Fig. 1

THEORY OF SILK WEAVING

Second Revised and Enlarged Edition

COPYRIGHT. 1921. by CLIFFORD & LAWTON

All rights reserved

GROLIER CRAFT PRESS, Printers. 229 West Twenty-eighth Street, New York City

The silk industry of America has of late years rapidly advanced to the front rank among the great textile industries of the world. It may indeed be proud of this position, to which that enterprising spirit and untiring energy peculiar to our nation, combined with our great technical and natural resources, has brought it.

That we are, on the other hand, not yet at the height of perfection we are also compelled to acknowledge, but if we consider the short space of time that the American industry has required for its development, as compared to the decades, almost centuries, to which some of the great European silk centers can look back, the fact is neither surprising nor discouraging.

While it must not be our aim to imitate or copy their ways, inasmuch as out conditions and circumstances are quite different from theirs, we may still profitably study their methods in order to overcome our deficiencies.

The greatest advantage which our competitors derive from such a long existence consists in having at their disposal a force of skilful, trained help. The manufacturers, appreciating the importance of this factor, make great efforts and pecuniary sacrifices to elevate and maintain the high standard of their industry.

For instance, they support textile schools and lecture courses, where young men can acquire a thorough technical education and equip themselves for a career of usefulness, thereby serving their own interests and at the same time furthering those of their chosen profession.

[pg 6]This beneficial influence cannot fail to exert itself from the standard of the higher employer down to that of the weaver, who would naturally take more pains and interest in his work than if he were a mere mechanical appendage to his loom in order to keep it in motion.

Very little has been done in his country for technical education as far as the silk industry is concerned, and it was on this special branch, that prompted the author to offer in the present little work a treatise on the theory of shaft weaving for broad silks and ribbons.

It is divided into three principal parts:

1st. Drawing-in the warp in the harness.

2nd. The weaves and their application.

3rd. Decomposition or analysis of the cloth.

To the foregoing there have been added in the revised and enlarged edition several additional parts covering the following: JACQUARD WEAVES, BOX LOOM WEAVES, including CREPES, and COST CALCULATIONS for plain and fancy weaves.

The subject while condensed, is made as clear and comprehensible as possible, and to many desirous of increasing their knowledge in this direction, this should prove a valuable help.

The author, through the medium of this work, hopes to win the approval and encouragement of the manufacturers, and will feel amply repaid should his efforts tend to develop a deeper interest in the "Queen of Textiles."

With this term we designate the operation preceding the weaving, by which all the warp-threads are drawn through the heddles of the harness.

The order in which this is done varies according to the weave and the nature of the fabric to be produced; so we distinguish:

Straight draws,

Skip draws,

Point draws,

Section draws.

These form the simplest and most common method of drawing-in. We begin with the first heddle on the left side of the shaft nearest to the warp-beam, then take the first heddle of second shaft and so on until all the shafts the set contains are used in rotation. This completes one "draw," and this operation is repeated until all the warp-threads are taken up.

The method of making the shaft nearest to the warp-beam the first, is almost universal with the silk business and is technically called drawing-in from back to front.

The opposite, or drawing in from front to rear, is used occasionally, however, and in this case makes the first heddle on the left hand side of the front shaft No. 1.

