, Prague, Lemberg, Teplitz, etc., and by the Imperial and Royal Theresianum Institute, and sanctioned for use in barracks, military hospitals, etc., by the Austrian Ministry of War, and for ambulance hospitals by the Red Cross, acts by means of a mixture of steam and hot air in such proportion that the steam, after expending its mechanical energy in inducting the hot air into the disinfecting chamber, is, by contact with the clothes or bedding of a lower temperature, not only condensed, but by condensation completely neutralizes the risk of injury through any chance excess of hot air. The boiler being practically open is inexplosive, and requires neither safety valves nor skilled attendance.

The heat generated in the furnace is utilized to the utmost, and the escaping vapors form a steam jacket in the double casing of the disinfecting chamber. The method of manipulation reduces the danger of contagion to a minimum, as the clothes or bedding are placed in specially constructed sacks in the sick chamber itself, and, after being tightly closed, the sacks are removed and hung in the disinfector. The stationary apparatus, which is constructed to disinfect four complete suits of clothes, including underlinen, or one complete set of bedding, including mattress, is specially adapted for hospitals, barracks, jails, etc. Its dimensions can easily be increased, but the size shown has proved itself, from an economical point of view, the best, as, where the quantity of articles to be disinfected varies, several apparatus can be erected at a less cost than one large one, and one or more be heated as the quantity of infected articles be small or large. In the accompanying drawing A is the boiler, which is filled by pouring water into the reservoir, B, until the same, entering the boiler at its lowest part through the tube, C, rises to the desired height in the water gauge, G. C acts also in the place of a safety valve. D is the fire space, E a movable grate, and F the coal hopper. The fuel consists of charcoal or coke. The boiler is emptied by the cock, H. I is a steam pipe connecting the steam space with the hot air tube, L¹. K is an auxiliary pipe to admit the steam into the chimney during stoppage for emptying and recharging the disinfecting chamber in continuous working. The admission of air is regulated by the handle, L, and the draught in the chimney, M, by the handle, N. O is the disinfecting chamber inclosed by the space, P, which acts at the same time as a steam jacket and as a channel for the downward passage of the vapors escaping from the chamber through the outlets, S. The lower portion of the disinfecting chamber, Q, is funnel-shaped for the better mixture and distribution of the steam and hot air, and to collect any condensation water. Q¹ is a sieve to catch any fallen article. The vertical tubes, S, which serve at the same time to strengthen the chamber, connect the lower portion of the steam jacket, P, with the circular channel, T, which is again connected with the chimney, M, by the tube, T'. The disinfection chamber is hermetically closed by the double cover, R, to the lower plate of which hooks for hanging the sacks are fastened. The cover fits in a sand bath, and is raised and lowered by means of the pulley chain, W, and the swinging crane, X. U is a thermometer indicating the temperature of the steam and hot air in the disinfecting chamber, V a cock for drawing off any condensation water, Y a battery connected with an electrical thermometer to be placed in the clothes or bedding, and Z the sacks in which the infected articles are hung.

The portable apparatus, as shown, for heating with gas, or even spirits of wine, can also be heated with a similar steam and hot air apparatus as the stationary disinfector. In country towns or villages, or even in cities, whose architectural arrangements permit, the portable disinfector can easily be drawn by one man into the courtyard or garden of any house, and the process of disinfection conducted on the spot. Its usefulness in campaigns for ambulance hospitals is self-evident. The letters denoting the several parts are the same as in the stationary apparatus. The portable disinfector is constructed to disinfect two complete suits of clothes or one mattress. The extremely favorable results are shown in the accompanying table of trials.—The Engineer.

TABLE OF RESULTS WITH WM. E. THURSFIELD'S STEAM AND HOT AIR DISINFECTORS.

| Series of Trials. | I. | II. | III. | IV. | V. | VI. | VII. | VIII. | IX. | X. | XI. | XII. | XIII. | XIV. | XV. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Portable Apparatus. | Stationary Apparatus. | ||||||||||||||

| Contents of boiler, in gallons | 3.85 | 4.18 | — | 4.18 | 4.18 | 4.18 | 5.7 | 5.7 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 |

| Water added during the process | — | 1.54 | — | — | — | — | 1.4 | 0.6 | 4.3 | — | — | 7.4 | 1.4 | — | — |

| Temperature of water degs. Fah. | — | — | — | 72 | 57 | 54 | 43 | 132 | 54 | 46 | 176 | 43 | 43 | 43 | 104 |

| Firing commenced with spirits of wine at hours min. | — | 2.12 | 9.10 | 4.30 | — | 10.0 | — | — | — | — | — | — | — | — | — |

| Firing commenced with gas at hours min. | 1.30 | — | — | — | 3.0 | — | — | — | — | — | — | — | — | — | — |

| Firing commenced with coke at hours min. | — | — | — | — | — | — | — | 1.10 | — | 8.15 | 1.13 | 1.43 | 2.54 | — | — |

| Firing commenced with charcoal at hours min. | — | — | — | — | — | — | 10.12 | — | 2.15 | — | — | — | — | 8.43 | 10.16 |

| Steam generated at hours min. | — | 2.34 | 9.28 | 4.41 | 3.15 | 10.18 | 10.35 | 1.34 | 2.38 | 8.53 | 1.20 | 2.3 | 3.19 | 9.3 | 10.23 |

| 212 deg. in chamber registered by external thermometer at hours min. | 2.30 | 2.40 | 9.34 | — | — | — | 10.50 | 1.52 | 2.45 | 9.3 | 1.28 | 2.18 | 3.37 | 9.12 | 10.31 |

| 212 deg. in clothes registered by electrical thermometer at hours min. | — | — | — | 5.25 | 4.18 | 12.12 | — | — | — | — | 1.55 | — | — | — | — |

| 221 deg. in clothes registered by electrical thermometer at hours min. | — | — | — | — | — | — | 11.51 | 2.34 | — | — | — | 3.50 | 4.26 | 10.4 | 12.03 |

| Highest temperature in chamber registered by external thermometer deg. | — | 270 | 250 | — | 324 | 255 | 302 | 275 | 293 | 320 | 284 | 284 | 302 | 284 | 275 |

| Mean temperature in chamber registered by external thermometer deg. | 241 | 257 | 239 | 266 | — | 253 | 266 | 266 | 284 | 284 | 266 | 266 | 284 | 266 | 266 |

| Trial closed at hours, min. | 4.45 | 4.10 | 11.4 | 5.45 | 4.30 | 12.30 | 11.51 | 2.35 | 4.30 | 11.0 | 2.10 | 3.50 | 4.35 | 10.10 | 12.03 |

| Max. therm. registered in mattress deg. | 262 | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| Max. therm. registered in overcoat deg. | — | 239 | 226 | — | — | — | 223 | 223 | 253 | 244 | 226 | — | — | — | 223 |

| Max. therm. registered in winter coat deg. | — | — | — | 232 | 223 | 214 | — | — | — | — | — | 230 | 232 | 223 | — |

| Max. therm. regis'd in winter trousers deg. | — | 243 | 239 | — | — | — | — | — | 262 | — | 253 | — | — | — | — |

| Max. therm. regis'd in summer trousers deg. | — | 246 | 252 | — | — | — | — | — | 280 | — | 264 | — | — | — | — |

| Time required to generate steam min. | — | 22 | 18 | 11 | 15 | 18 | 23 | 24 | 23 | 38 | 7 | 20 | 25 | 20 | 7 |

| Time required to generate 212 deg. in chamber min. | 60 | 28 | 24 | — | — | — | 38 | 42 | 30 | 48 | 15 | 35 | 43 | 29 | 15 |

| Time required to generate 212 deg. in clothes min. | — | — | — | 55 | 78 | 132 | — | — | — | — | 42 | — | — | — | — |

| Time required to generate 221 deg. in clothes min. | — | — | — | — | — | — | 99 | 85 | — | — | — | 127 | 92 | 81 | 107 |

| Total duration of process min. | 135 | 118 | 114 | 75 | 90 | 150 | 99 | 85 | 135 | 105 | 57 | 127 | 101 | 87 | 107 |

| Water evaporated, in gallons | — | — | — | 1.65 | 1.90 | 2.75 | 4.3 | 3.3 | 6.93 | — | — | 9.24 | — | 3.63 | 4.84 |

| Consumption of spirits of wine pints | — | — | — | 3.0 | — | 9.6 | — | — | — | — | — | — | — | — | — |

| Consumption of gas, in cubic feet | — | — | — | — | 70 | — | — | — | — | — | — | — | — | — | — |

| Consumption of cokes, in cbs | — | — | — | — | — | — | — | 6 | — | — | 8.8 | 16.5 | — | — | — |

| Consumption of charcoal, in cbs | — | — | — | — | — | — | 8.8 | — | — | — | — | — | — | 14.3 | 13.8 |

N.B.—In every case, even in the trials V. and X., in which the temperature in the disinfecting chamber rose above 320 deg. Fah., the clothes, owing to the complete saturation of the hot air with live steam, remained absolutely unimpaired.