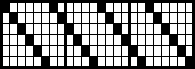

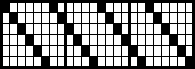

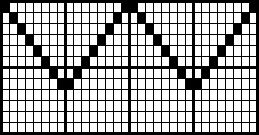

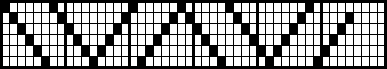

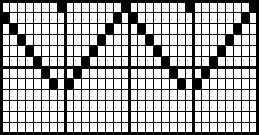

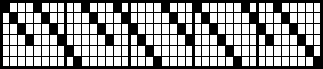

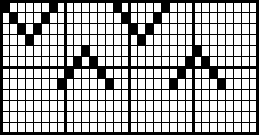

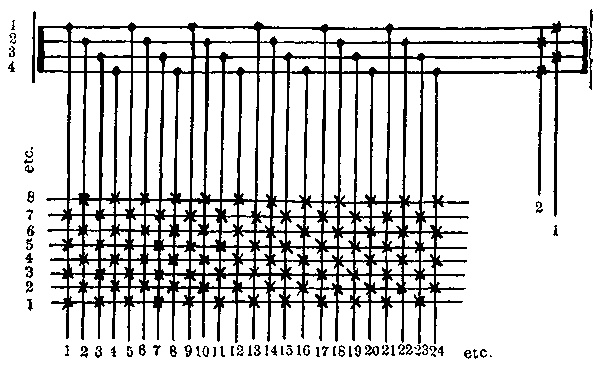

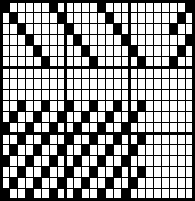

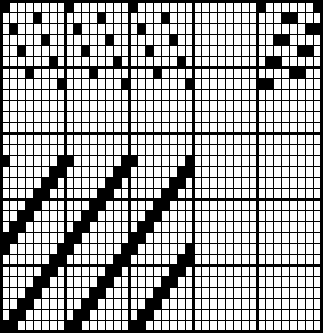

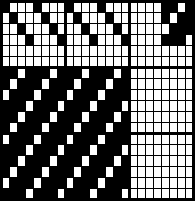

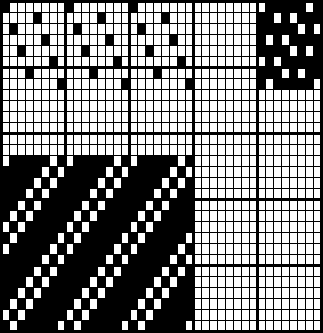

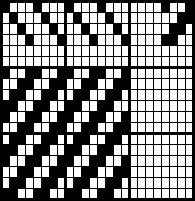

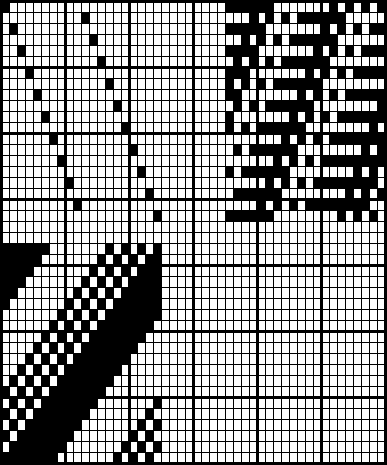

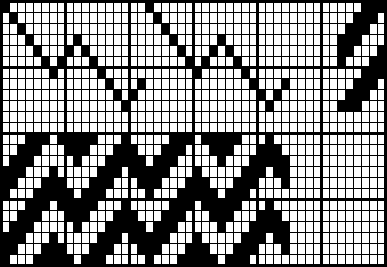

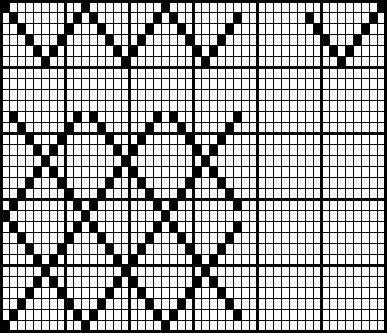

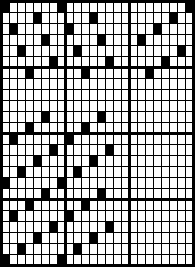

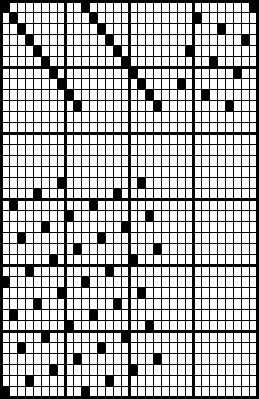

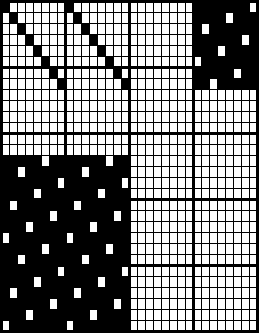

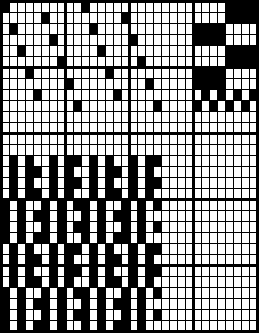

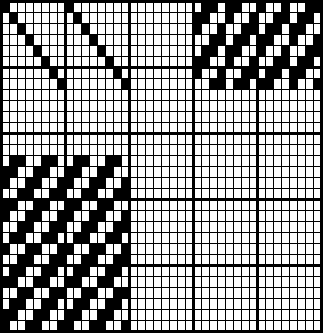

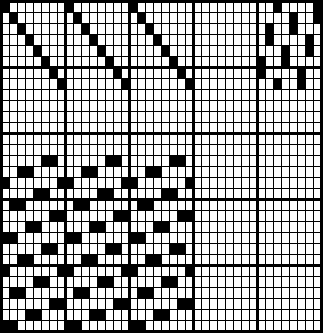

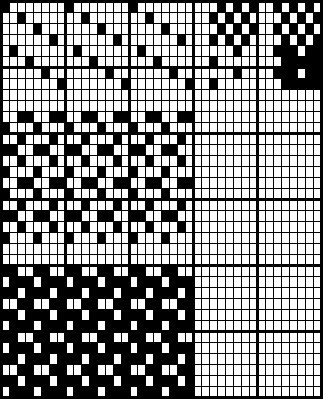

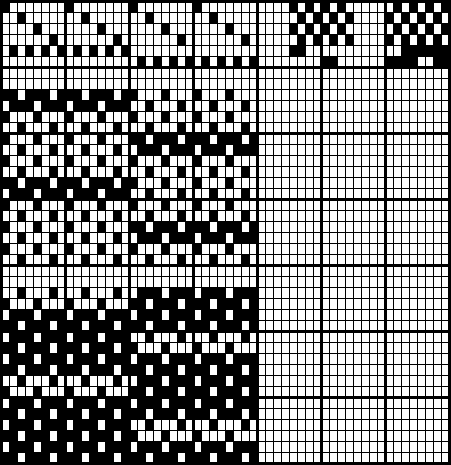

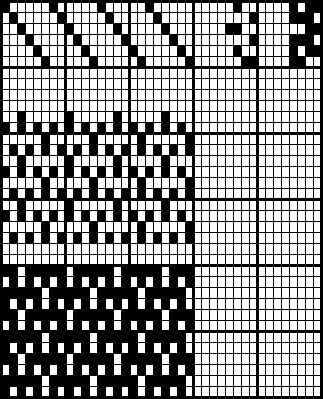

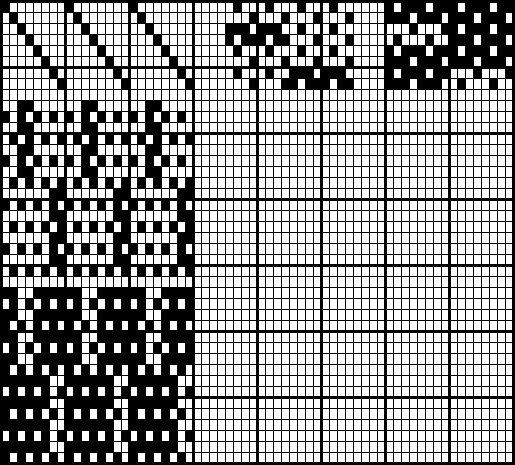

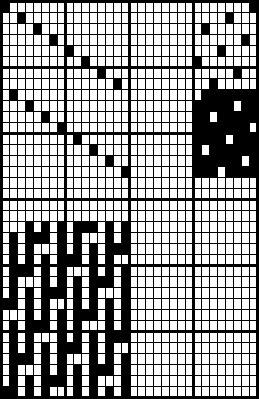

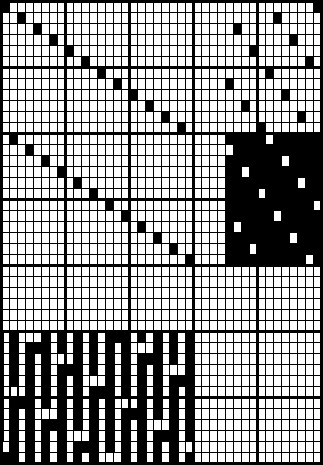

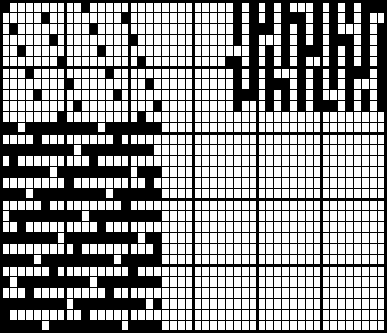

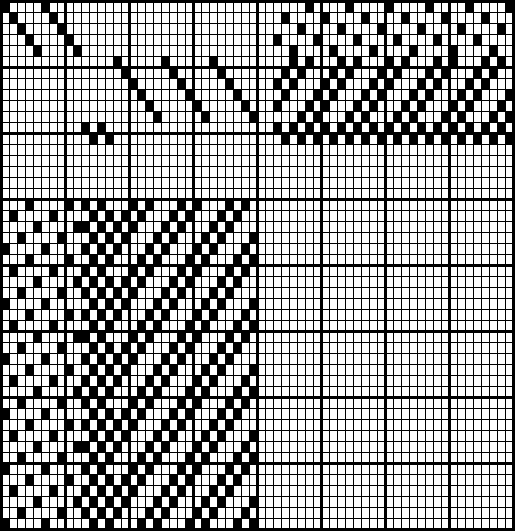

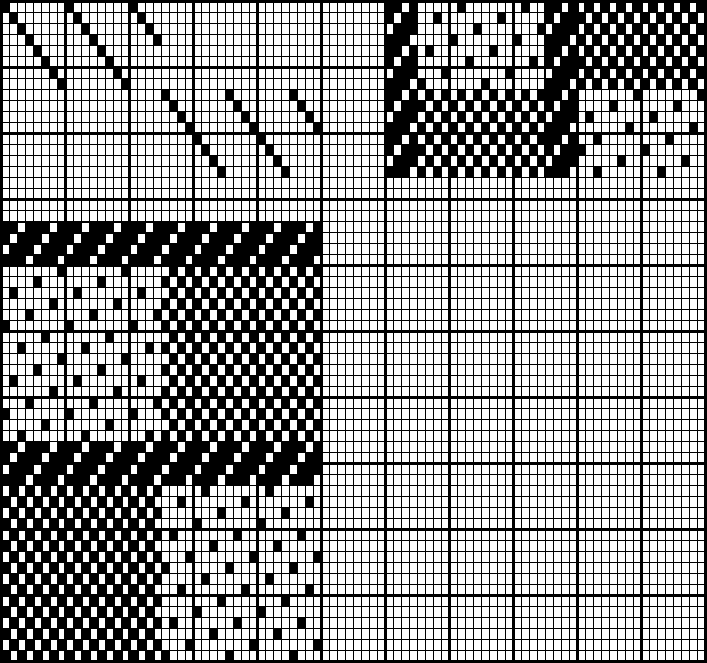

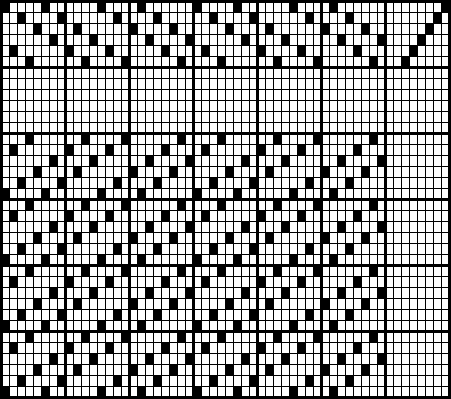

The making out of the Drawing-in Draft, which must indicate the arrangement or the rotation in which the warp-threads are drawn in, can be done in various ways, of which we will mention the two most popular methods. The first is by using common designing paper, and indicating the rotation by dots. The horizonal rows of squares represent the shafts, the vertical rows the warp-threads. Fig. 1 shows four repeats of a straight draw on six harness marked out according to this idea. A second method is to use paper ruled horizontally, the lines representing the shafts; and to draw vertical lines [pg 9] for the warp-threads. The latter are made to stop on the lines bearing the number of the shafts into which the respective threads are to be drawn. Fig. 2 is such a draft, illustrating six repeats of a draw on four harness from "Front to Rear."

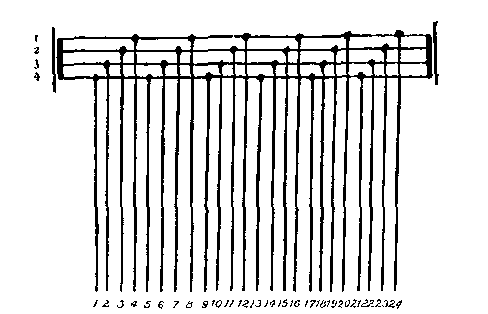

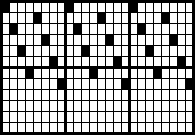

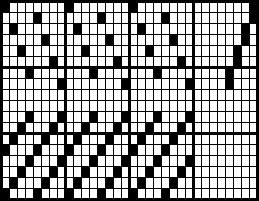

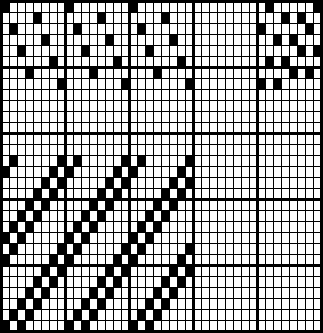

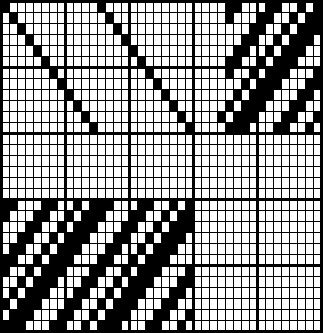

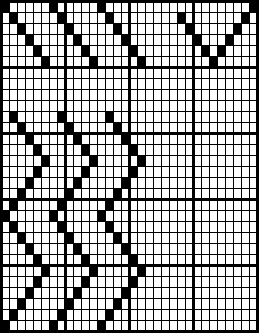

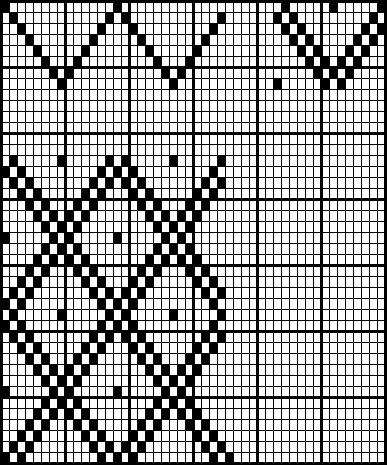

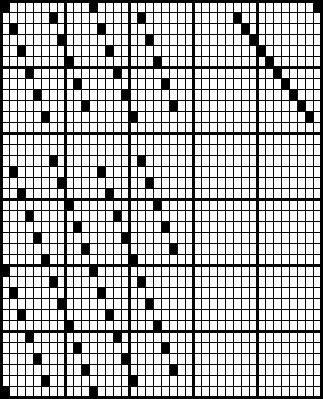

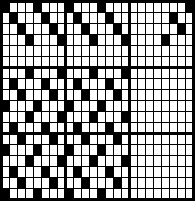

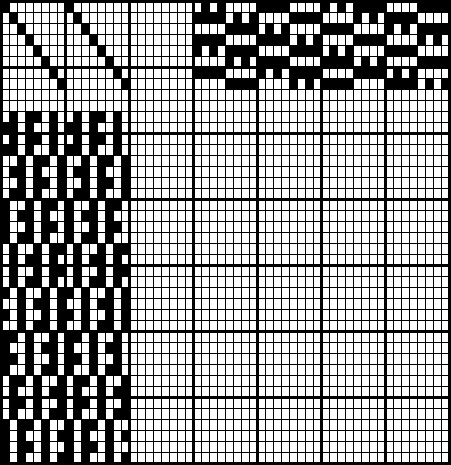

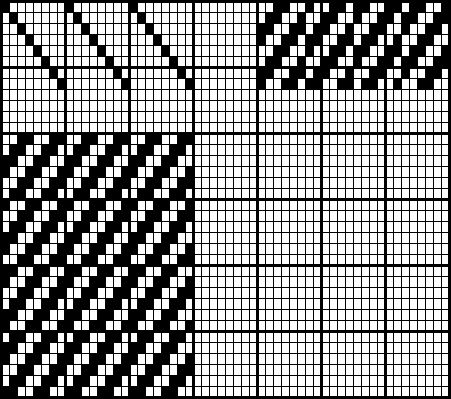

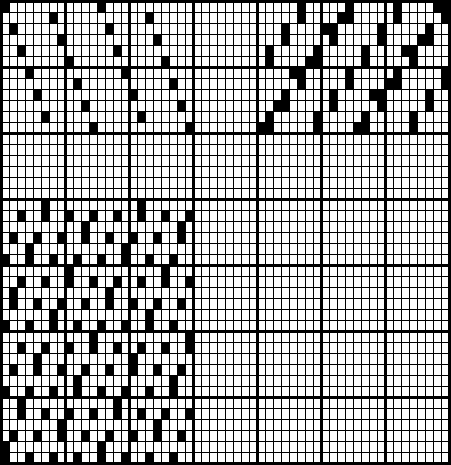

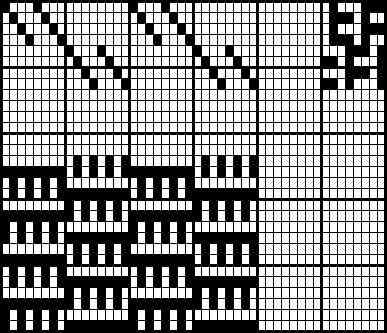

The draws coming under this heading are used very extensively in silk weaving, especially for fabrics requiring a heavy warp and a large number of shafts. Enter first the odd and then the even shafts. An 8 harness draw of this kind, of which three repeats are shown in Fig. 3, runs as follows: 1, 3, 5, 7, 2, 4, 6, 8.

Fig. 4 is a 12 harness draw of the same class.

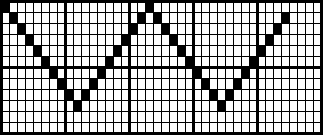

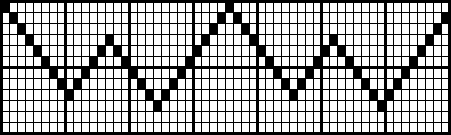

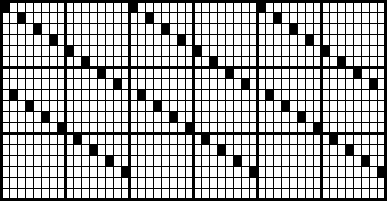

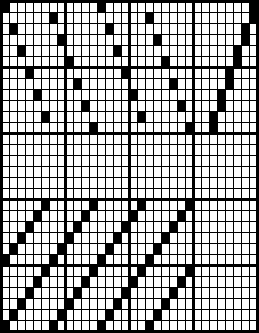

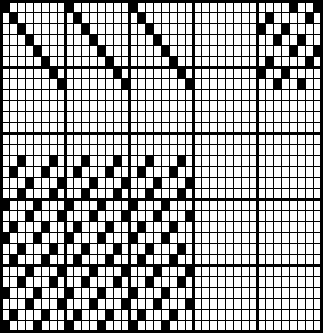

Point draws are a combination of a regular straight draw from back to front and one from front to back, the first and the last shafts only being used once, while the rest receive two ends each in one repeat of the draw. Fig. 5 illustrates a regular point draw in 2 repeats on 10 shafts. It will be seen that 14 ends make a repeat; in fact, the number of warp-threads required for one draw will always be double the number of harness less 2, hence a 12 harness regular point draw will require 22 warp-threads for a repeat.

The drawing-in draft illustrated in Fig. 6 is a slight variation of the regular point draw; it consists, as will be seen, of a draw from back to front, and also a full one from front to back, there by causing a double point.

Another change from the regular point draw is illustrated in Figs. 7 and 8; this class may be called Broken point draws, because a new draw is begun before the other one is complete. Fig. 9 also comes in this class and represents a zigzag draw on 10 harness.

The drawing-in drafts which we have described under the head of "Point draws," are used mostly to obtain the various pointed and zigzag effects.

This division of drawing-in drafts is used extensively in silk manufacturing; for instance, in all fabrics having a ground warp and a binder warp, also in double-face goods, or where two different weaves are combined in one effect.

One or more threads are drawn on the first section, then one or more on a second and third, if the harness is divided in so many sets.

The following examples will illustrate the principle of these draws.