The column "water evaporated" shows the quantity of live steam passing through the disinfecting chamber averages 13 cubic feet per minute with gas or spirits, and 22 cubic feet with charcoal or coke in the portable and 33 cubic feet in the stationary apparatus. Trials VI., VII., and VIII. took place in open air.

According to trial XII., from 28 to 30 complete suits of clothes can be disinfected at an expenditure of about 75 cbs. of coke per diem.

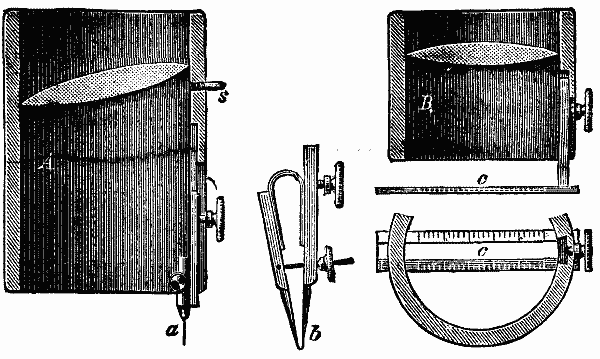

This arrangement consists in a cylindrical metal or horn mounted lens two to four centimeters long, and magnifying two or three times, and two or three centimeters in diameter, whose side is provided with a contrivance for holding after it has been pushed into place a copying needle, a protractor, etc.

While hitherto the architect in using millimeter paper must hold separately in his hands a magnifying glass and needle, while the engraver holds the engraving tool inclined in one hand and the magnifying glass in the other, or must work under a large lens standing on three feet, it is now possible by a firm connection between the lens and needle or other instrument to draw directly with one hand and under the lens. In the accompanying cut one of these lenses is shown in section, A, in which the glass is set obliquely, in whose focus the needle, a, is held and the field of view is enlarged. A longer description is unnecessary, as the illustration gives the best explanation. It need only be remarked that the stud, s, projecting a little near the glass, is for the purpose of preventing the instrument from leaving the position coinciding with the plane of the drawing. For architects and engineers is provided a small compass, b, of about 2 cm. diameter, for laying off parallel widths, for making smaller scales and the like. In these cases it is substituted for the needle. In like manner for calculating cross profiles by graphical methods, for reading parallel divisions, for estimating areas, or revising maps, a finely divided prismatic ivory rule, c, can be placed under the glass, B, and will do good service. In this case the plane of the lens must be perpendicular to the axis of the tube.

For draughtsmen a parallel drawing pen, something like b, is used, which gives several lines at once, perfectly parallel and close together; or a drawing pen with which the smallest signatures, such as boundary stones and figures, can be made neatly and exactly, which is secured like the needle, a, and for which the cylinder serves also as pen holder, offers a great advance.

Thus a whole series of instruments can be used with the lens. For instance, a naturalist can use with it a knife or other instrument. To avoid injury from the instruments, one should, in laying down the cylinder, place it on its side. It is also recommended that on the outer tube of the frame, which is appropriately lacquered of black color, white arrows should be placed in the direction of the points of the instrument, so that the eyes shall be protected from injury in handling the instrument, as by the points being stuck into the pupil, owing to lifting the instrument in an inverted position.—Zeitschrift fur Instrumentenkunde.

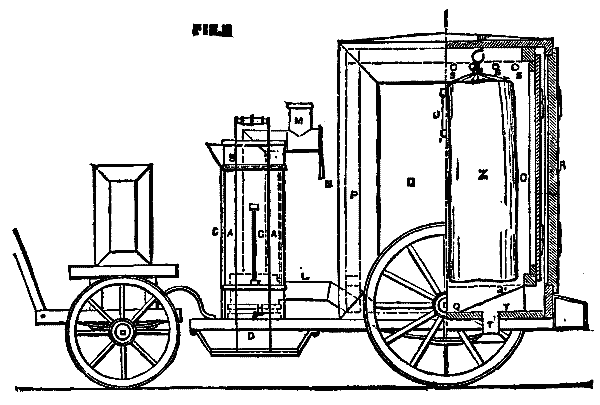

That style of machine for moulding candles in which the candles are forced out at the top by means of a piston is the one most employed, and it is an apparatus of this kind that we illustrate herewith. In its construction, this apparatus presents some important improvements in detail which it is of interest to set forth. The improvements made by the Messrs. Barlow have been studied with a view of manufacturing candles with conical ends, adapted to all chandeliers, without interfering with rapidity of production or increasing the net cost.

These gentlemen have likewise so simplified the continuous system of drawing the wick along as to prevent any loss of cotton. In the next place, the structure of the moulds, properly so called, is new. Instead of being cast, as is usually the case, they are rolled and drawn out, thus giving them smooth surfaces and permitting of their being soldered, are assembled by means of threaded bronze sockets. The engravings between Figs. 3 and 4 show these two modes of fixation. At a may be seen the old method of junction by soldering, and at b the screwing of the moulds into the socket. This machine consists of a box which is alternately heated and cooled, and which is fixed upon a frame, A, at the lower part of which are located the wick bobbins, E. Toward the top of the machine there is a mechanism for actuating the two pairs of jaws, B, which grasp the candles forced upward by the play of the pistons, D. This mechanism, which is controlled by a lever, acts by means of an eccentric.

The pistons, D, are hollow, and are provided above with pieces which form the small end of the candles. Instead of using tin, as is usually done, the Messrs. Barlow employ galvanized iron in the construction of these pistons, and mount them through screw rings—no soldering being used. For this reason, any workman whatever can quickly replace one of the tubes. All the pistons are placed upon a horizontal table, which is made to rise and descend at will, in order to regulate the length of the candles and remove them from the mould. A winch transmits the motion which is communicated to it to two pairs of pinions that gear with racks fixed to the frame to lift the table that supports the pistons. How these latter are mounted may be seen from an inspection of Figs. 3 to 5. This new arrangement of spiral springs for the purpose is designed to hold the pistons on the table firmly, and at the same time to prevent the shock that their upper ends might undergo in case of an abrupt turn of the winch. Moreover, the forged iron plate, H, is not exposed to breakage as it is in other machines, where it is of cast iron. The bobbins already mentioned revolve upon strong iron rods, and the moving forward of the wick in the moulds is effected automatically by the very fact of the manufactured candles' being forced out. These latter are held in position through the double play of the jaws, B, while the stearic acid is flowing into the upper part of the moulds. The cotton wick is thus drawn along and kept in the axis of the candles.

One peculiarity of the machine consists in the waste system applied to the mould box. Steam or hot or cold water is sent into the latter through the conduit, L, starting from a junction between pipes provided with cocks. When the water contained in the box is in excess, it flows out through the waste pipes, G, which terminate in a single conduit. Owing to the branchings at T, and to the cocks of the conduits that converge at L, it is very easy to vary the temperature of the box at will. The warm or cold water or steam may be admitted or shut off simultaneously.

When first beginning operations, the wick is introduced into each mould by hand. The piston table is raised by means of the winch, and is held in this position through the engaging of a click with a ratchet on the windlass. A fine iron rod long enough to reach beneath the pistons and catch the end of the wick is next introduced. After this is removed, the wick is fixed once for all, and in any way whatever, to the top of the mould. This operation having been accomplished, the piston table is lowered, and the machine is ready to receive the stearic acid. The moulds are of tin and are open at both ends. In order to facilitate the removal of the candles, they are made slightly conical. When the candles have hardened, the ends are equalized with a wooden or tin spatula, and then the piston table is raised. At this instant, the jaws, B, are closed so as to hold the candles in place. The latter, in rising, pull into the mould a new length of wick, well centered. A slight downward tension is exerted upon the wick by hand, then a new operation is begun. During this time, the candles held between the jaws having become hard, their wicks are now cut by means of the levers, C, and they are removed from the machine and submitted to a finishing process.—Revue Industrielle.

In several former notes and articles in these pages, we have spoken of the severe crisis through which the old established, or "Leblanc," process has now for some years been passing. It is, in fact, pushed well nigh out of the running by the newer process, known as the "ammonia-soda" process, and would have had to give up the battle before now were it not for the fact that one of its by-products, bleaching powder, cannot, so far, be produced at all by the ammonia-soda works. The bleaching powder trade has thus remained in the hands of the workers of the Leblanc process, and its sale has enabled them to cover much of the loss which they are suffering on the manufacture of soda ash and caustic soda.