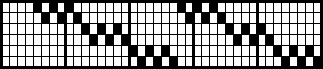

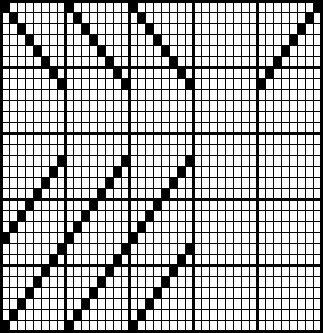

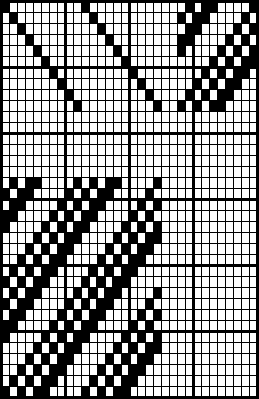

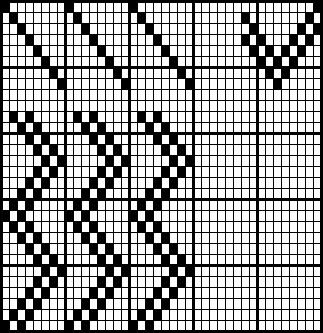

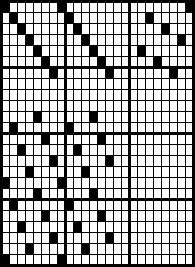

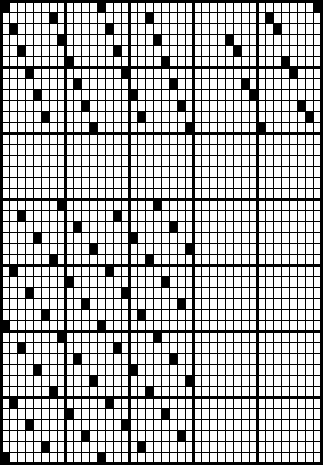

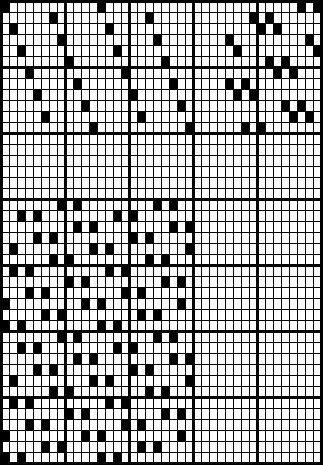

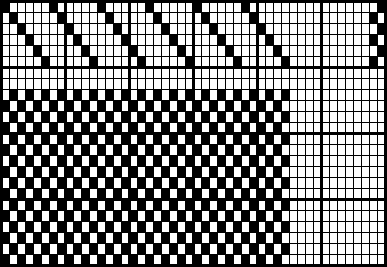

In Fig. 10, shafts 1, 2, 3, 4 from the first set, shafts 5 and 6 the second, 8 threads are drawn straight on the first, then 2 on the second section.

Fig. 11, first set shafts 1 to 6 inclusive, second set shafts 7 and 8.

Fig. 12 is drawn end and end on two sections having 8 shafts each.

Figs. 13, 14 and 15, while not strictly belonging to the class of section draws, may, however, be considered under this heading. The idea is to draw a certain number of ends in one part of the harness and another group in another part, be it straight, point or skip, which will cause the effect on the cloth to be accordingly transposed or broken up.

[pg 15]In any woven fabric we distinguish two systems of threads, the Warp or Chain, running lengthways in the cloth, and the Filling or Weft, crossing the former at right angles.

This crossing or interlacing consists of every individual warp-thread being placed alternately under and over one or more threads of the filling system. The arrangement of this interlacing is technically called the Weave, and the variety in which the points of crossing can be distributed is practically endless.

It is principally the weave that lends to a fabric its character, influenced, of course, by the material used, the size and tension of the threads and the combination of the colors.

The weaves are divided into three main classes: the Foundation weaves. In the silk business they are known under the following names:

The Taffeta Weave,

The Serge Weave,

The Satin Weave.

In the foundation weaves each thread effects only one crossing in one repeat of the weave, and the points of interlacing occur in a given rotation. A repeat in the foundation weaves comprises the same number of warp-threads as of [pg 16] picks or filling threads, and if this number is 8, for instance, the weave is called an 8-shaft or an 8-harness weave. In marking out a weave, the warp-threads are represented by vertical lines, the filling by horizontal ones, or in each case by the space between these lines. The places where a warp-thread lies over the filling are marked with paint or simply with a cross. In a similar manner we mark out the chain draft, which indicates the rotation in which the shafts are raised.

This is the simplest and oldest method of interlacing. The odd numbers of warp-threads cross the even numbers after every pick; hence of two warp-threads one will always go over the first pick and under the second, and the other end under the first and over the second pick. Taffeta cloth, therefore, has the same appearance on both sides, and in cotton and wool weaving this weave is technically—and properly indeed—called the Plain Weave. It has the smallest repeat, 2 warp-threads and 2 picks, and the exchanging of warp and filling is the most frequent possible. The cloth thus produced is firmer and stronger than that obtained with any other weave.

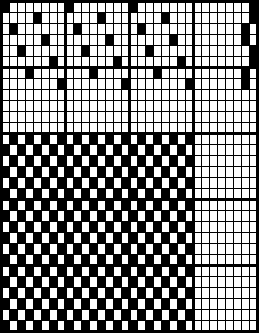

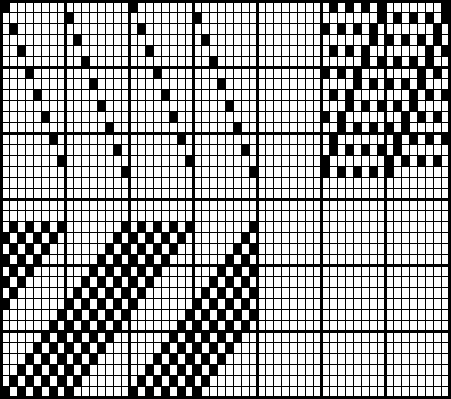

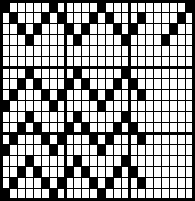

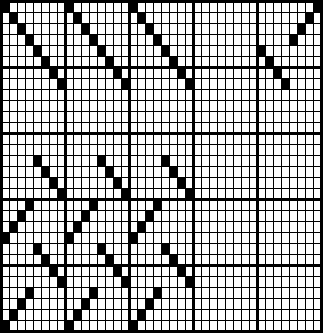

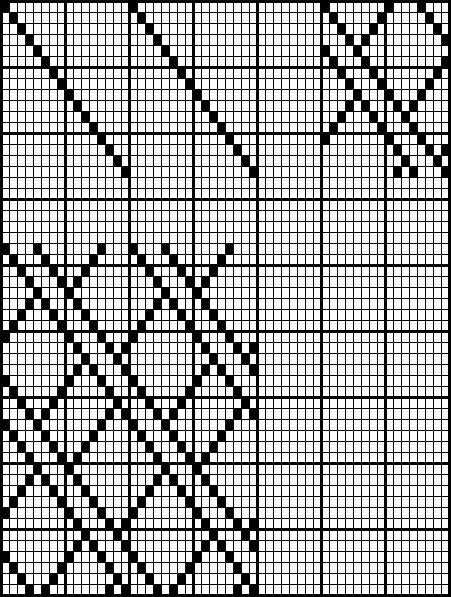

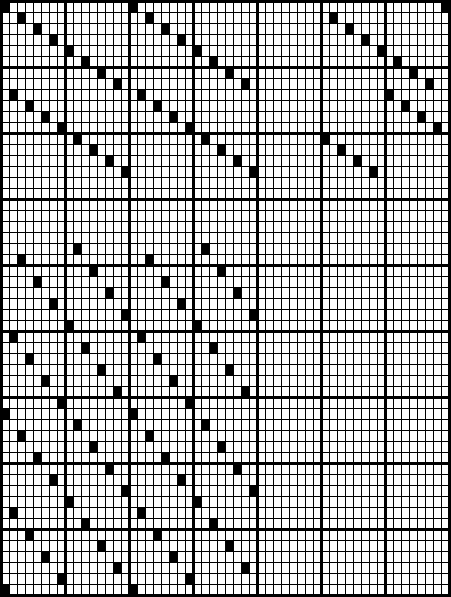

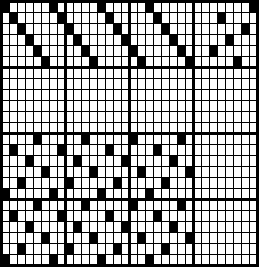

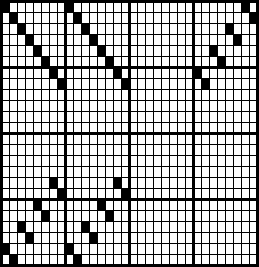

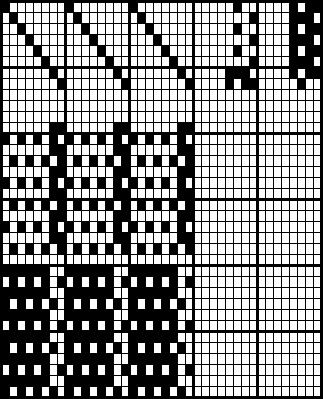

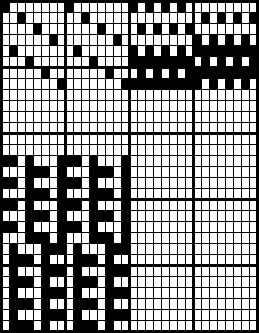

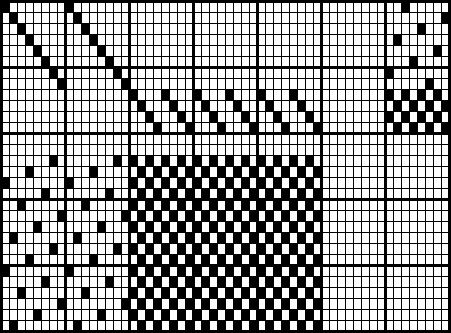

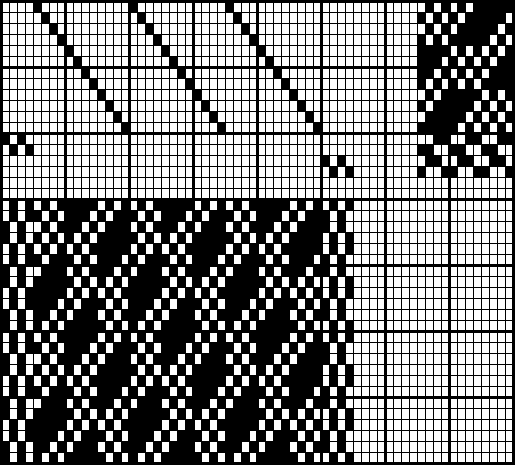

Fig. 16 is a taffeta on 4 shafts straight draw, the draft executed in the manner which we have already mentioned in explaining the drawing-in drafts.

Fig. 17 on common designing paper, illustrates a taffeta made on 8-harness, skip draw.

Be it mentioned that the drawing-in draft and the chain draft will be added throughout this work, the former over the weave to correspond with the respective warp-threads, the latter to the right of the drawing-in draft.

In this weave the working of the warp is the same as in taffeta, except that instead of one pick, two or more are inserted in the same shed. It is mostly used in selvedges, where it serves to give more firmness to the edge of an otherwise loosely woven cloth, and prevents the weaving ahead of the edge in a tight weave. Gros de Tours is sometimes used, especially when cotton or wool filling is employed, with a view to lay two picks nicely side by side, whereas a thread entered two ply with the taffeta weave will always receive some twist, which may disturb the perfect evenness of the fabric.

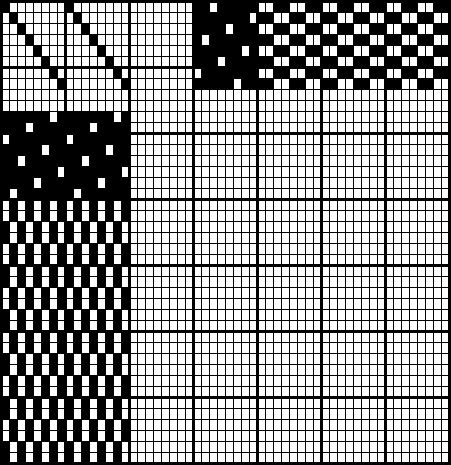

Fig. 18 is a Gros de Tours with two picks on four harness straight through.

Fig. 19 illustrates this weave with three picks drawn end and end on two sections of four shafts each.

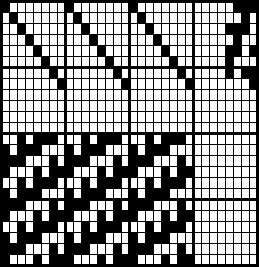

While the taffeta weave produces either an entirely smooth fabric, or one with a distinct transverse rib as in gros-grain, the twill weave forms diagonal lines on the cloth, running either from left to right or from right to left.

To make a twill, not less than three ends and three picks are required, of which each thread floats over two of the other system and interlaces with the third. The rotation of the interlacing is always consecutive, that is it moves with each succeeding pick one thread to the right (or to the left if the lines are to run in that direction). If warp and filling have the same texture, that is the same number of threads in a given space, the twill lines will form an angle of 45°; if the warp stands closer than the filling, the incline will be steeper, and in the opposite case the angle will approach more the horizontal.

The weaves can be expressed in numbers, for instance: the 3-end twill warp effect would be marked 2-1, which indicates that each warp-thread goes over two and under one pick.

Twill weaves are called evensided when the arrangement of "warp up" and "filling up" are evenly balanced, and unevensided if either warp or filling predominate on the face of the fabric; the latter class is therefore subdivided in Warp effects and Filling effects.