In brief outline, the old Leblanc process consists in the following operations: Salt is decomposed and boiled down with sulphuric acid. Sulphate of sodium is formed, and a large amount of hydrochloric acid is given off. This is condensed, and is utilized in the manufacture of the bleaching powder mentioned above. The sulphate of sodium, known as "salt cake," is mixed with certain proportions of small coal and limestone, and subjected to a further treatment in a furnace, by which a set of reactions take place, causing the conversion of the sulphate of sodium of the "salt cake" into carbonate of sodium, a quantity of sulphide of calcium being produced at the same time. The mass resulting from this process is known as "black ash." It is extracted with water, which dissolves out the carbonate of sodium, which is sold as such or worked into "caustic" soda, as may be required. The insoluble residue is the "alkali waste," which forms the vast piles, so hideous to look at and so dreadful to smell, which surround our large alkali works.

The sulphuric acid required for the conversion of the salt into "salt cake" is made by the alkali manufacturer himself, this manufacture necessitating a large plant of "lead chambers" and accessories, and keeping up an immense trade in pyrites from Spain and Portugal. The development of the alkali trade in this country has been something colossal, and the interests involved in it and connected with it are so great that anything affecting it may safely be said to be of truly national importance, quite apart from what technical interest it may possess.

The "ammonia-soda" process, which has played such havoc with the old style of manufacture, proceeds on totally different lines. Briefly stated, it depends on the fact that if a solution of salt in water is mixed with bicarbonate of ammonium, under proper conditions, a reaction takes place by which the salt, or chloride of sodium, is converted at once into bicarbonate of sodium, the bicarbonate of ammonium being at the same time converted into chloride of ammonium.

The bicarbonate of sodium settles out at once as insoluble crystals, easily removed, marketable at once as such, or easily converted into simple carbonate of sodium, and further into caustic soda, as in the ordinary "old" process. The residual chloride of ammonium is decomposed by distillation with lime, giving ammonia for reconversion into bicarbonate of ammonium, and chloride of calcium, which is a waste product.

The maker of "ammonia" soda works direct on the brine, as pumped from the salt fields. His plant is simpler and less costly, and he arrives at his first marketable product much more rapidly and with very much lower working costs than the maker of Leblanc soda, in spite of all the great mechanical improvements which have of late years been introduced into the old process, and which have cheapened its work.

The original patents on the use of ammonium bicarbonate have, we understand, long since expired. But the working details of the process and much of the most successful apparatus have undergone great development and improvement during late years, all the important points being covered by patents still in force, and mainly, if not wholly, in the hands of the one large firm which is now carrying on the manufacture in this country, and is controlling the market.

The one weak spot of the ammonia-soda process, as we mentioned before, is its inability to supply hydrochloric acid or chlorine, and so allow of making bleaching powder. Time after time it has been announced positively that the problem was solved, that the ammonia-soda makers had devised a method of producing hydrochloric acid or chlorine, or both, without the use of sulphuric acid. But the announcements have so far proved baseless, and at present the Leblanc makers are getting incredulous, and do not much excite themselves over new statements of the kind, though they know that if once their rivals had this weapon in their hands the battle would be over and the Leblanc process doomed to rapid extinction.

Such is at present the state of the struggle in this great industry, and the above outline sketch of the two processes is designed to give some idea of the conditions to such of our readers as may not have any special knowledge of these manufactures.

At the present moment great interest is being taken in a new process, about to be put to work on a large scale, which is designed to take up the cudgels against the ammonia process and enable the Leblanc makers to continue the fight on something more like equal terms.

We allude to the process proposed and patented by Messrs. Parnell & Simpson, and about to be worked by the "Lancashire Alkali and Sulphur Company," at Widnes. We recently had the opportunity of inspecting fully the plant erected, and of having the method of procedure explained to us. We look upon the new process as such a spirited attempt to turn the tide of a long and losing battle, and as so very interesting on its own merits, that an account of it in these pages will be thoroughly in place.

The main idea of the process is to combine the "Leblanc" and the "ammonia-soda" manufacture. But in place of using caustic lime to decompose the ammonium chloride and get back the ammonia, the "alkali waste" spoken of above is employed, it being found that not only is the ammonia driven off, but that also the sulphur in the "waste" is obtained in a form allowing of its easy utilization, it and the ammonia combining to form ammonium sulphide, which passes over in gaseous form from the decomposing apparatus. This ammonium sulphide is, as we shall see, quite as available for the working of the ammonia-soda manufacture as pure and simple ammonia, and all the sulphur can be obtained from it.