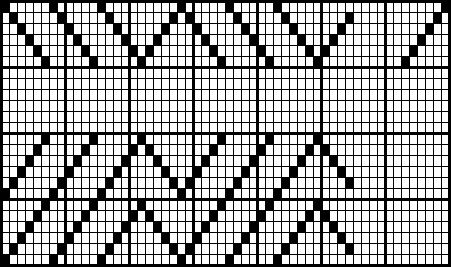

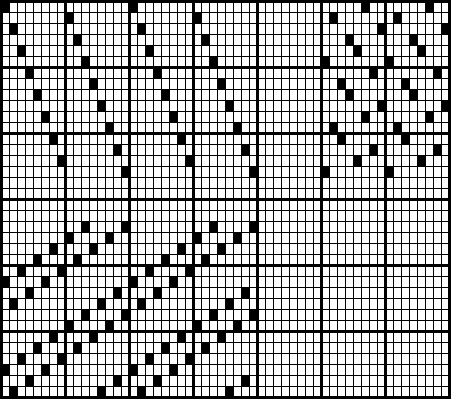

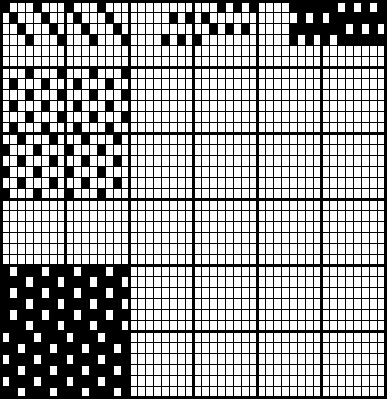

In the following a number of serge weaves are illustrated, the French designations being added in some cases, as they are still extensively used in the trade.

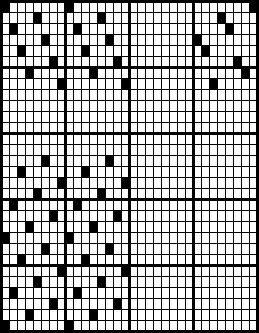

[pg 21]Satin de Lyon, 2-1.

On 6 harness straight through.

Levantine, 3-1

On 8 shafts skip draw.

Polonaise, 5-1

On 12 harness skip draw.

Serge grosse côte, 7-1

On 8 shafts straight through.

Serge remaine, 6-2

On 8 shafts skip draw.

Serge, 5-1, 1-1.

On 8 shafts skip draw.

Serge, 4-2, 1-1, 1-1.

On 10 harness straight through.

Serge, 7-1, 1-1, 1-1, 1-1, 1-1.

On 16 shafts skip draw.

Levantine, 3-1.

On 4 shafts straight through.

Serge, 5-1, 1-1.

On 8 shafts skip draw.

Surah, 2-2

On 4 shafts straight through.

Croise, 3-3, 2-2, 1-1.

On 12 shafts straight through.

Serge, 7-7, 1-1, 1-1, 1-1

On 20 shafts skip draw.

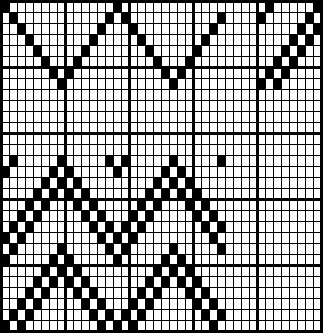

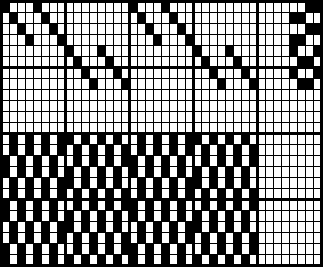

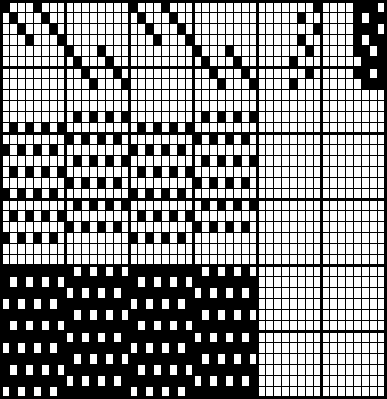

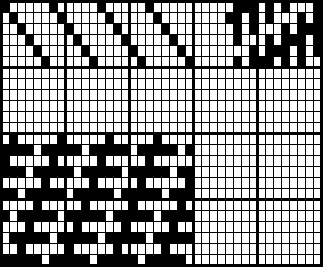

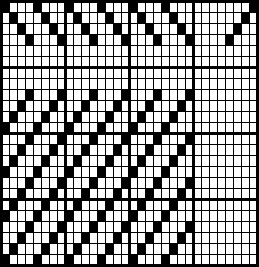

in the direction of the filling and also of the warp.

On 4 shafts point draw, weave 3-1.

On 6 shafts point draw, drawn as follows:

Eighteen ends from back to front and 4 ends from front to rear, weave 5-1.

On 8 shafts pointed draw, weave 5-1, 1-1.

On 10 shafts, with weave 3-3, drawn as follows:

| 7 | threads | from | back to front. |

| 3 | " | " | front to rear. |

| 6 | " | " | back to front. |

| 2 | " | " | front to rear. |

On 6 shafts straight draw, pointed weave 5-1.

On 8 shafts straight through, pointed weave 5-1, 1-1.

Broken pointed twill, on 8 harness.

On 6 shafts point draw, pointed weave 5-1.

On 8 shafts point draw, pointed weave 5-1, 1-1.

Fancy twill, on 16 shafts straight draw.

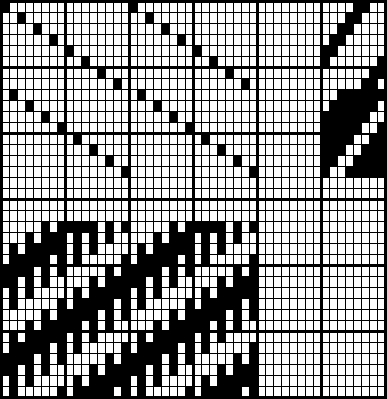

The distinct diagonal lines which characterize the class of weaves explained in the previous chapter are absent in the satin weaves; and while the interlacing in the former is done in a strictly consecutive order, we endeavor to scatter the points of stitching in the latter as much as possible, in order [pg 33] to create an entirely smooth and brilliant surface on the cloth.

In all satins the number of ends in a repeat is the same in warp and filling.

The lowest repeat of a regular satin comprises five threads of each system, and the interlacing is done in the following order:

| The | 1st | pick | with the | 1st | warp-thread |

| " | 2d | " | " | 3d | " |

| " | 3d | " | " | 5th | " |

| " | 4th | " | " | 2d | " |

| " | 5th | " | " | 4th | " |

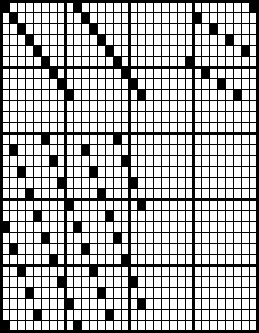

Fig. 43 illustrates this weave. An examination of the rotation, as given above, will show that every warp-thread intersects two picks apart from its neighbor. The number "2" is in this case what is technically known as the counter, that is the number which indicates the points of interlacing by adding it to number 1 and continuing so until all the warp-threads are taken up.

The following is the rule to find the counter for any regular satin:

Divide the number of harness into two parts, which must neither be equal nor have a common divisor. Any of these two numbers can be used for counting off, but usually the smaller one is taken. According to this rule we obtain a regular satin

| On | 5 | harness | with counter | 2 |

| " | 7 | " | " | 2 or 3 |

| " | 8 | " | " | 3 |

| " | 9 | " | " | 2 or 4 |

| " | 10 | " | " | 3 |

| " | 11 | " | " | 2, 3, 4 or 5 |

| " | 12 | " | " | 5 |

| " | 13 | " | " | 2, 3, 4, 5 or 6 |

| " | 14 | " | " | 3 or 5 |

| " | 15 | " | " | 2, 4 or 7 |

| " | 16 | " | " | 3, 5 or 7. |

The 4 harness broken twill, Fig. 53, is sometimes classed among the satins.

The 6 harness satin, Fig. 54, is irregular; as a counter cannot be derived from number 6 by the given rule. The rotation generally used is 1, 3, 6, 4, 2, 5.

5 harness Satin, "Satin de Chine."

Straight draw, counter 2.

7 harness Satin, "Satin Merveilleux."

Skip draw, counter 2.

7 harness satin

Straight draw, counter 3.

8 harness satin "Duchese"

Skip draw, counter 3.

9 harness satin

Straight draw, counter 4.

10 harness satin

Straight draw, counter 3.

11 harness satin

Skip draw, counter 5.

12 harness satin

Skip draw, counter 5.

16 harness satin

On 2 sections of 8 shafts each, drawn end and end, counter 7.

8 harness satin, warp effect.

Straight draw, counter 3.

Satin Turc.

On 4 shafts straight through.

Satin à la Reine

On 6 shafts straight draw.

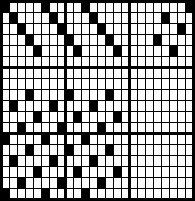

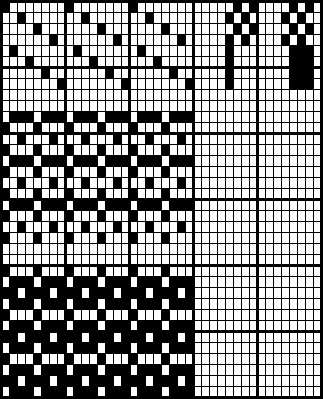

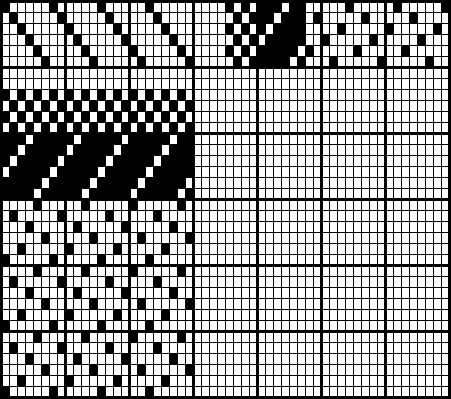

Royale is a modification of the regular Gros de Tours, inasmuch as the rib line, which in the latter runs straight across the cloth, is broken off after a given number of warp-threads. These groups, which may comprise 8, 12 or more threads, will interlace each one pick higher than the preceding one.

Royale of 8 ends

On 2 sections of 4 shafts each.

Velours Ottoman or Faille française.

In order to obtain a broader rib than that of Gros de Tours, and at the same time to lend firmness to the fabric, we add to the ground warp, which forms the ribs, another [pg 42] or binder warp, which works continually taffeta, while the ground warp changes only every 3 or 4 picks for the rib.

Faille française.

| 4 | ends of | ground | on the | first | section of | 8 | shafts, | skip draw. |

| 1 | " | binder | " | second | " | 2 | " |

Velours Ottoman without a Binder-warp.

In this weave, of which Fig. 57 illustrates a specimen, comprising 8 warp-threads and 32 picks in a repeat, the rib contains 4 picks. Of the 8 warp-threads, 3 float over and 3 under the rib, while the 2 others bind taffeta, which latter function is executed by 2 other threads in the next rib.

[pg 43]

One variety is obtained by interlacing the warp-threads alternately one or more picks behind, and then a number of picks ahead of their respective neighbors; so the complete arrangement of the points of binding in a repeat will generally form two parallel diagonal lines. This will cause the twill lines to appear less pronounced than is the case in the regular twill, and the character of the fabric approaches more that of the satin.

[pg 44]

Satin Sergé.

On 8 shafts, straight draw.

Côte Satinée.

On 16 harness, skip draw.

Rhadzimir-Surah 2-2. After a certain number of picks of the regular surah all the warp-threads are crossed in two's thereby causing a sort of a rib or cut line across the fabric.

[pg 45]Rhadzimir of 4 picks.

On 8 shafts, straight draw.

Rhadzimir of 6 picks.

On 8 shafts, straight draw.

Satin Soleil shows a satin-like surface with a cross line appearance. Fig. 62 illustrates it as made on 8 shafts, straight draw.

Satin Grec is a 12-harness satin, in which a taffeta point is added to each place of interlacing, thus giving the cloth a much firmer hand. Fig. 63 represents this weave on 12 shafts, skip draw.

[pg 47]

Peau de Soie. An 8-shaft satin with one point added on the right or left to the original spots, giving the fabric a somewhat grainy appearence. Fig. 64 represents a peau de soie on 8 shafts, straight through.

Fleur de Soie. The face is a satin de Lyon (2-1 twill), with a backing interlaced on the 12-shaft satin principle, Fig. 65, on 12 shafts, skip draw.

are in their construction related to the taffeta, and are used mostly in the form of stripes as an additional ornament to a fabric. The threads going into the composition of these effects exchange continually from taffeta interlacing to floating over a certain number of threads, and must be introduced either in warp or filling close enough to make the floats cover up the taffeta work entirely, and thus enable the material used to show up with the full brilliancy it possesses.

Cannele effects can be produced in two distinct ways. One is to let every individual thread work alternately taffeta and float, while in the other method one thread weaves always taffeta, and a second thread is used for the cannele exclusively. These latter threads must come from a separate warp, which is introduced to embellish the ground or taffeta part of the fabric.

The floating threads can either stitch all on one pick and so form a continuous cut line, or be divided in groups, of which one will bind in the middle of the floats of the other group. The following designs show both the face and backside of the respective weaves:

[pg 50]Alternating Cannele of 6 picks.

On 4 shafts, straight through.

Canelle (2 beams). Over 3 picks, interlacing on every fourth pick, drawn end and end on 2 sections of 4 shafts each.

Cannele over 5 picks, binding on the sixth, but every second thread advanced 3 picks (to the middle of the float of the first thread), drawn end and end on 2 sections of 4 shafts each.

Cannele arranged in groups of 8 threads, floating over 6 picks and binding on the seventh and eighth, drawn on 2 sections, with 4 shafts in first and 2 in second section.

Repp on 8 shafts straight through. Rotation of filling. 1 pick taffeta, 1 pick float (rib).

Repp of 8 threads, on 2 sections of 4 shafts each, 8 ends per section.

Repp of 5 threads, binding on the sixth; every second pick binds on the middle of the first pick. On 6 harness straight draw.

Repp in groups, floating over 6 ends and binding on the seventh and eighth on 8 shafts straight draw.

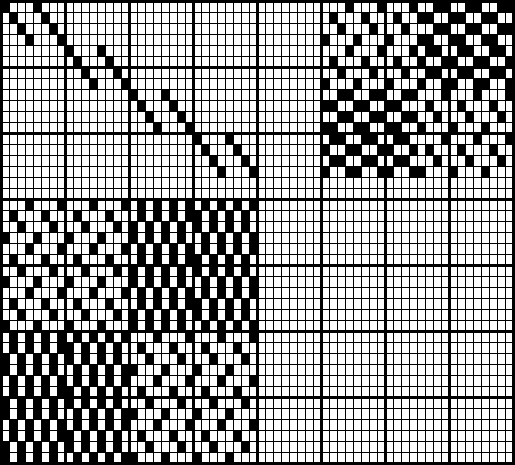

In this class we find either two systems of warp or of filling so combined that only one will be visible on either side. The color on one side is generally different from the other, and so may the interlacing be of a different nature on face and back. In the latter case great care must be exercised not to allow the weave on one side to disturb the one on the other, and as a rule the points of interlacing of the first warp or filling system are placed as much as possible in the middle of the floats of the second. This will prevent either color or weave to be seen on the opposite side, as the floats of one side will naturally lay themselves over the binders of the other. The number of ends in a repeat of the two weaves must either be alike or one a multiple of the other.

Levantine on 8 shafts straight draw.

Serge 6-2 on 2 sections of 8 shafts each.

8 shaft satin on 2 sections of 8 harness each.

12 shaft satin on 2 sections of 12 shafts each.

Cannele of 8 picks on 2 sections of 4 shafts each.

Serge 5-1 on 6 harness straight draw.

10 harness satin on 10 shafts skip draw.

Repp on 2 sections of 4 shafts each, 8 threads per section.

With this name we designate fabrics in which stripes of a different interlacing run in the direction of the warp. In combining these weaves it is advantageous to have them contrast distinctly, for instance, a short weave such as taffeta or Gros de Tours, with a longer and looser one such as satin, sergé or cannele, also changes from warp to filling effects. Care must be taken to arrange the joining of the two weaves so that the last thread of one weave will cross the first thread of the other. This will prevent the threads from either stripe to slide over into the other, and so make a clean cut line.

Pekin. A stripe of

| 2 | dents of | 8 | ends each, | 8 shaft Satin, | on 8 | shafts | straight | draw. |

| 12 | " | 2 | " | Taffeta | " 4 | " | " | " |

Pekin. A stripe of

| 12 | ends | Cannele | of | 6 picks on 1st section of 4 shafts. |

| 12 | " | Repp | " | 6 threads on 2d and 3d section of 2 shafts each. |

Pekin. A stripe of

| 10 | ends | 5 leaf Satin | on the | 1st | section of | 5 | shafts | straight | draw. |

| 4 | " | Taffeta | " | 3d | " | 2 | " | " | " |

| 18 | " | Serge 3-1, 1-1 | " | 2d | " | 6 | " | " | " |

While pekins are formed by warp stripes, bayadère shows us stripes of different weaves running in the direction of the filling. The rules given in the previous chapter as to the joining of the weaves will also apply here. The warp which was raised on the last pick of the weave must stay down wherever possible on the first pick of the following weave. The number of shafts employed must go up evenly in the repeat of each one of the weaves that go into the make up of the bayadère.

Bayadère

| A stripe of | 24 | picks | Gros de Tours | } on 8 shafts straight through. |

| " | 8 | " | 8-shaft Satin, |

Bayadère

| A stripe of | 18 | picks | 6-shaft Satin | } } on 6 shafts, straight draw. } |

| " | 6 | " | Serge 5-1, | |

| " | 4 | " | Taffeta, |

If pekin and bayadère stripes are combined, we obtain checked fabrics, and of these an endless variety and pleasing effects can be produced with the aid of suitable color combinations.

Check

| of 16 | threads | and | 12 | picks | of | the 4 end broken twill, |

| and 16 | " | " | 12 | " | " | Royale of 8 threads, |

| drawn on 4 sections of 4 shafts each. | ||||||

Check

| of | 20 | threads | and | 16 | picks | of | 8-shaft Satin, |

| " | 20 | " | " | 16 | " | " | Taffeta, |

| 4 | " | " | Surah 3-1, | ||||

| drawn on 2 sections of 8 shafts each. | |||||||

Under the name of Disposition we comprise all those points and details which we must ascertain before we can proceed with the construction of a fabric. They are:

1. The weave.

2. Length and width of the cloth.

3. The stock and the dyeing thereof.

4. Reed calculation (number of dents and ends per inch and total number of dents required).

5. Drawing-in the warp in harness and reed.

6. Texture and arrangement of warp (warping ticket)

7. Arrangement of harness.

8. Reduction of filling.

9. Calculation of warp and filling.

10. Finishing.

11. Calculation of cost.

[pg 68]If a given sample is to be reproduced or imitated, it must be analyzed, and the following hints will greatly facilitate this operation to the beginner.

Cut the sample straight on two sides, and draw out a number of warp and filling threads until there is a small fringe of perhaps ¼ of an inch. This will allow a thread to be raised a little for examination, without danger of its falling out of the fabric. In most cases it is easier to dissect the filling side, that is, the interlacing of each warp-thread in the threads of the filling system. With the help of the microscope or counting glass we can easily determine over and under how many picks that thread passes and the points of interlacing are accordingly marked on designing paper. This being done for at least the length of a repeat warpways, we take it out and examine the following thread, and so on until the repeat filling-ways is complete. It is advisable to ascertain how many picks ahead or back of the first examined thread the next following one binds before taking the former out.

A knowledge of the construction of weaves as explained in the foregoing chapters will enable us to determine the weave of a simple pattern by merely raising a warp-thread with a needle on any point of interlacing and counting off how many picks apart from this place it makes an impression.

To the length and width which the finished product is to have, we must add a certain allowance for shrinkage and taking up of warp during weaving. It may differ from one to ten per cent., according to the texture and weave of the fabric, and can be ascertained with sufficient accuracy by stretching out and measuring a thread of warp and filling and comparing their length with the respective measurements of the sample to be reproduced.

[pg 69]Under this heading we must give the particulars as to nature, twist, quality and size of the silk, and the directions for the dyeing, whether bright or souple, and in what colors, also whether to be weighted or not.

The size is generally ascertained (in practical work) by comparing it with other silk of which the exact count is known. Another method is to count the number of cocoon threads which a thread of the sample contains, adding to that 1/3 or ¼, according to the quality of the silk; the result will be the count in deniers. To obtain it in drams, divide the latter number by 17,3 as 1 dram is equal to 17,3 deniers.

Suppose we find 20 cocoon ends in a thread of silk: add 1/3, and we have 26-2/3 deniers, which, divided by 17,3 make 1,54 drams.

As silk is always more or less uneven, it is safer to count the cocoon fibers of several threads and to take average thereof.

It requires the experience of years to judge with any degree of certainty as to the origin and quality of silk, whether it be "classical," "extra," "sublime," etc.

There are machines wherewith to ascertain exactly the twist, that is, the number of turns the silk has received in the throwing process.

In the dyeing we distinguish two great classes, of which the names themselves give a good definition. "Bright" has a brilliant luster, while "souple" has more of a dull, subdued appearance. To find out whether the silk has been weighted in the dyeing process, we may compare it with other silk of which the exact conditions are known, or we may burn a small quantity of it. Unweighted silk does not burn readily and leaves a residue of white ashes, while heavy weighted silk burns lively, leaving black, charry ashes.

[pg 70]We count the number of repeats of the weave in a given space, generally ¼ or ½ inch, and multiply this with the number of threads one repeat contains, which gives us the reduction of the warp.

Suppose we had a taffeta, which, as we know, has only 2 ends to a repeat, and counted 30 interlacings per ¼ inch on one pick; we would have 60 threads per ¼ inch or 240 per one inch. In this case the reed may be 80 by 3 or 60 by 4.

Another instance: In an 8-shaft satin we count 10 warp-threads, which bind on the same pick in ¼ inch; this, multiplied by 8, equals 80 ends per ¼, or 320 per one inch; the reed will be an 80 with 4 in a dent or a 64 by 5.

In short, the number of the reed is found by dividing the number of warp-threads that are to go in one dent, in the number of ends per inch. Sometimes, the reed marks are clearly visible in a sample by holding the latter against the light. Silk fabrics move with very few exceptions within the limits of 50 and 90 dents per inch.

To learn the full number of dents required for the width of the cloth, simply multiply the dents per one inch with the width, adding a certain allowance for shrinkage. The edges, of course, must also be taken in consideration, and very often the dents that are taken up by the latter are used to counter-balance that shrinkage.

Here we must specify the number of dents that contain the same number of ends, and whether the latter are single or double, also the number of shafts and the method of drawing-in.

[pg 71]To make out the warping ticket, we need to ascertain the total number of ends, whether leased single or double, and the arrangement of the colors.

This is governed by the number of ends to be drawn in and the necessary shafts. If we have, for instance, 100 threads per inch to be drawn on 4 shafts, we must give each shaft 25 heddles per inch. There are generally between 25 and 45 heddles per inch on one shaft.

Here we state the number of picks per inch, give directions as to doubling, if such is necessary, and if more than one color or shuttle is used, the rotation thereof.

The system adopted in this country for specifying the size of silk is based on the weight in drams (avoirdupois) of a skein containing 1000 yards. A skein, thus weighing 5 drams, is technically called 5-dram silk. The number of yards of 1-dram silk to a pound must accordingly be 256000. The formulas for figuring the amount of silk required for a piece of cloth are as follows:

| Multiply: | Number of ends × length × count | = lbs |

| Divide by: | 1000 yards × 256 drams |

| Multiply: | Picks × xply × width × length of piece × count | = lbs |

| Divide by: | 1000 yards × 256 drams |

The result in both cases will be in pounds.

The system of grading the silk which is in vogue in Europe, and which is employed by a number of mills on this side, is as follows:

| 1 | skein of | 500 | meters, | weighing | 0,05 | grams | = 1 | denier | international | |

| or 1 | " | 476 | " | " | 0,053 | " | = 1 | " | Turin | system |

| or 1 | " | 476 | " | " | 0,051 | " | = 1 | " | Milan | " |

The warp calculation, taking the international denier, would run:

| ends in warp × length × denier × 0,05 gram | |

| divided by: | 500 meters |

| for the filling: | Picks per meter × xply × width × denier × 0,05 gram |

| divided by: | 500 meters |

Result in metric weight, kilograms and grams.

Give directions as to the process of finishing to which the goods are to be subjected, whether to be pressed, calendered, sized, moiréd, etc.

If all the foregoing conditions are ascertained, and a sample or a piece of the fabric executed, it remains to the manufacturer to determine the exact figure at which he can produce the article. That this must be done with great accuracy is naturally of the utmost importance, and the calculator [pg 73] must know in the first place the raw stock prices, and also be acquainted with the details of the manufacturing process and the rates of wages paid therein. As a rule, the manufacturer establishes a scale of prices covering all the items of labor cost, mill expenses, etc., and uses this as a basis for his calculations.

A rule or formula for this operation cannot very well be given, as the methods vary in almost every establishment, each choosing the one best adapted to its ideas or dictates of circumstances and conditions.