In outline the process is as follows: We will suppose that a quantity of bicarbonate of sodium has been just precipitated from a brine solution, and we have the residual ammonium chloride to deal with. This is decomposed by "alkali waste," giving a final liquor of calcium chloride, which is run to waste, and a quantity of ammonium sulphide gas. This latter is led at once into a solution of salt in water, till saturation takes place. Into this liquor of brine and ammonium sulphide pure carbonic acid gas is now passed. The ammonium sulphide is decomposed, pure sulphureted hydrogen gas is given off, which is conducted to a gas holder and stored, while ammonium bicarbonate is formed in the liquor, which brings about the conversion of the salt into bicarbonate of sodium, ready for removal and preparation for the market.

It will be observed that we printed the word pure in italics in speaking of the carbonic acid used. This is one of the great points in the process, as in order that the sulphureted hydrogen gas obtained shall be concentrated and pure, only pure carbonic acid can be used in liberating it. The apparatus employed in its preparation is perhaps the most ingenious part of the works, and well worthy of attention by others besides alkali makers. The method is based on the fact that if dilute impure carbonic acid is passed into a solution of carbonate of sodium, the carbonic acid is absorbed, bicarbonate of sodium being formed, and the diluting gases passing away.

The bicarbonate of sodium on heating gives up the extra carbonic acid, which can be collected and stored pure, while the liquor passes back to simple carbonate of sodium, to be used over again as an absorbent. This is not at all new in theory, of course, nor is this the first proposal to use it commercially; but it is claimed that this is the first successful working of it on a large scale.

The gases from a large limekiln supply the dilute carbonic acid gas, which contains 25 per cent. to 30 per cent. of pure gas, the principal diluting gas being, of course, nitrogen. This kiln gas is drawn from the kiln by a blowing engine, and is first cooled in two large receivers. It is then forced into the solution of sodium carbonate in the absorption tower, 65 ft. high by 6 ft. diameter, filled with the liquor. The tower has many diaphragms and perforated "mushrooms," to cause a proper dispersion of the gases as they ascend through the liquor. The strength of liquor found best adapted for the work is equal to a density of about 30° Twaddell. After saturation the mud of bicarbonate of sodium is drawn off and passed into the "decomposer," a tower 35 ft. high by 6 ft. 6 in. in diameter, with perforated shelves, into which steam is blown from below, the liquor passing downward. The bicarbonate is decomposed, pure carbonic acid being given off. This is passed through a scrubber and into a gas holder ready for use. The liquor, which has now returned to the state of simple carbonate of sodium, only requires cooling to be ready to absorb a fresh lot of carbonic acid gas. The cooling is effected in a tower packed loosely with bricks, the hot liquor trickling down against a powerful current of air blown in from below. Liquor has been cooled in this way, in once passing through the tower, from 220° Fahr. to 58° Fahr., but of course the exact cooling obtained depends more or less on the temperature of the atmosphere.

The next stage of the process, if we follow on after the preparation of the pure carbonic acid, is the employment of the gas for the decomposition of the ammonium sulphide absorbed in a brine liquor as above explained. The brine and ammonium sulphide are contained in what is known as a "Solvay tower," provided with proper means for dispersion and absorption of the carbonic acid gas. The precipitated bicarbonate of sodium is removed and washed, and prepared for the market in whatever form is required, the sulphureted hydrogen gas being led to a holder and stored, as before stated.

The decomposition of the ammonium chloride by means of "alkali waste" is carried out in a specially designed still. This is a tower 45 ft. high by 8 ft. diameter, divided by horizontal plates into compartments of about 3 ft. 8 in. in height. These compartments communicate with one another by means of pockets, or recesses, in the shell of the tower. A vertical shaft, with arms, revolves in the tower. The "waste" is fed in at the top by means of hopper and screw feed. The liquor is heated by steam blown in to over 212° Fahr. The ammonium sulphide is led direct into an absorbing vessel full of brine.

It now only remains to see how it is proposed to deal with the sulphureted hydrogen gas which represents the sulphur recovered from the waste. It can be burnt direct to sulphurous acid and utilized for the production of vitriol perfectly pure and free from arsenic, commanding a special price. But Messrs. Parnell & Simpson state that by a method of restricted combustion they are able to obtain nearly all the sulphur as such, and put it on the market on equal terms with the best Sicilian sulphur. We did not gather that this has yet been done on the working scale, however.

It will be seen that it is proposed that a Leblanc alkali maker shall continue to produce a portion of his make by the old process, but shall erect plant to enable him to make another portion by the Parnell & Simpson method, using his Leblanc "waste" in place of the caustic lime now employed by the ammonia soda people. He is thus to have the benefit of the cheaper process for, say, half his make, while he further cheapens the ammonia method by saving the cost of lime and by recovering the sulphur otherwise lost in his waste.

The saving in lime is stated to be one ton for each ton of sodium carbonate produced, or in cash value about 10s. per ton at Widnes, while the sulphur saved is estimated to be 6 cwt. per ton of sodium carbonate. We reproduce these figures with all reserve, not being ourselves sufficiently specialists to judge of them. But we were assured that they represent the minimum expected, and reasons were given to us to show that they would probably be exceeded.

Another gain for the Leblanc maker would be that he will escape the cost of removal and disposal of a portion of his refuse or waste.

The plant now erected was calculated for a yield of one hundred tons carbonate of sodium and about thirty-five tons of sulphur per week, but it now appears likely that this will be exceeded; while the carbonic acid plant was supposed to be equal to a yield of 6 tons of pure gas per day, and is now found capable of doing twice as much.

A few weeks will now bring this new combination process into the active and crucial test of the markets. Chemists and chemical engineers have all along taken a keen interest in the ingenious ideas of Parnell & Simpson. Commercial men are no less interested in the financial result of the experiment about to be tried at the expense of a few gentlemen of Liverpool and district. So far as we can learn, opinions are to some extent divided, though many good judges are very hopefully inclined. For our own part, speaking with diffidence, as being a little off our regular track of work, we will only say that we were favorably impressed with what we saw and heard; and we certainly wish the venture that full success which its cleverness and its pluck, as well as its great importance at this crisis, deserve for it.—Engineering.

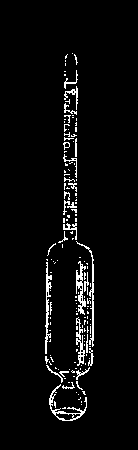

An important subject for investigation, which has not yet been satisfactorily determined, is the temperature at which it is most beneficial to distill coals of various qualities. The practice of allowing the charge to remain in the retort for some time after most of the gas has been driven off, to enable (it is said) the retort to recover heat for the next charge, often leads to misconception as to the true temperature of carbonization. The effect of this is to equalize the temperatures inside and outside the retort. This inside temperature is not maintained, the temperature outside not being high enough to transmit the heat with sufficient rapidity; and so, in an apparently hot retort, the coal may be carbonized at a comparatively low temperature. A truer test of temperature is that of the outside of the retort, which should be not less than 400° to 500° Fahr. above the temperature necessary for proper carbonization. In all experiments relating to temperature pretending to any degree of accuracy, a pyrometer of some kind should be used. Judging of the temperature by the color is often misleading. Not only may the eye be deceived, but different clays do not present the same appearance at the same temperature. A good, reliable pyrometer to estimate temperatures to (say) 2500° Fahr. is much wanted.

Experience during the last few years with the high temperatures obtained by the use of regenerative furnaces has led me to the conclusion that higher heats than are usual may be employed with advantage, as regards both the quantity and the quality of gas, provided the retorts are heated uniformly throughout their length, and the weight and duration of the charge are so adjusted that the coal does not remain longer in the retort than is just sufficient to drive off the gas; and that the more rapidly the coal is carbonized, the better are the results. In two retorts of the same size, one making 5,000 and the other 10,000 cubic feet per day, the gas will be twice as long in contact with the surface of the retort in the former as in the latter—to the probable detriment of its quality, and increased tendency to stoppage in the ascension pipes.

A subject closely allied to that just alluded to is the temperature of the gas as it leaves the retort. Until within the last few years, it was generally assumed that this was not higher than from 200° to 300° Fahr.; and a very plausible theory was given to account for such a comparatively low temperature. A discussion which took place a few years ago in the Journal of Gas Lighting showed that at that time opinions on this subject were not unanimous. But the conclusion arrived at seemed to be that the gas was not higher in temperature than that before stated; and if higher temperatures were observed, they were due to the tarry matter in the gas, and were not those of the gas itself. A little reflection is sufficient to show that the existence of gas intimately mixed with tarry matter at a high temperature, without being itself raised to that temperature, is a physical impossibility.