[pg 75]Taffeta glacé

| Length and Width—One piece 100 yards long, 18¾ inches wide. |

| Stock and Dye—Warp.— | Ital. Organ., 24/26 deniers = 1,47 drams, brown, bright, 14/16 oz. |

| Filling.— | Japan Tram, 28/30 deniers = 1,65 drams, gold, bright 14/16 oz. |

| Reed Calculation— | Per | 1 | inch, | 70 | dents | at 3 single ends. |

| " | 18¾ | " | 1313 | " | ||

| add | 13 | " | = 1% for shrinkage | |||

| —— | ||||||

| Total . . . | 1326 | dents | ||||

| Drawing in—1st edge, | 9 | dents | at 3 double | ends. |

| Ground, | 1308 | " | at 3 single | " |

| 2d edge, | 9 | " | at 3 double | " |

| on 6 shafts, straight through. | ||||

| Warping Ticket—1st edge, | 27 | double | ends, | brown. |

| Ground, | 3924 | single | " | " |

| 2d edge, | 27 | double | " | " |

| —— | ||||

| Total . . . | 4032 | single | ends. | |

| Length of warp 110 yards, including 10% for take up. | ||||

| Harness—6 | shafts, | 3978 | heddles | per | 19 | inches. |

| 1 | " | 35 | " | " | 1 | " |

| Reduction of Filling—Per inch, 100/102 picks, 2 ends. |

| Warp Calculation—? lbs = | 4032 ends. |

| 1 end = | 110 yards. |

| 1000 yards = | 1,47 drams. |

| 256 drams = | 1 lb. |

| 100 = | 104 (4% waste). |

| 4032×110×1,47×104 | = 2,65 lbs., or 2 lbs. 10,4 oz. |

| 1000×256×100 |

| Filling Calculation—? lbs. = | 100 yards |

| 1 yard = | 36 inches. |

| 1 inch = | 102 picks. |

| 2 ends. | |

| 1 pick = | 19 inches. |

| 36 inches = | 1 yard |

| 1000 yards = | 1,65 drams. |

| 256 drams = | 1 lb. |

| 100 = | 108 (8% waste). |

| 100×36×102×2×19×165×108 | = 2,73 lbs., or 2 lbs. 11,7 ozs. |

| 36×1000×256×100 |

Surah 3-1

| Length and Width—1 piece 50 yards long, 23½ in. wide. |

| Stock and Dyeing—Warp.— | Ital. Organ., 1,30 drams = 20/24 deniers, black, bright, 40/50% = 22/24 ozs. |

| Filling.— | Cotton No. 120/2 black. |

| Reed Calculation— | Per | 1 | inch, | 80 | dents | at 2 single ends. |

| " | 23½ | inch | 1880 | " | ||

| add | 36 | " | = 2% for shrinkage | |||

| —— | ||||||

| Total . . . | 1916 | dents | ||||

| Drawing in—1st edge, | 8 | dents | 2 double | ends. |

| Ground, | 1900 | " | 2 single | " |

| 2d edge, | 8 | " | 2 double | " |

| on 4 shafts, straight draw. | ||||

| Warping Ticket—1st edge, | 16 | double | ends, | black. |

| Ground, | 3800 | single | " | " |

| 2d edge, | 16 | double | " | " |

| —— | ||||

| Total . . . | 3864 | single | ends. | |

| Warp 54 yards long = 8% for take up. | ||||

| Harness—4 | shafts, | 3832 | heddles | per | 24 | inches. |

| 1 | " | 40 | " | " | 1 | " |

| Reduction of Filling—Per 1 inch, 120 picks, 1 end. |

| Warp Calculation—? lbs = | 4264 ends. |

| 1 end = | 54 yards. |

| 1000 yards = | 1,30 drams. |

| 256 drams = | 1 lb. |

| 100 = | 104 (4% waste). |

| 3864×54×1,30×104 | = 1,10 lbs., or 1 lb. 1,06 oz. |

| 1000×256×100 |

| Filling Calculation—? lbs. = | 50 yards |

| 1 yard = | 36 inches. |

| 1 inch = | 120 picks. |

| 1 pick = | 24 inches. |

| 36 inches = | 1 yard |

| 840 yards = | 1 skein. |

| (No. 120/2) 60 skeins = | 1 lb. |

| 100 = | 110 (10% waste). |

| 50×36×120×24×110 | = 3.14 lbs., or 3 lbs. 2.24 ozs. |

| 36×840×60×100 |

Satin Duchesse.

| Length and Width—One warp 300 yards long, 10 pieces of 60 yards 23 inches wide, 2 pieces in width, with one cut edge. |

| Stock and Dyeing—Warp.— | Ital. Organ., 1-55/100 drams, black, bright, 20/22 oz. |

| Filling.— | Jap. Tram., 1-8/10 and 2-7/10 drams, black, souple, 40/44 oz. |

| We should use for this fabric 1 end filling, 5-thread, 4-5/10 drams, but as we have none of this size on hand, we take: 1 end, 2 thread, 1-8/10 drams, and 1 end, 3 thread, 2-7/10 drams. |

| Reed Calculation— | 1 | inch, | 66 | dents | 4 single ends. |

| 46 | " | 3036 | " | ||

| add | 54 | " | (1¾% shrinkage). | ||

| —— | |||||

| Total . . . | 3090 | dents | |||

| Drawing in— | 1st edge, | { | 2 | dents | 6×2, | black. |

| { | 13 | " | 4×2, | white. | ||

| Ground, | 1514 | " | 4×1, | black. | ||

| Cut Edge | { | 2 | " | 6×2 | black. | |

| { | 1 | " | 2×4, | " | ||

| { | 3 | " | empty. | |||

| { | 1 | " | 2×4, | " | ||

| Ground, | 1514 | " | 4×1, | black. | ||

| 2d edge, | { | 2 | " | 6×2, | black. | |

| { | 13 | " | 4×2, | white. | ||

| Satin on 8 shafts, straight draw. Cross-thread for split edge on 3 shafts, see design. | ||||||

| Warping Ticket— | Edge, | { | 12/2 | black. | } | ||||||||||||||||||||||||

| { | 52/2 | white. | } | ||||||||||||||||||||||||||

| Ground, | 6056/1 | black. | } twice over. | ||||||||||||||||||||||||||

| Edge, | { | 12/2 | black. | } | |||||||||||||||||||||||||

| { | 52/2 | white. | } | ||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||

| Harness—8 | shafts, | 12368 | heddles | 47 | in. |

| 1 | " | 33 | " | 1 | " |

for the split edge 3 shafts, of which one has only half a heddle.

| Filling—Per 1 in., 80 picks, 2 ends (as described before). |

| Warp Calculation—? lbs = | 12224 ends, black (416 white). |

| 1 end = | 318 yards. |

| 1000 yards = | 1,55 drams. |

| 256 drams = | 1 lb. |

| 100 = | 104 (4% waste). |

| (416) | 12224×318×1.55×104 | = 24,477 | lbs. | org. | black. |

| 1000×256×100 | = 0,833 | " | " | white. |

| Filling Calculation—? lbs. = | 300 yards |

| 1 yard = | 36 inches. |

| 1 inch = | 80 picks. |

| 1 pick = | 47 inches. |

| 36 inches = | 1 yard |

| 1000 yards = | 4,5 drams. |

| 256 drams = | 1 lb. |

| 100 = | 108 (8% waste). |

| 300×36×80×47×4,5×108 | = 21,414 lbs. |

| 36×1000×256×100 |

Armure Satinée

| Length and Width—One piece 60 yards long, 19 in. wide. |

| Stock and Dye—Warp.— | Jap. Organ., 1,48 drams, black, bright, 18/20 oz. |

| Filling.— | 3 threads Jap. Tram., 2,95 drams, black, bright, 24/26 oz. |

| Reed Calculation— | Per | 1 | inch, | 60 | dents | × 4 single ends. |

| " | 19 | " | 1140 | " | ||

| 32 | " | (3% for shrinkage). | ||||

| —— | ||||||

| Total . . . | 1172 | dents | ||||

| Drawing in—1st edge, | 12 | dents | × 4 double. | |

| Ground, | 1148 | " | × 4 single. | |

| 2d edge, | 12 | " | × 4 double. | |

| on 12 shafts, straight through, | ||||

| or on 6 shafts, as design indicates. | ||||

| Warping Ticket—1st edge, | 48/2 | black. | |

| Ground, | 4592/1 | " | |

| 2d edge, | 48/2 | " | |

| —— | |||

| Total . . . | 4784 | single ends 64 yards long. | |

| =6½% for take up. | |||

| Harness—6 | shafts, | 4688 | heddles | per | 19½ | inches. |

| 1 | " | 40 | " | " | 1 | " |

| Reduction of Filling—Per 1 inch, 104 picks, 2 ends. |

| Warp Calculation—? lbs = | 4784 ends. |

| 1 end = | 64 yards. |

| 1000 yards = | 1,48 drams. |

| 256 drams = | 1 lb. |

| 100 = | 104 (4% waste). |

| 4784×64×1,48×104 | = 1,84 lbs., or 1 lb. 13,44 ozs. |

| 1000×256×100 |

| Filling Calculation—? lbs. = | 60 yards |

| 1 yard = | 36 inches. |

| 1 inch = | 104 picks. |

| 2 ends. | |

| 1 pick = | 19½ inches. |

| 36 inches = | 1 yard |

| 1000 yards = | 2,95 drams. |

| 256 drams = | 1 lb. |

| 100 = | 108 (8% waste). |

| 60×36×104×2×19,5×2,95×108 | = 3,03 lbs., or 3 lbs. 0,48 ozs. |

| 36×1000×256×100 |

Surface Printed Armure.

| Length and Width—One piece 50 yards long, 18½ in. wide. |

| Stock and Dyeing—Warp.— | Ital. Organ., 1,50 drams, 24/28 deniers, white bright, pure dye. |

| Filling.— | 5 thread Ital. Tram., 4 drams, 13/14 deniers, white, bright, pure dye. |

| Reed Calculation— | Per | 1 | inch, | 52 | dents | 2×2. |

| " | 18½ | " | 962 | " | ||

| 20 | " | (2% shrinkage). | ||||

| —— | ||||||

| Total . . . | 982 | dents. | ||||

| Drawing in—1st edge, | 7 | dents | 4×2 gros de Tours. | |

| Ground, | 968 | " | 2×2 armure | |

| 2d edge, | 7 | " | 4×2 gros de Tours. | |

| Armure ground on 12 shafts, straight draw. | ||||

| Gros de Tours, edges on 4 shafts. | ||||

| Warping Ticket— | Ground warp, 54 yards. 1936/2 white. |

| Gros de Tours edges, 55 yards. 2×28/2 white, on separate rolls. | |

| Total | . . . 3984 single ends. |

| Harness—12 | shafts, | 1936 | heddles | per | 18½ | inches. | |

| 1 | " | 8-2/3 | " | " | 1 | " | |

| 4 Shafts gros de Tours edges, with 28 heddles on each side. | |||||||

| Reduction of Filling—Per 1 inch, 96 picks, 1 end. |

| Warp Calculation—? lbs = | 3984 ends. |

| 1 end = | 54 yards. |

| 1000 yards = | 1,50 drams. |

| 256 drams = | 1 lb. |

| 100 = | 104 (4% waste). |

| 3984×54×1,50×104 | = 1,31 lbs., or 1 lb. 4,96 ozs. |

| 1000×256×100 |

| Filling Calculation—? lbs. = | 50 yards |

| 1 yard = | 36 inches. |

| 1 inch = | 96 picks. |

| 1 pick = | 19 inches. |

| 36 inches = | 1 yard |

| 1000 yards = | 4 drams. |

| 256 drams = | 1 lb. |

| 100 = | 108 (8% waste). |

| 50×36×96×19×4×108 | = 1,54 lbs., or 1 lb. 8,64 ozs. |

| 36×1000×256×100 |

After weaving, the small flower effects have to be printed on the cloth.

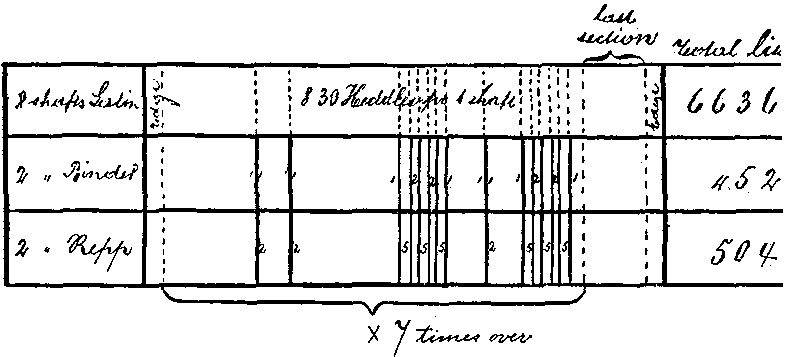

Pekin: 8 shaft satin and repp.

| Length and Width—1 piece 100 yards long, 20¼ in. wide. |

| { | Ital. Organ., 1-35/100 drams, black, bright, 20/22 oz. |

| Stock and Dyeing—Warp. { | Ital. Organ., 1-15/100 drams, sky, bright, pure dye |

| { | Cotton No. 100/2, scarlet. |

| Filling.— | 3 threads, Jap. Tram., 2-8/10 drams, scarlet, bright, 14/16 oz. |

| { 6×1, | black | satin | ||||||

| Reed Calculation— | Per | 1 | inch, | 68 | dents | { 6×2, | colored | " |

| { 2×1, | " | repp. | ||||||

| " | 20¼ | " | 1377 | " | ||||

| add | 23 | " | (1½% for shrinkage). | |||||

| —— | ||||||||

| Total . . . | 1400 | dents | ||||||

| Drawing in—1st edge, | 7 | dents | 6×2 | satin. | } | |

| Ground, | 34 | " | 6×1 | " | } | |

| 2 | " | 6×2 | " | } | ||

| 10 | " | 6×1 | " | } twice | } | |

| 2 | " | 2×1 | repp. | } over | } | |

| 10 | " | 6×1 | satin. | } | ||

| 2 | " | 6×2 | " | } | ||

| 39 | " | 6×1 | " | } | ||

| 5 | " | 2×1 | repp. | } twice | } | |

| 4 | " | 6×1 | satin. | } over | } 7 times | |

| 5 | " | 2×1 | repp. | } over | ||

| 15 | " | 6×1 | satin. | } | ||

| 2 | " | 2×1 | repp. | } | ||

| 15 | " | 6×1 | satin. | } | ||

| 5 | " | 2×1 | repp. | } twice | } | |

| 4 | " | 6×1 | satin. | } over | } | |

| 5 | " | 2×1 | repp. | } | ||

| 5 | " | 6×1 | satin. | } | ||

| 28 | " | 6×1 | " | } | ||

| 2d edge, | 7 | " | 6×2 | " | } |

| Satin | on | 1st | section | of | 8 | shaft | skip draw. |

| Binder | " | 2nd | " | " | 2 | " | |

| Repp | " | 3d | " | " | 2 | " |

On each side of every repp stripe two ends of the satin warp must be entered on the 2 binder shafts (2d section), to prevent the ends of the satin to slide over into the repp stripes.

| Warping Ticket—I. | Beam satin, 106 yards. | |||||||||||

| 1st edge, | 42/2 | black. | ||||||||||

| Ground, | 204/1 | " | } | 7 times over | ||||||||

| 12/2 | sky. | } | ||||||||||

| 180/1 | black. | } | ||||||||||

| 12/2 | sky. | } | ||||||||||

| 234/1 | black. | } | ||||||||||

| 48/2 | sky. | } | ||||||||||

| 180/1 | black. | } | ||||||||||

| 48/2 | sky. | } | ||||||||||

| 30/1 | black. | } | ||||||||||

| 168/1 | " | } | ||||||||||

| 2d edge, | 42/2 | " | ||||||||||

| ||||||||||||

| II. | Beam repp, 110 yards. | |||||||||||

| 4/1 | scarlet. | } | 7 times over | |||||||||

| 4/1 | " | } | ||||||||||

| 10/1 | " | } | ||||||||||

| 10/1 | " | } | ||||||||||

| 10/1 | " | } | ||||||||||

| 4/1 | " | } | ||||||||||

| 10/1 | " | } | ||||||||||

| 10/1 | " | } | ||||||||||

| 10/1 | " | } | ||||||||||

| 504 single ends scarlet cotton | ||||||||||||

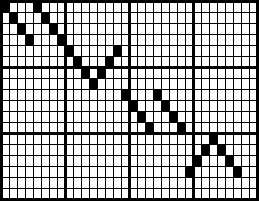

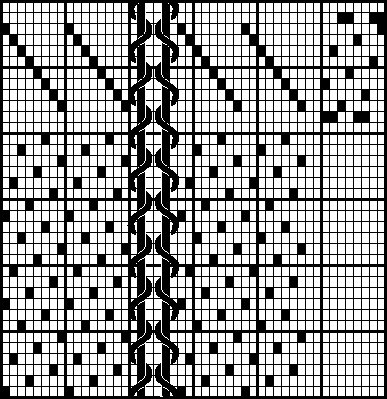

This warp has to be beamed in stripes. Make out a diagram for the warper the same as shown in Fig. 95.

[pg 98]

| Harness—Fig. 95 shows how to make a diagram of a harness for a Pekin. The heddles are marked per one shaft. As the repp stripes are only small ones, we use for the satin a full harness, that is, one without open spaces for the repp stripe. All together we have in the satin warp 6888 single and double ends to draw in; of these 252 ends are used for binders, on both sides of the repp stripes. Thus remain for |

| 8 | shafts, | 6636 | heddles | per | 20½ | inches. |

| 1 | " | 40 | " | " | 1 | " |

| Reduction of Filling—Per inch, Per 1 inch, 144 picks, 1 end. |

| Warp Calculation—? lbs = | 6132 ends (1680 ends sky). |

| 1 end = | 106 yards. |

| 1000 yards = | 1,35 drams (sky 1,15 drams). |

| 256 drams = | 1 lb. |

| 100 = | 104 (4% waste). |

| 6132×106×1,35×104 | = 3,56 lbs. for black, or 3 lbs. 8,96 ozs. 10,4 oz. |

| 1000×256×100 |

| 1680×106×1,15×104 | = 0,83 lbs. for sky, or 0 lbs. 13,28 ozs. |

| 1000×256×100 |

| ? lbs = | 504 ends. |

| 1 end = | 110 yards. |

| 840 yards = | 1 skein. |

| (No. 100/2) 50 skeins = | 1 lb. |

| 100 = | 104 (4% waste). |

| 504×110×104 | = 1,37 lbs. scarlet cotton, or 1 lb. 5,92 ozs. |

| 840×50×100 |

| Filling Calculation—? lbs. = | 100 yards |

| 1 yard = | 36 inches. |

| 1 inch = | 144 picks. |

| 1 pick = | 21 inches. |

| 36 inches = | 1 yard |

| 1000 yards = | 2,8 drams. |

| 256 drams = | 1 lb. |

| 100 = | 108 (8% waste). |

| 100×36×144×21×2,8×108 | = 3,57 lbs., or 3 lbs. 9,12 ozs. |

| 36×1000×256×100 |

Jacquard weaves usually show on a plain ground figure or flower effects. To obtain these effects the ground is made of one weave, say taffeta, while the figures or flowers are produced in another weave, say satin.

We enter the warp through a jacquard harness, and according to the repeat use a 200, 400, 600, 900, 1200, etc., hook jacquard machine, which means 200, 400, 600, 900 and 1200 ends per repeat.

With a 600-hook machine a larger repeat can be produced than with a 499-hook machine. For instance, if we want to make a cloth the figures of which are to be two inches apart, it is a two-inch repeat, and use the count of 50/4 or 200 ends per inch, we can use a 400-hook machine, 2 in. x 200 ends. But we can make this cloth also on a 1200-hook machine, only the repeat must be designed three times. The advantage of using a 1200-hook machine with the count 50/4 is that 2, 3, 4, 6-inch repeats can be produced, while with a 400-hook machine, only a 2-inch repeat can be made.

There is no end to all the different weaves and the possible flower and other pattern effects that can be made with the jacquard machine. For a jacquard weaving plant the designing is the most important factor.

Box looms are required for weaves such as bayadères, checks, plaids (see pages 63-65), bengalines, crêpes, etc., where two or more shuttles are needed to bring out the effect.

For the crêpes (crêpe de chine, crêpe georgette) only two shuttles are needed, while plaids and other articles are made with more shuttles.

To weave such articles the loom or the lay must be fitted with two or more shuttle boxes on one or both sides of the loom.

[pg 101]If a manufacturer decides to change plain looms to box looms or buy new box looms, it is wise to get 4 × 4 boxes, or four shuttle boxes on each side.

With these looms about everything can be made that is called for in box-loom effects, and as styles change, it is wise to be prepared.

The calculator first ascertains for the warp: What silk will be used, the cost of the same, total number of ends in the warps for the amount of silk, cost of throwing, dyeing, winding, warping, twisting, entering, and weaving.

Then the filling: Silk to be used, how much, cost of silk, cost of throwing, dyeing, winding, doubling, quilling.

After this determine the cost of weaving, cloth picking, finishing, factory costs, and selling expenses.

To-day most of the operations are paid by "piece work."

The calculator must always take into consideration that poor raw silk or poor dyeing make production slow, increase the cost of labor, and also that more waste will be made.

THROWING: Regular organ usually has 16 turns per inch in the first twist and 14 turns to the inch in the second or reverse twist. Tram receives only one twisting, about three turns to the inch.

As the warp twisting-in is paid for at so much per hundred or thousand ends, no matter how short or long the warp is, it is a saving to make the warps as long as possible, especially in raw, black and staple colors.

The calculator must not forget the cost of entering the first warp in a harness, also the reeding.

Most mills figure the cost of harness and reed in the expense accounts. If plain and fancy goods are made an extra percentage should be figured for the latter.

[pg 102]EXPENSES are figured differently, as almost every manufacturer has his own system. If a mill makes only a few staple articles it is easy to put down the cost of expenses. Say the mill has a production of 500,000 yards per year, that the expense amounts to $35,000, the cost then is 7 cents per yard.

Manufacturers making all kinds of goods sometimes figure the expenses in percentage, say, for plain goods, with a few picks, like gros-grain, peau de soie, etc., 10 per cent. per yard. Taffeta, satin, etc., having more picks, 12½ per cent. per yard, and fancy and jacquard goods, 15 per cent. per yard. In the expense account we include all charges except raw silk, throwing, dyeing and piece work.

SELLING EXPENSES. Before a calculation is finished we must add the selling expenses to the cost, also take account of the trade discount. Small mills usually sell through a commission house, which pays all expenses and charges a certain commission. Many large firms have their own selling end, and some have their sales guaranteed by a commission house or a bank.

[pg 103]The prices marked in the following calculations are about as in "normal times." Absolutely correct piece work prices cannot be given as different localities have different prices.

Calculations are usually made per 100 yards, 100-meter warps.

Most goods gain from 3 to 7 per cent. in weaving. That is, if we make a warp of 300 meters for a satin and we obtain 315 yards of cloth, this gain should not be calculated, as usually there is no account taken of samples used in the selling department. But the loss in length should be figured and taken account of on goods with a heavy rib, such as moiré, faille, etc.

DISP. 7—A 3 1/3-inch repeat can be obtained with a 600-hook jacquard machine, seven repeats in a width of 23 inches.

DISP. 8—Taffeta weave, but the two cotton picks must go in one hole. This article can only be made with at least two shuttle boxes on each side. For warping use a single and double cross reed, heavy cotton, no knots must be tied.

DISP. 10—This article must be warped with as much tension as possible and no knots should be tied in. Silk is to be delivered on bobbins from throwster.

DISP. 9—Can also be made with Canton silk for filling and may be called Canton crêpe. As Canton silk is much cheaper than Japan, the manufacturer can use 4-thread Canton instead of 3-thread Japan for filling at a little difference in cost, thus the cloth will be heavier, but Canton silk is not as even and clean as Japan.