In a paper read to a Continental gas association about a year ago, the writer stated, as the result of many experiments, that unless the temperature in the ascension pipe rises above 480° Fahr., thickening of the tar in the hydraulic main and choking of the ascension pipe will certainly occur. This led me to make a series of experiments, extending over many months, on the temperature of the gas in the ascension pipes at different points and at various times during the charge. The results of these experiments may be of some interest, and may lead to further investigation. The temperatures were taken by mercurial thermometers registering 600° Fahr., except those near the mouthpiece, which were taken by a Siemens water pyrometer. Every care was exercised to insure accuracy; and the instruments were carefully adjusted. At a distance of 18 inches from the mouthpiece, the temperatures varied from an average of 890°, shortly after the retort was charged, to 518° at the end of the charge; at 12 feet distant from the mouthpiece, the corresponding temperature was 444°, falling to 167° at the end of the charge; and at 22 feet, the average temperature varied from 246° at the commencement to 144° at the end of the charge. These are the averages of a number of experiments. In some instances they were considerably above these averages—temperatures over 900° being frequently obtained. This is about the temperature of a low red heat, and is much higher than any I have seen recorded. When the gas was allowed to issue from a hole in the ascension pipe, 1¼ inches in diameter, 18 inches above the mouthpiece, a strip of lead held about an inch from the orifice was freely melted.

In the settings on which these experiments were made, the middle ascension pipe takes the gas from the two central retorts; and it is of interest to note that in this pipe the temperature of the gas 18 inches from the upper retort was found to be 1014° Fahr., and at the point where it entered the hydraulic main it was 440° Fahr. Zinc was freely melted by the gas issuing from a hole 18 inches from the mouthpiece. The temperatures always fall toward the end of the charge; the fall of temperature in the ascension pipe being a good indication that the charge is worked off. They increase with the heat of the retort and with the weight of the charge.

Experiments were also made to ascertain the temperature of the gas in the retort; and for this purpose one of Murrie's pyrometers was used, the action of which depends on the pressure produced by the vaporization of mercury in a malleable iron tube. The end of this tube was first rested on the top of the coal, but not in contact with the retort. It reached about 18 inches into the retort, and therefore was not in the hottest part. In this position the temperature indicated shortly after charging the retort was 1110° Fahr., gradually rising to 1640° Fahr. The end of the tube was then embedded in the coal, when the pyrometer indicated a temperature of 1260° Fahr. within 30 minutes after the retort was charged; gradually rising toward the end of the charge as before. At the time these temperatures were taken, the retorts were each producing 10,000 cubic feet of gas per day. I had no opportunity of testing the accuracy of the statement that, with lower temperatures, there is a tendency to stoppage of the ascension pipes; but with these high temperatures (contrary to what might be expected) there is no trouble from stoppages.

These experiments, so far as they have gone, lead to the conclusion that the temperature of the gas as it is evolved from the coal is not less than 1200° Fahr., and that cooling commences immediately on the gas leaving the retort. The temperatures being far above that of liquefaction, the gases are cooled very rapidly. The temperature of the gas in the ascension pipe depends on the rapidity with which the gas is evolved—that is to say, the greater the quantity produced in a given time, the less effective is the cooling action of the mouthpiece and the ascension pipe; and although I had no opportunity of testing it, I should expect to find that with retorts making from 5,000 to 6,000 cubic feet of gas per day, the maximum temperature in the ascension pipe 18 inches from the mouthpiece will not exceed 400° to 500° Fahr., while with lower heats and lighter charges the temperatures will be still lower. That these temperatures have some effect in causing or preventing stoppage in the ascension pipes there can be no doubt; and it is important that this subject should be thoroughly investigated.

It is of interest to consider what must be the physical condition of the gas at these high temperatures. All the hydrocarbons which are afterward condensed must then be in the condition of gases having various degrees of condensability, mixed with and rendered visible by a cloud of carbon particles or soot. If this soot could be removed from the gas at this stage without reducing the temperature, we should probably have no thick tar or pitch, but only comparatively light-colored oils; and it might possibly lead to an entirely different mode of conducting the process of condensation.

These are a few of the subjects on which it is extremely desirable that we should possess that complete information which can only be obtained by well-directed investigations with different materials and under varying conditions. There are many others in connection with carbonization and purification which might be mentioned; but I think I have said sufficient to show the necessity that exists for more minute investigation and research. Investigations such as are here indicated do not involve any large expenditure of money; but they do require care and intelligence to prevent errors being made. Experiments should not be condemned as defective because the results differ from old-established theories; yet when this does happen, it is in all cases better to suspect the new experiment rather than the old theory, until the results have been fully established.—Wm. Foulis, Journal of Gas Lighting.