[pg 104]| Article—TAFFETA GLACE Reed 70/3 | ||||

| Disp. 1 | Width 18¾ in. | |||

| Warp— | Ital. Ex. Class 12/14 | $5.00 | raw silk | |

| .60 | throwing | |||

| 2-Thread Organ. brown bright | .45 | dyeing | ||

| 16-oz. | .15 | winding | ||

| —— | ||||

| raw lbs. 2.60 | $6.20 | $16.23 | ||

| Warping—4032 at 3¢. | 1.21 | |||

| Twisting—3978 at 25¢. per 300 meters | .33 | |||

| Filling—Jap. Tram. Best No. 1 13/15 | $4.25 | raw silk | ||

| .45 | throwing | |||

| 2/2 ends 104 picks | .45 | dyeing | ||

| .15 | winding | |||

| gold bright 16 oz. | .15 | doubling | ||

| .10 | quilling | |||

| —— | ||||

| raw lbs. 2.73 | $5.55 | 15.02 | ||

| Weaving | 7.00 | |||

| Picking | 1.00 | |||

| Finishing | 1.00 | |||

| Expenses | 7.00 | |||

| —— | ||||

| $48.79 | ||||

| 5% trade discount | ||||

| 7½% selling commission | ||||

| Divide by 87½ | ||||

| Cost per yard = $0.5576 | ||||

| Article—SURAH 3-1 Reed 80/2 | ||||

| Disp. 2 | Width 36 in. | |||

| Warp— | Ital. Ex. Class. 10/12 | $5.20 | ||

| .65 | ||||

| 2-Thread Organ. bright black | .81 | discount 15% | ||

| 24 oz. | .30 | dyed 20% | ||

| —— | ||||

| lbs. 3.36 | $6.96 | $23.39 | ||

| Warping—5904 at 2¾¢. | 1.62 | |||

| Twisting—5872 at 35¢.—600 lb. warp | .25 | |||

| Filling—cotton 120/1 | $1.25 | |||

| .10 | dye | |||

| black 1 end 120 picks | .08 | winding | ||

| .07 | quilling | |||

| —— | ||||

| lbs. 9.50 | $1.50 | 14.25 | ||

| Weaving | 12.00 | |||

| Picking | 1.50 | |||

| Finishing | 2.00 | |||

| Expenses | 7.00 | |||

| —— | ||||

| $62.01 | ||||

| 5% discount | ||||

| 6% commission | ||||

| Divide by 89 | ||||

| Cost per yard = $0.6967 | ||||

| Article—SATIN DUCHESSE Reed 66/4 | ||||

| Disp. 3 | Width 2×23 in. | |||

| Warp— | Ital. Ex. Class. 12/14 | $5.00 | ||

| .60 | ||||

| 2-Thread Organ. black bright | .73 | |||

| 22 oz. | .21 | |||

| —— | ||||

| lbs. 8.50 | $6.54 | $55.59 | ||

| Warping—12624 at 2¾¢ | 3.47 | |||

| Twisting—12256 at 25¢. 600 meters | .51 | |||

| Filling—Jap. Tram No. 1—14/16 | $4.00 | |||

| .40 | ||||

| black souple 44 oz. | 1.60 | net | ||

| .40 | ||||

| 1/2 and 1/3 = 1/5 80 picks | .40 | doubling | ||

| .30 | ||||

| —— | ||||

| lbs. 7.14 | $7.10 | 50.69 | ||

| Weaving | 13.00 | |||

| Picking | 2.00 | |||

| Finishing | 2.50 | |||

| Expenses | 8.00 | |||

| —— | ||||

| $135.76 | ||||

| Divide by 89 | ||||

| Cost per yard = $0.7627 | ||||

| Article—ARMURE SATIN Reed 60/4 | ||||

| Disp. 4 | Width 26 in. | |||

| STOCK AND DYE | ||||

| Warp— | Jap. Ex. 12/14 | $4.75 | ||

| .60 | ||||

| 2-Thread Organ. black bright | .64 | |||

| 20 oz. | .19 | |||

| —— | ||||

| lbs. 4.30 | $6.18 | $26.57 | ||

| Warping—6520 at 2¾¢. | 1.79 | |||

| Twisting—6424 at 25¢. 600 meters | .27 | |||

| Filling—Jap. Tram No. 1 16/18 | $4.00 | |||

| .30 | ||||

| black bright 26 oz. | .94 | |||

| .25 | ||||

| 2/3 ends 104 picks | .25 | |||

| .17 | ||||

| —— | ||||

| lbs. 6.80 | $5.91 | 40.19 | ||

| Weaving | 10.00 | |||

| Picking | 1.00 | |||

| Finishing | 1.00 | |||

| Expenses | 7.00 | |||

| —— | ||||

| $87.82 | ||||

| Divide by 89 | ||||

| Cost per yard = $0.9867 | ||||

| Article—PRINTED ARMURE Reed 52/2/2 | ||||

| Disp. 5 | Width 18½ in. | |||

| STOCK AND DYE | ||||

| Warp— | Ital. Ex. Class. 12/14 | $5.00 | ||

| 2-Thread Organ. white bright | .60 | |||

| P.D. | .23 | |||

| .12 | ||||

| —— | ||||

| lbs. 2.62 | $5.95 | $15.59 | ||

| Warping—3984/1 at 3¢. | 1.20 | |||

| Twisting—1992/2 at 30¢. 300 meters | .20 | |||

| Filling—Ital. Tram. souple 13/14 | $4.50 | |||

| .30 | ||||

| white bright P.D. | .23 | |||

| .10 | ||||

| 1/5 end 96 picks | .07 | |||

| .17 | ||||

| —— | ||||

| lbs. 3.08 | $5.20 | 16.02 | ||

| Weaving | 8.00 | |||

| Picking | 1.00 | |||

| Finishing | 5.00 | |||

| Expenses | 8.00 | |||

| —— | ||||

| $55.01 | ||||

| Divide by 87½ | ||||

| Cost per yard = $0.6287 | ||||

| Article—SATIN STRIPED REPS Reed 60/62 | ||||

| Disp. 6 | Width 20¼ in. | |||

| STOCK AND DYE | ||||

| Warp— | Ital. Ex. Organ. 24/26 | $5.00 | ||

| black bright 22 oz. | .60 | |||

| .73 | ||||

| .21 | ||||

| —— | ||||

| lbs. 3.56 | $6.54 | $23.28 | ||

| Ital. Ex. Organ. 18/20 | $5.20 | |||

| .65 | ||||

| sky bright P.D. | .23 | |||

| .12 | ||||

| —— | ||||

| lbs. .83 | $6.20 | 5.15 | ||

| Cotton 100/2 | $1.00 | |||

| .12 | ||||

| .08 | ||||

| —— | ||||

| scarlet lbs. 1.37 | $1.20 | 1.64 | ||

| Warping—8316 at 4¢. | 3.32 | |||

| Twisting—7434 at 50¢. 300 meters | 1.24 | |||

| Filling—Jap. tram. No. 1 14/16 | $4.00 | |||

| .35 | ||||

| scarlet bright 16 oz. 1/3 ends | .45 | |||

| .15 | ||||

| 144 picks. lbs. 3.57 | .10 | |||

| —— | ||||

| $5.05 | 18.04 | |||

| Weaving | 12.00 | |||

| Picking | 1.00 | |||

| Finishing | 1.00 | |||

| —— | ||||

| $66.67 | ||||

| Expenses 15% | 10.00 | |||

| —— | ||||

| $76.67 | ||||

| Divide by 87½ | ||||

| Cost per yard = $0.8763 | ||||

| Article—MESSALINE BROCADE Reed 60/3 | ||||

| Disp. 7 | Width 23 in. | |||

| Warp—Jap. Ex. 13/15 | $4.50 | |||

| .60 | ||||

| 2-Thread navy bright 16 oz. | .45 | |||

| .15 | ||||

| —— | ||||

| lbs. 3.20 | $5.70 | $18.24 | ||

| Warping—4320 at 3¢. | 1.30 | |||

| Twisting—4260 at 30¢. 300 meters | .41 | |||

| Filling—Jap. Tram No. 1 13/15 | $4.00 | |||

| .35 | ||||

| emerald ex. bright dye 24 oz. | .95 | |||

| .25 | ||||

| 1/3 ends 100 picks | .15 | |||

| —— | ||||

| lbs. 2.50 | $5.70 | 14.25 | ||

| Weaving | 9.00 | |||

| Picking | 1.00 | |||

| Finishing | 1.00 | |||

| —— | ||||

| $45.20 | ||||

| Expenses 15% | 6.78 | |||

| —— | ||||

| $51.98 | ||||

| Divide by 87½ | ||||

| Cost per yard = $0.5941 | ||||

| Article—BENGALINE Reed 72/2 by 1 single; 1 double | ||||

| Disp. 8 | Width 36 in. | |||

| Warp—Jap. ex. 13/15 | $4.50 | |||

| .60 | ||||

| 2-Thread Organ. black bright | .64 | |||

| 20 oz. | .19 | |||

| —— | ||||

| lbs. 5.77 | $5.93 | $34.22 | ||

| Warping—7964 at 2¾¢. | 2.19 | |||

| Twisting—5296 at 30¢. 600 meters | .27 | |||

| Filling—56 picks by | $4.50 | |||

| 5 organ. 2 Cotton | .60 | |||

| .64 | ||||

| .19 | .45 | |||

| .12 | .10 | |||

| —— | ||||

| 40 picks Organ. as warp | $6.05 | .08 | 6.05 | |

| lbs. 1 | .07 | |||

| 16 picks black cotton 15/4 | —— | |||

| lbs. 22.50 | $ .70 | 15.75 | ||

| Weaving | 12.00 | |||

| Picking | 1.50 | |||

| Finishing | 3.00 | |||

| Expenses | 8.00 | |||

| —— | ||||

| $82.98 | ||||

| Divide by 91 | ||||

| Cost per yard = $0.9119 | ||||

| Article—CREPE DE CHINE (Taffeta weave) Reed 60/2/2 | ||||

| Disp. 9 | Width 40 in. 44½ in. in reed | |||

| Warp—Jap. Ex. Grege 20/22 | $4.50 | |||

| .05 | winding | |||

| —— | ||||

| 2% waste lbs. 5.60 | $4.55 | $25.48 | ||

| Warping—5340/2 at 2½¢. | 2.67 | |||

| Twisting—5340/2 at 25¢. 600 meters | .23 | |||

| Filling—Jap. No. 1 13/15 | ||||

| 4 ends hard twist 60 turns | $4.00 | |||

| 1.25 | throwing | |||

| 84 picks by 2 right, 2 left twist | 0.05 | quilling | ||

| —— | ||||

| 25% waste and shrinkage | $5.30 | |||

| lbs. 6.00 | 31.80 | |||

| Weaving | 9.00 | |||

| Finishing and dyeing | 5.00 | |||

| Picking | 1.00 | |||

| Expenses | 7.00 | |||

| —— | ||||

| $82.18 | ||||

| 5% discount | ||||

| 5% selling expense | ||||

| Divide by 90 | ||||

| Cost per yard = $0.9131 | ||||

| Article— | CREPE GEORGETTE Reed 50/2 | |||

| (Taffeta weave) by 1 right, 1 left twist | ||||

| Disp. 10 | Width 40 in. 47 in. in reed | |||

| Warp—Ital. Ex. Class 16/18 Raw | $5.20 | |||

| 1.60 | ||||

| —— | ||||

| 2-Thread hardtwist 75 turns | $6.80 | $36.72 | ||

| 30% shrinkage and waste lbs. 5.40 | ||||

| Warping—4640/1 30/2 4760 at 4¢. | 1.90 | |||

| Twisting—4700 at 50¢. 600 meters | .40 | |||

| Filling—Same silk as warp | ||||

| 100 picks by 2 right, 2 left twist | $5.20 | |||

| 1.60 | ||||

| .10 | ||||

| —— | ||||

| lbs. 5.00 | $6.90 | 34.50 | ||

| Weaving | 15.00 | |||

| Picking | 1.00 | |||

| Finishing and dyeing | 6.00 | |||

| —— | ||||

| $95.52 | ||||

| Expenses 12½% | 11.94 | |||

| —— | ||||

| $107.46 | ||||

| Divide by 87½ | ||||

| Cost per yard = $1.2281 | ||||

ARTICLE REED

---------------------------------------------------------------------

DISP WIDTH

---------------------------------------------------------------------

WARP

---------------------------------------------------------------------

| | | | |

--------------------------------------------+---+---+---+---+--------

| | | | |

--------------------------------------------+---+---+---+---+--------

| | | | |

--------------------------------------------+---+---+---+---+--------

| | | | |

WARPING | | | | |

--------------------------------------------+---+---+---+---+--------

TWISTING | | | | |

--------------------------------------------+---+---+---+---+--------

FILLING | | | | |

--------------------------------------------+---+---+---+---+--------

| | | | |

--------------------------------------------+---+---+---+---+--------

| | | | |

WEAVING | | | | |

--------------------------------------------+---+---+---+---+--------

PICKING | | | | |

--------------------------------------------+---+---+---+---+--------

FINISHING | | | | |

--------------------------------------------+---+---+---+---+--------

EXPENSES | | | | |

--------------------------------------------+---+---+---+---+--------

| | | | |

| | | | |

--------------------------------------------+---+---+---+---+--------

PRICE PER YARD

DRAWING-IN, 7

Straight Draws, 7

Skip Draws, 9

Point Draws, 9

Section Draws, 10

THE WEAVES AND THEIR CONSTRUCTION, 15

The Taffeta Weave, 17

Gros de Tours Weaves, 19

Serge Weaves, 20

Twill Weaves, 20

FILLING EFFECTS 21

Satin de Lyon, 21

Levantine, 21

Polonaise, 22

Serge grosse coté, 22

Serge Romaine, 23

Serge, 23

WARP EFFECTS, 25

Levantine, 25

EVENSIDED TWILLS, 26

Surah, 26

Croise, 26

POINTED TWILLS, 27

SATIN WEAVES, 32

Satine de Chine, 34

Satin Merveilleux, 34

7 Harness Satin, 35

Duchesse, 35

IRREGULAR SATINS, 39

Satin Ture, 39

Satin à la Reine, 40

DERIVATIVE WEAVES, 41

From the Taffeta, 41

From the Twills, 43

From the Satin Weave, 46

Cannele and Repp Weaves, 49

DOUBLE FACED FABRICS, 55

Warp Effects, 55

FILLING EFFECTS, 58

Pekins, 60

Bayadères, 63

[pg 112]Checks and Plaids, 65

DECOMPOSITION, 67

The Weave, 68

Length and Width of the Fabric, 68

The Stock and Its Dye, 69

Reed Calculation, 70

Drawing-in the Warp in Harness and Reed, 70

Warping Ticket, 71

Harness Arrangement, 71

Reduction of the Filling, 71

Calculation of Warp and Filling, 71

Finishing, 72

Calculation of Cost, 72

DISPOSITIONS, 75

JACQUARD WEAVES, 100

Box Loom Weaves Including Crêpes, 100

Manufacturing Costs, 101

CALCULATIONS, 103

Calculation Blank, 110

[pg 113]373 Fourth Avenue New York.

Established 1882. A monthly magazine devoted exclusively to dress silks, ribbons, and all silken materials, reflecting the progress of mill and market, fashions, trade events and news. Published on the first of each month.

Subscription: United States, $3; Canada, $3.50; Foreign, $4 a year.

The great international authority on silk.

A practical and logical system of standardizing raw silks. Price, $4.25 postpaid.

The most complete and authentic dictionary ever published on silk terms, from the raw silk to the finished broad and narrow silks, including weaves, styles, patterns, effects, colors, trade-marks, etc. Bound in cloth, 93 pages, price, $1.50 postpaid.

A valuable book treating on color contrasts and harmonies. It will assist the manufacturer, styler, designer and retailer in the selection of colors. Colored plates and diagrams illustrating the fundamental principles of the subject, of inestimable value to either student or artisan. Price, $1.50 postpaid.

An encyclopedia of furnishings, decorations, furniture. Contains 2,731 illustrations, 266 pages, size 9¼ x 12; 112 fabric illustrations, covering all periods. Price, $6.00 postpaid.